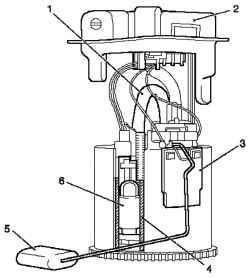

Fig. 6.11. Block diagram of an antilock braking system MK70

NOTICE The electric motor of the pump should not be disconnected from the hydraulic modulator.

6.2. General test procedures Checking and adjustment of the brake system Check brakes on a dry, clean, relatively smooth and level road. The results of brake testing will be unreliable if the road is wet, slippery or covered with mud. Because of this, adhesion of all tires are different. At the test results will also influence the road, which were biased, because the tires will roll somewhat misleading. Check your brakes at various speeds the car with light and slam on your brakes to avoid locking the brakes and skidding tires. Lock the wheels when braking does not provide complete information on the effectiveness of the brakes as compared to inhibition when the wheels can rotate and the braking distance is less than the. This is because a locked wheel sliding traction coefficient less than when it was rolling. In the process of braking affect three main factors: - On different wheels will vary in terms of tire adhesion, resulting in uneven braking forces. Air pressure and retreading must be the same; - Brake force on the front and rear axles should be proportional to the force at which the vertical loads; - Violation of the angles of the wheels may cause that the car is under braking to pull to the side. To check the leakage of brake fluid, press the brake pedal when the engine speed at idle and the gear lever in neutral position. If the pedal gradually falls at constant pressure, then there is a leak in the system. Visually check for leaks and brake fluid level in the tank master brake cylinder. Slight drop in brake fluid level is due to normal wear pads. Abnormally low levels of interpretation of a leak in the system. In the hydraulic system is possible both internal and external leakage. If the brake fluid level is normal, check the length of the rod of the vacuum brake booster. If found inadequate length of the rod, adjust the length or replace the rod. Check the master cylinder in the following order: - Check for damage master cylinder or the lack of leakage of brake fluid around the master brake cylinder. Lowering the level of brake fluid can only talk about leaking. Abnormal conditions is also moisturizing the surface of the master brake cylinder; - Check your connection to pull the pedal and the length of the rod. If they are normal, disassemble the master cylinder and check for stretching or swelling of the glands of the cylinder, then there is no wear rubber parts, If you have swollen glands, possibly using non-standard or contaminated brake fluid. If found contaminated brake fluid, all components should be dismantled and cleaned, and all rubber parts replaced. All piping should also be washed. Unsuitable brake fluid, or mineral oil or water in the fluid can cause boiling brake fluid, or damage to rubber components. If the main oil seals of the piston in the master cylinder swelled, it means that the rubber components are corrupted. This malfunction can be confirmed by the swollen glands cylinder piston brake drum on wheels. If you wear rubber is confirmed, sort out all the details of the hydraulic system, rinse them with alcohol. Before building dry details of the flow of compressed air. Replace all rubber parts in the system, including hoses. When using the brake mechanism to verify the absence of fluid seals. If liquid is detected, replace the gaskets. If the condition of oil seals piston in the master brake cylinder is normal, check for leaks or overheating. If these conditions are not detected, drain the brake fluid, fill the master cylinder and re-drain the fluid from the system.

442