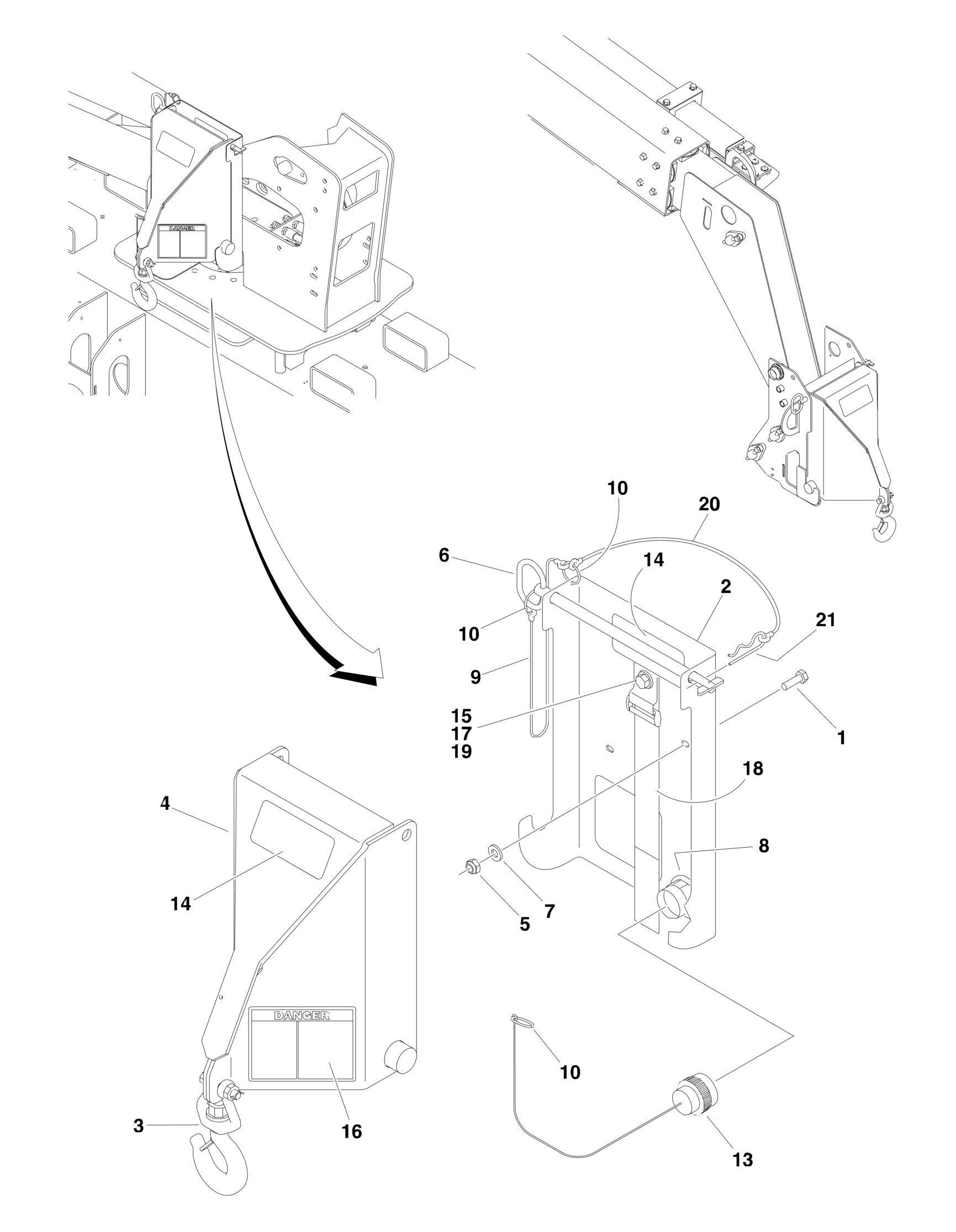

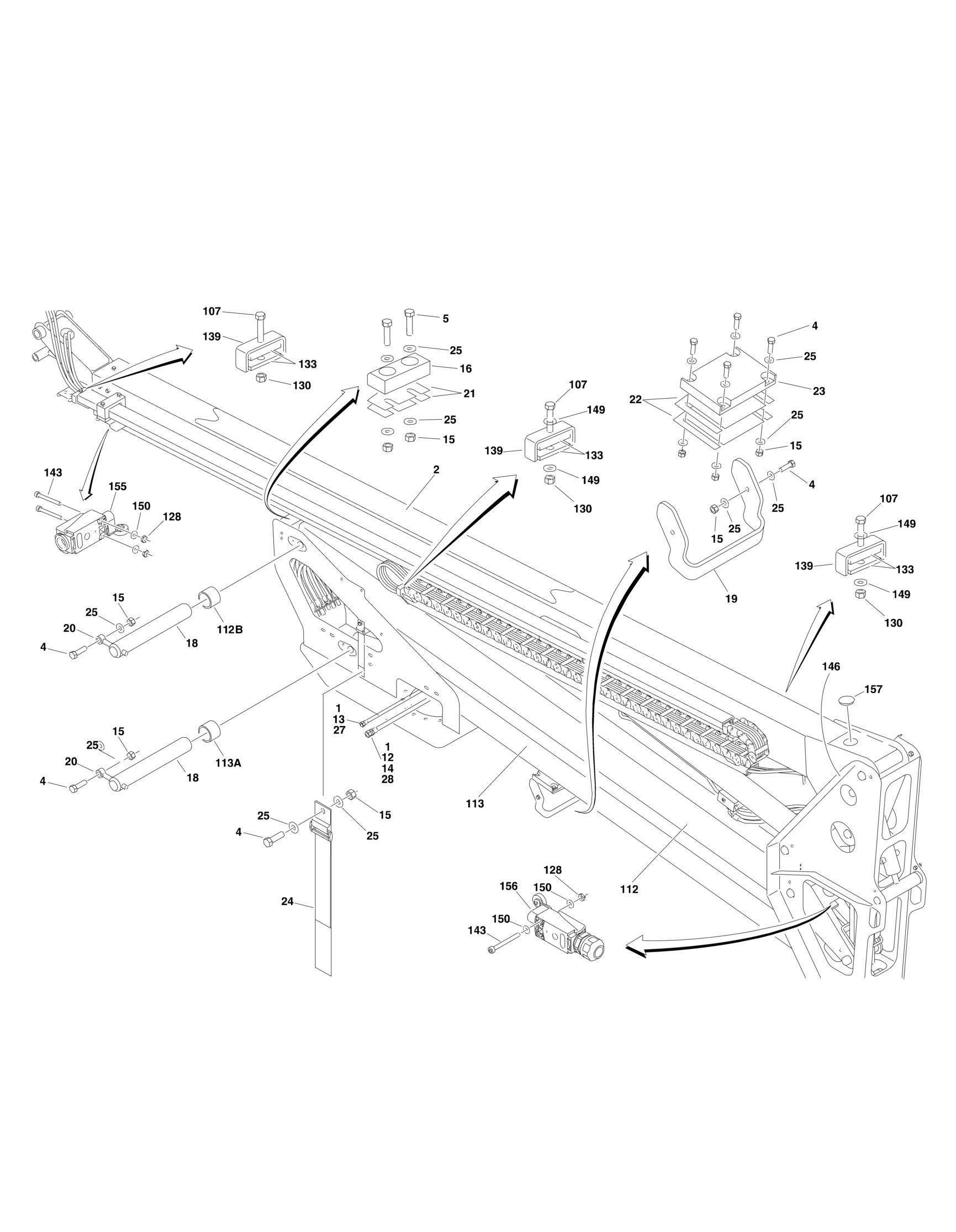

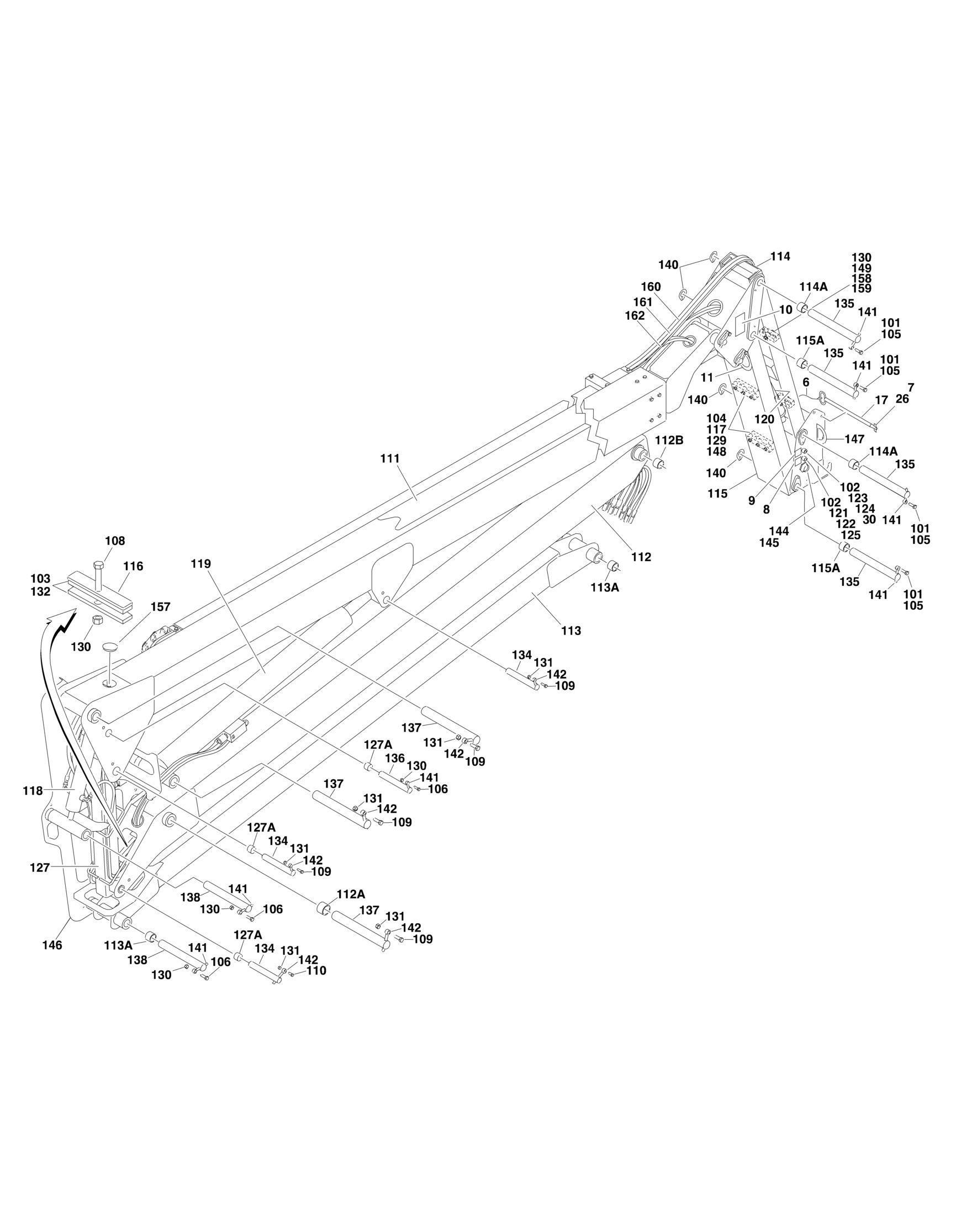

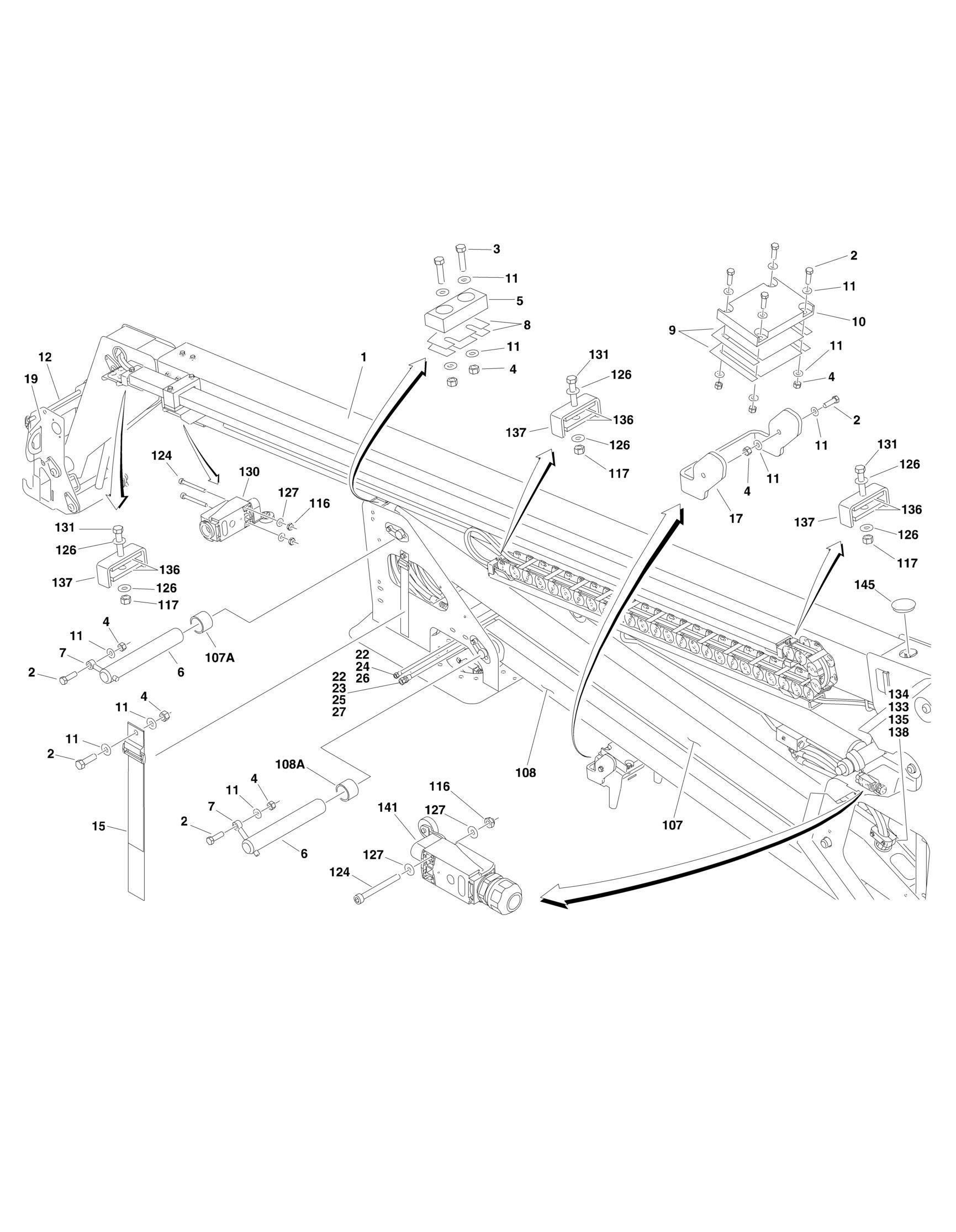

