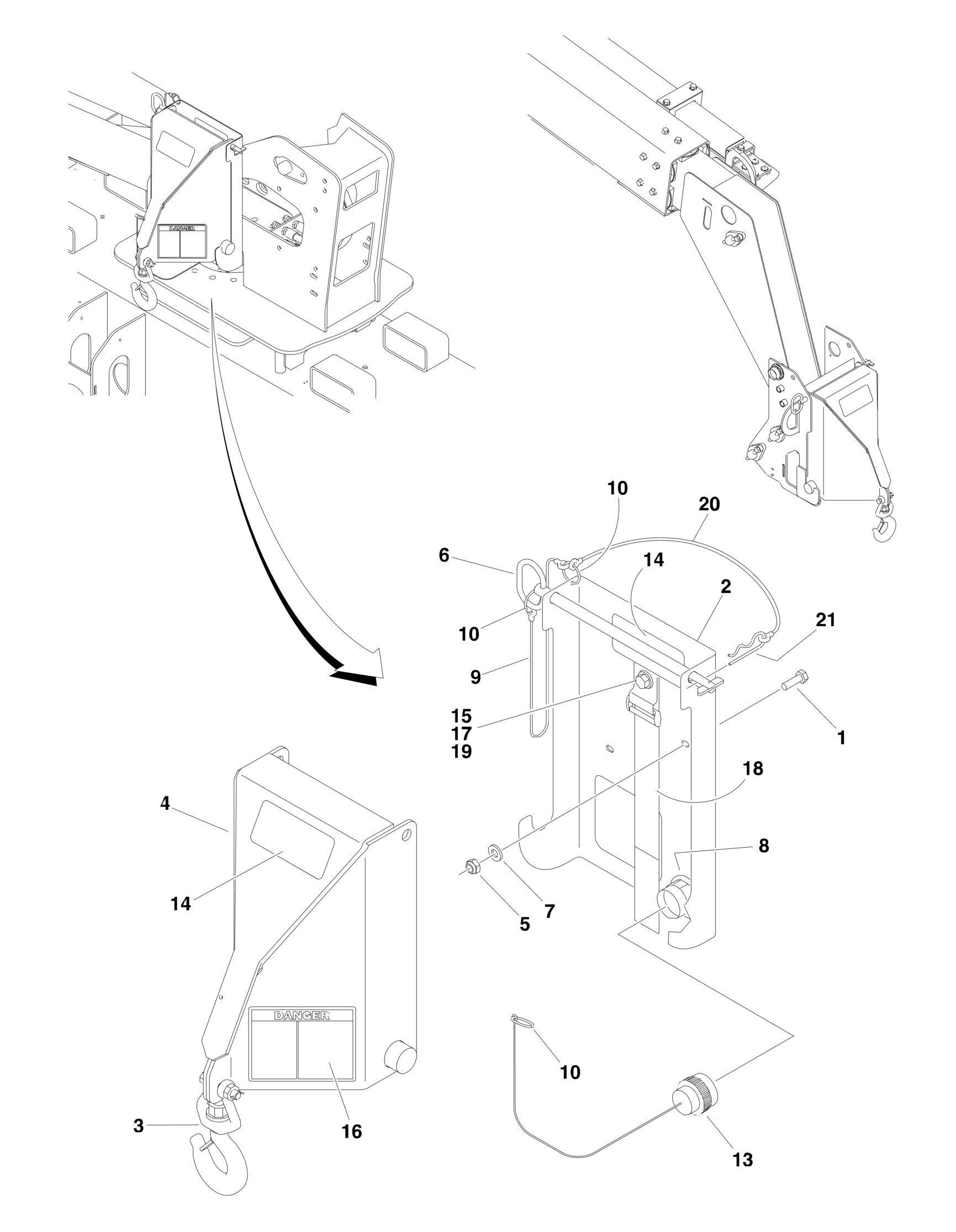

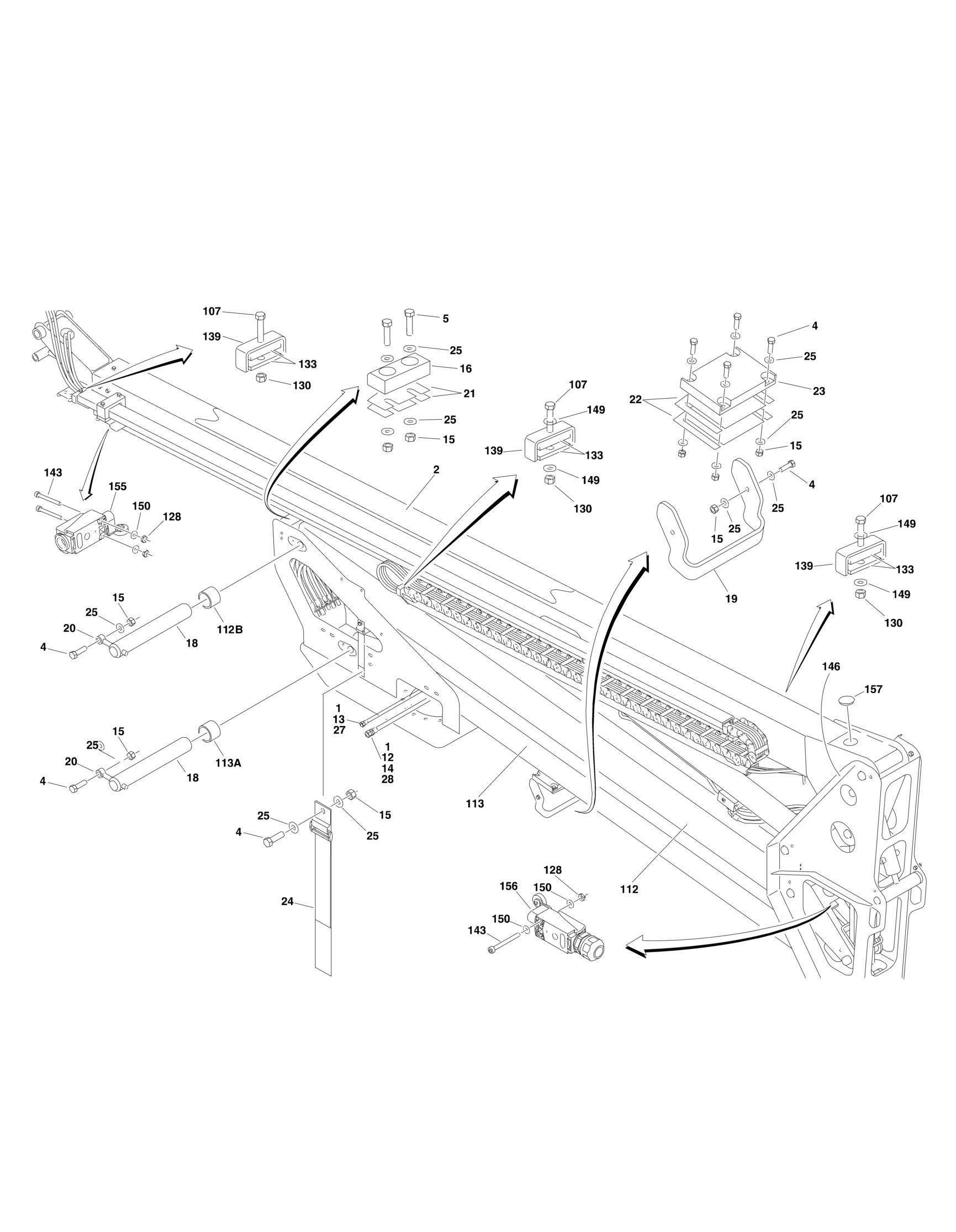

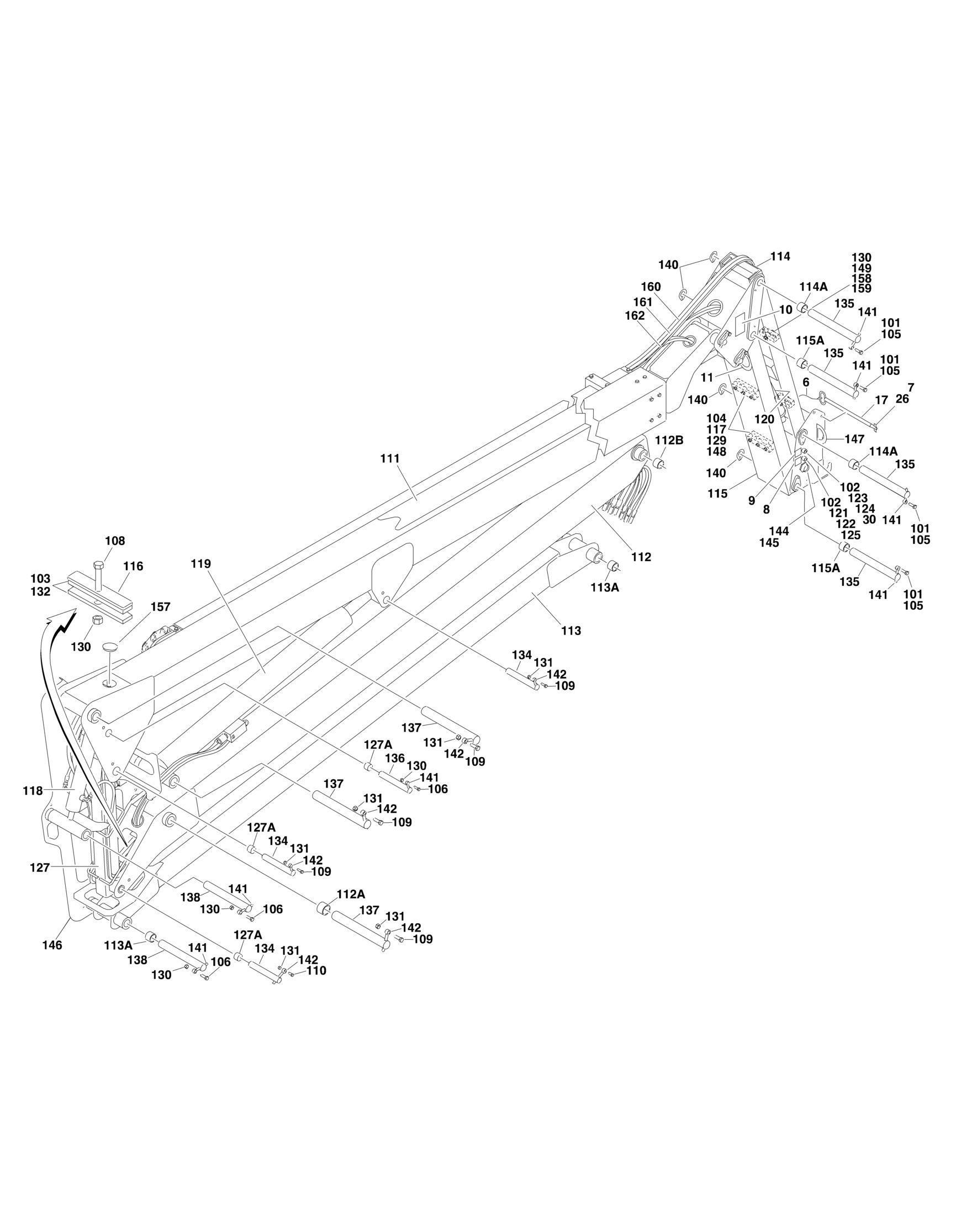

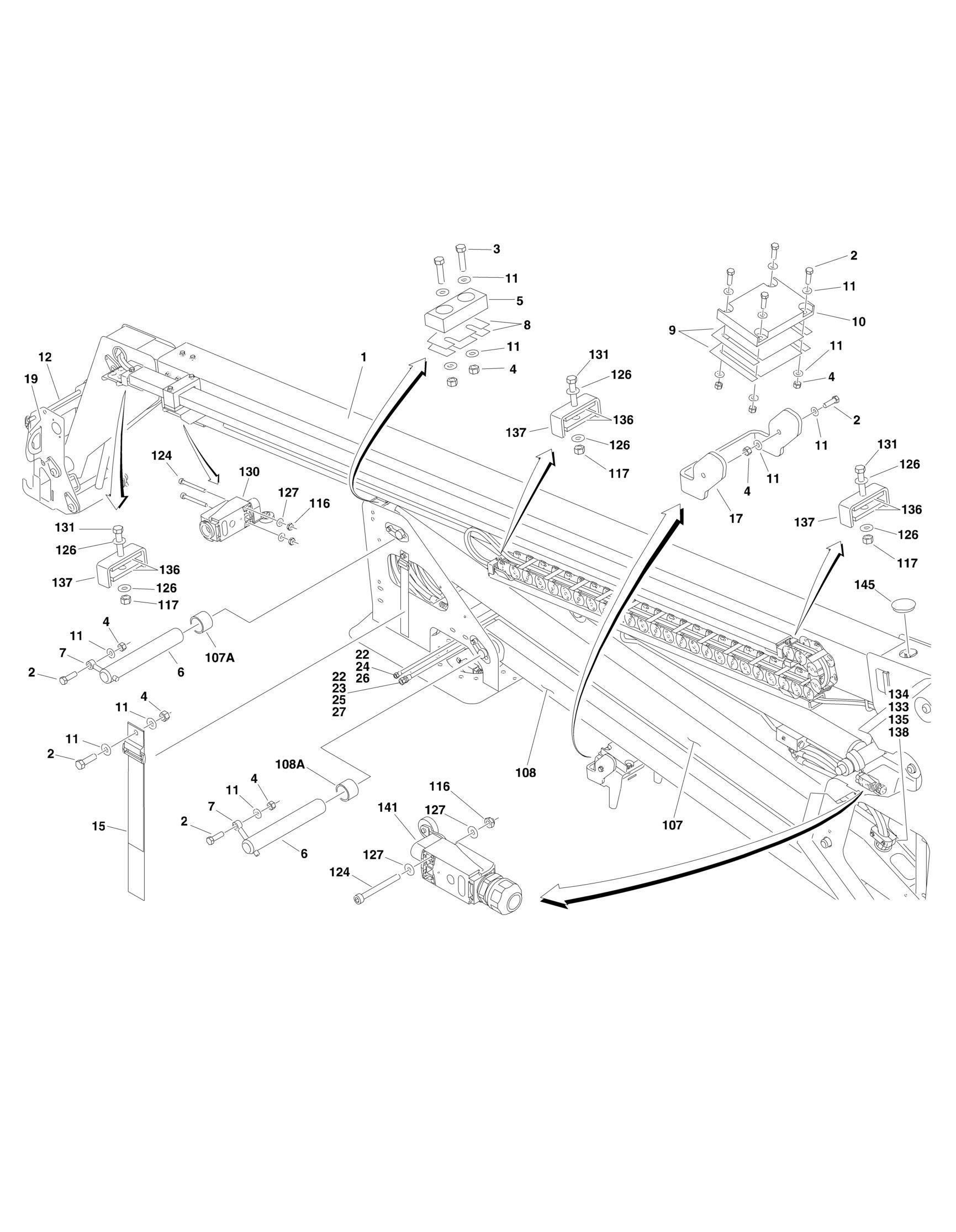

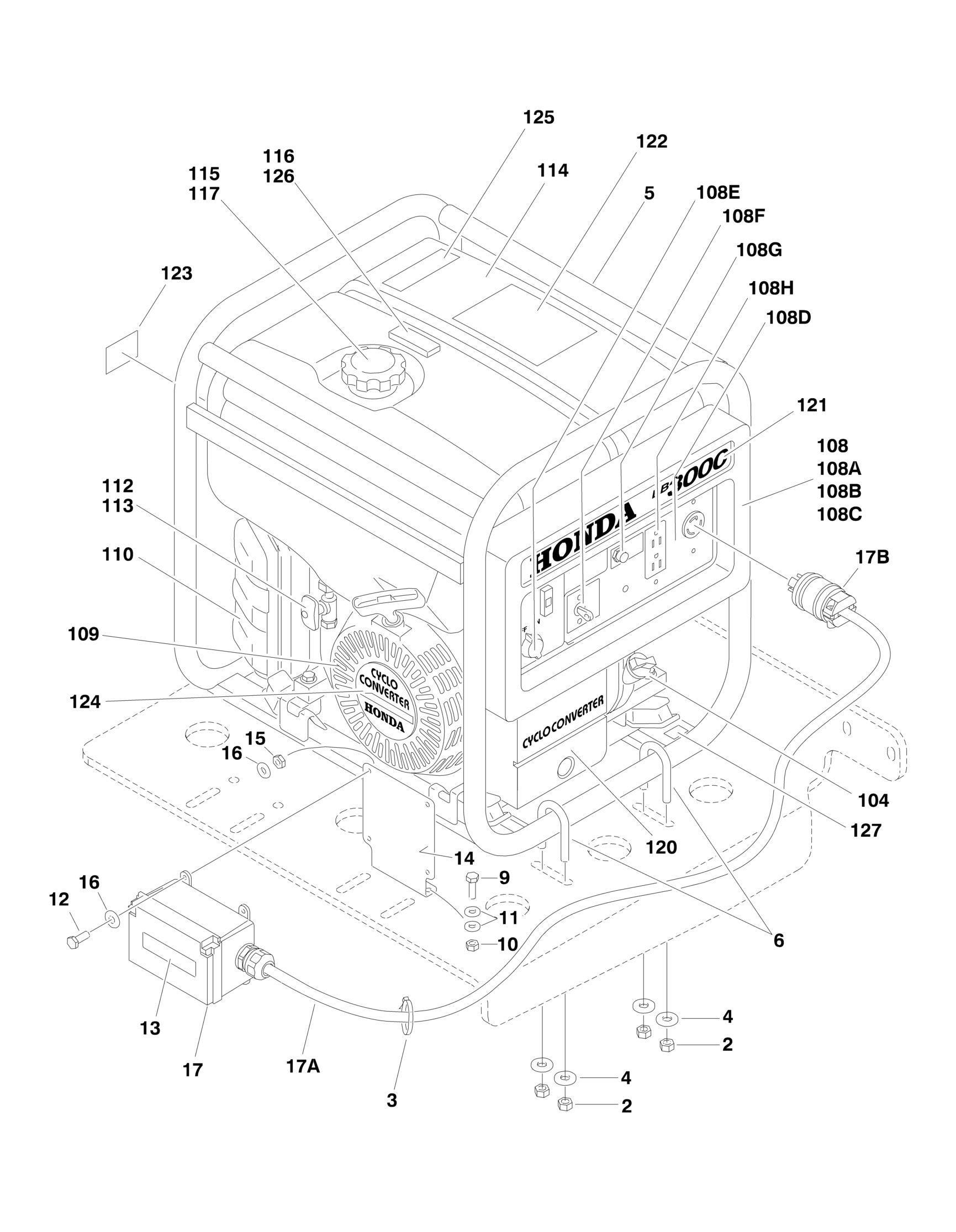

