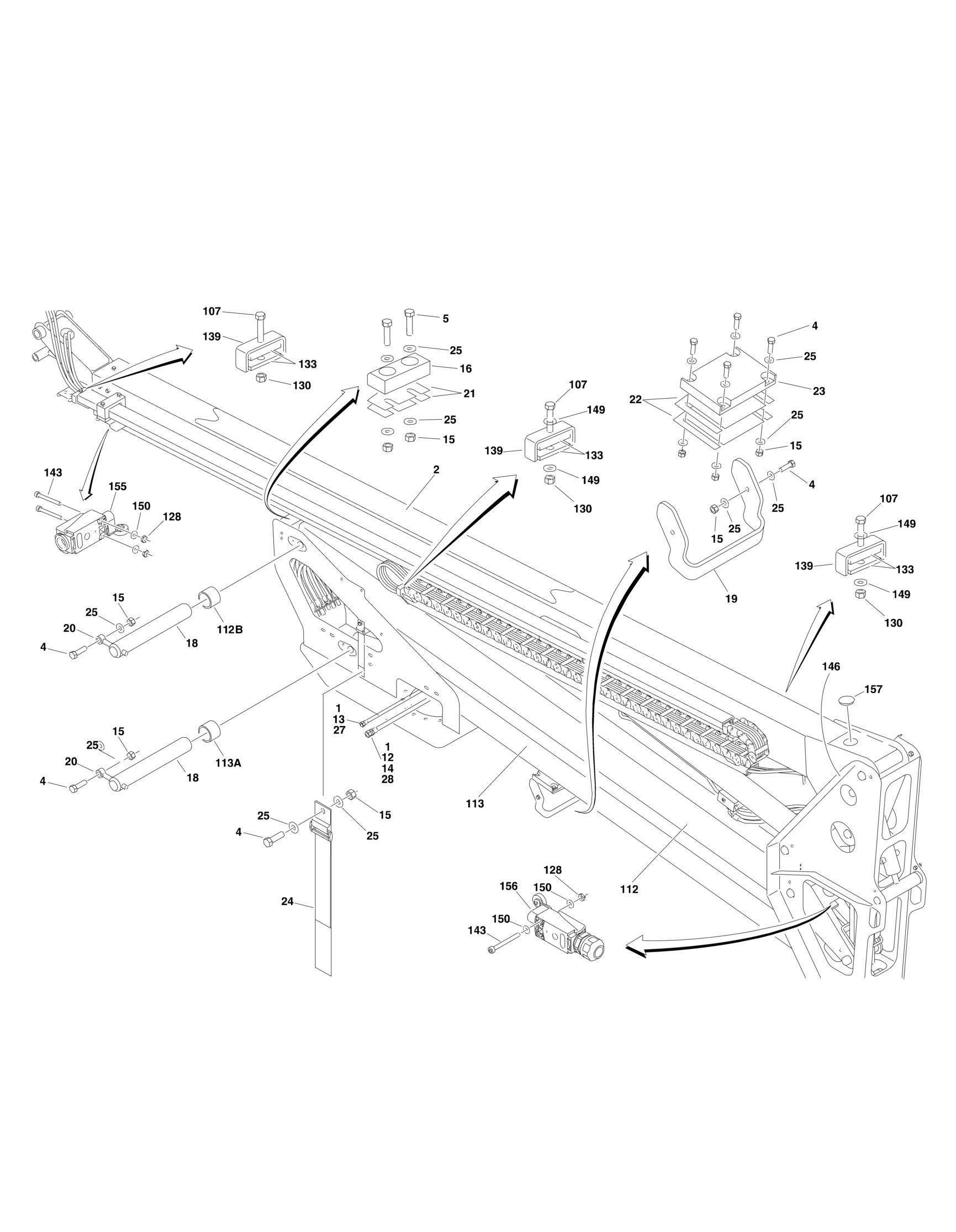

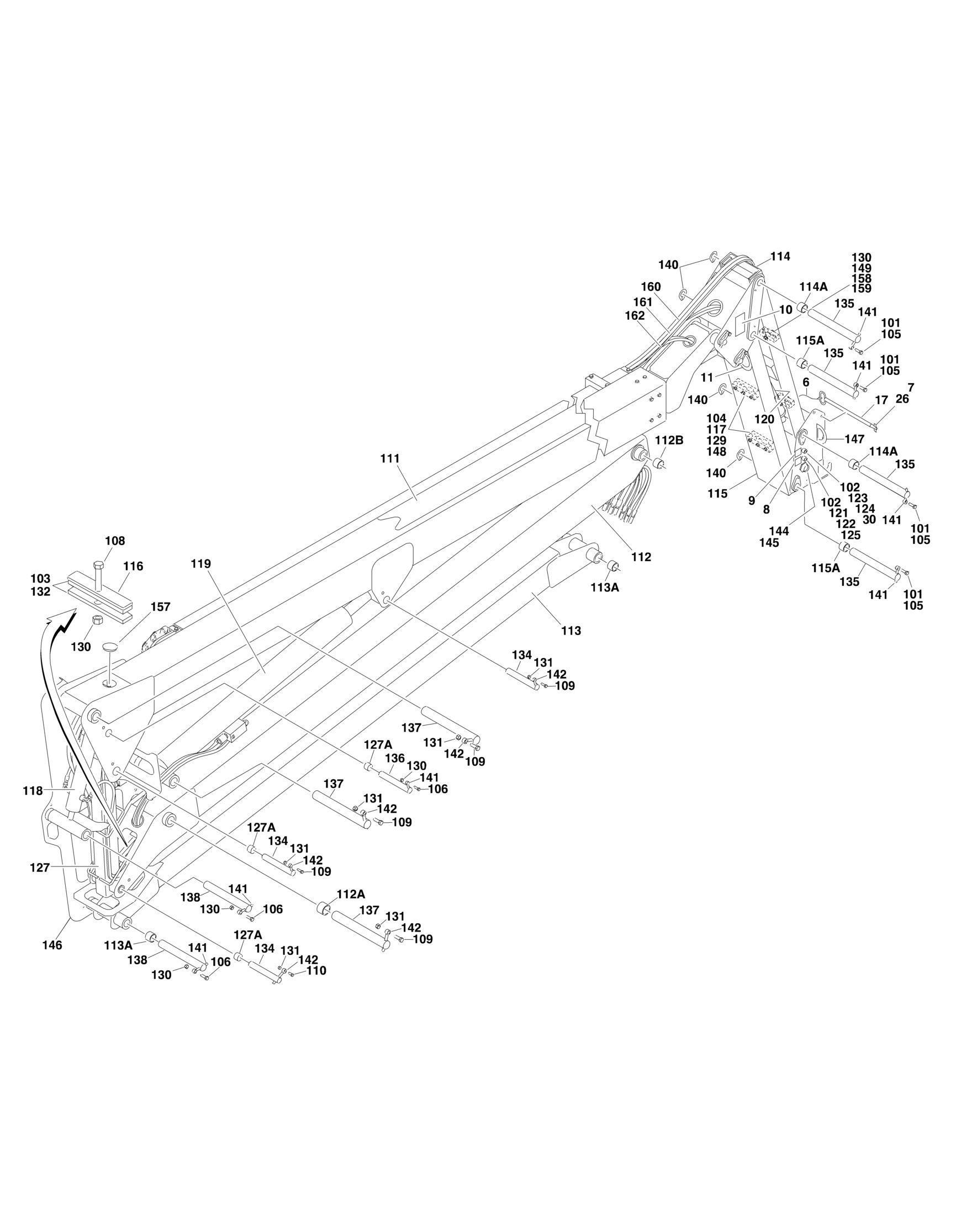

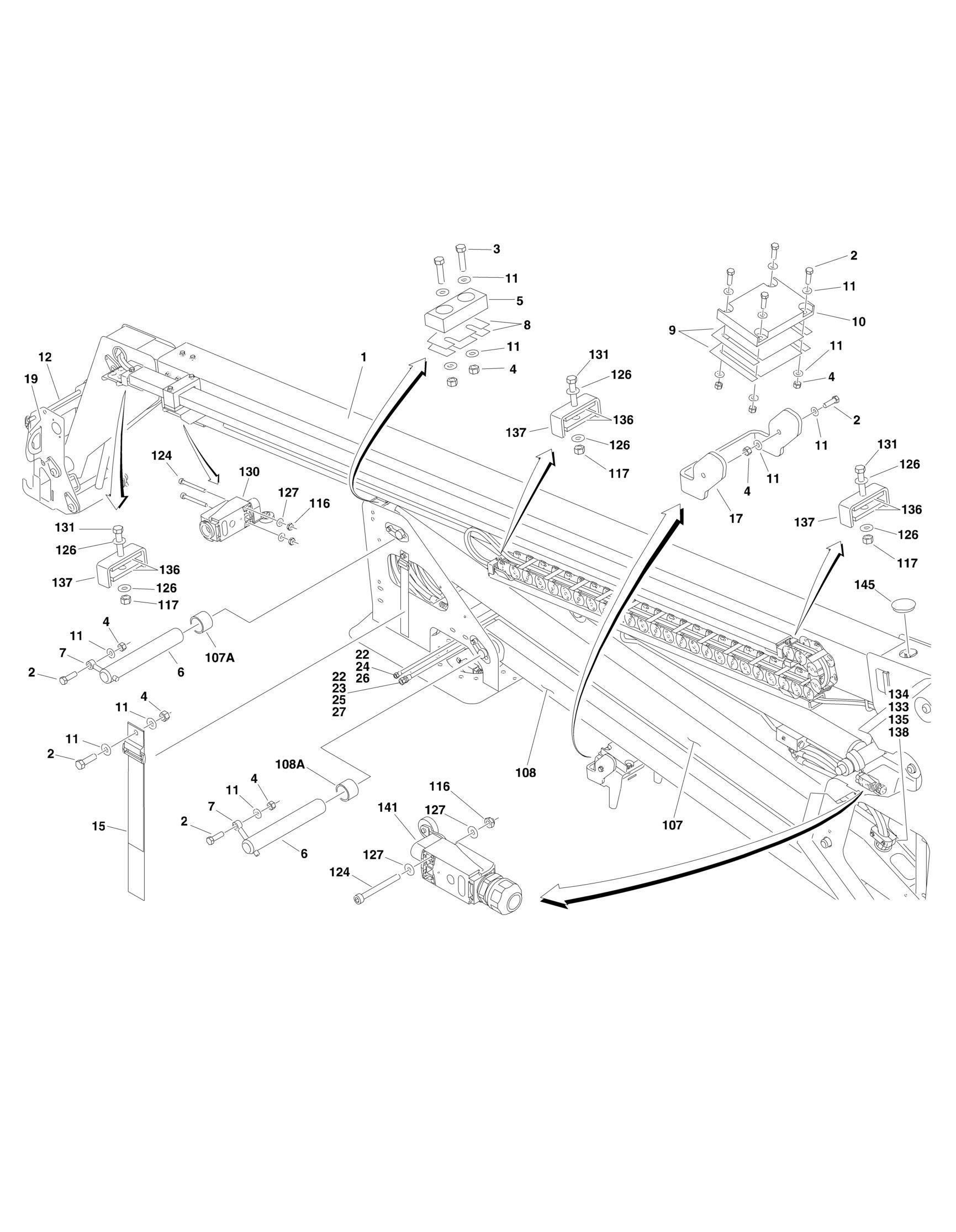

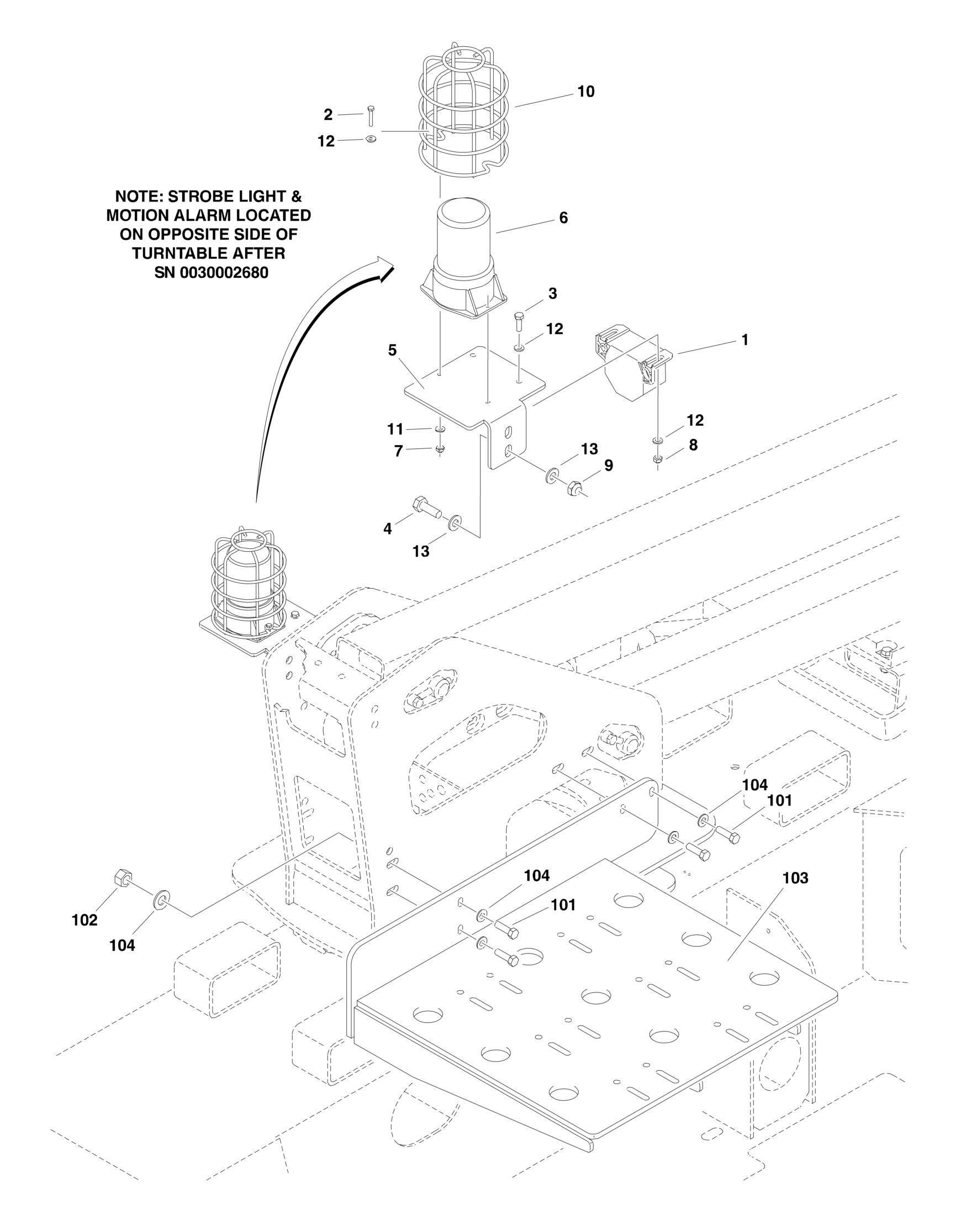

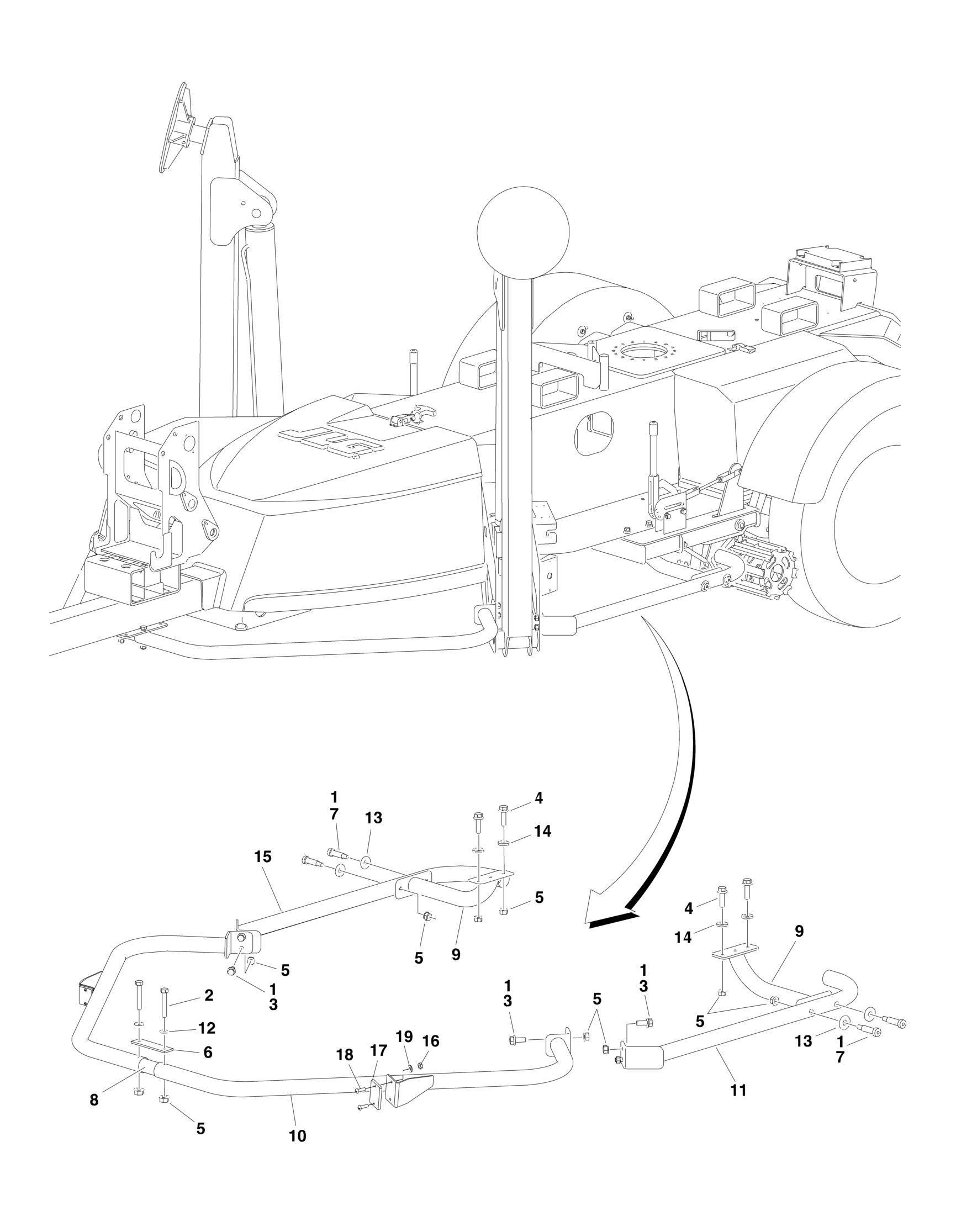

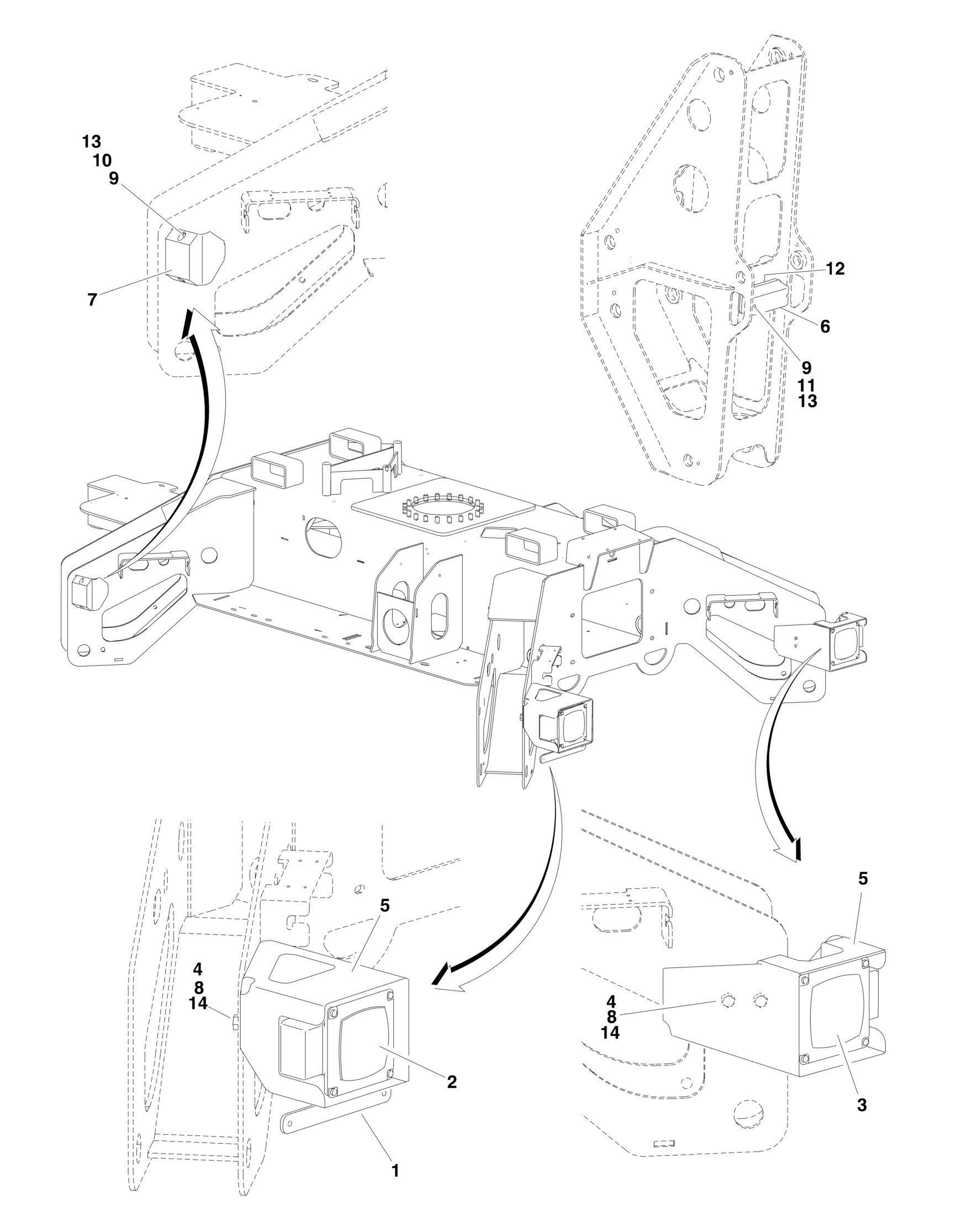

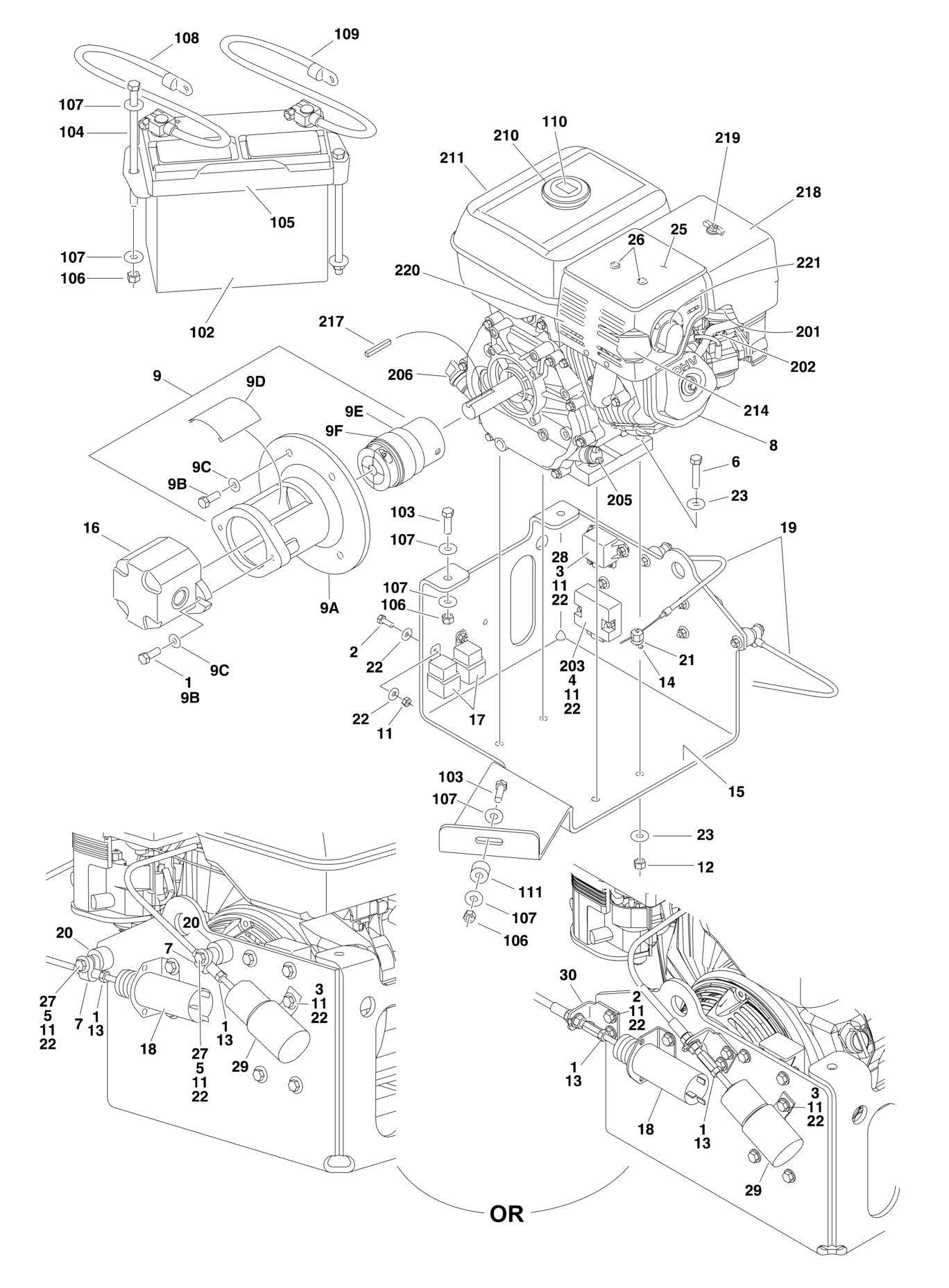