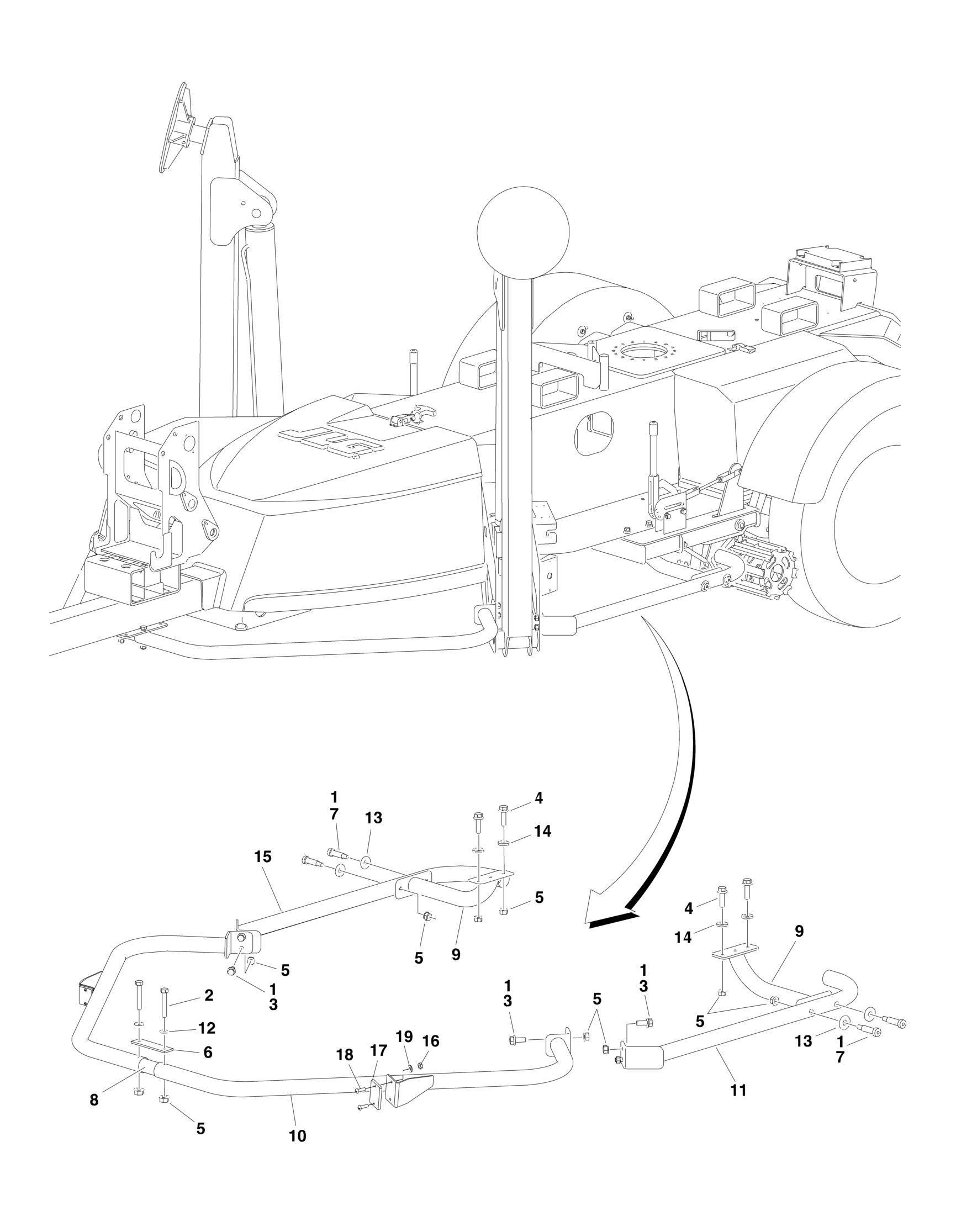

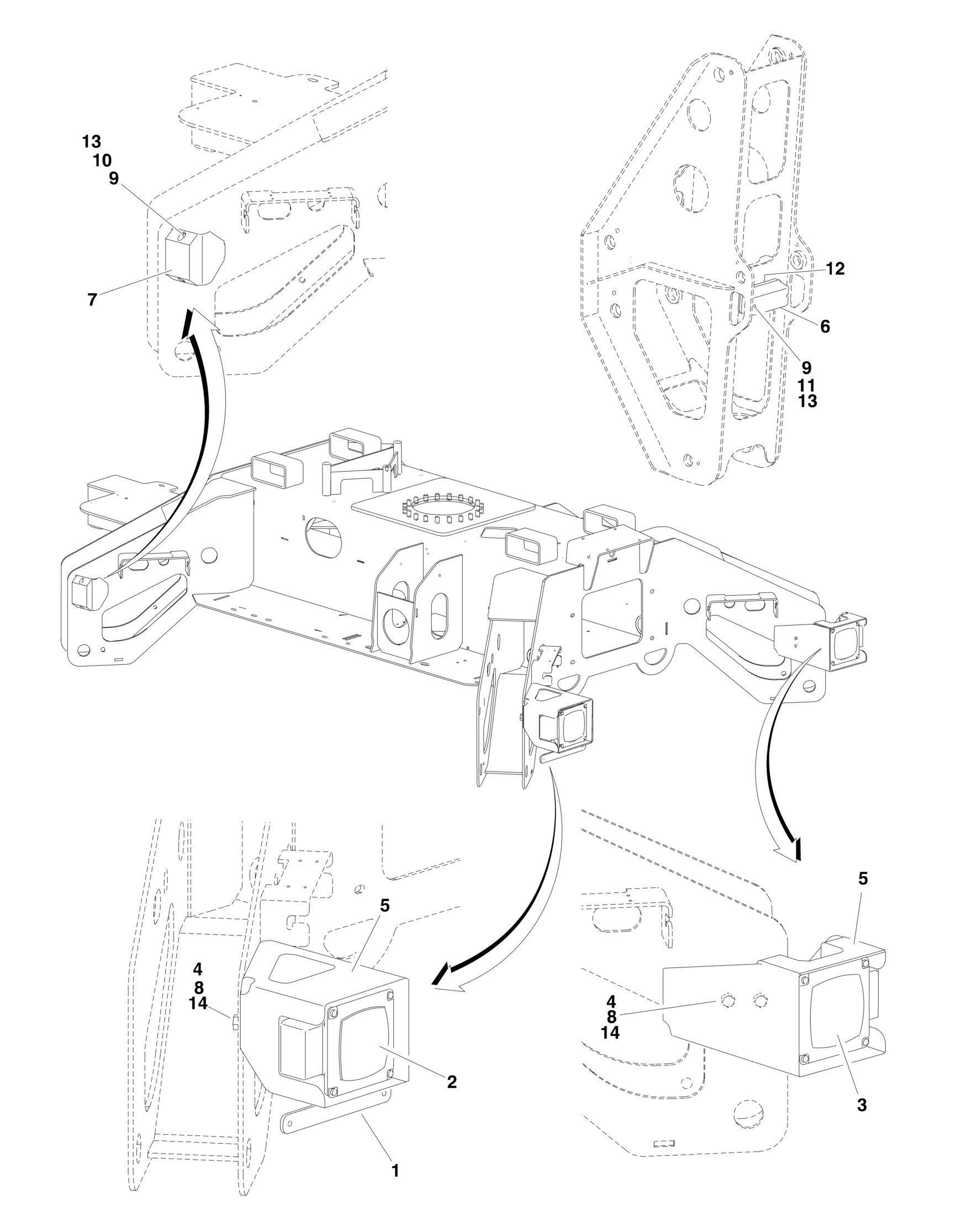

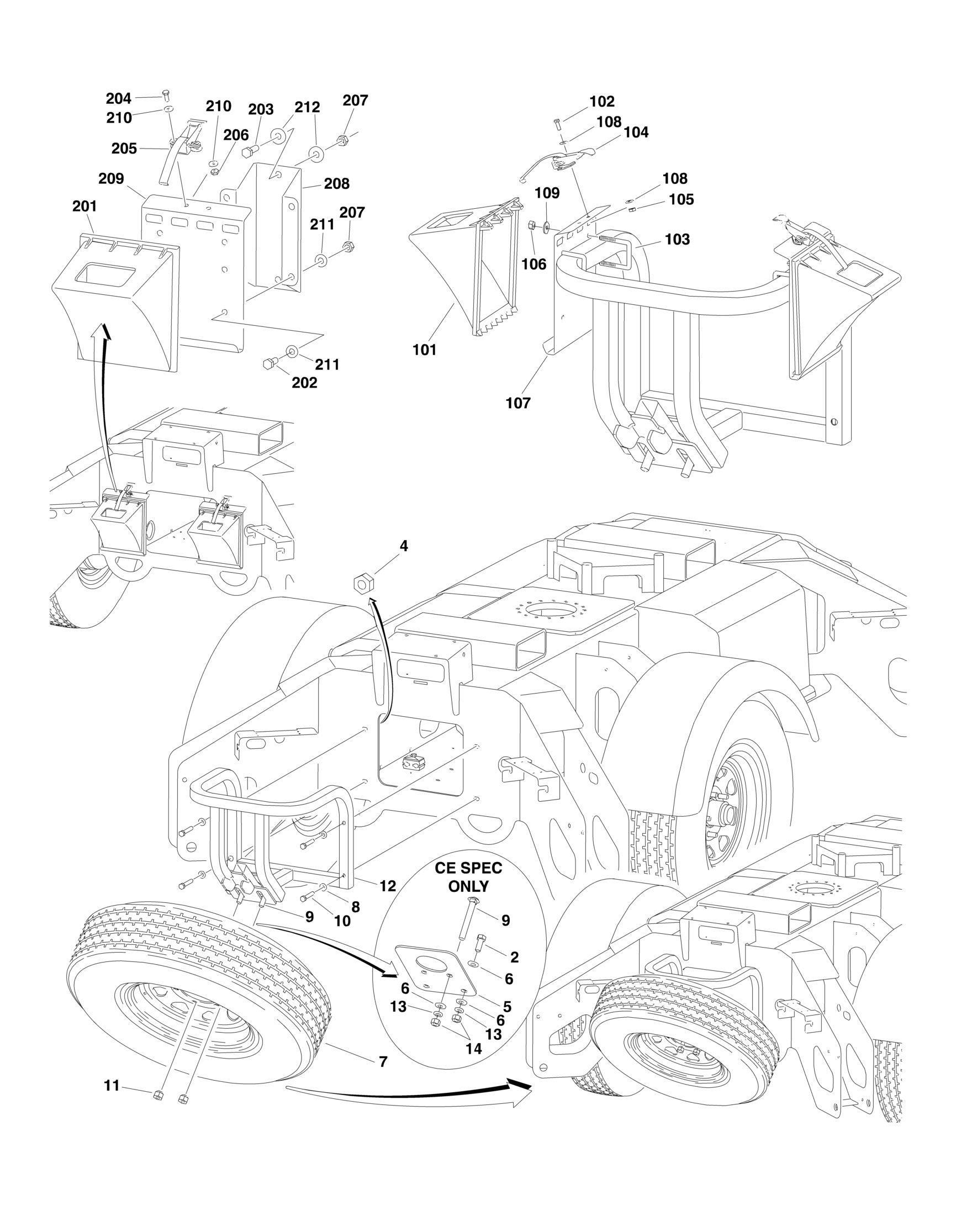

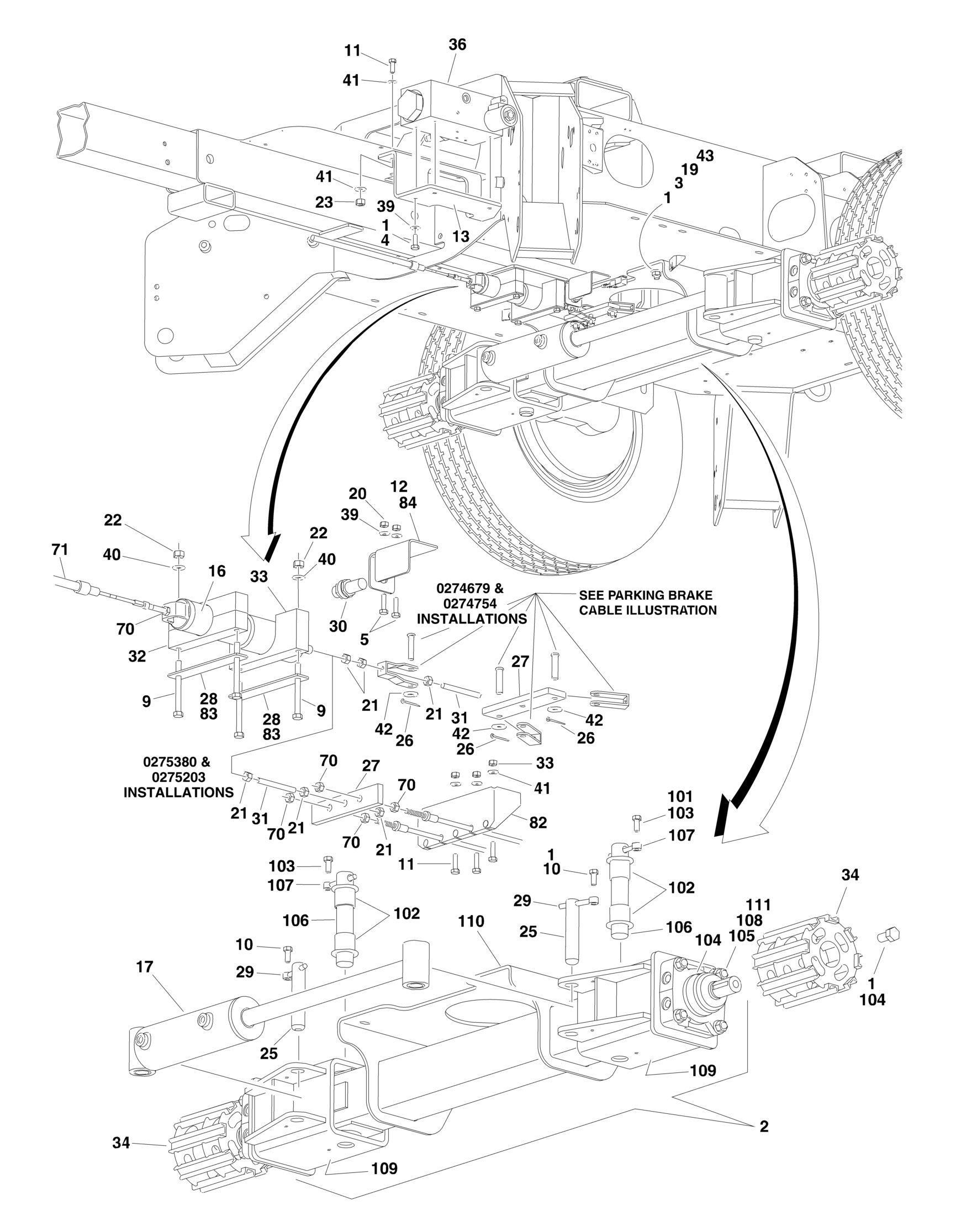