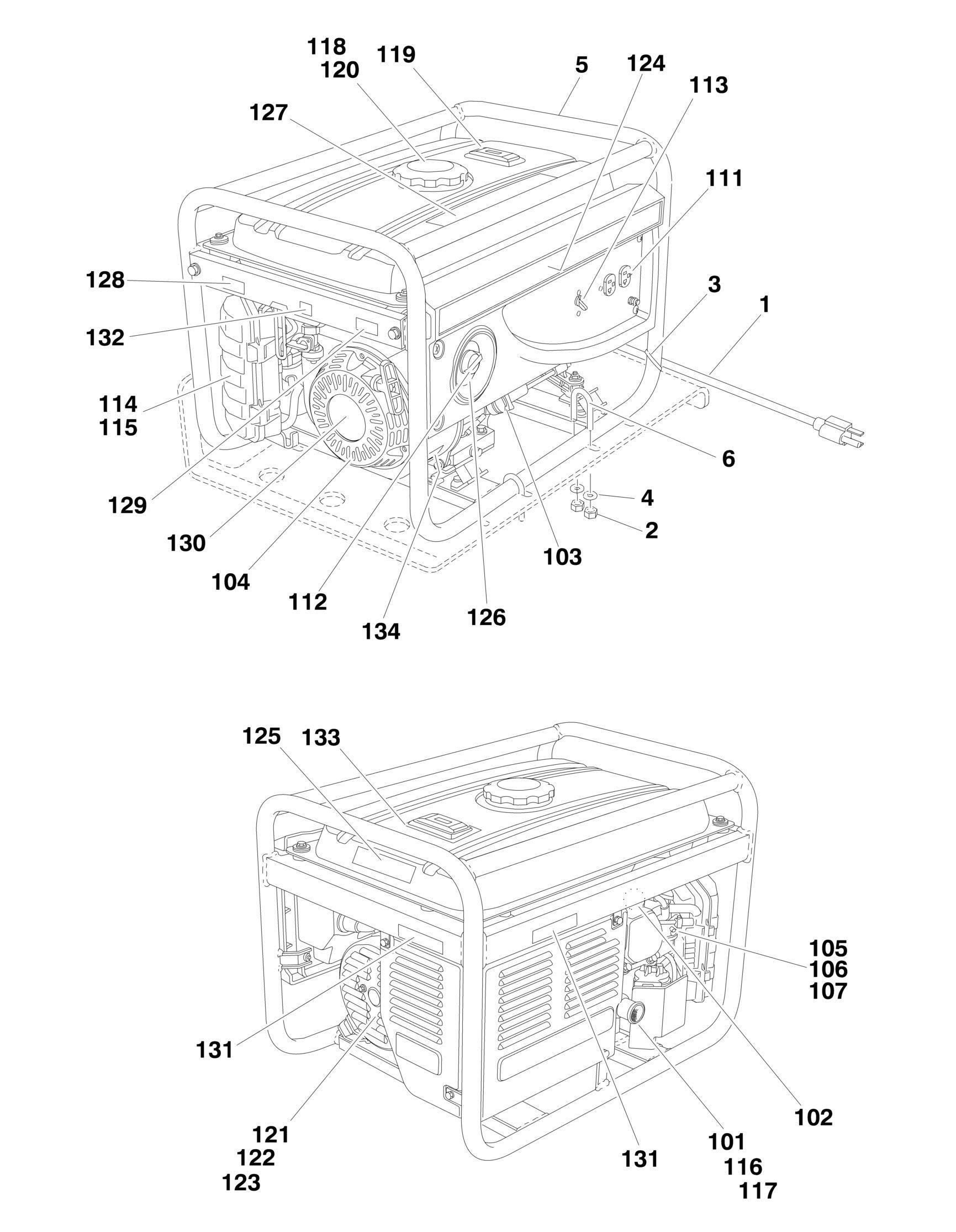

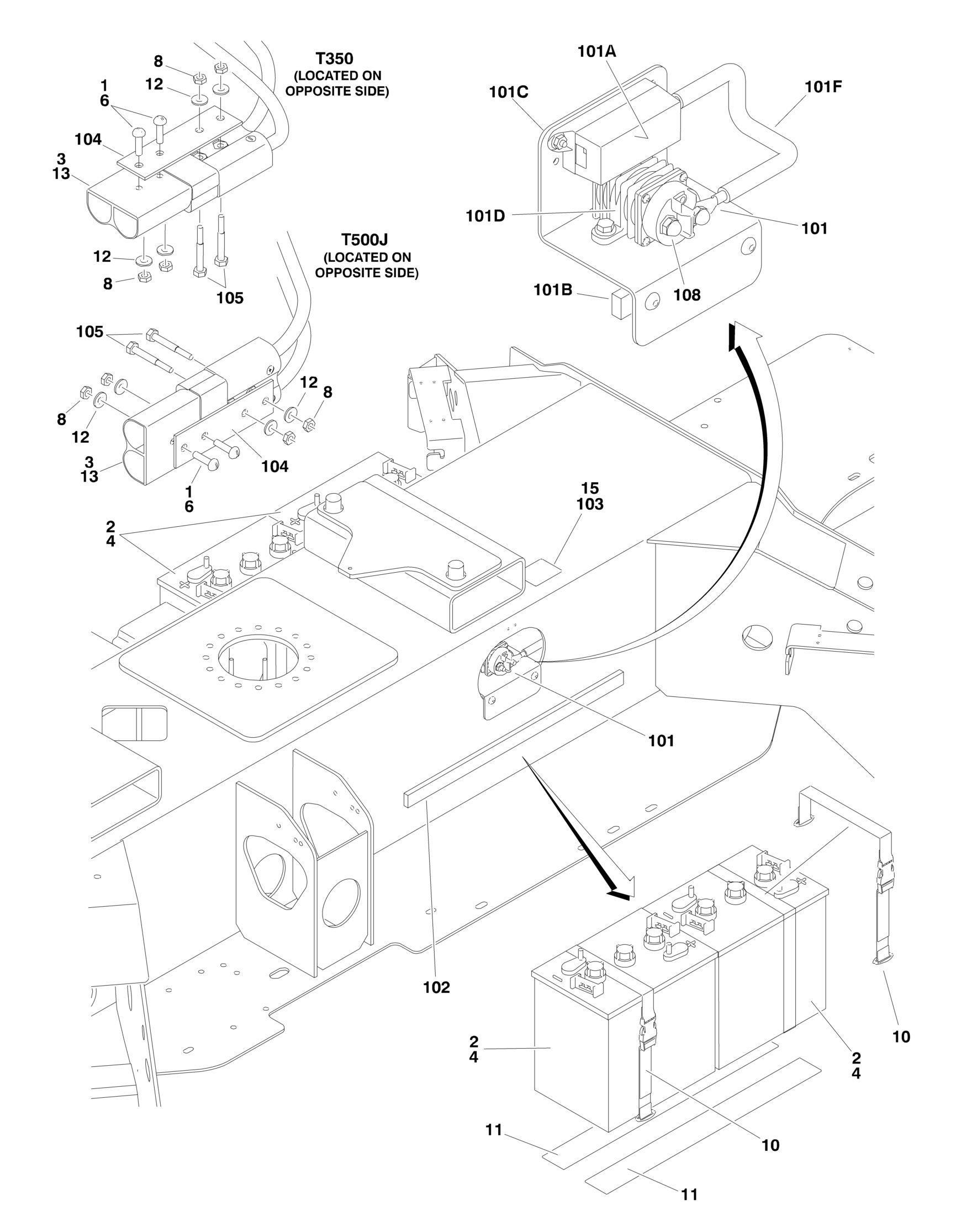

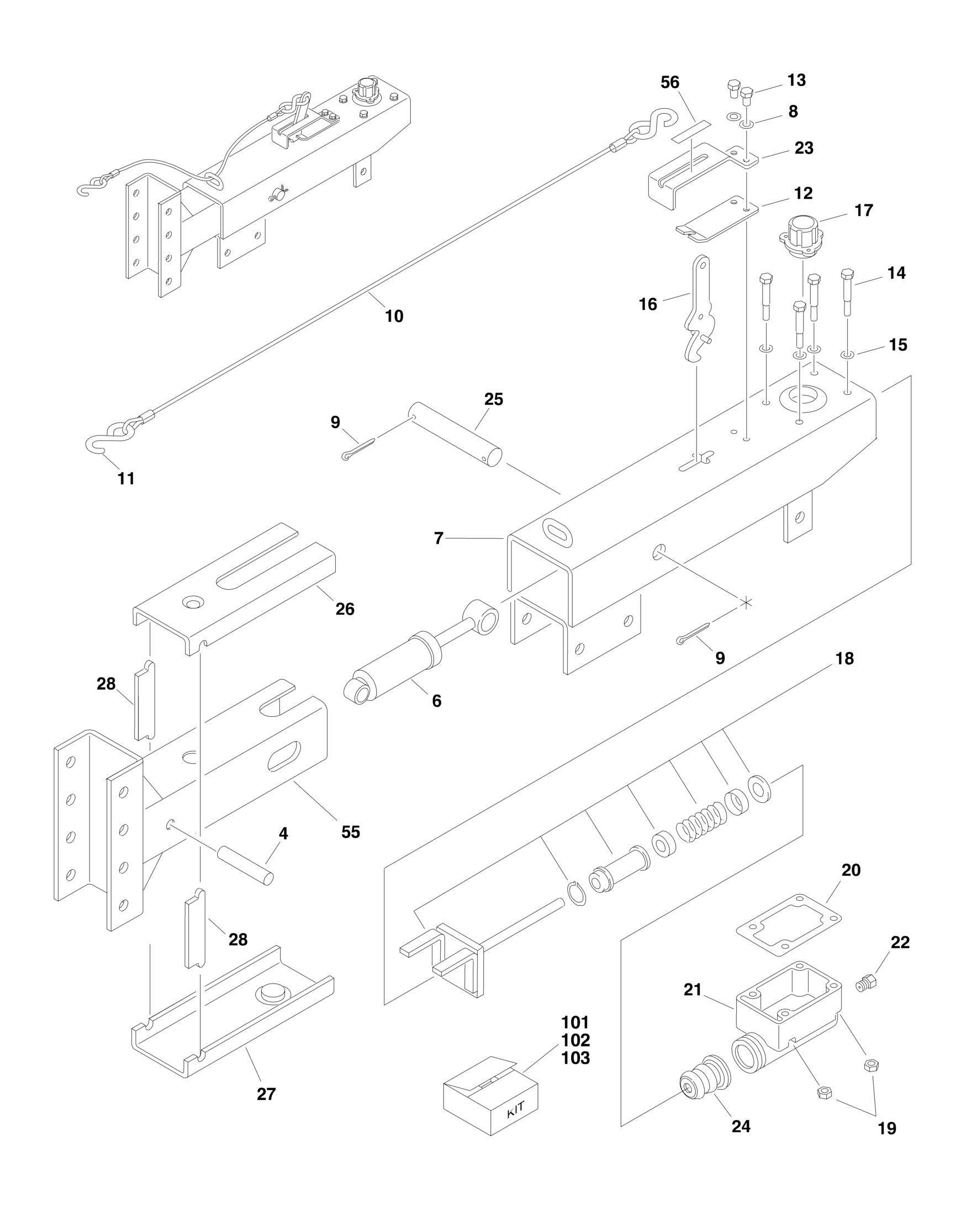

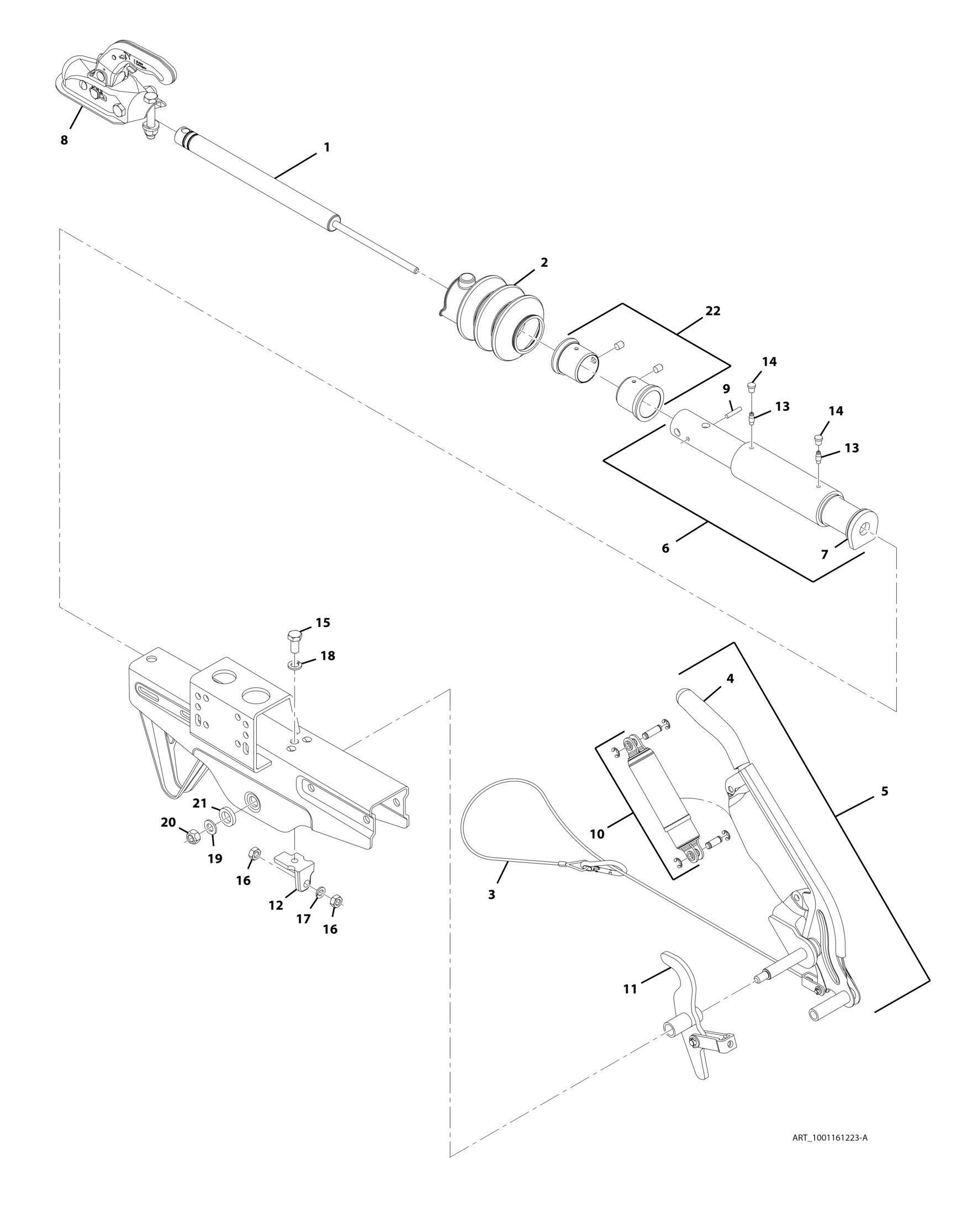

