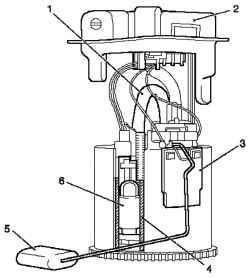

Fig. 2.59. Verification procedure

Check the pressure drop in the cylinders 3, 4 and 2, using the same method. Tested piston cylinder is mounted in the position of TDC. The sequence of cylinders: 1-3-4-2. Defines the position at TDC matching labels 1, 2, 3 and 4, the star of a camshaft (Figure 2.59). Continue to rotate the camshaft at 180 ° in the direction of motor rotation (corresponding to 90 ° on the pulley camshaft) to the combination of marks on camshaft pulley with the marks on the lid of the cylinder head. Determine the position of TDC for the 4 th and 2-th cylinder, respectively. Crankshaft rotate slowly and evenly. Installation components Replace spark plug with a special tool KM-194-E, torque 25 Nm Connect the ignition module for spark plugs and tighten the cylinder head at point 8 Nm Install the ignition module cover on the lid of the cylinder head. Connect the wiring harness connector to the ignition module. Replace the cover oil-filling neck. Set the cover expansion tank coolant. Insert the oil dipstick hole. Install the upper part of the toothed belt cover on the back cover of the toothed belt tightening torque 6 Nm Replace the air filter housing with the sensor mass air flow. To do so, attach the hose to the inlet of the air intake tube and attach the clamp. Tighten the attachment bolt. Connect the wiring harness connector sensor mass air flow. Install pipe deflection air pressurization and tighten the 4 bolts fastening. Insert the vacuum line to the bracket. Install the air hose and attach the two pressurization clamp. Remove the seal turbocharger inlet pipe. Connect the vent hose to the lid of the engine cylinder head and attach the clamp. Connect the inlet pipe to the turbocharger and attach the clamp. Connect the inlet pipe to the air intake hose and secure clamp. Install an insulating cover, tighten its mounting point 4 Nm

Checking compression (1,4-1,8 liter engines) NOTE Before the verification procedure warming up the engine to operating temperature (oil temperature - 80 ° C).

164