3 minute read

Removal and assembly of the differential (gearbox F13

NOTE Use new O-ring.

Replace the cover gearbox. Check the fluid level in the gearbox.

NOTE Transmission is installed.

Withdrawal

Disconnect the shafts of the wheels of the gearbox.

NOTE Shafts wheels remain in the wheel hubs.

Remove the back cover by unscrewing the mounting bolts 9. Remove the back cover.

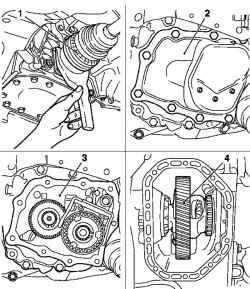

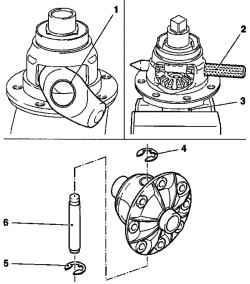

Fig. 3.75. Removal of the

differential: 1 - shafts of the wheels 2, 3 - back cover, 4 - differential

Remove the differential (Figure 3.75). Remove the 2 sealing rings of the shaft of the wheel cage and gearbox.

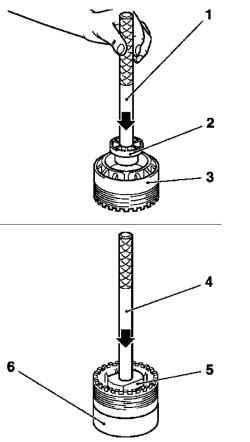

Fig. 3.76. Removing the sealing

rings and the tapered roller bearing: 1, 2 - special tools, 3 - cage, 4, 5, 6 Special tools

Remove the O-ring shaft wheels with special instruments KM-454-2 and KM-454-4 (Figure 3.76). Remove the outer ring of taper roller bearing of the cage.

NOTE It is only necessary in case of replacement of the bearing.

Install the outer ring taper roller bearing seats in the 303 IM. Remove the outer ring of a taper roller bearing with special instruments KM 304 and KM 451 (Fig. 3.76). Remove the outer ring of a taper roller bearing of the gearbox

NOTE It is only necessary when replacing the bearing in the gearbox.

Remove 2 internal rings of tapered roller bearings from the differential. Do not change the place of external and internal ring when reusing bearings. When repairing the speedometer gear (drive) must be destroyed. During the assembly is not installed again.

Fig. 3.77. Removing the inner

rings of roller bearings: 1 - inner ring of tapered roller bearings, 2, 3, 4 - special tools; 5 - speedometer gear (lead)

Remove the inner ring of the taper roller bearing with pomoschyuspetsialnyh tool KM-161-B, KM-1613 and KM-161-4 (Figure 3.77). Remove the gear ring with the differential housing.

NOTE Use protective vise.

Remove the differential housing.

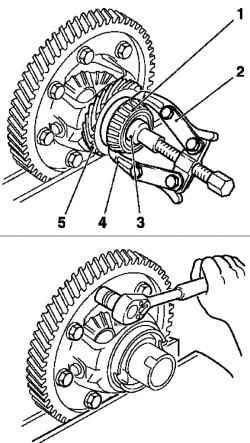

Fig. 3.78. Removing the locking

rings: 1 - toothing differential 2 retaining rings

Remove the 2 retaining rings with a conical axis.

Remove the cone axis. Remove the wheels and shafts poluosevye gears with a special tool KM-458-A. Remove the plastic clip.

Setting

Insert the plastic clip in the differential.

NOTE Lubricate the rotating elements, bearings and the surface of contact transmission oil.

NOTE It should be possible to set the ring (1) plastic clips in the guide leading the gears in the housing

Assemble the differential housing. Replace gears and satellite differential in housing differential.

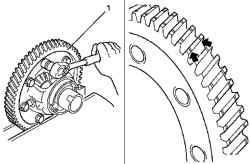

Fig. 3.79. Building housing the

differential: 1 - Ring 2, 3 - a special tool, 4, 5 - retaining rings, 6 - cone axis

Hold the differential housing in a vise using a special device KM-458-A (Figure 3.79).

NOTE Use protective vise.

Install central satellite differential with special prisposobleniyaKM 456. Install the conical axis. Install 2 new retaining rings (Fig. 3.79). Attach the gear ring (1)

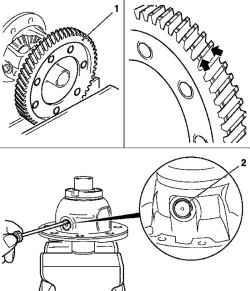

Fig. 3.80. Accession toothed

crown: 1 - toothing

NOTE Replace top gear only in pairs. Pay attention to the identification groove (arrows in Figure 3.80) in the upper part of the tooth.

Tighten the 8 new bolts fastening point 40 Nm (+30 +15) °.

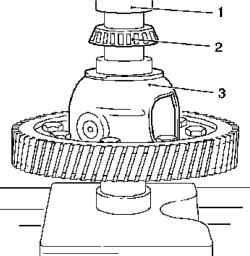

Set 2 internal rings of tapered roller bearings (Figure 3.81). Install the inner ring of taper roller bearing with a special tool KM-453 in the case of the differential (Figure 3.81). Insert the 2 outer rings of tapered roller bearings. Install exterior ring taper roller bearing with the help of special instruments KM 304 and KM 451 in the gearbox and cage. Install O-rings, shafts of the wheels. Install O-rings, shaft wheel with a special tool KM-446 in the cage and the transmission housing. Fig. 3.82. Installation of external