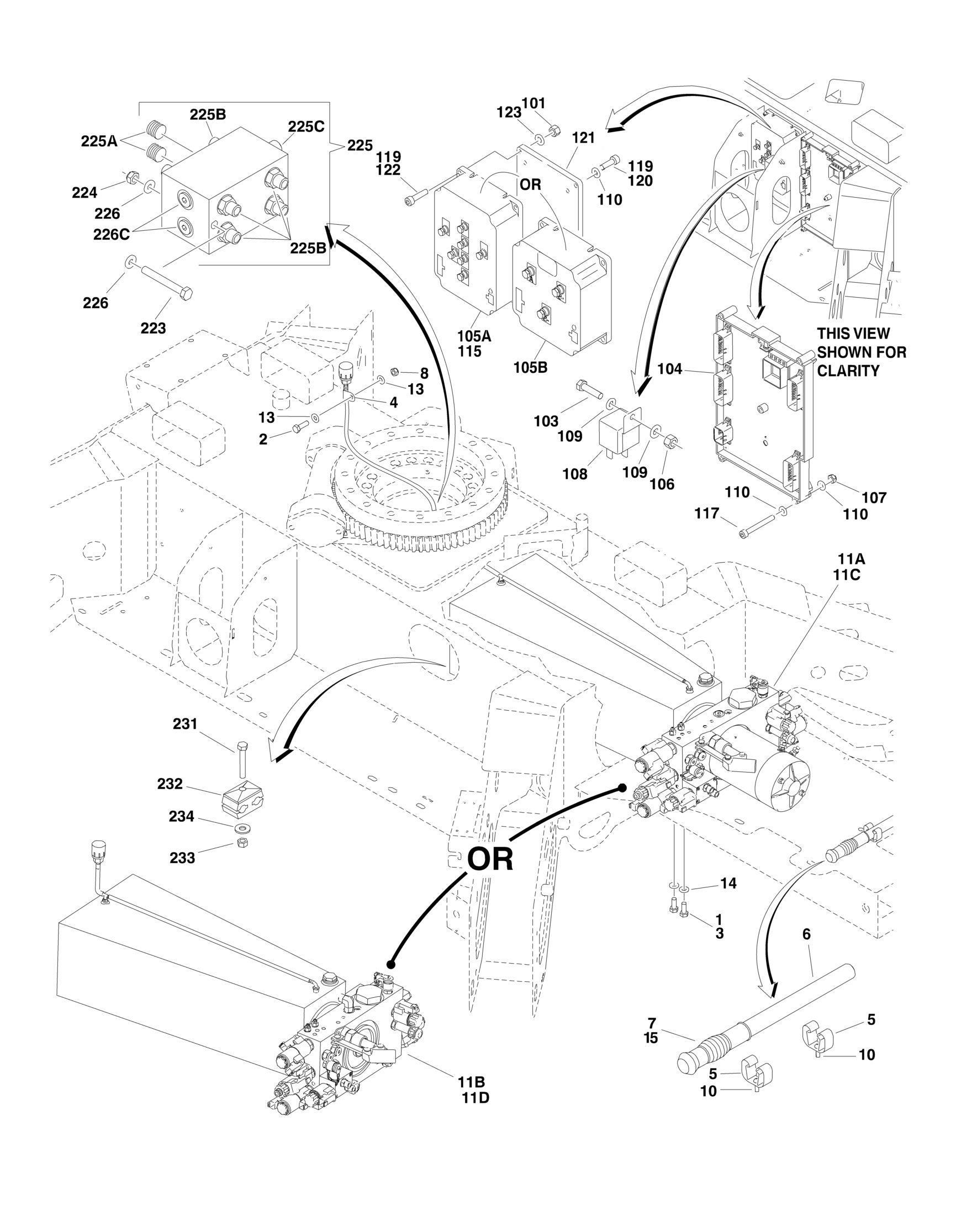

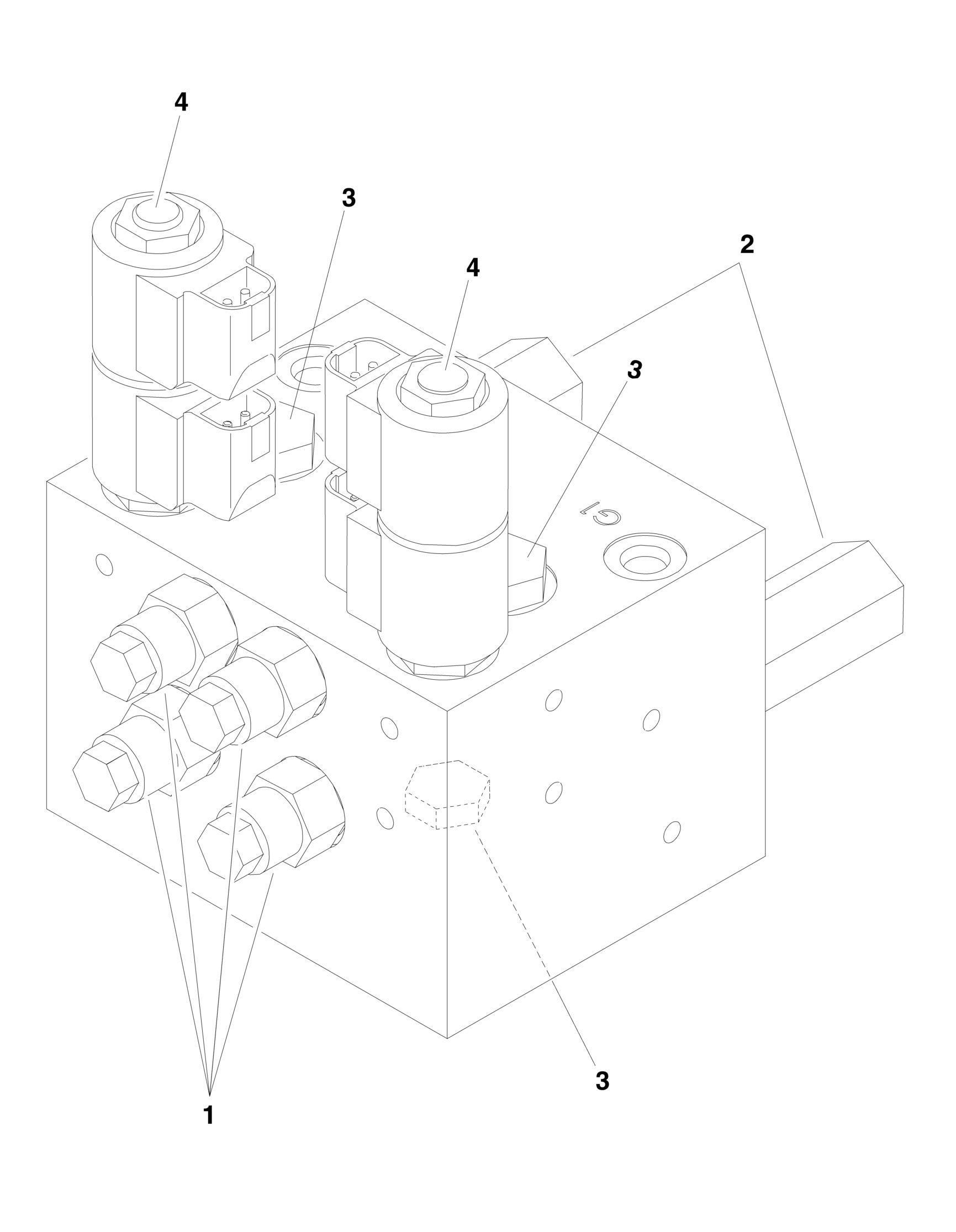

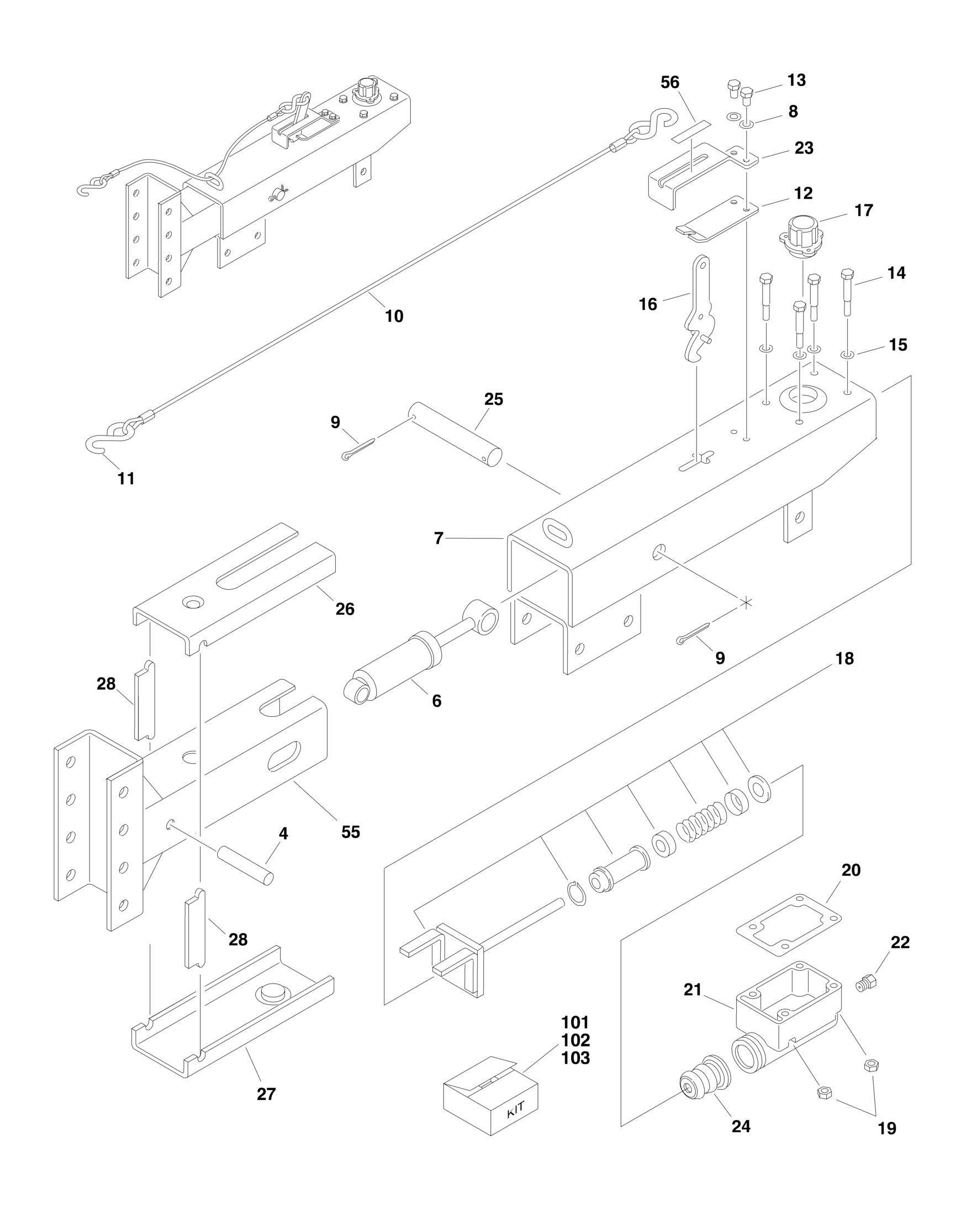

SECTION 1 - FRAME FIGURE 1-21. CONTROL MODULES AND VALVES INSTALLATION ITEM

4641342

QTY Ref Ref Ref Ref Ref AR Ref 1 1 3 1 2 1 1 Ref 1 1 2 Ref 1

11B

4641344

1

11C

4641343

1

11D

4641345

1

13 13 13 14 15

4811900 4711400 4811900 0100081

1 2 2 2 3 4 5 6 7 8 8 8 10 11 11A

PART NUMBER 0273616 0273618 0273617 0273619 0100011 0700610 0700812 0760810 1320263 1380136 2560122 2560123 3290605 3290805 3820017