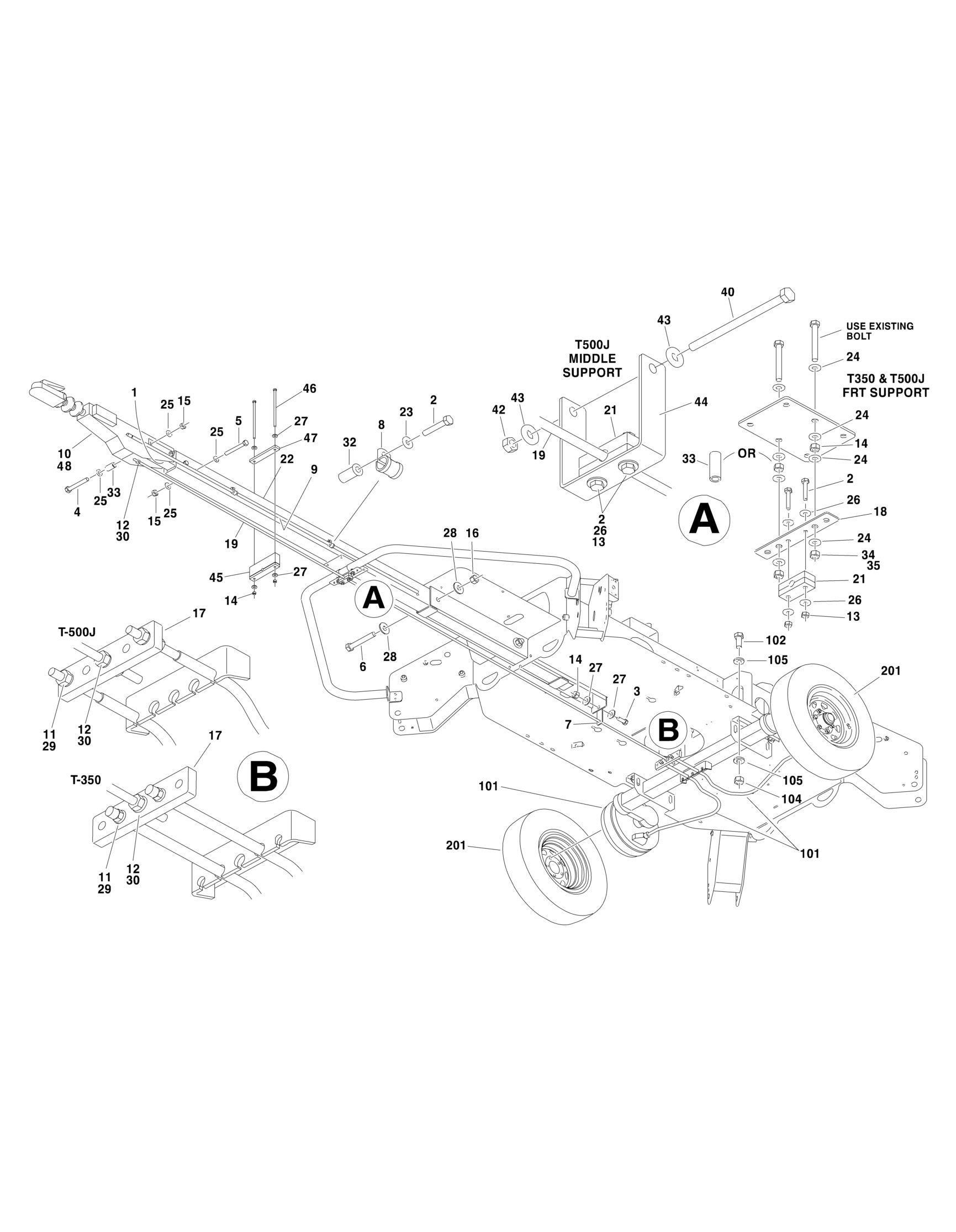

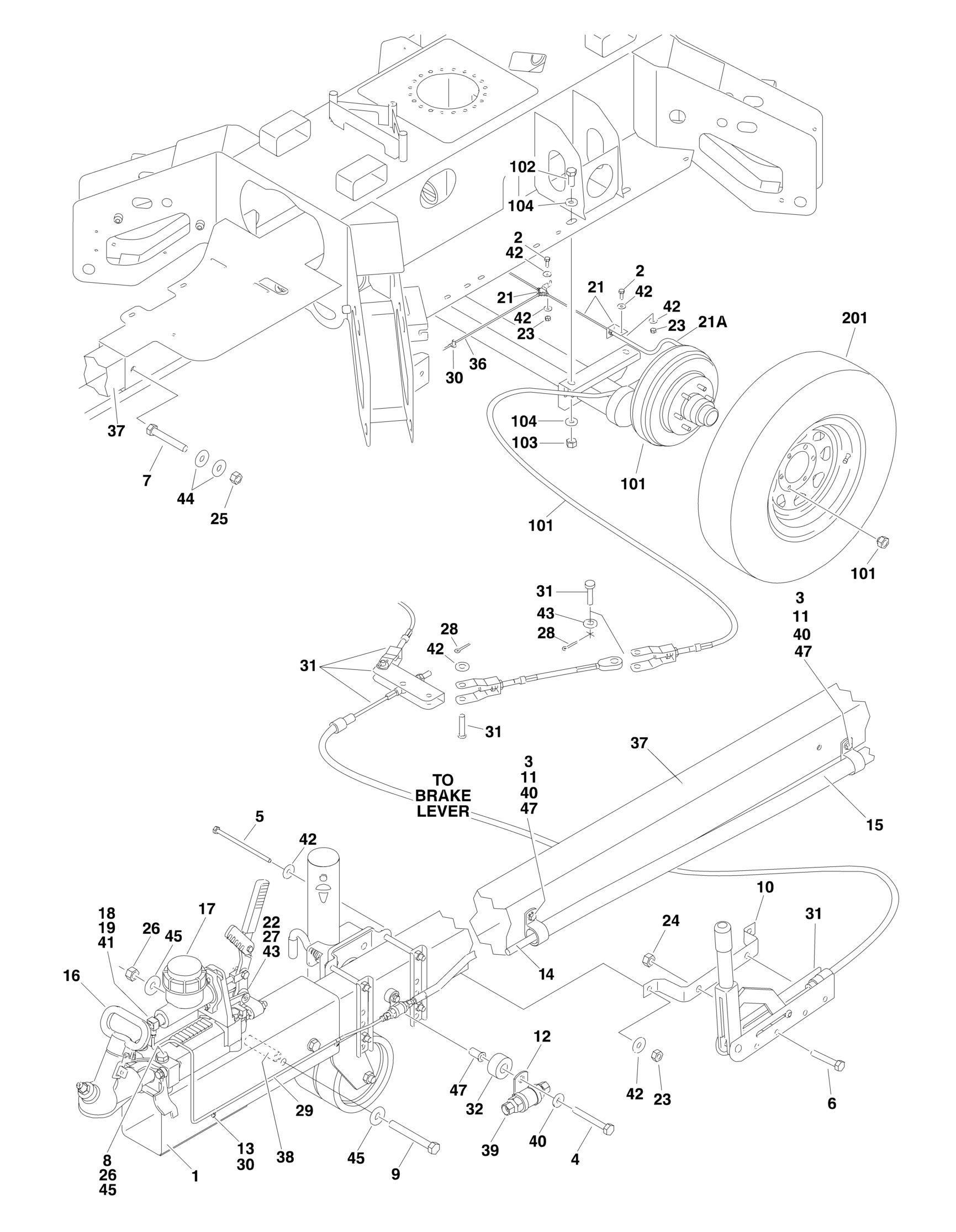

SECTION 1 - FRAME FIGURE 1-26. BATTERIES INSTALLATION (ELECTRIC POWERED MACHINES) (SN 0030001804 through 0030012032) ITEM