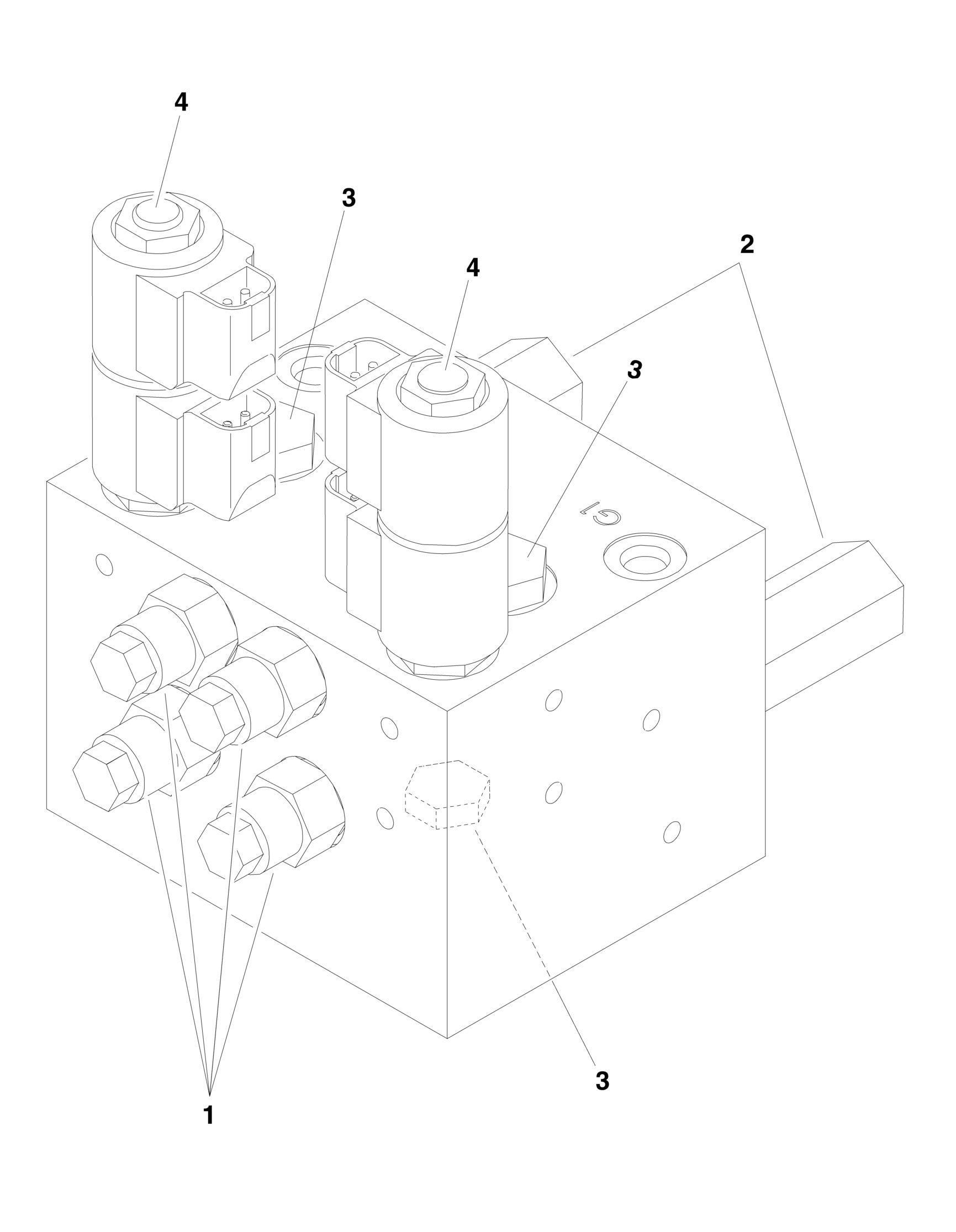

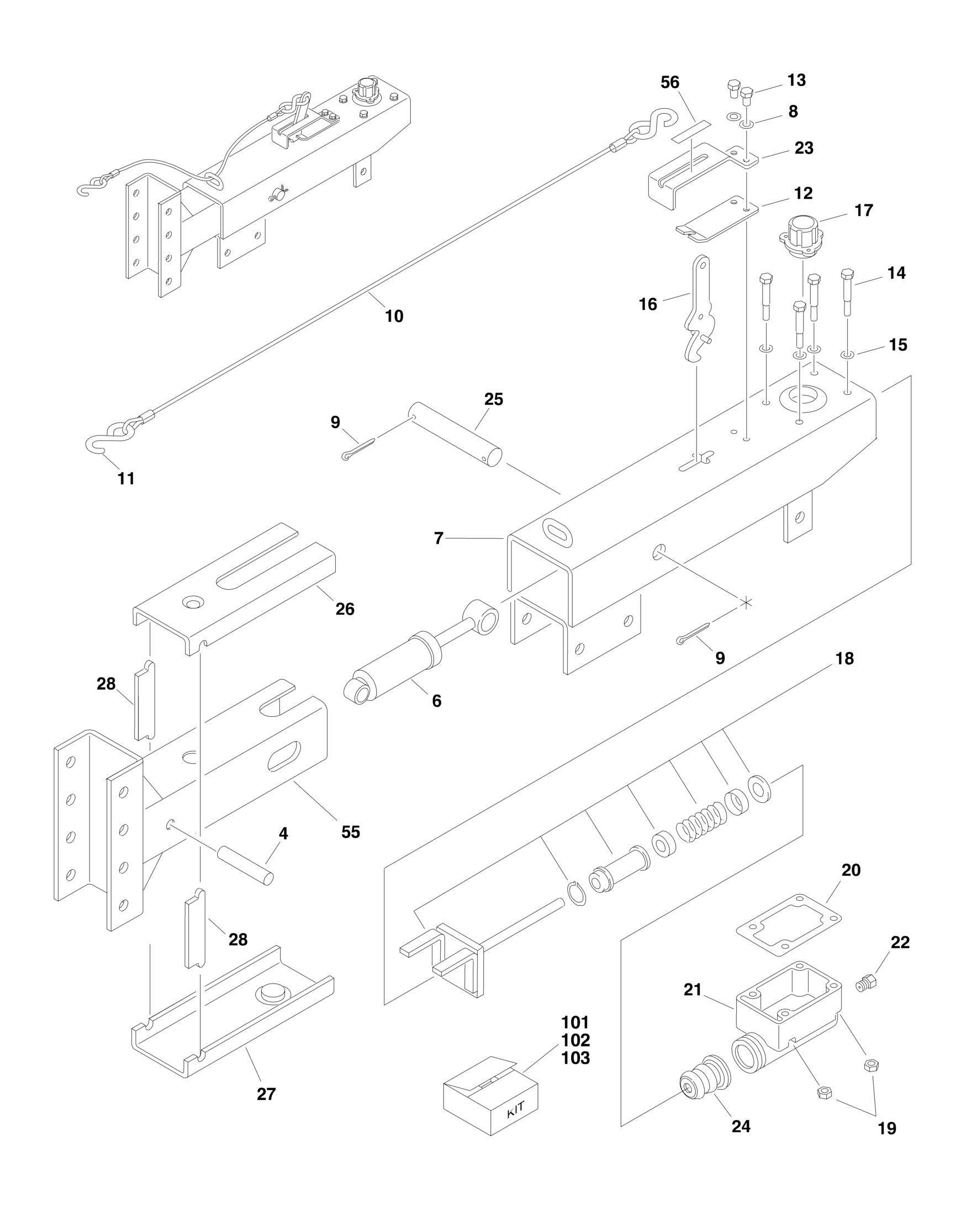

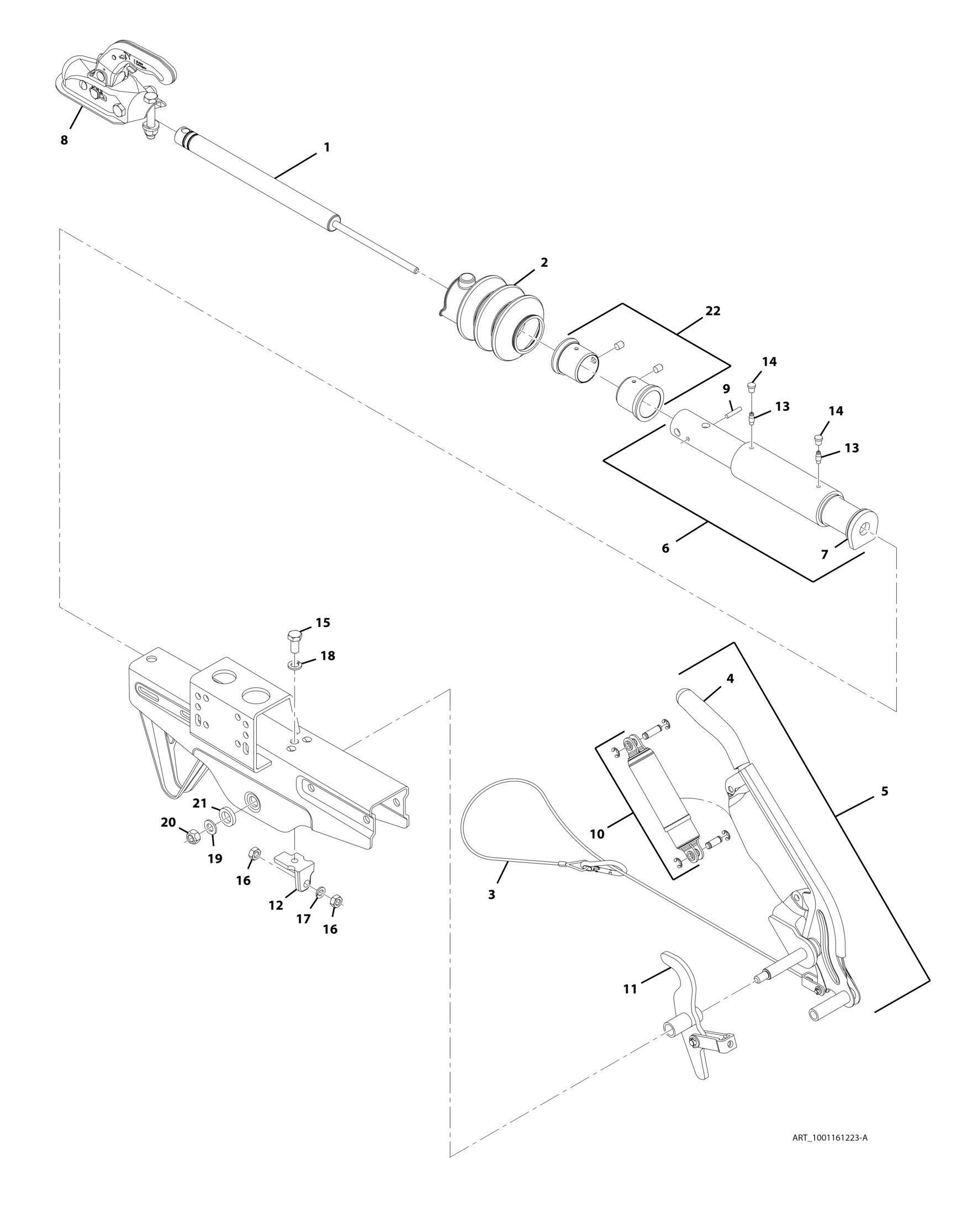