0273793

Ref 2 2 3 AR Ref Ref

0275776

Ref

9984274 0273794 3311405 0700510 1600370

Ref Ref 4 1 1

105 105A

1600371

Ref 1

105A

1600412

1

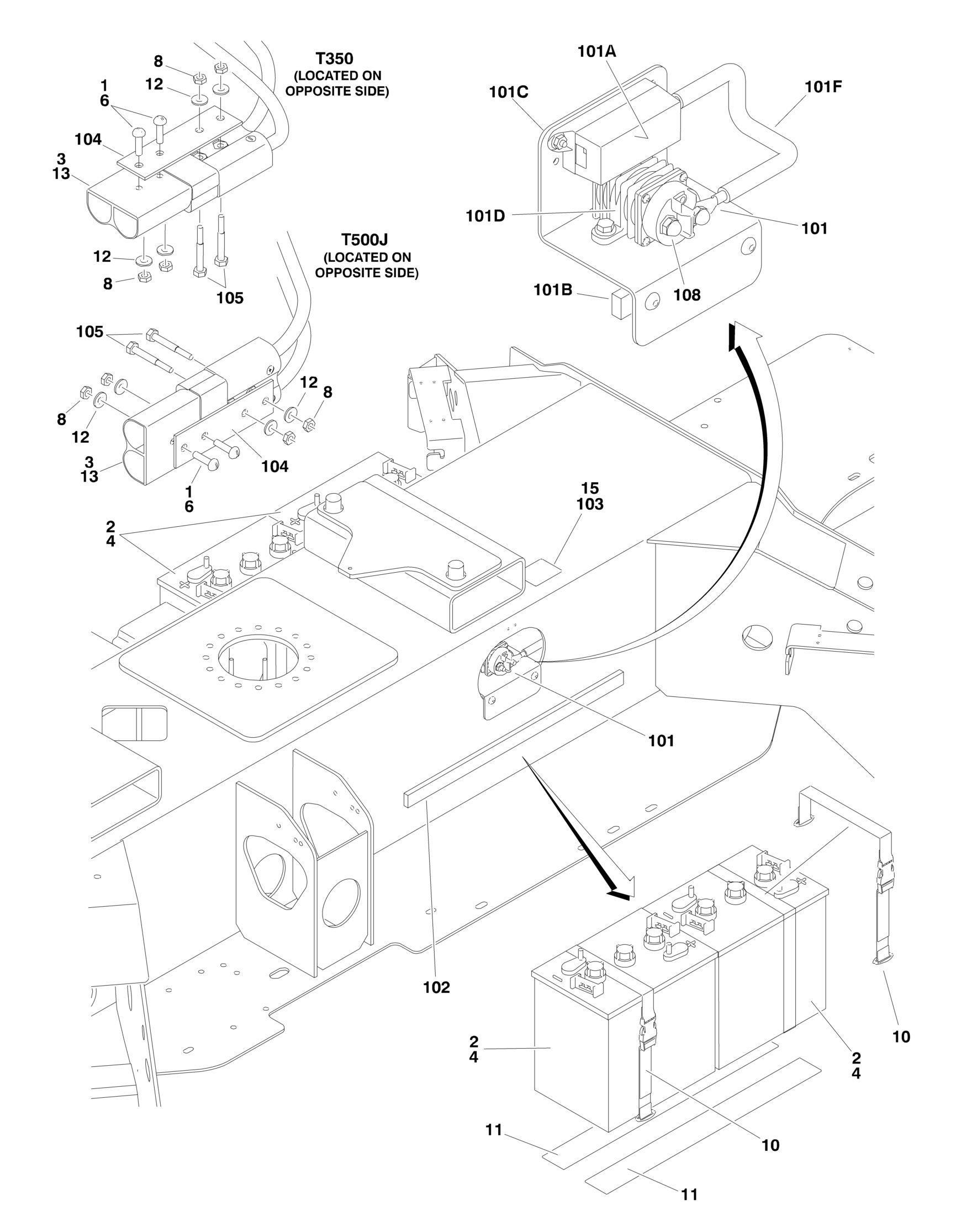

101 103 104

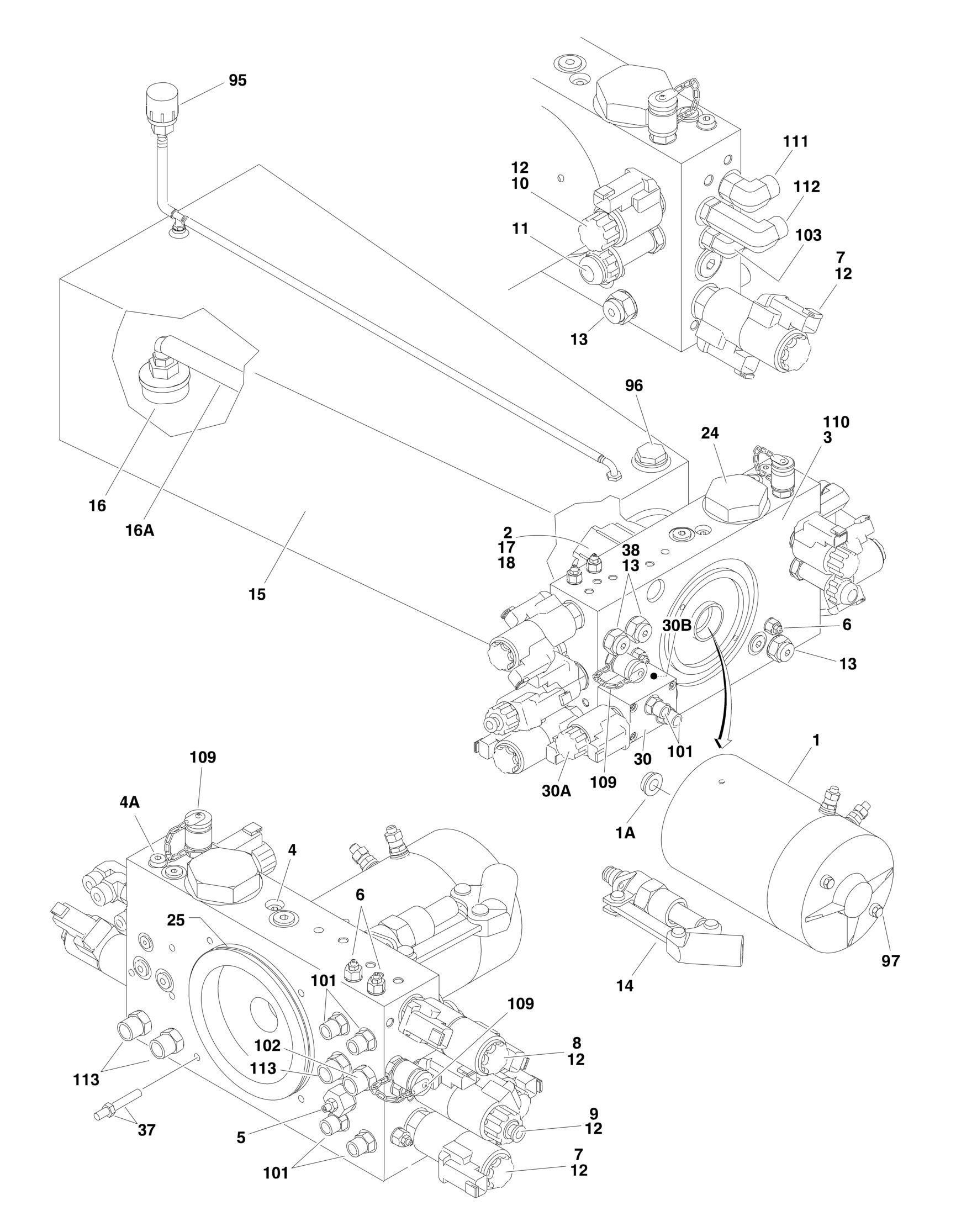

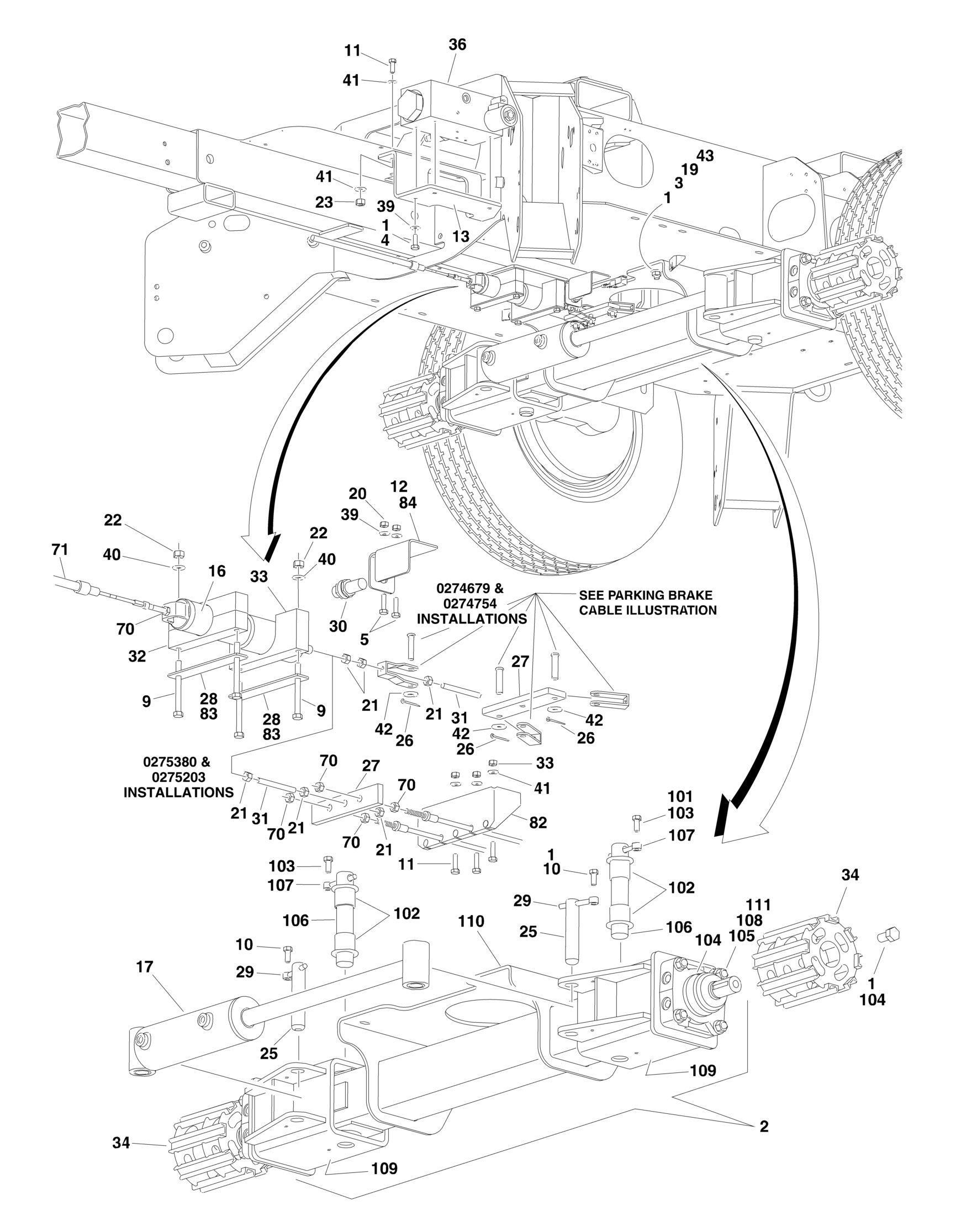

3121199

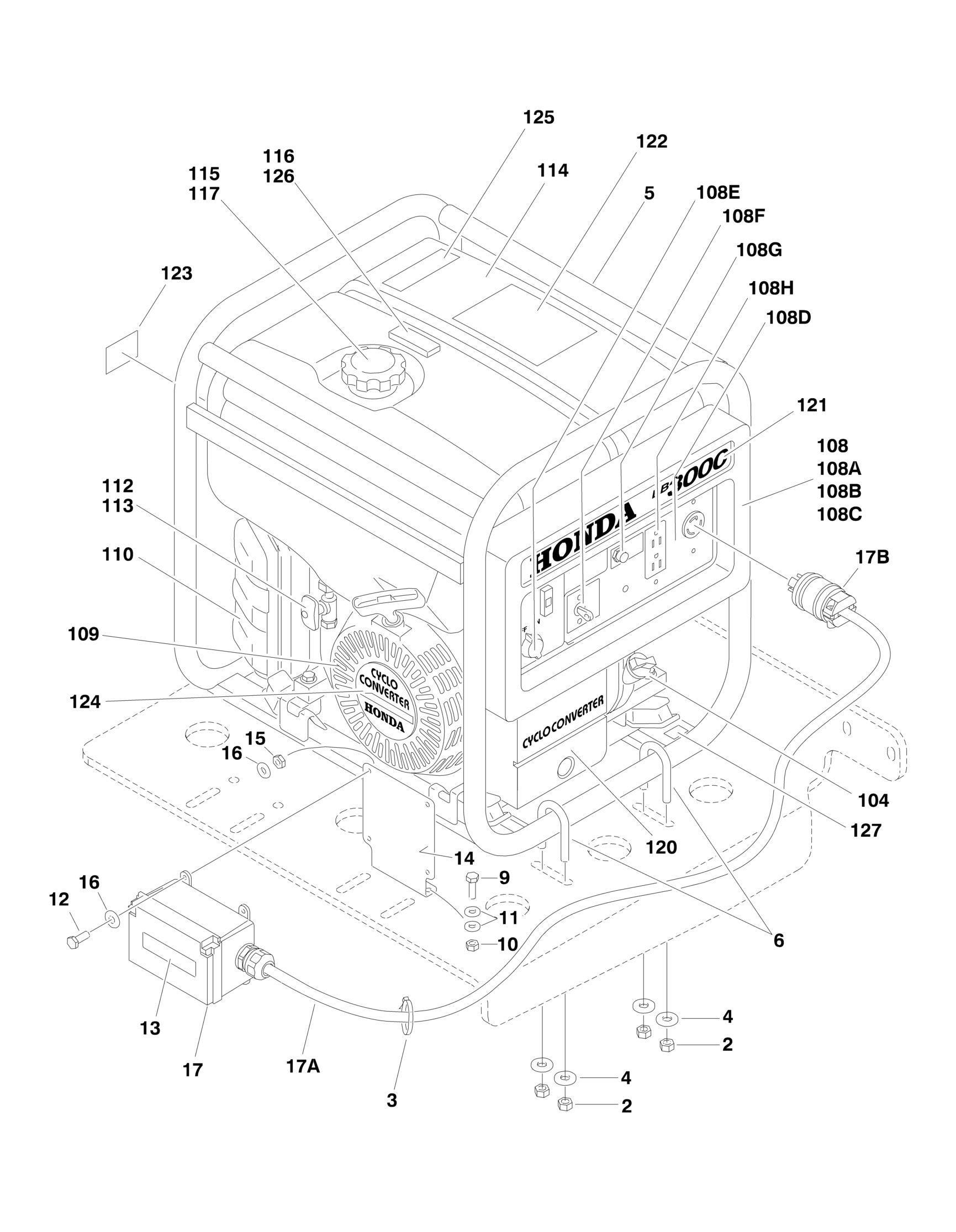

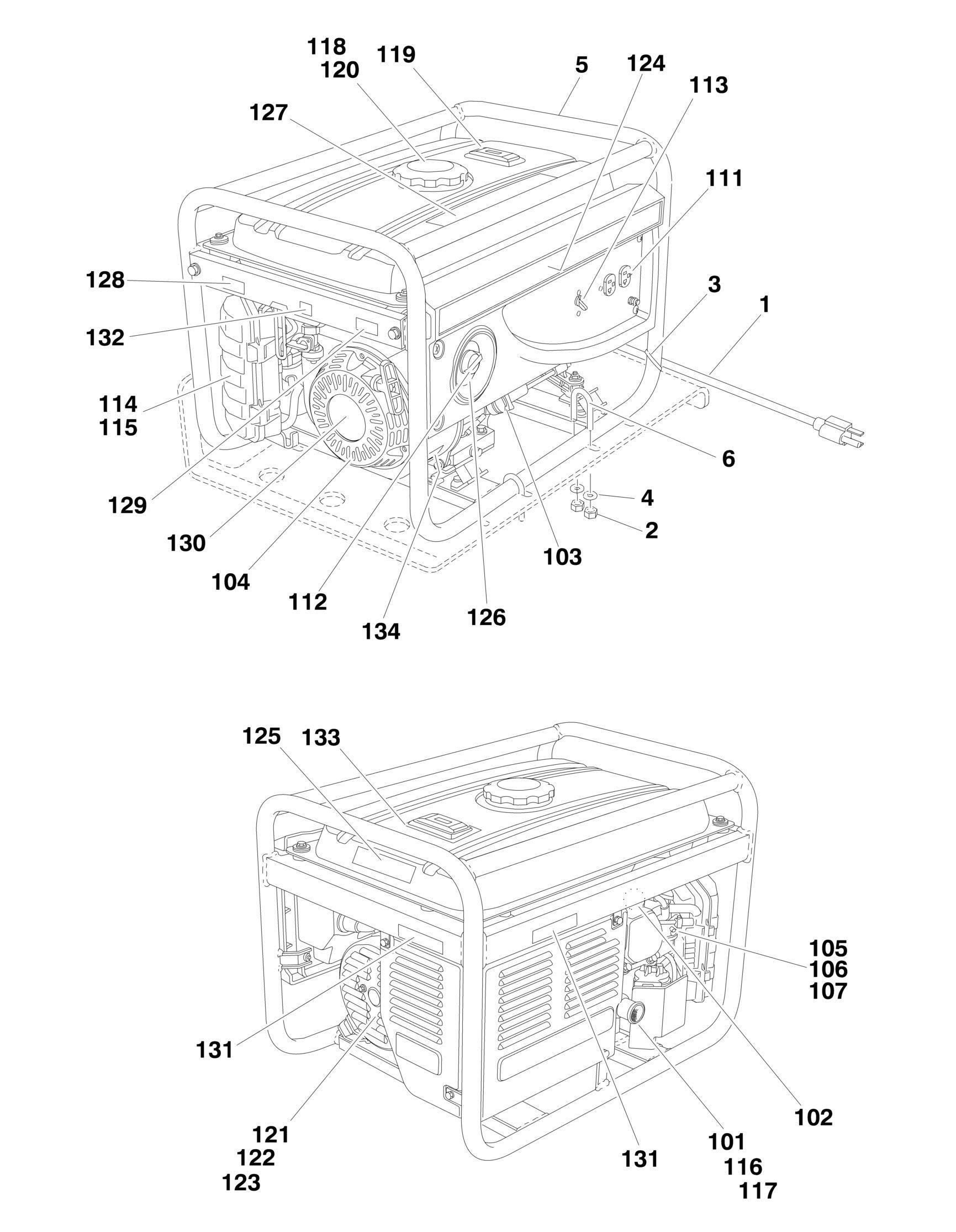

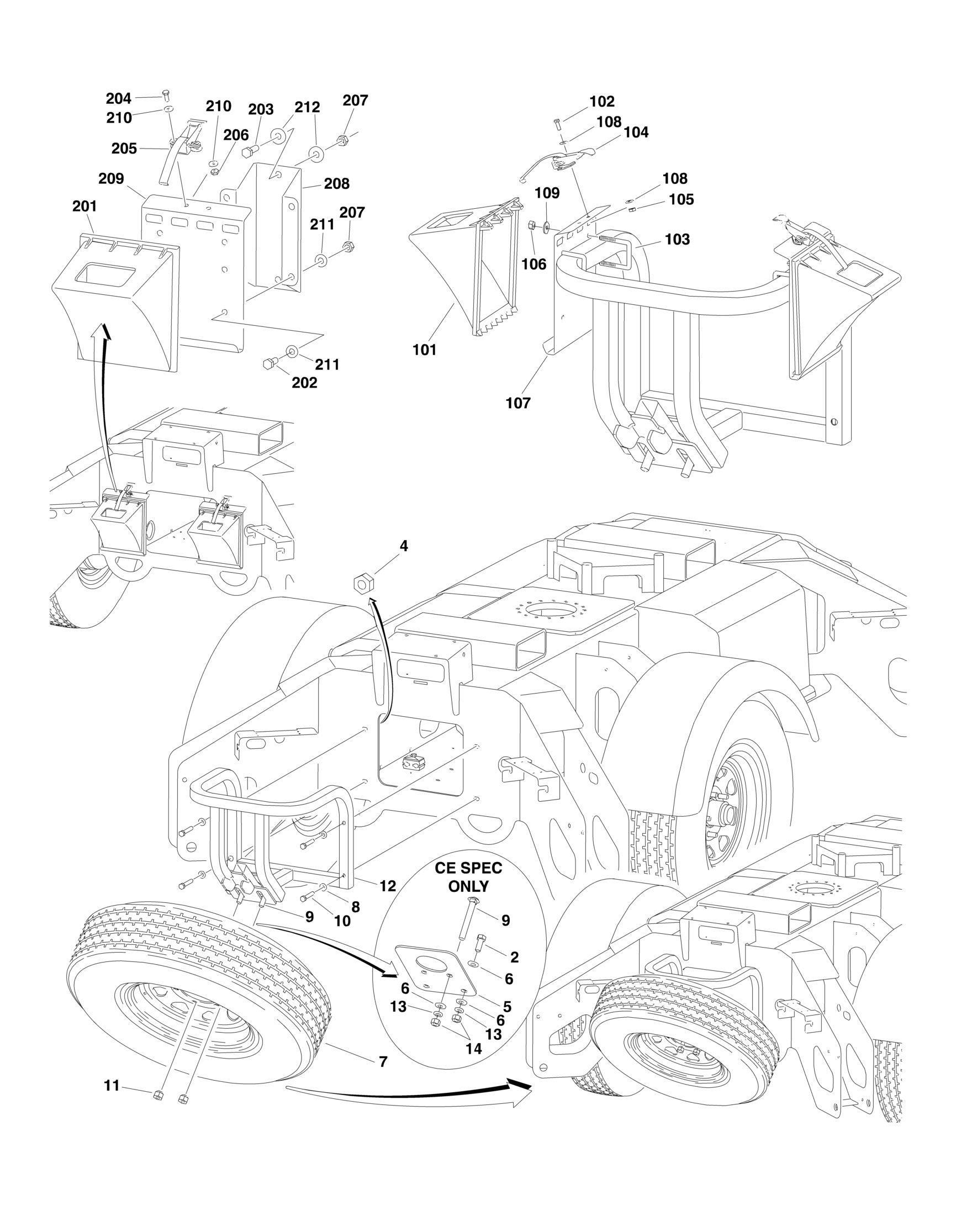

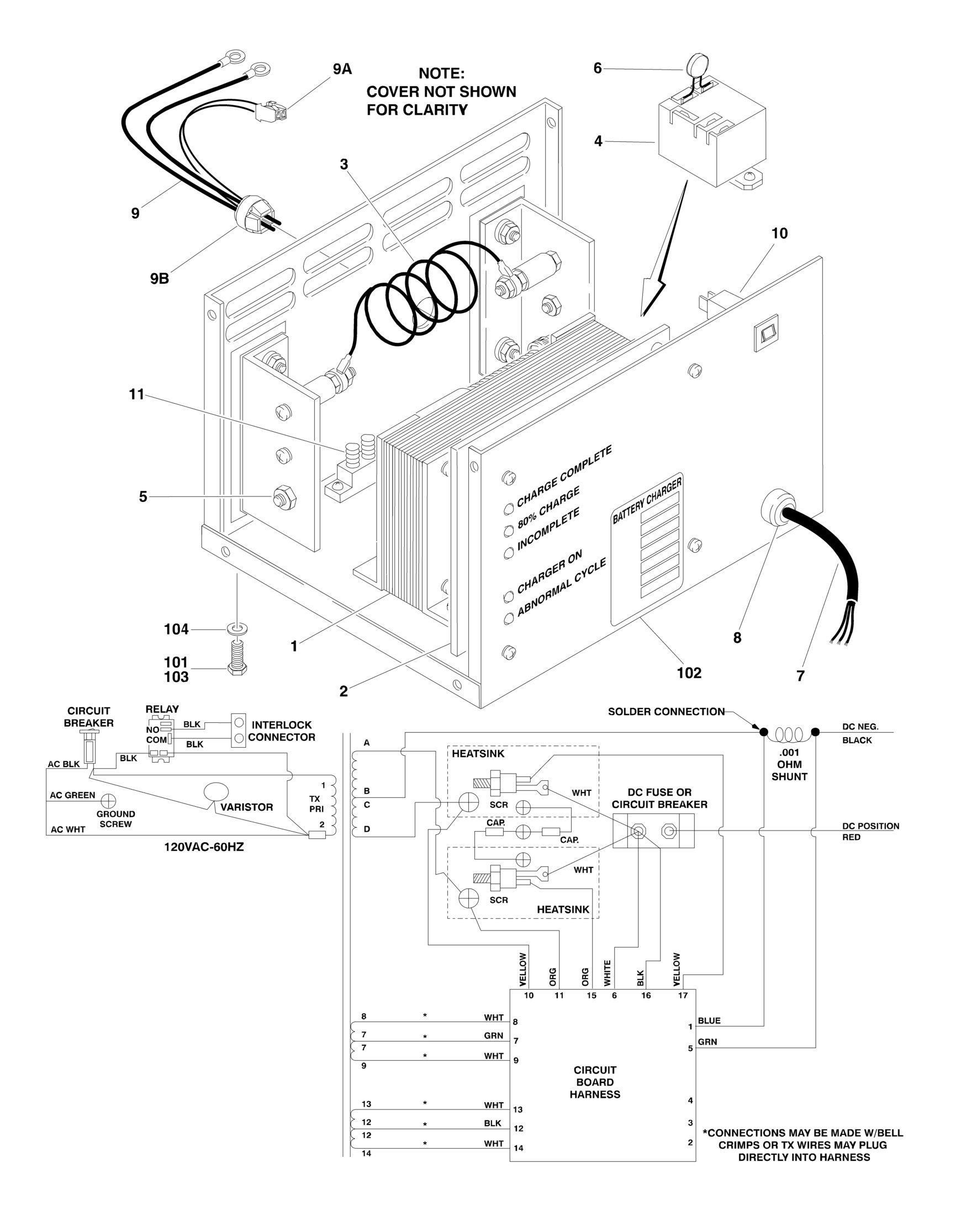

