1 minute read

Replacing piston rings

NOTE Surfaces of contact rods and connecting rod bearing caps are selected individually, and therefore they can not be rearranged or prevent their injuries. to avoid damage, do not put rods and caps on the contact surface. Pay attention to the loading position - hot flashes (arrow) on the covers of some types of bearings are pointing in the direction of the gearbox.

8 Loosen the mounting bolts. Clear all sites, check and replace if necessary. Install new connecting rod bearings bushings and cover their motor oil. Attach the lid to the connecting rod bearings connecting rod. 8 Tighten the mounting bolts moment 13 Nm and Dauvergne at +60 ° and +15 °. Use new bolts.

NOTICE Always use screws M6, 5.

Remove the piston rod.

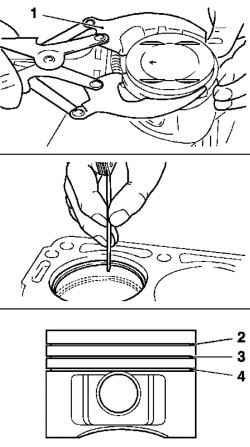

Fig. 2.235. Removal of piston

rings: 1 - puller; 2 - compression ring of rectangular cross section 3 conical compression ring, 4 maslosemnoe ring

Remove the piston ring pliers to remove the piston rings (Fig. 2.235). Clean the ring grooves. Clean the grooves of piston rings compression rings of rectangular cross section, conical compression ring and the ring maslosemnogo using broken piston ring. Check gap. Install piston rings into the cylinder. Check the clearance probe.

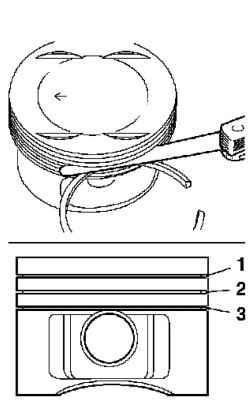

Fig. 2.236. Check clearance of

piston rings: 1 - compression ring of rectangular section, 2 - conical compression ring 3 - maslosemnoe ring

Check vertical clearance of a piston ring groove in a piston ring probe (Fig. 2.236). Compression ring of rectangular section. Conical compression ring. Maslosemnoe ring. Install piston rings. Install piston rings in annular grooves, special tongs. Marking «TOP» should be on top. Set clearances piston rings. The first piston ring (right ring) in position 1. The second piston ring in position 4.

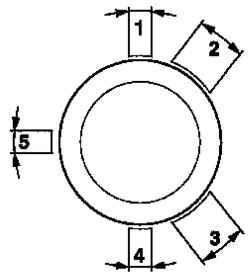

Fig. 2.237. Experimental setup of

piston rings

Intermediate ring maslosemnogo ring in position, drives maslosemnogo ring in position and / or 3 (Fig. 2.237).