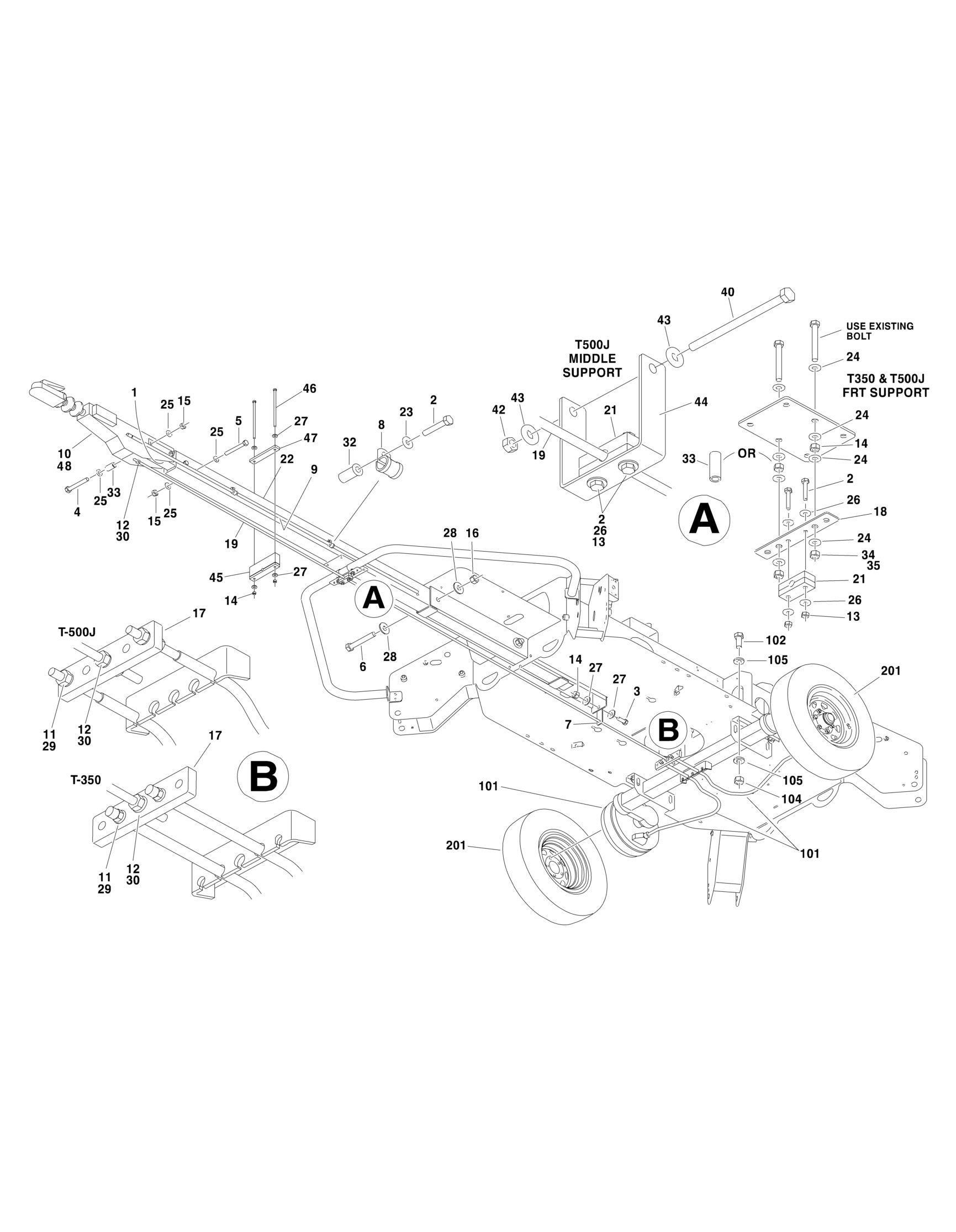

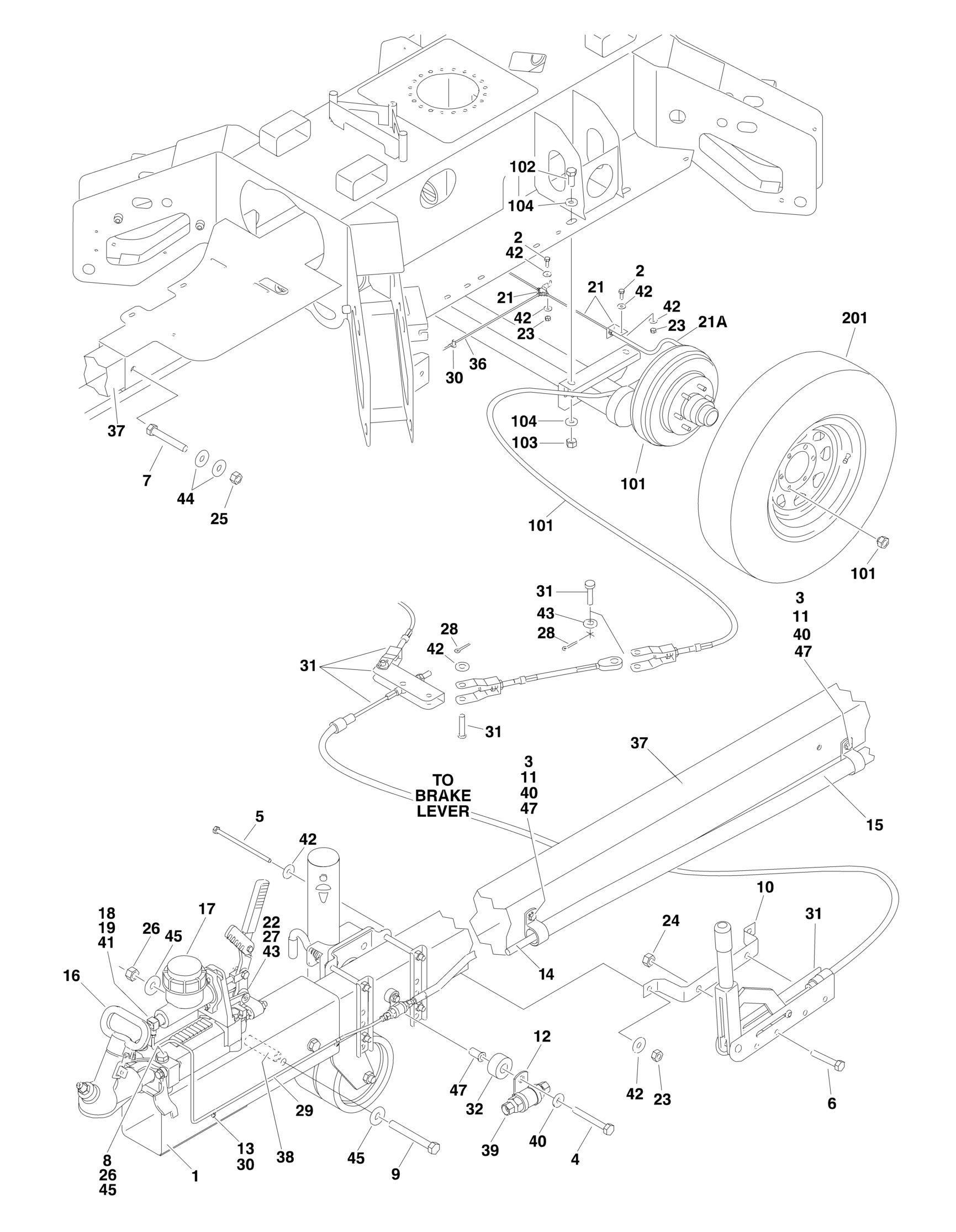

SECTION 1 - FRAME FIGURE 1-34. OUTRIGGERS INSTALLATION ITEM

4210012 4210019 4210013