PART NUMBER 0275709

QTY Ref Ref

0275718 1001201419

Ref Ref

0100048 0100051

AR AR Ref 4 4 1

1 2 4 4 4 5

0400215 1001112112 1701644

6 7 8 9 10

1702155 3300506 4220306 4240177 4420038

11

1 2 1 4 80 in in/2m Ref

11 11 12 13

4923020 4923428 0630541 3311608

1 1 8 8

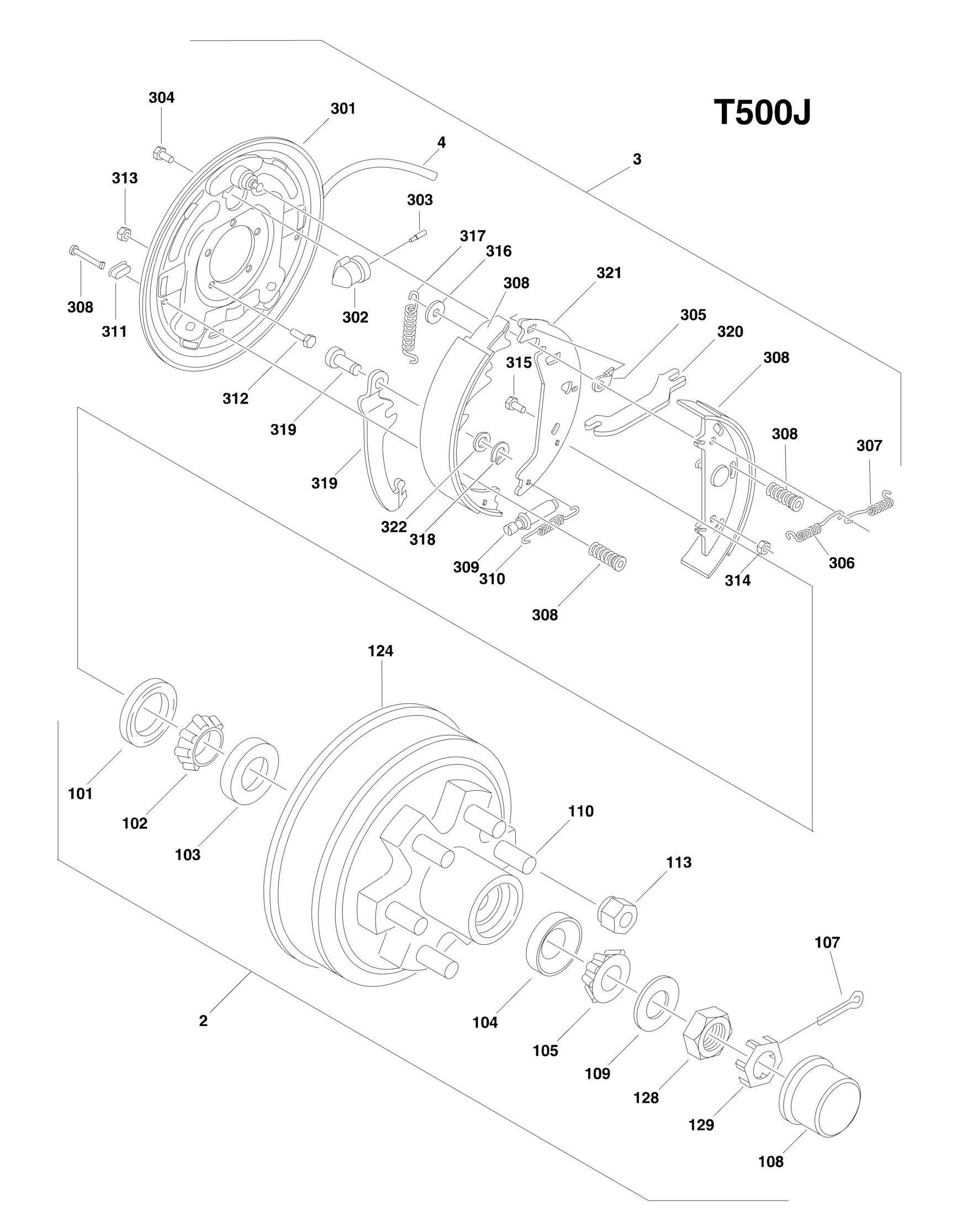

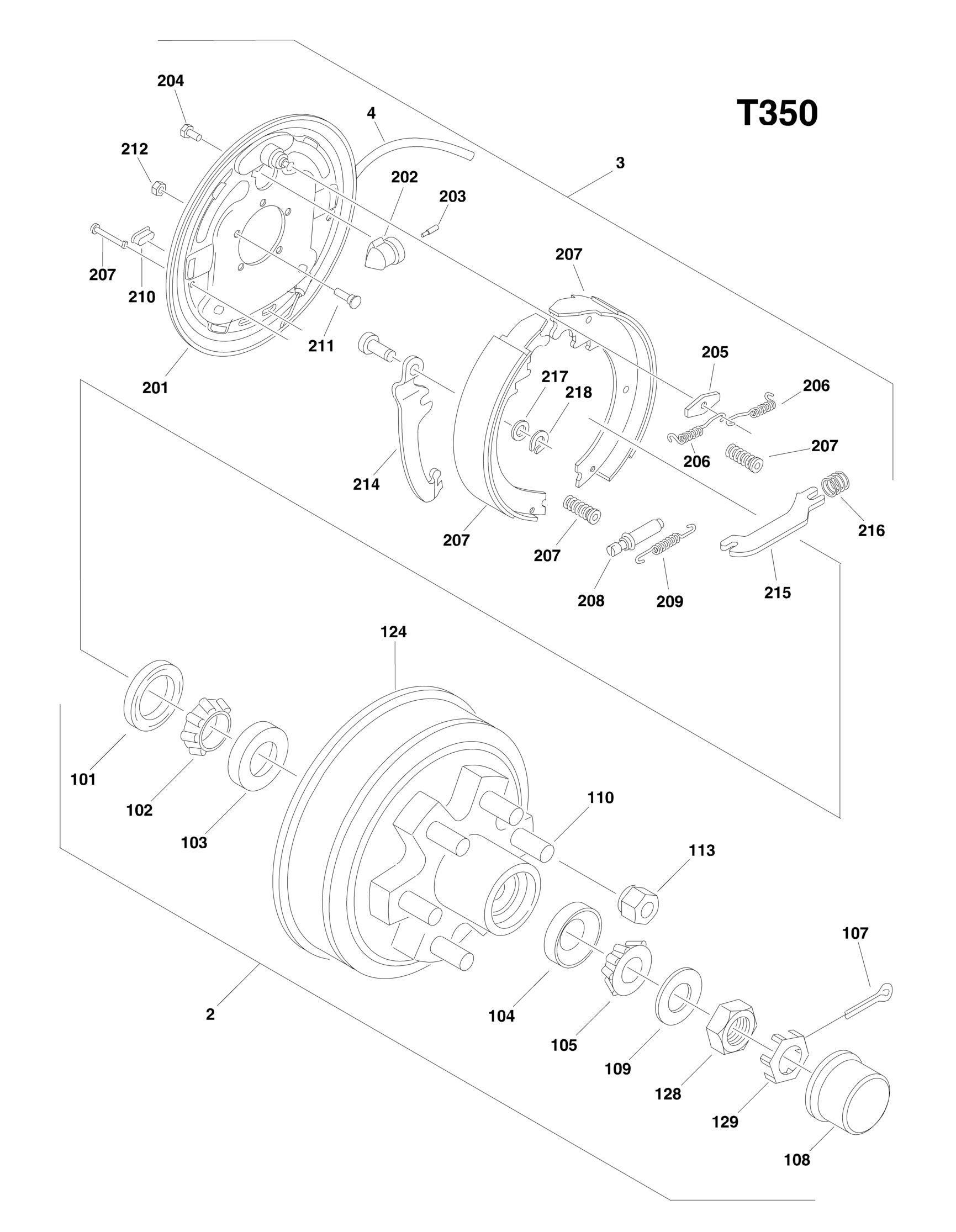

