2 minute read

Removing and installing cylinder head (engine 2.0 l

NOTICE Do not apply sealer roller kremnievorganicheskogo (gray) in the slots or on the inner edge. Apply silicone sealant roller (gray) on the outer edge of the groove on the basis of the cylinder thickness about 2 mm.

Attach the base of the cylinder block to (tighten by hand) 22 bolts. Use new bolts. 10 Tighten the screws on the inside (M8) moment of 25 Nm and Dauvergne at +60 °. 12 Tighten the bolts (M6) outside the point of 10 Nm and Dauvergne at +60 °.

Withdrawal

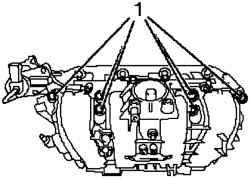

Fig. 2.209. Bolts fastening intake

manifold: 1 - screw fixing

Separate the intake manifold from the cylinder head. To do this, loosen the 6 mounting bolts (Fig. 2.209). Remove the seal. Clean the sealing surfaces. Separate chain tensioner from the cylinder head. Unscrew the 2 screws fastening. Disconnect the oil pressure sensor on the cylinder head. Disconnect the exhaust gas recirculation valve from the cylinder head. Loosen the 4 bolts fastening. Remove the spark plug with a special tool KM-194-E. Check the label before the dismantling of the camshaft bearing caps. Camshaft drive exhaust valves, the identification of: 1-3-5-7-9. Camshaft drive intake valves, identification: 2-4-6-8-10. Remove the camshaft drive exhaust valves.

NOTE When otvorachivanii camshaft bearing caps, provide a smooth transition from the camshaft bearing.

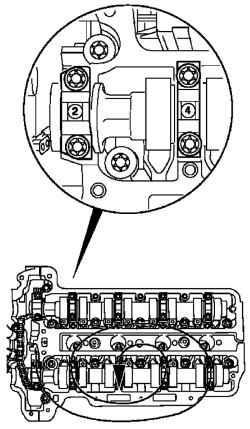

Loosen the camshaft bearing caps gradually on 1/2-1 turnover. Loosen the mounting bolts 10. Remove the camshaft bearings. Put in the correct order. Remove the camshaft drive exhaust valves Loosen the camshaft bearing caps gradually on 1/2-1 turnover. Loosen the mounting bolts 10. Remove the camshaft bearings, put in the correct order. Remove the camshaft drive the intake valves Remove the valve tappets and hydraulic tappets from the cylinder head.

Place shot tappets and hydraulic tappets apart in the sequence of withdrawal

Setting

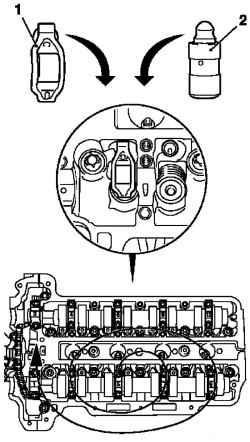

Clear all withdrawn items. Set tappets and hydraulic tappets in the cylinder head. Cover the surface friction of clean engine oil. Coat the camshaft bearing lubricating paste (gray). Install camshaft drive the intake valves. Cover the surface friction of the lubricant paste (gray). Install camshaft drive intake valves

NOTE Install camshaft so that the cams of the cylinder number 1 has been in the position of TDC ignition (cams directed outwards).

NOTICE Check the label and location.

Install camshaft bearing cap.

NOTE Tighten bolts gradually in a spiral, starting from the center (Fig. 2.211).

Tighten the bolts 10 point 8 Nm Install camshaft drive exhaust valves. Cover the surface friction of the lubricant paste. Install camshaft drive exhaust valves

NOTE Install camshaft so that the cams of the cylinder number 1 has been in the position of TDC ignition (cams directed outwards).

Install camshaft bearing cap. Replace the cover camshaft bearings.

NOTE Tighten bolts gradually in a spiral, starting from the center.

Tighten the bolts 10 point 8 Nm Replace the spark plugs in the cylinder head using a special tool KM-194-E, tighten the moment 25 Nm Attach the exhaust gas recirculation valve to the cylinder head. Use a new gasket. Tighten the 4 bolts fastening point 8 Nm Attach the oil pressure sensor to the cylinder head and tighten the moment 20 Nm Use new O-ring. Attach the chain tensioner to the cylinder head. Tighten the 2 screws and tighten the mounting point 8 Nm Attach the intake manifold to cylinder head Install 4 new o-rings. 6 Tighten the mounting bolts and tighten the moment 10 Nm