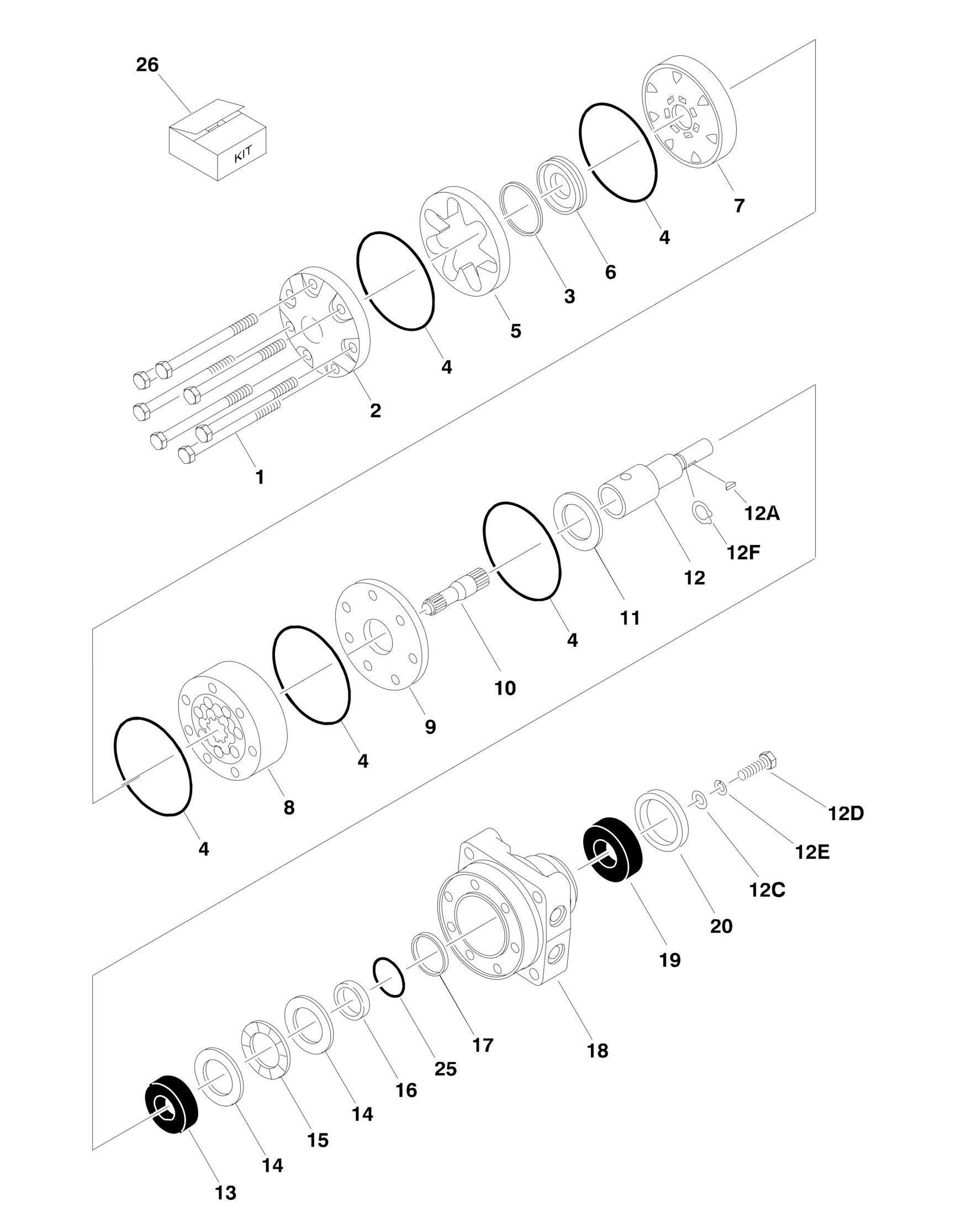

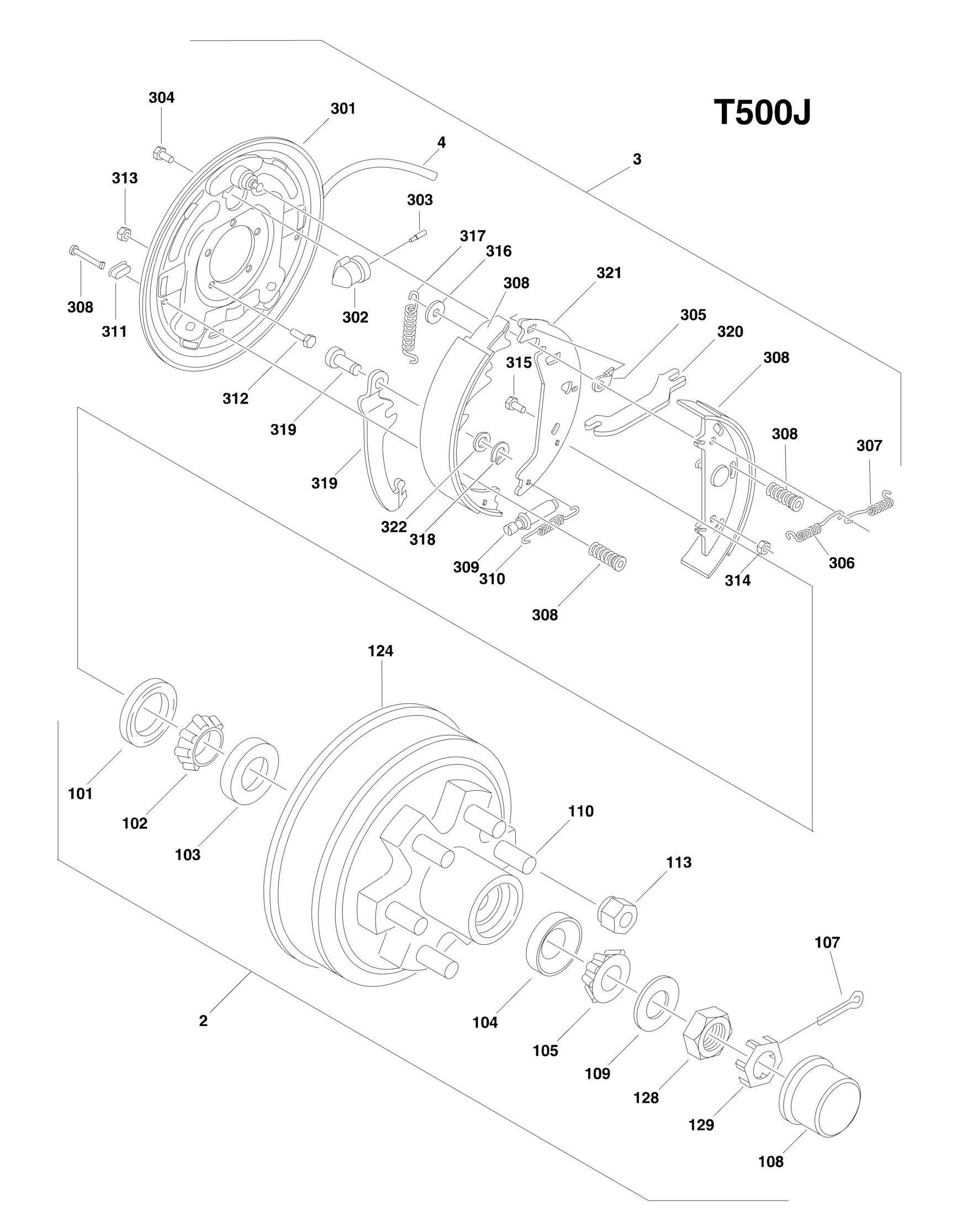

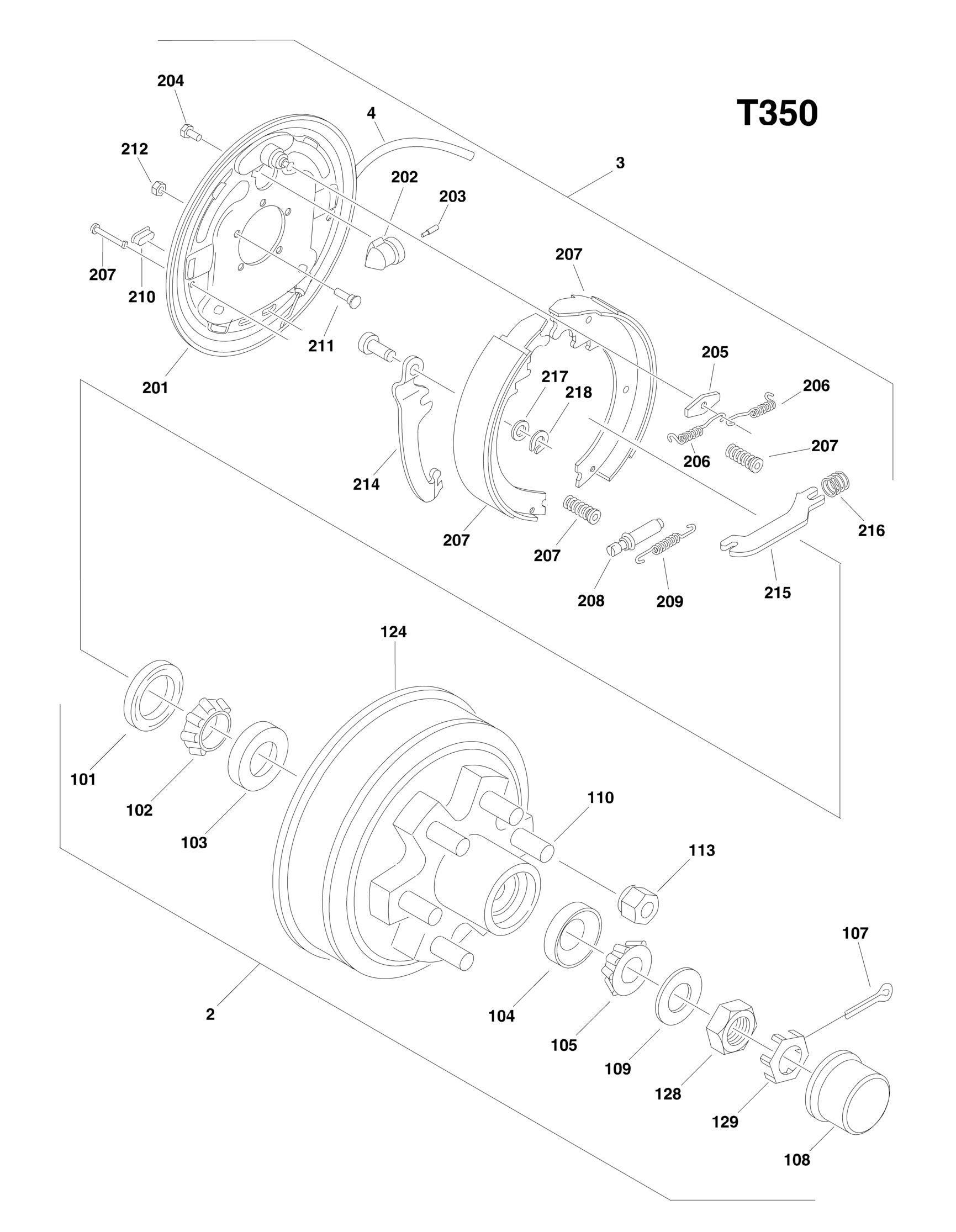

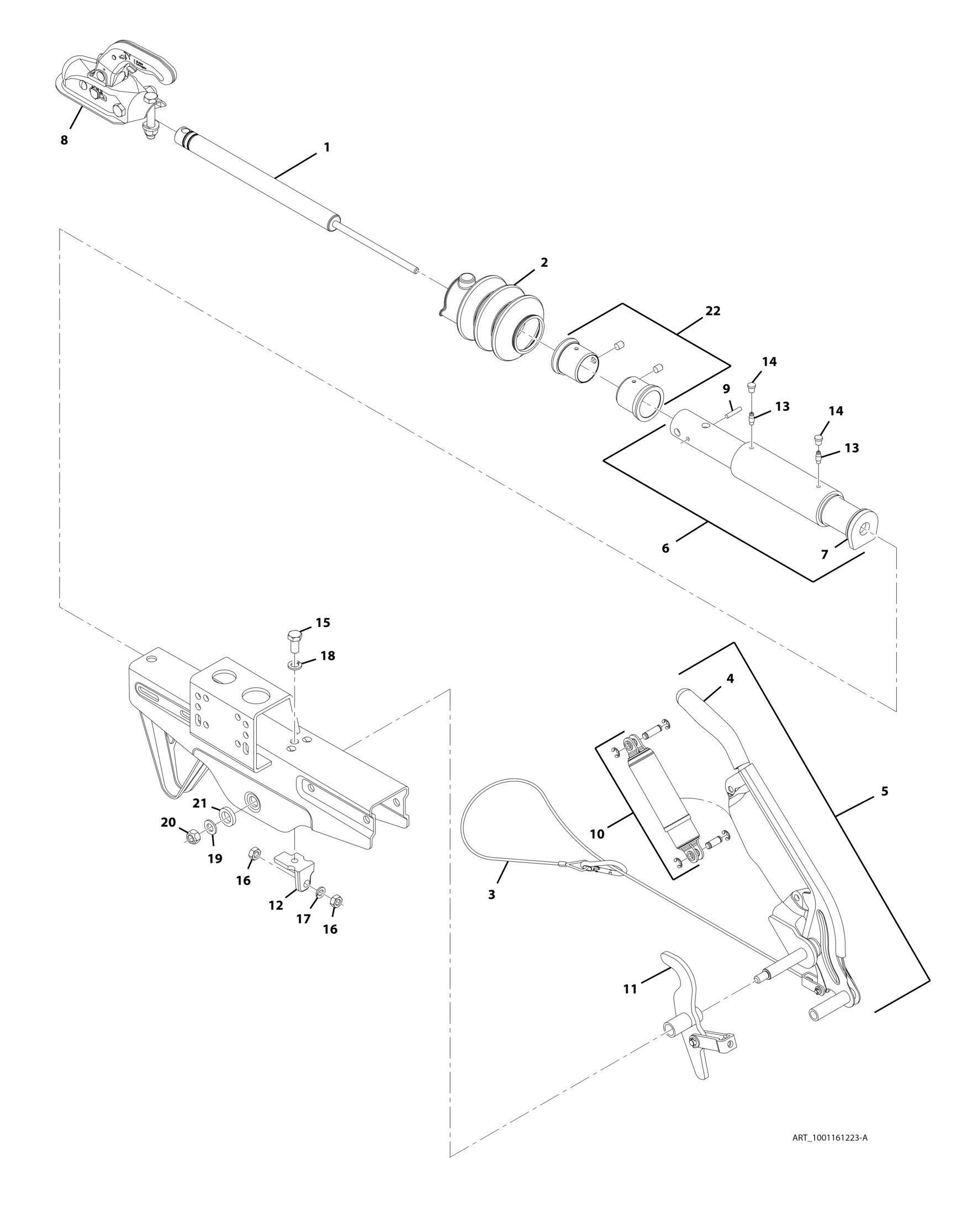

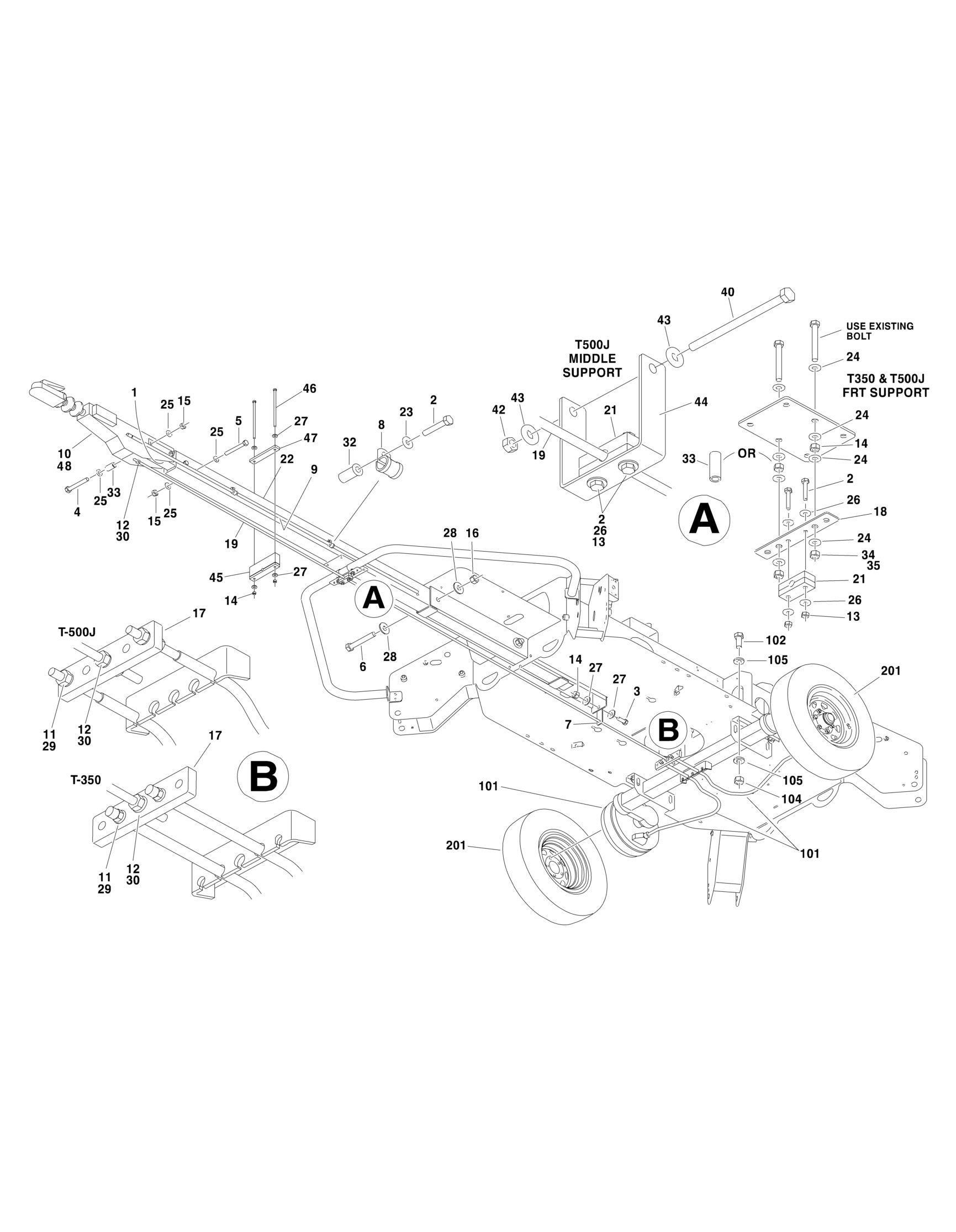

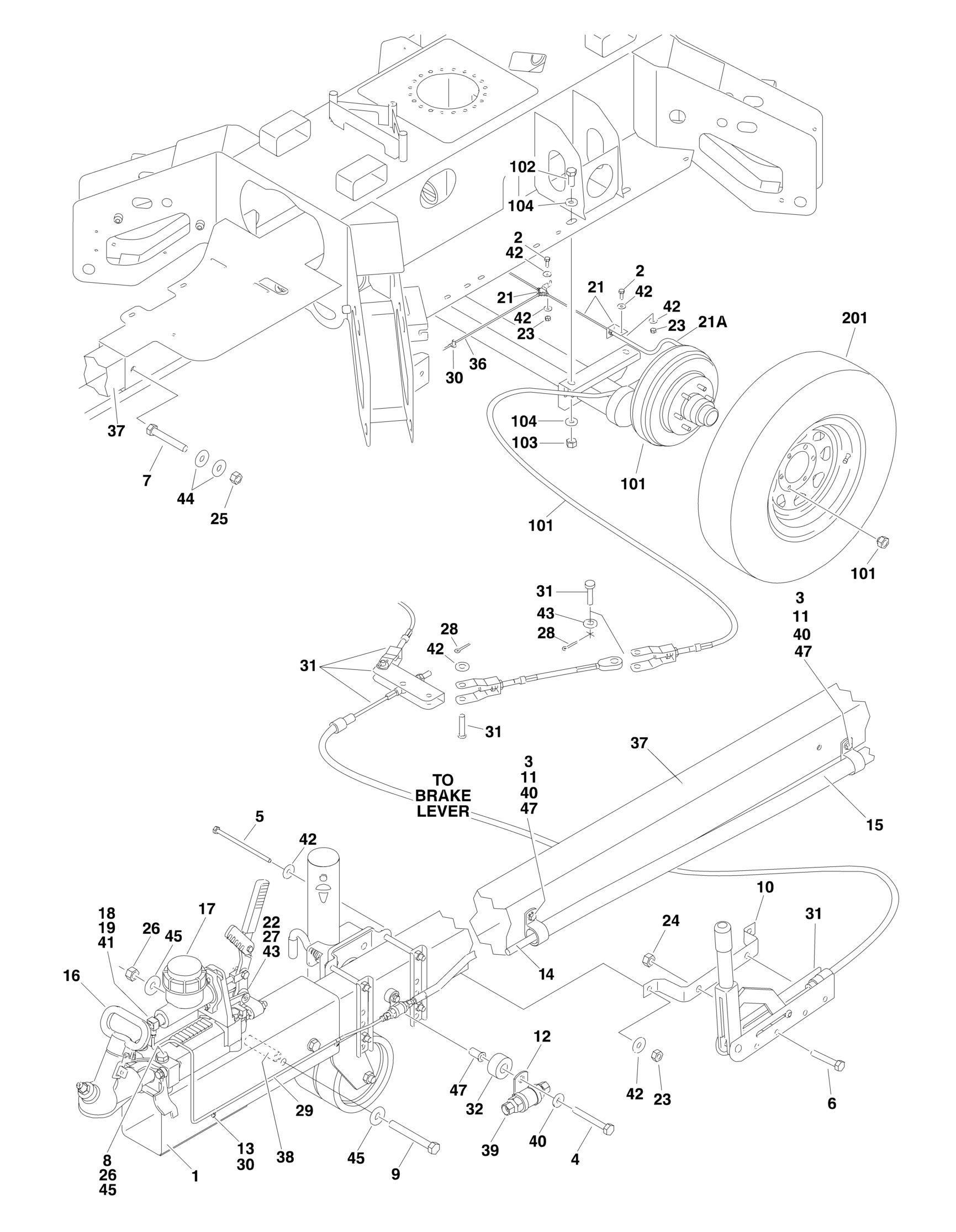

DESCRIPTION CONTROL VALVE INSTALLATION Control Valve Installation T350 Electric Powered Control Valve Installation T350 Gas Powered Control Valve Installation T500J Electric Powered Control Valve Installation