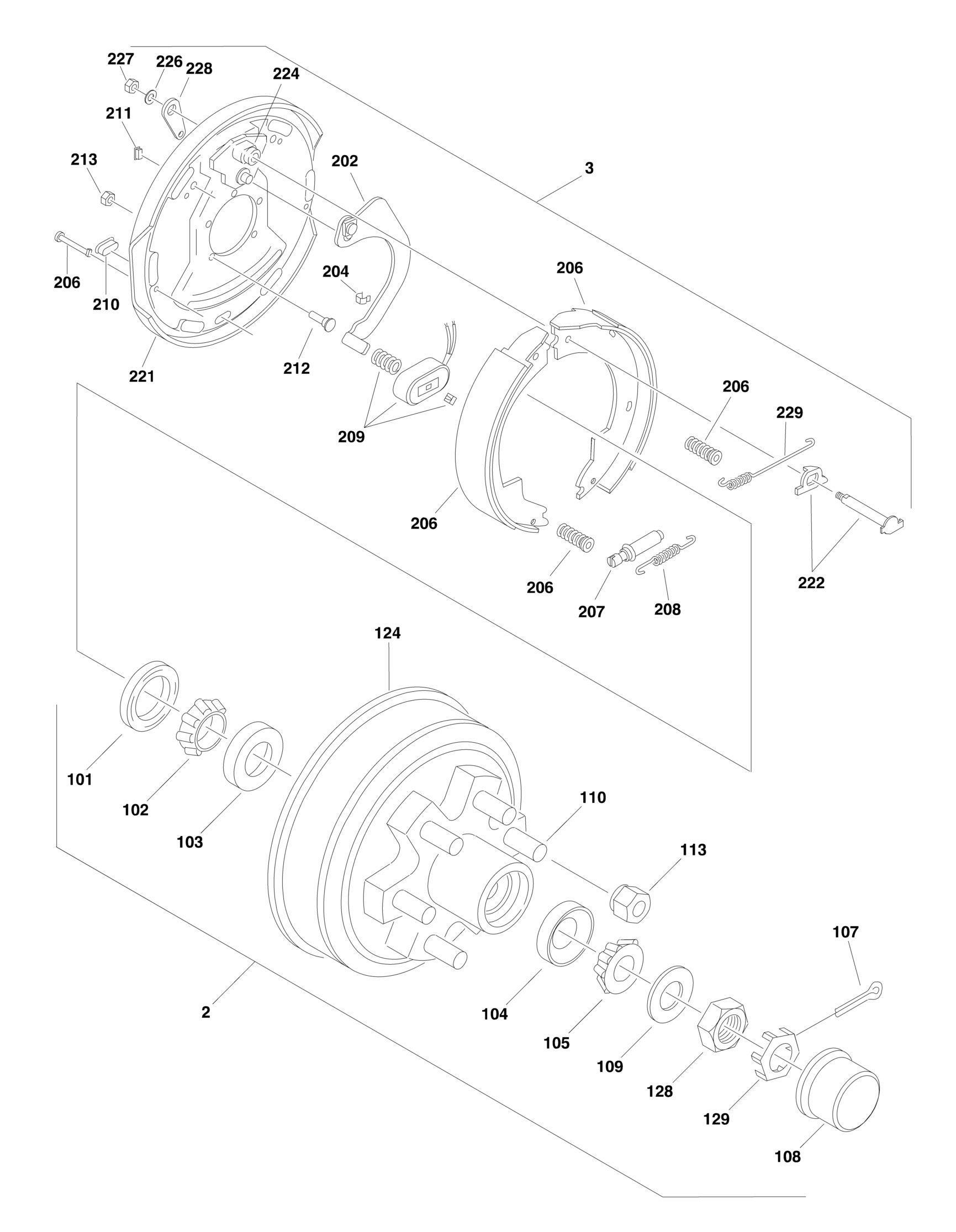

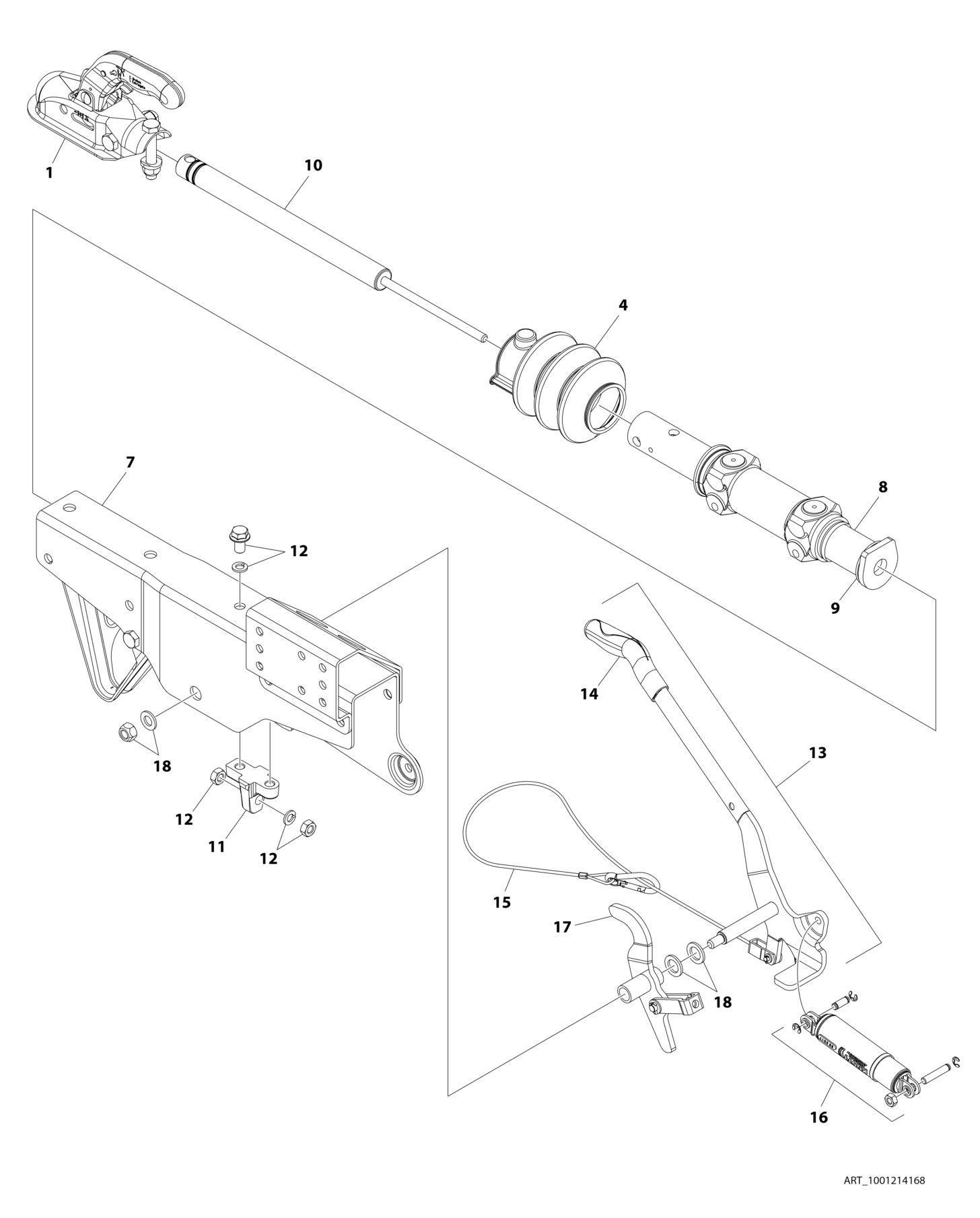

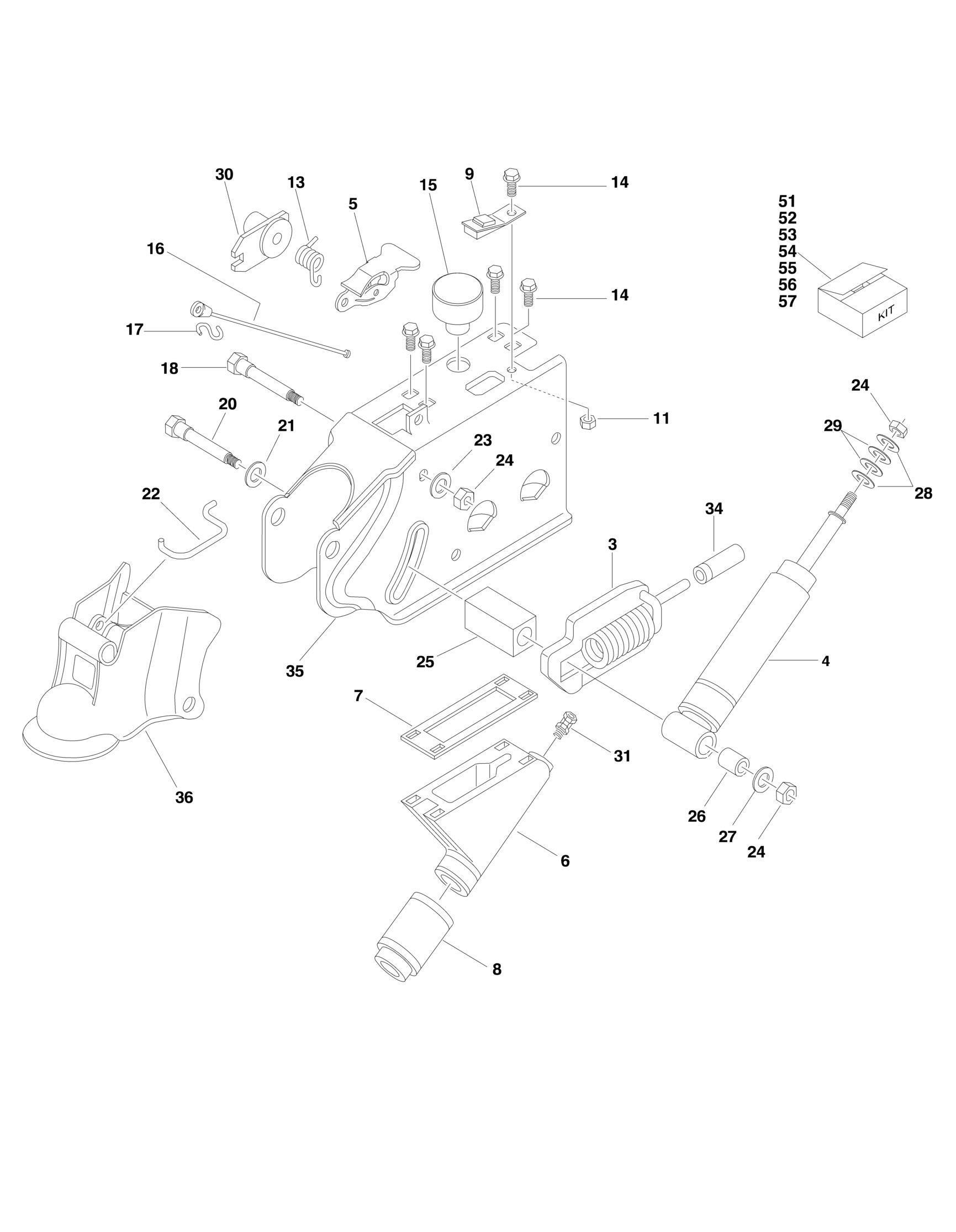

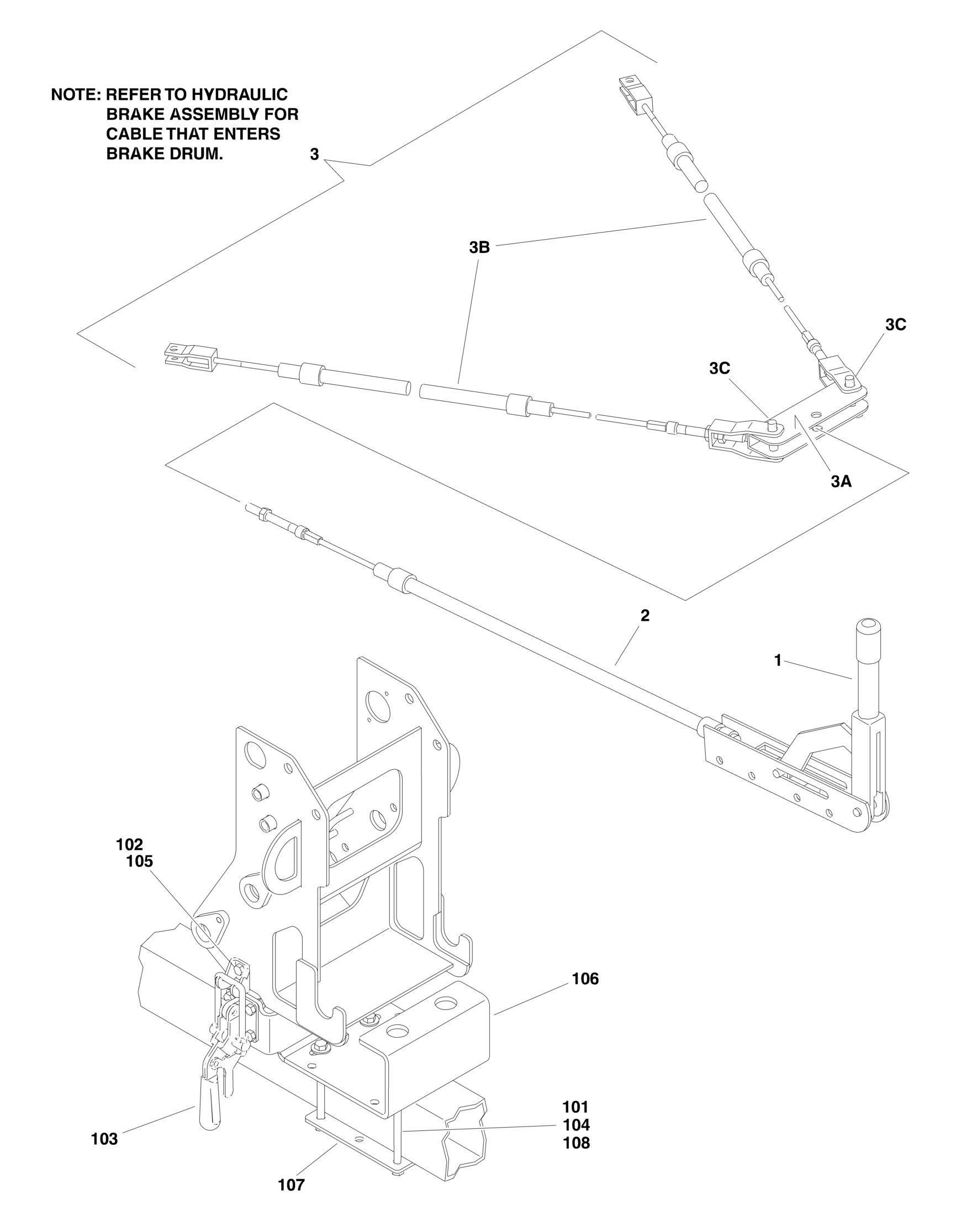

14 20 101 102 103 104 105 106 107 108 109 110 111 112 113

0100011 1001104509 0275439 0630468 0641407 0721004 0903560 2400087 2400088 3311405 3311005 3576773 3740150 4711000 4711400 4923545

AR 4 Ref 2 2 2 1 1 1 2 2 1 1 2 2 1

114

4923570

1

3121199

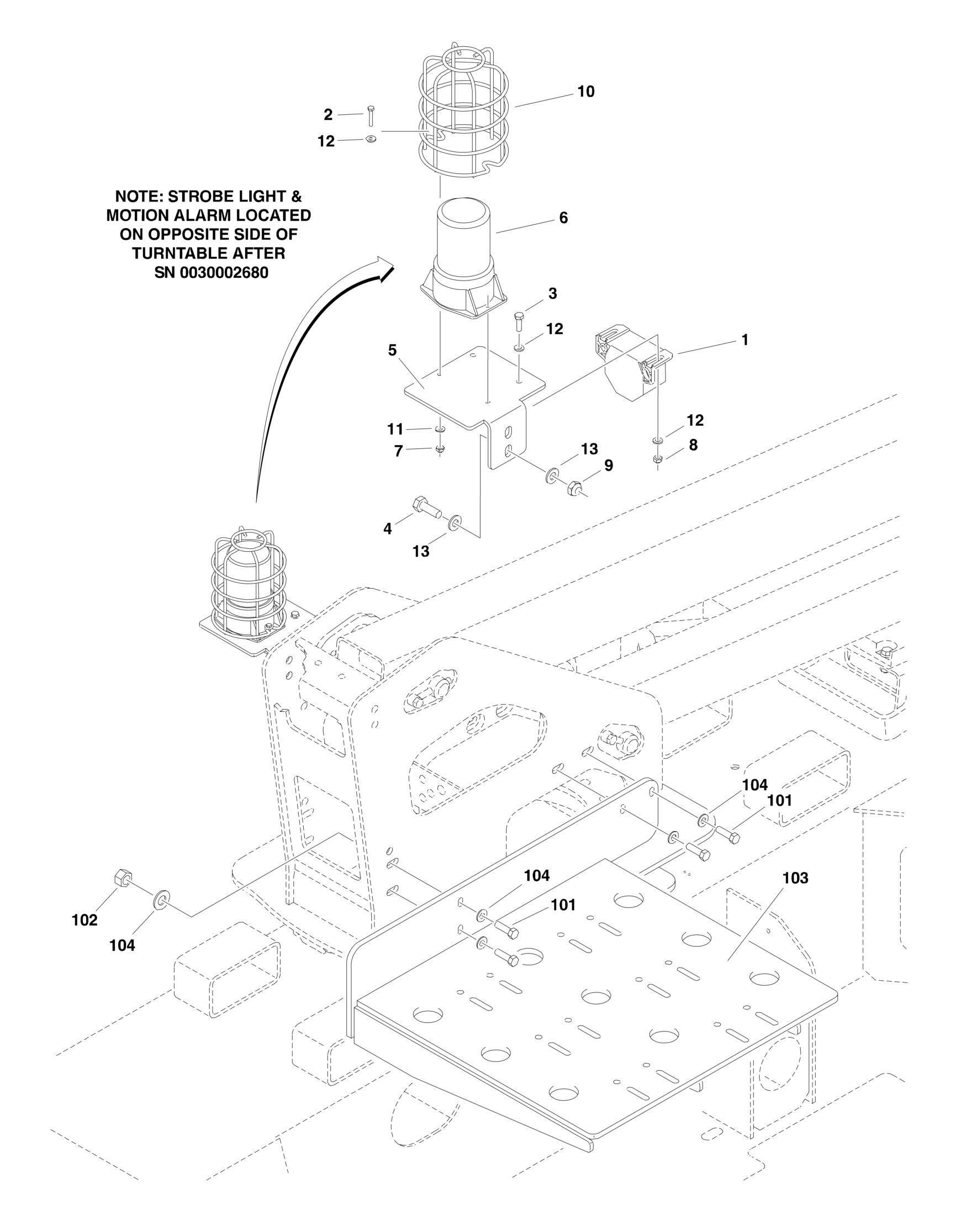

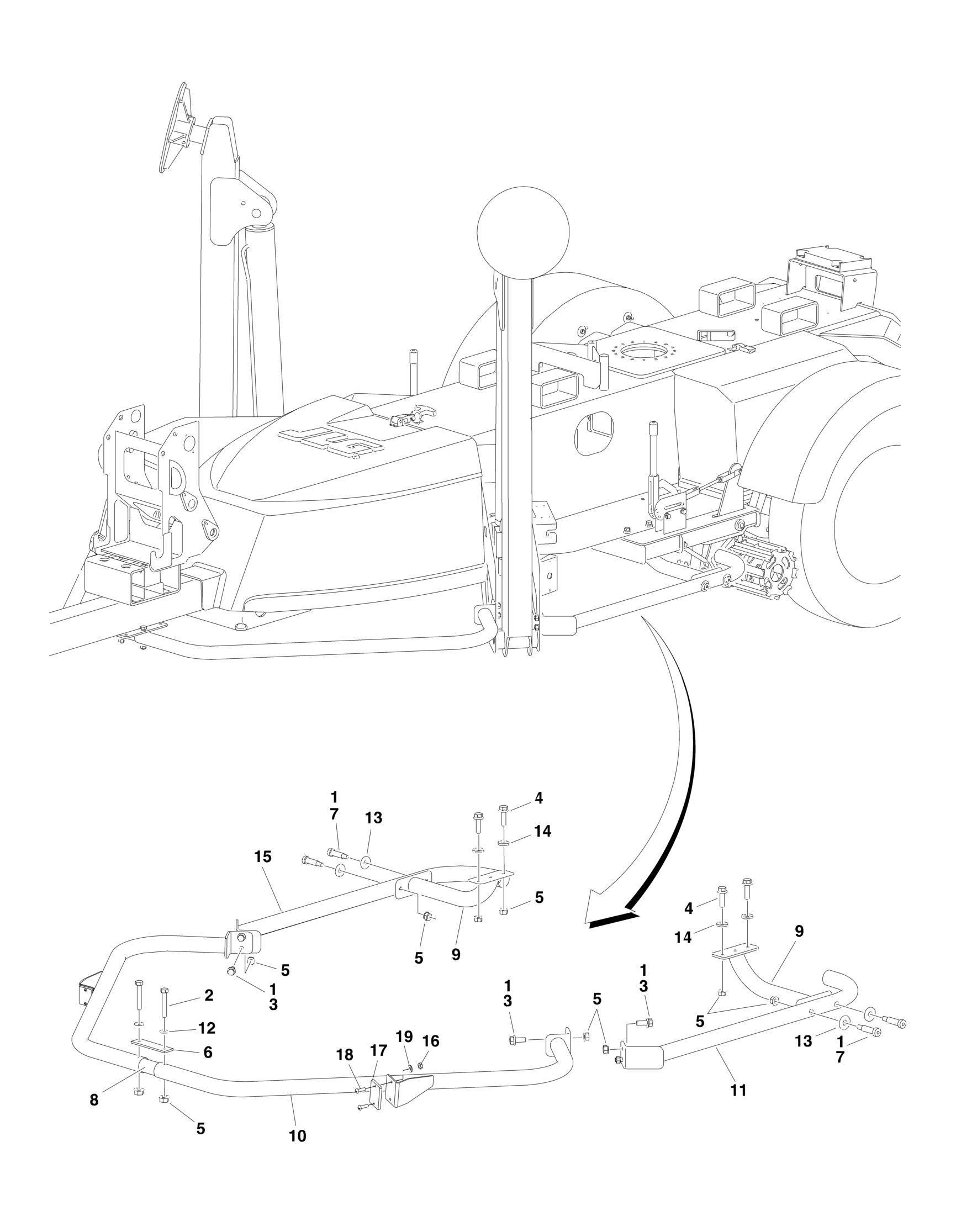

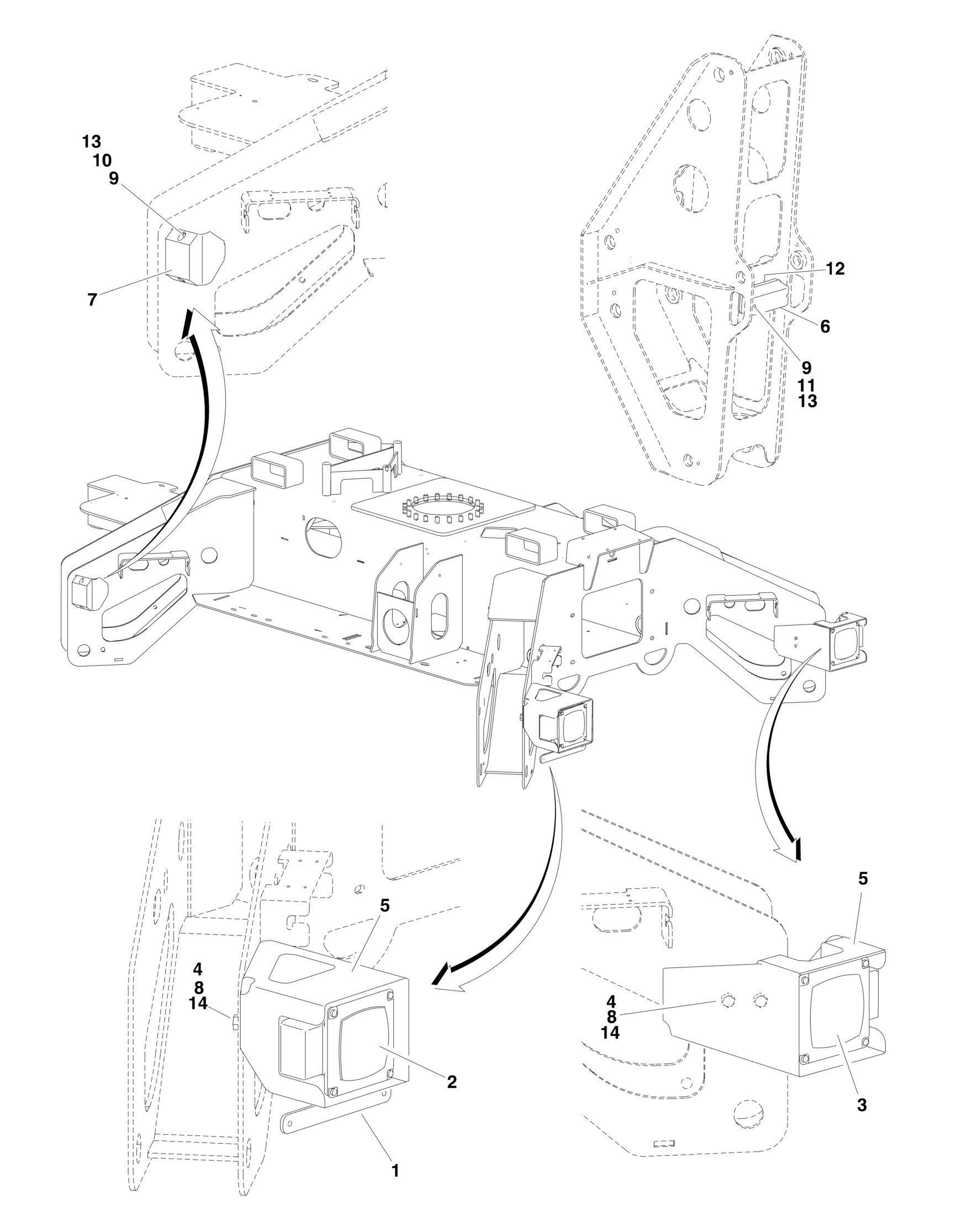

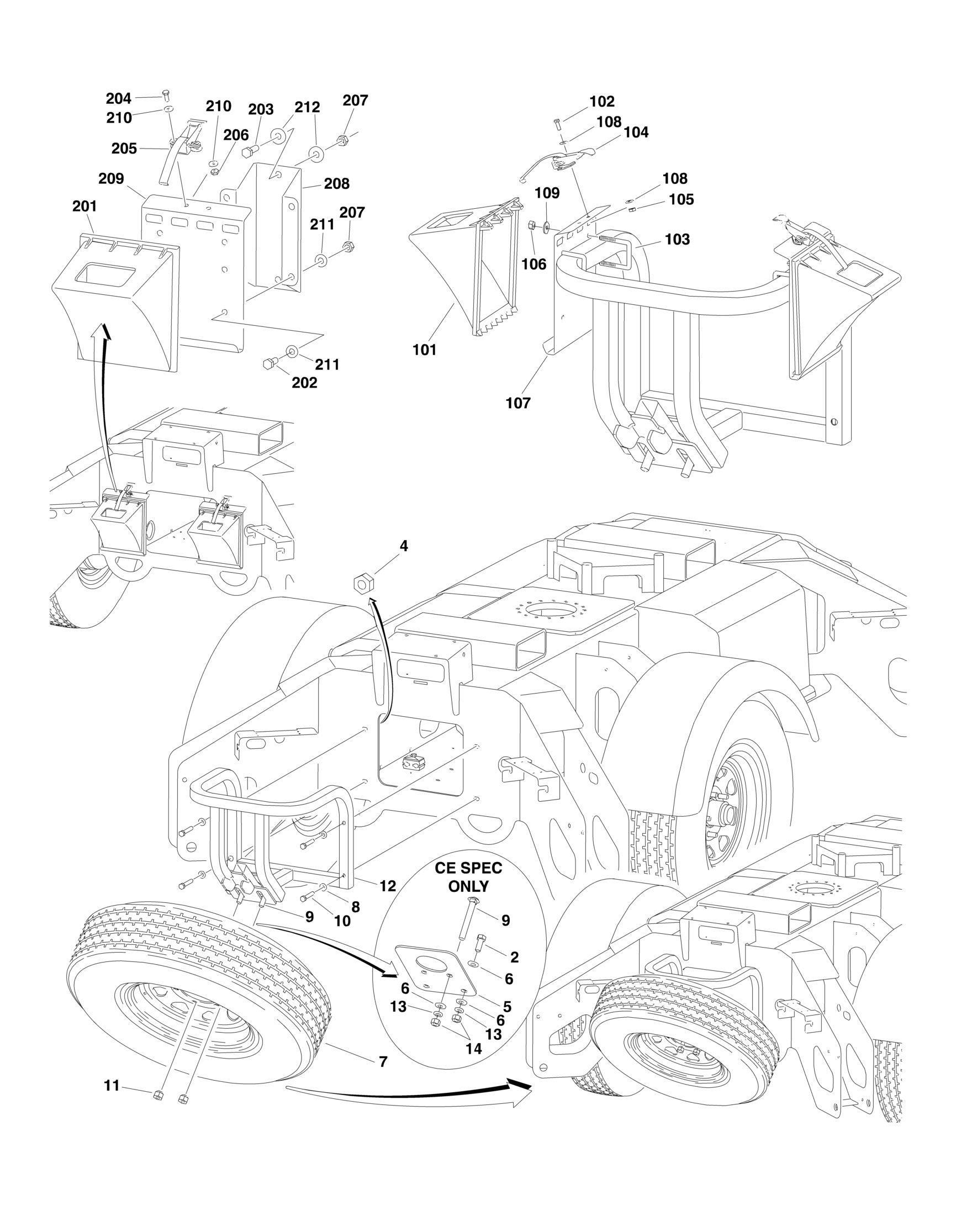

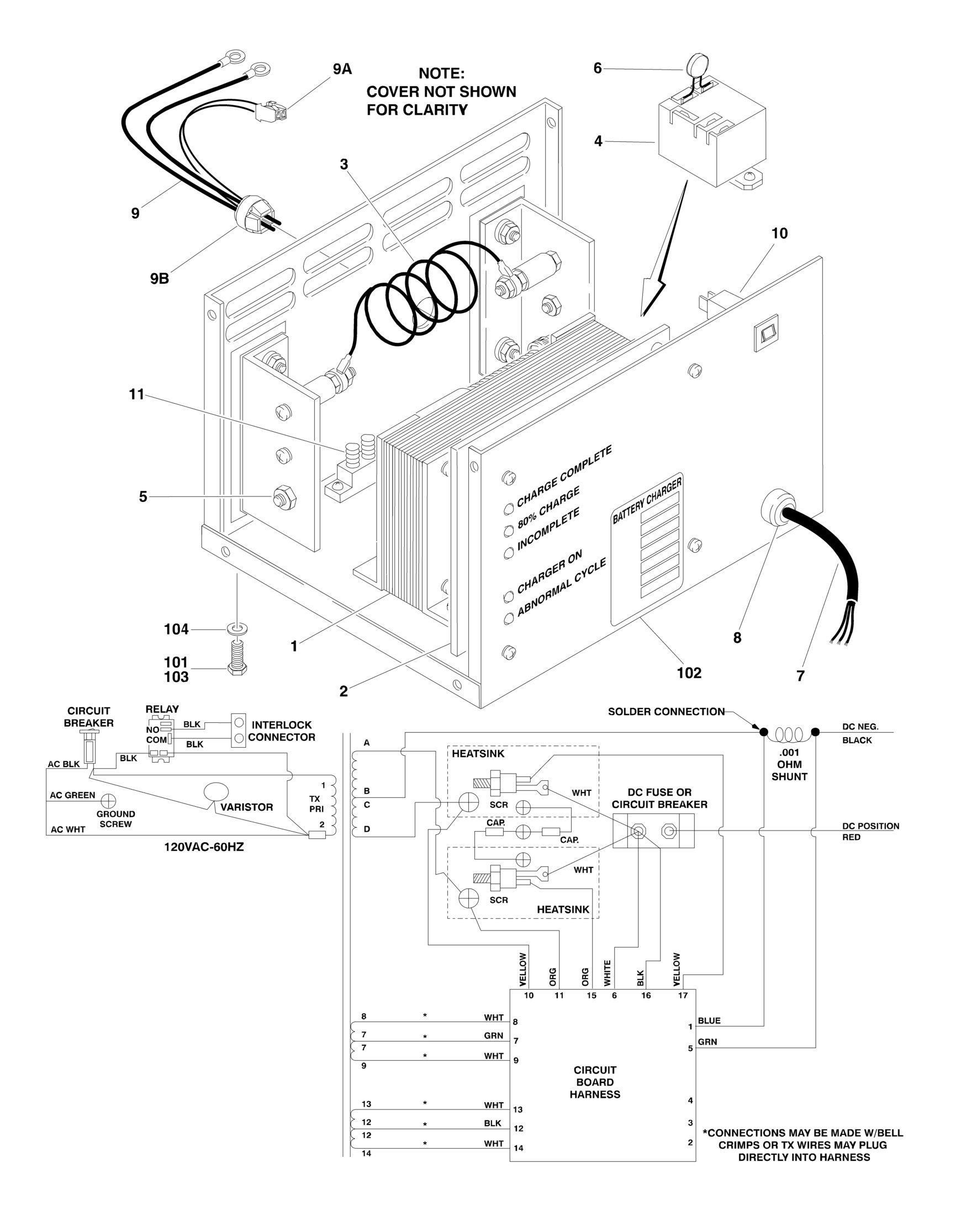

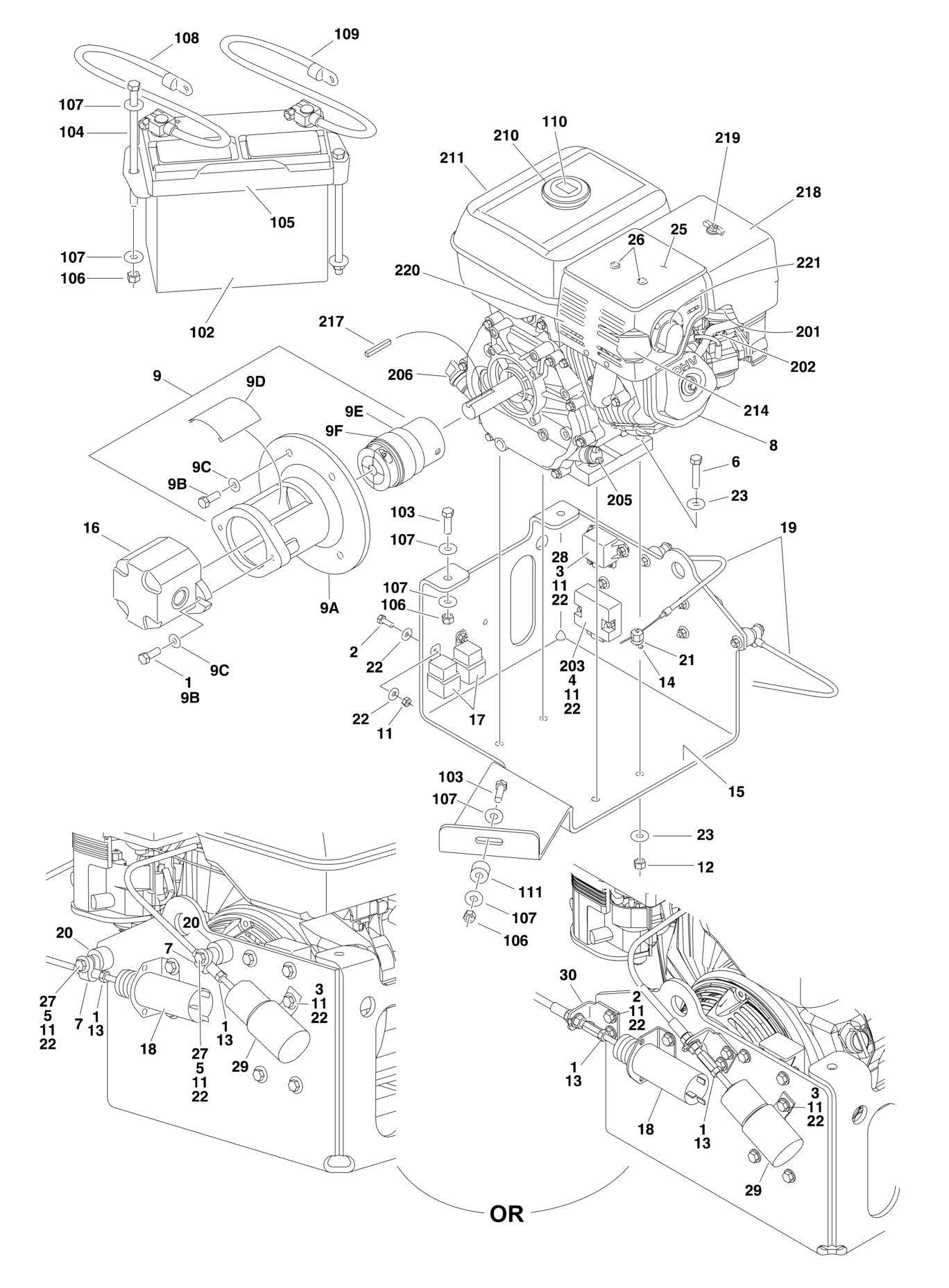

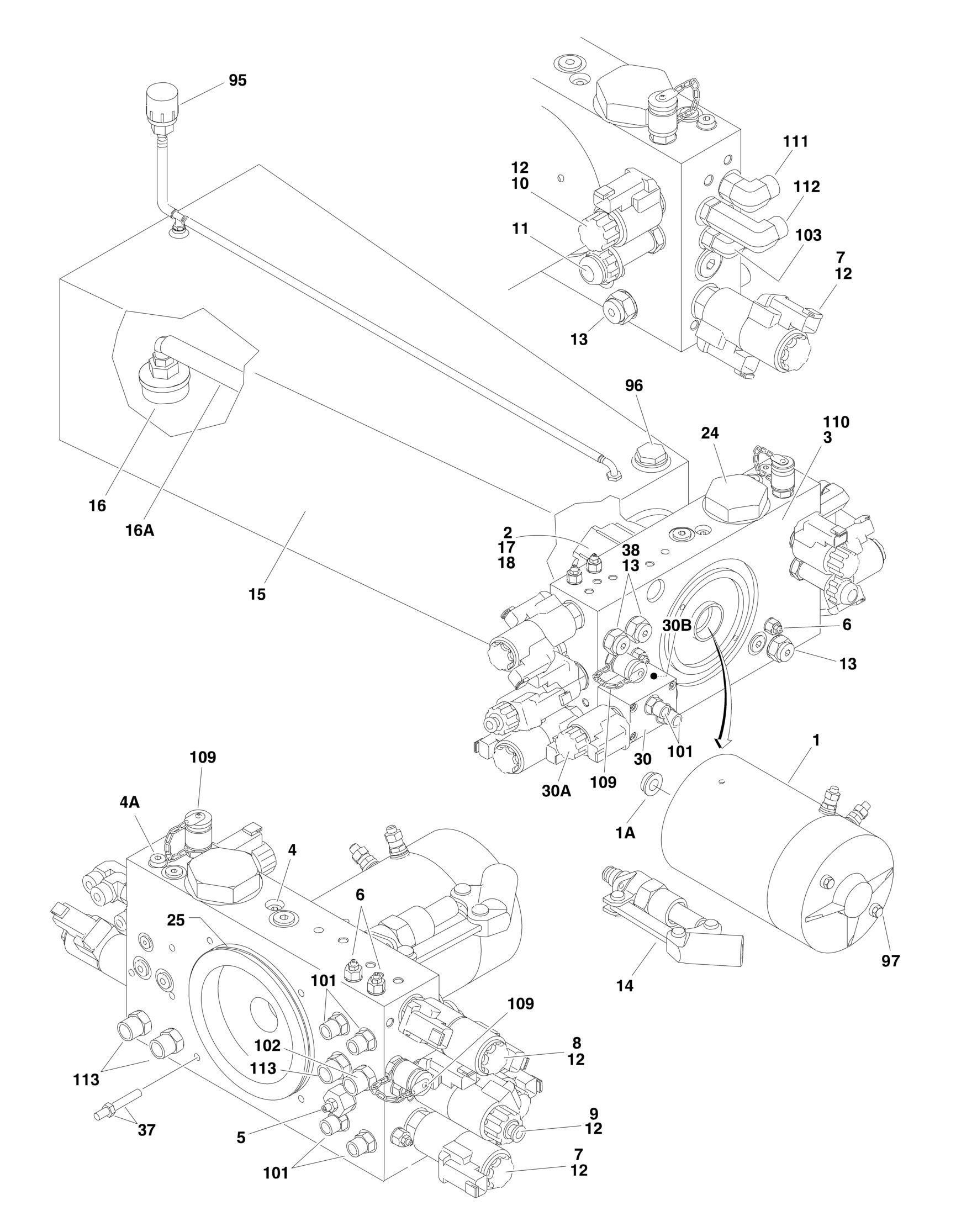

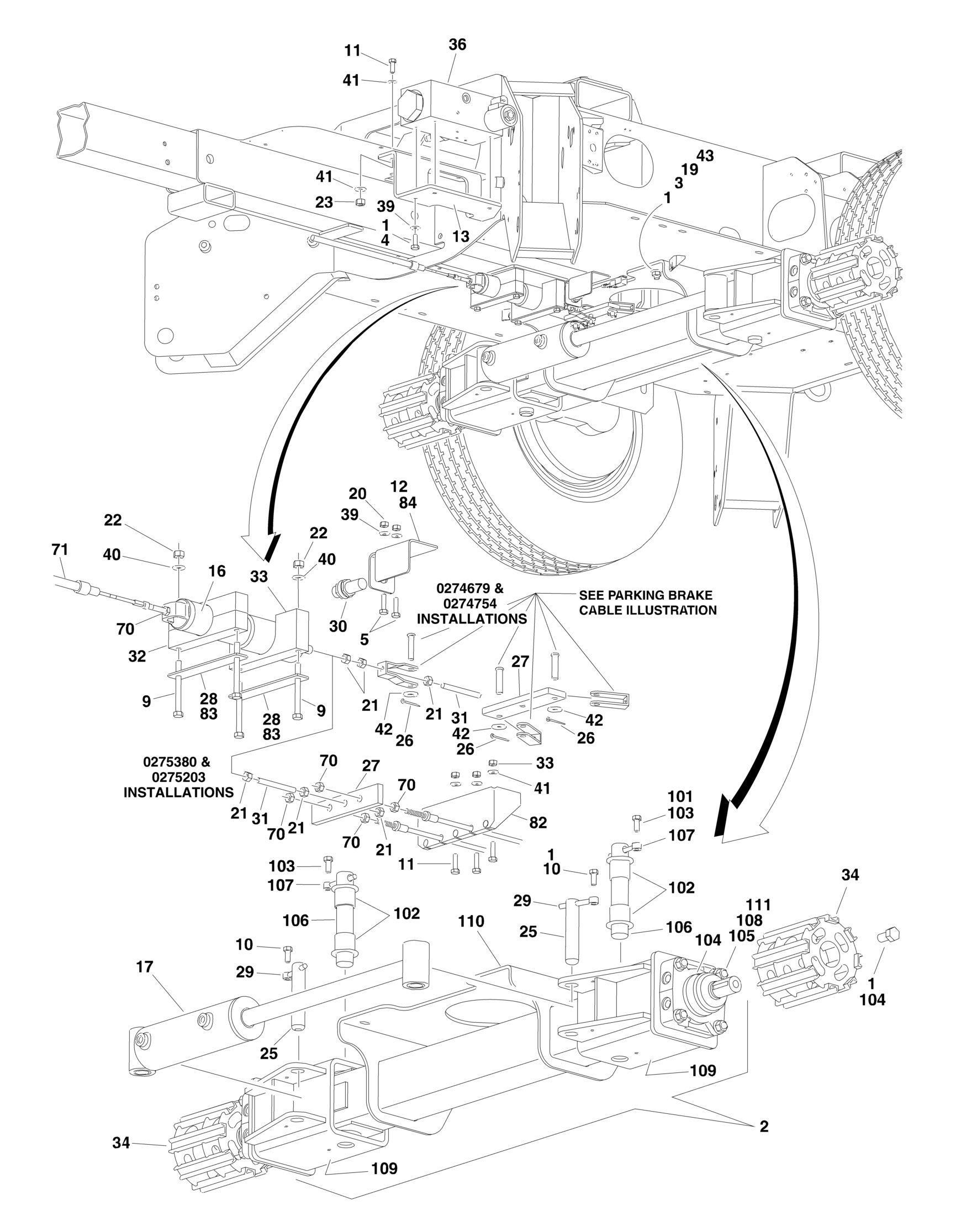

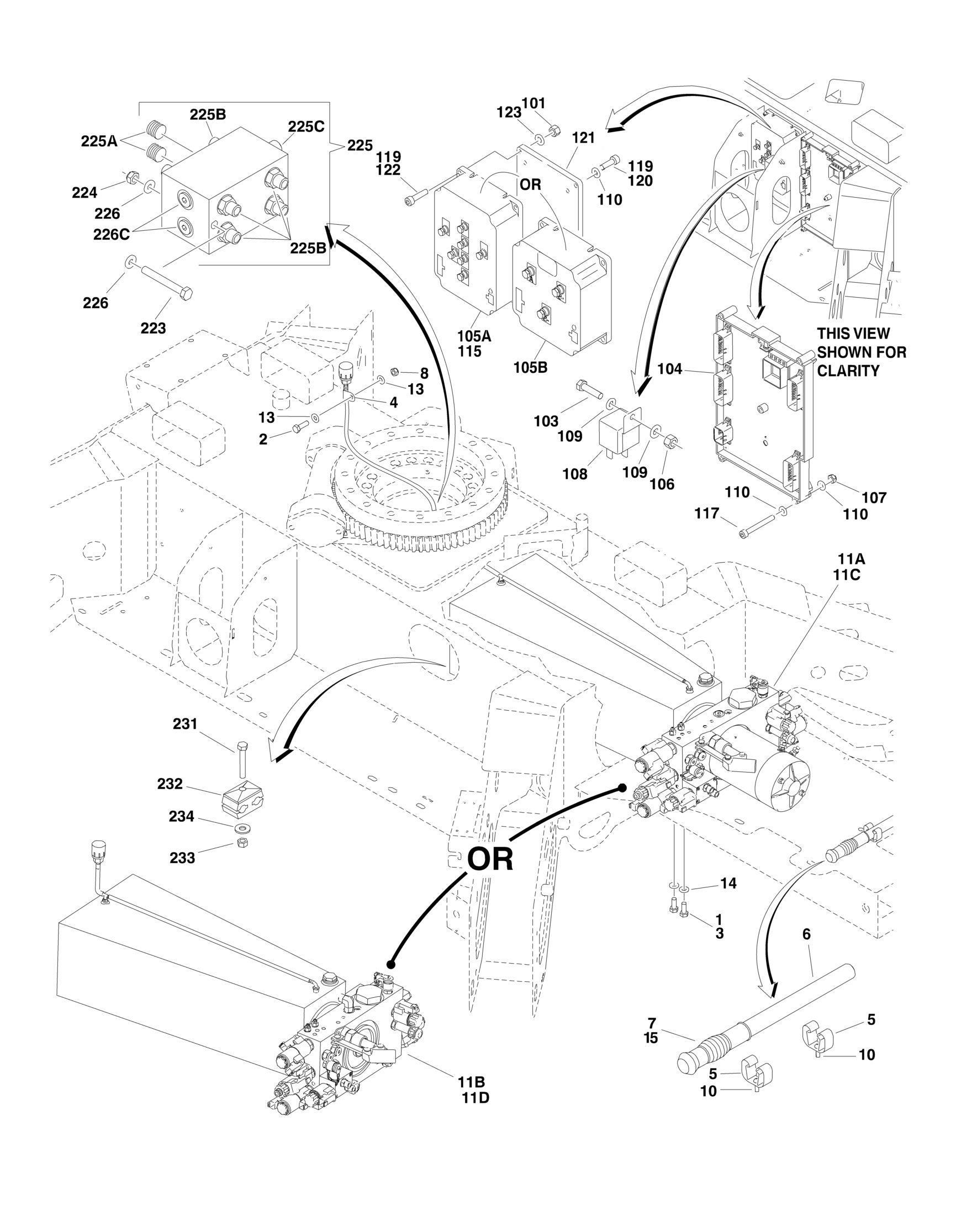

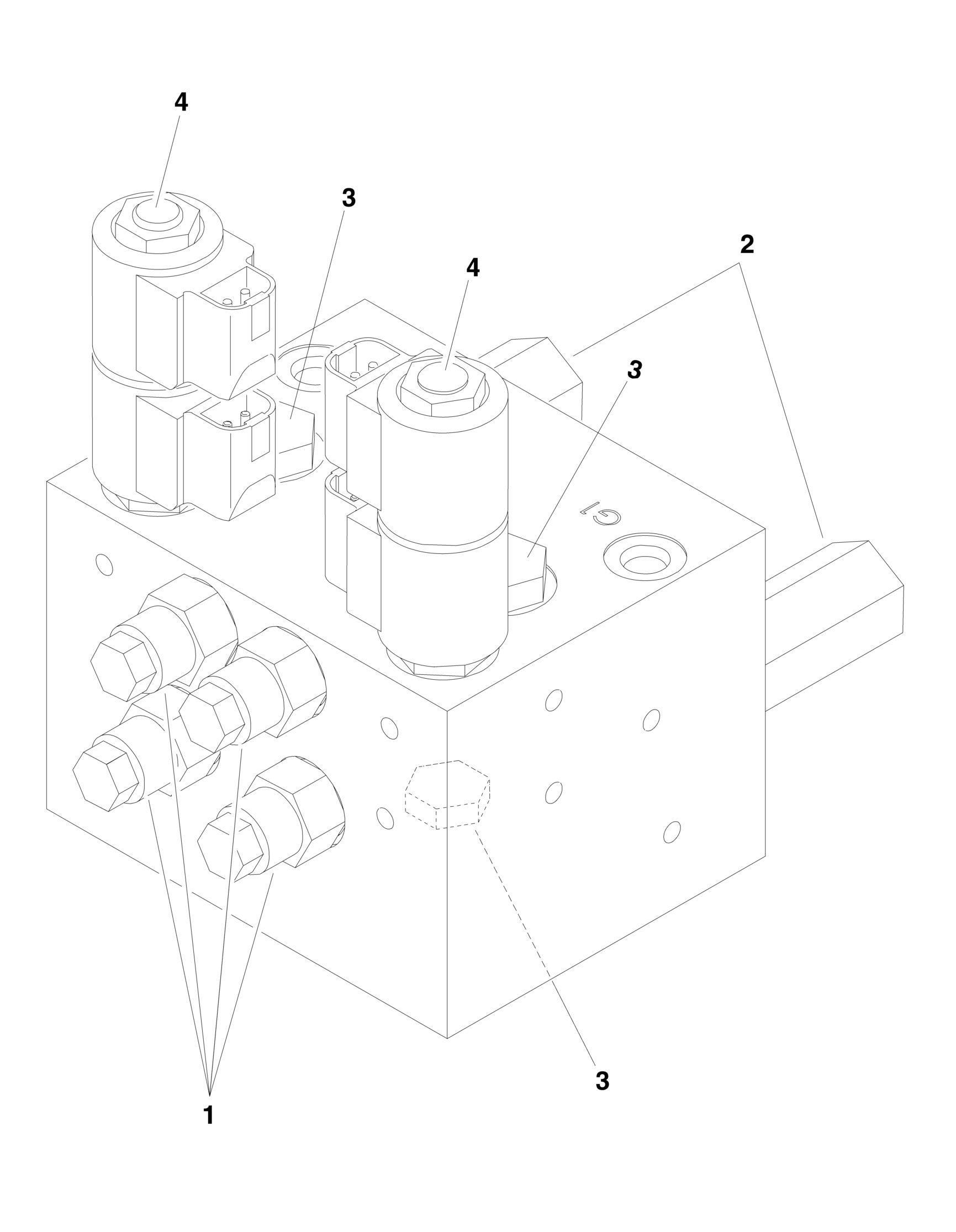

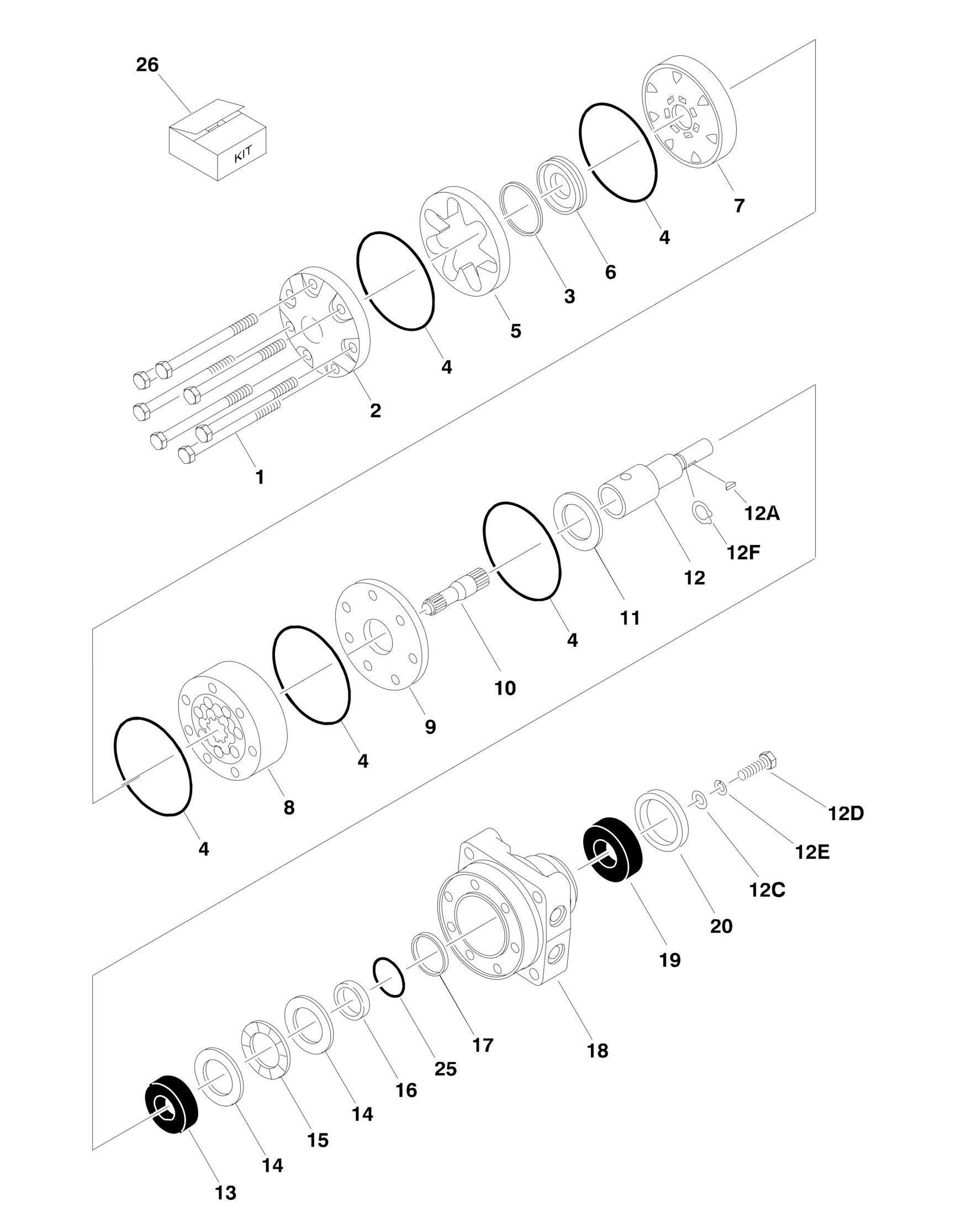