T500J Gas Powered Compound, Locking Bolt Options: Bolt 6mm x 20mm (T350) Bolt 8mm x 25mm (T500J) Bolt 8mm x 20mm Clamp Clip, Gripper Handle Grip, Handle Locknut Options: Locknut 6mm x 20mm (T350) Locknut 8mm x 25mm (T500J) Rivet 5/32in Control Valve Assembly Options: Control Valve Assembly T350 Electric Powered (See CONTROL VALVE ASSEMBLY (ELECTRICAL POWERED MACHINES) for Breakdown) Control Valve Assembly T350 Gas Powered (See CONTROL VALVE ASSEMBLY (GAS POWERED MACHINES) for Breakdown) Control Valve Assembly T500J Electric Powered (See CONTROL VALVE ASSEMBLY (ELECTRICAL POWERED MACHINES) for Breakdown) Control Valve Assembly T500J Gas Powered (See CONTROL VALVE ASSEMBLY (GAS POWERED MACHINES) for Breakdown) Flatwasher Options: Flatwasher 8mm (T350) Flatwasher 1/4in Thin (T500J) Flatwasher 8mm Loctite #454 CONTROL MODULE INSTALLATIONS Electric Machines without Drive Option (Prior to SN 0030001804) Electric Machines without Drive Option (SN 0030001804 through 0030012032) Electric Machines with Drive Option Gas Machines Locknut 1/4in-20NC (Prior to SN 0030001397) Bolt 5mm x 20mm Module, Ground Control (Note: Control System must be recalibrated when Module is replaced) Controller, Sevcon Options: Electric Powered Machines without Drive (Prior to SN 0030001804) Electric Powered Machines without Drive (SN 0030001804 through 0030012032)

T350/T500J

REV E E E E

H F D F

73