DESCRIPTION BATTERIES INSTALLATION Batteries Installation T350/T500J without Drive Option (Prior to SN 0030001896) Batteries Installation T350/T500J with Drive Option Batteries Installation – AGM Batteries T350/T500J without Drive Option (SN 0030006791 through 0030012032) Grease, Dielectric Grease, Battery Terminal Batteries Options: Battery - 6V/220Amp AGM Battery - 6V/220Amp Decal - Battery Charger (Not Shown - DECAL SECTION For Location) Decal - Battery Disconnect Nut, Acorn 5/16in-24 Pad, Battery (Prior to SN 0030003105) Strap, Tie-Down (Prior to SN 0030003105) Tape, Rubber Battery Cables Kit (Not Shown - See ELECTRICAL SECTION for Breakdown) Without Drive Option With Drive Option Bolt, Battery Hold-Down (SN 0030003105 through 0030012032) Nut, Serrated 3/8in-16NC (SN 0030003105 through 0030012032) Compound, Locking Plate, Hold-Down (SN 0030003105 through 0030012032) CONTACTOR INSTALLATION Screw 5/16in-18NC x 1in Bolt 1/4in-20NC x 7/8in Screw, Machine #10-24NC x 1/2in Bracket, Contactor Mount Fuse - 300 Amp Fuseholder Locknut 1/4in-20NC Locknut #10-24NC Bar, Clamping Relay Flatwasher #10 Thin Flatwasher 1/4in Thin Cable, Electrical (Fuse to Battery B+) (See ELECTRICAL SECTION for Breakdown) Cable, Electrical

T350/T500J

REV B E A

C

93