QTY Ref Ref Ref Ref Ref 4 Ref Ref 4 4 Ref 4 4 4 4 8 8 Ref 4 4 4

21

4210025

4

21

4210016

4

21

4210027

4

22 27 27 27 28 28 28 29 29 29 30 30 30 33 34

4811400

4210012 4210019 4210013

8 Ref 4 4 Ref 8 8 Ref 8 8 Ref 4 4 8 8 Ref Ref Ref Ref

4210025

Ref

4210016

Ref

2 4 6 6 6 8 8 8 10 17 19 20 21 21 21 21

3121199

PART NUMBER 0273712 0274375 0273715 0274321 0701014

3422426 3421986 3423148 3423147 3841143 4812000 3290405 4031512

3423185 3423186 3760115 3760133 3760115 3760237 1706121 1706264 4740446 4740333

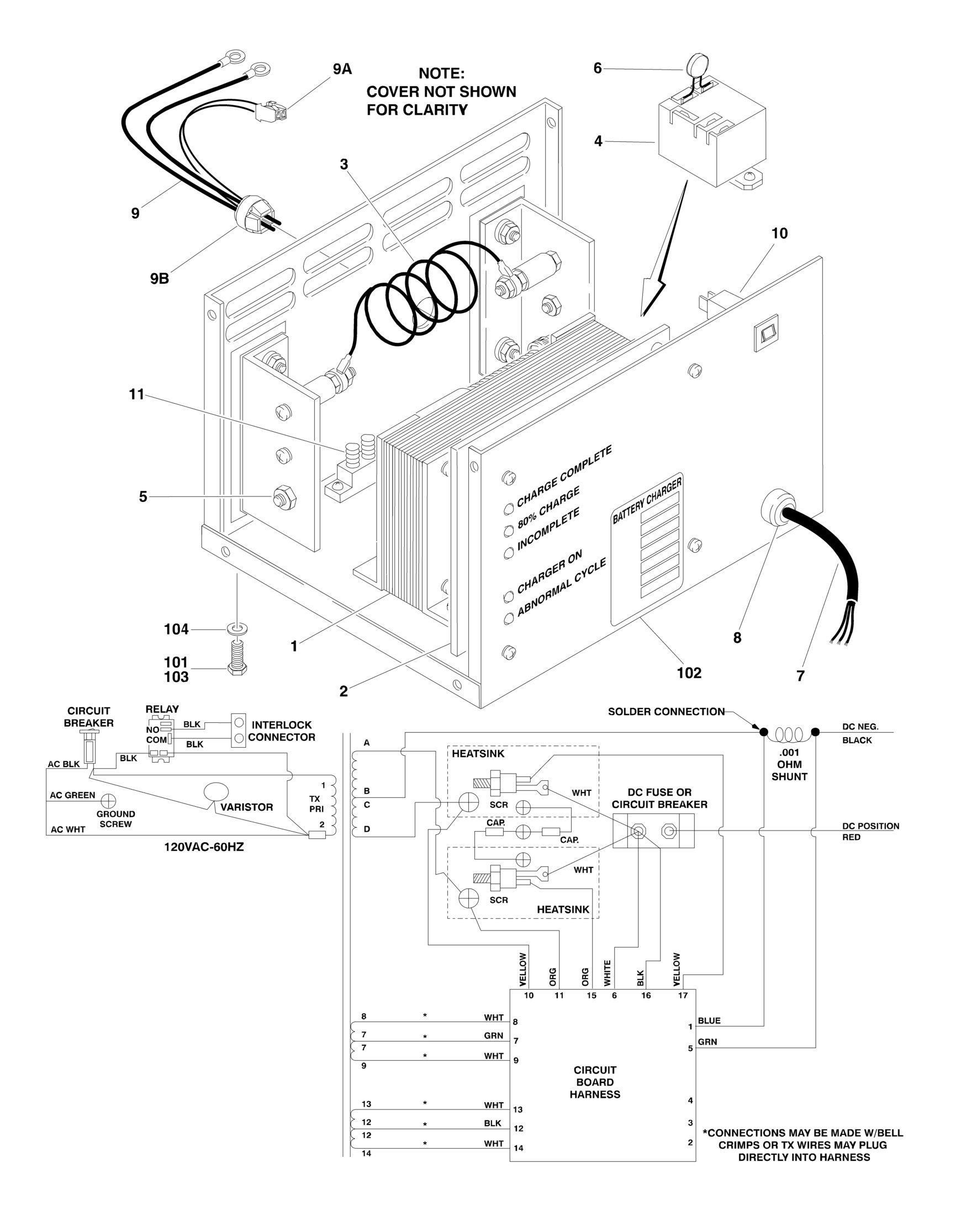

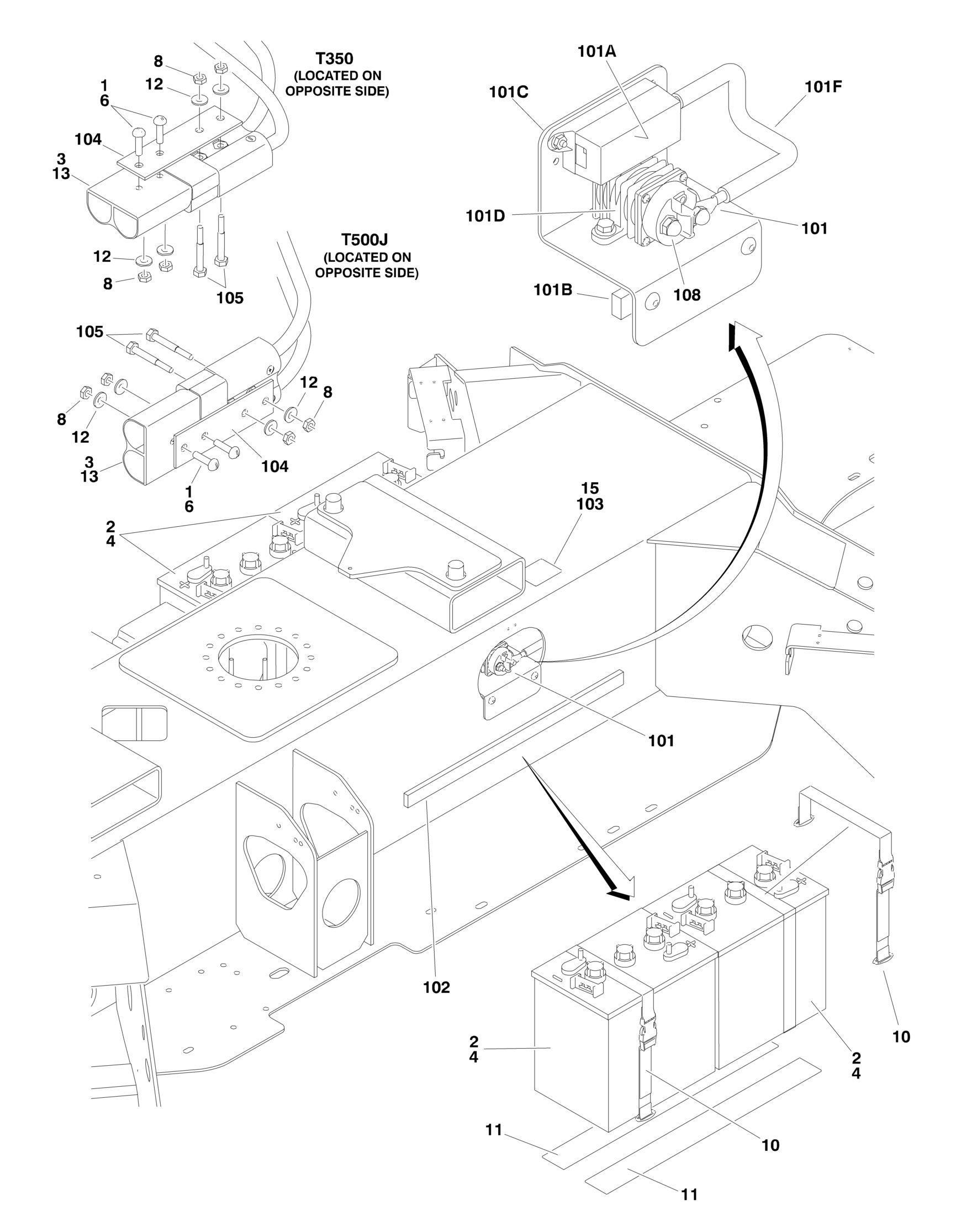

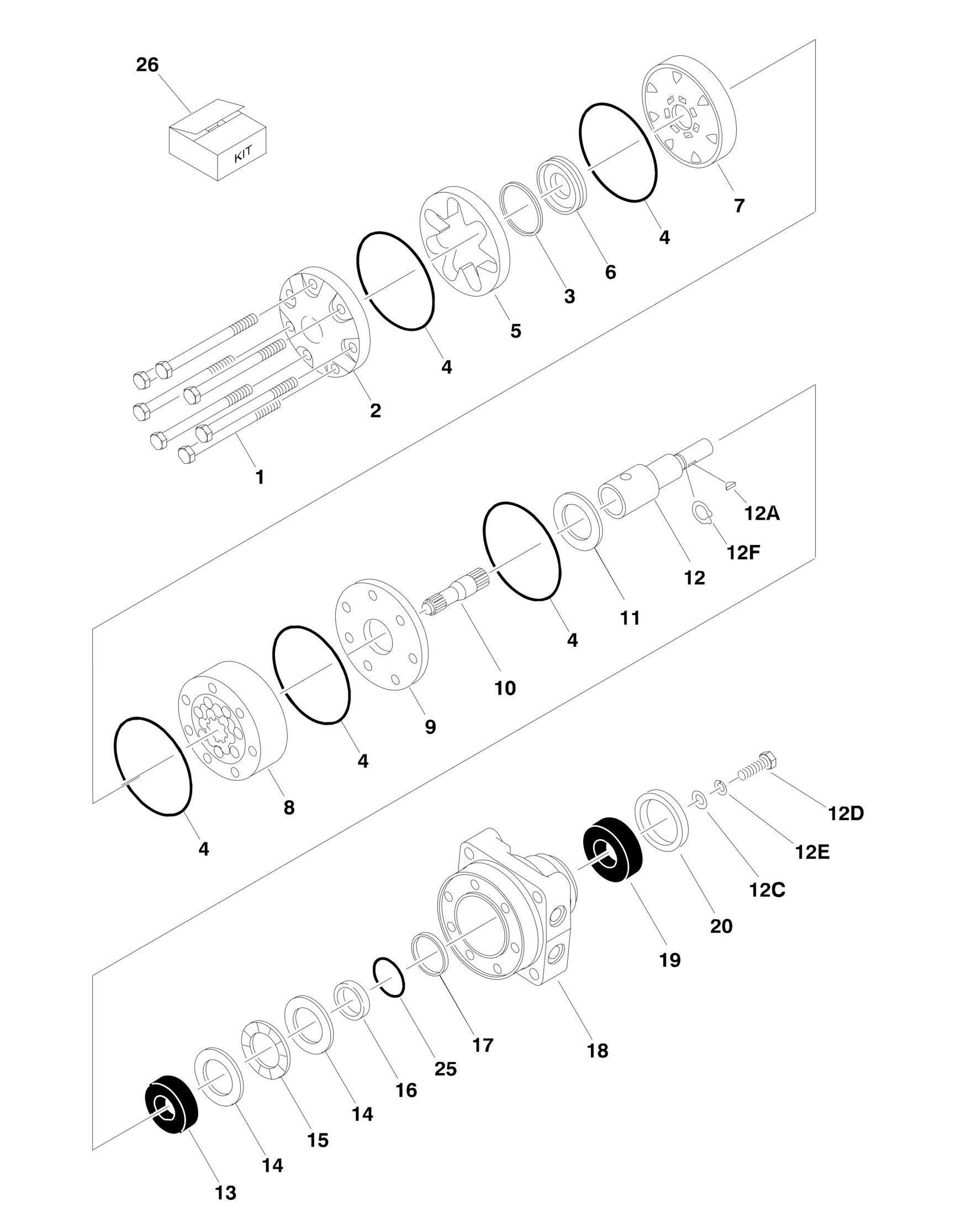

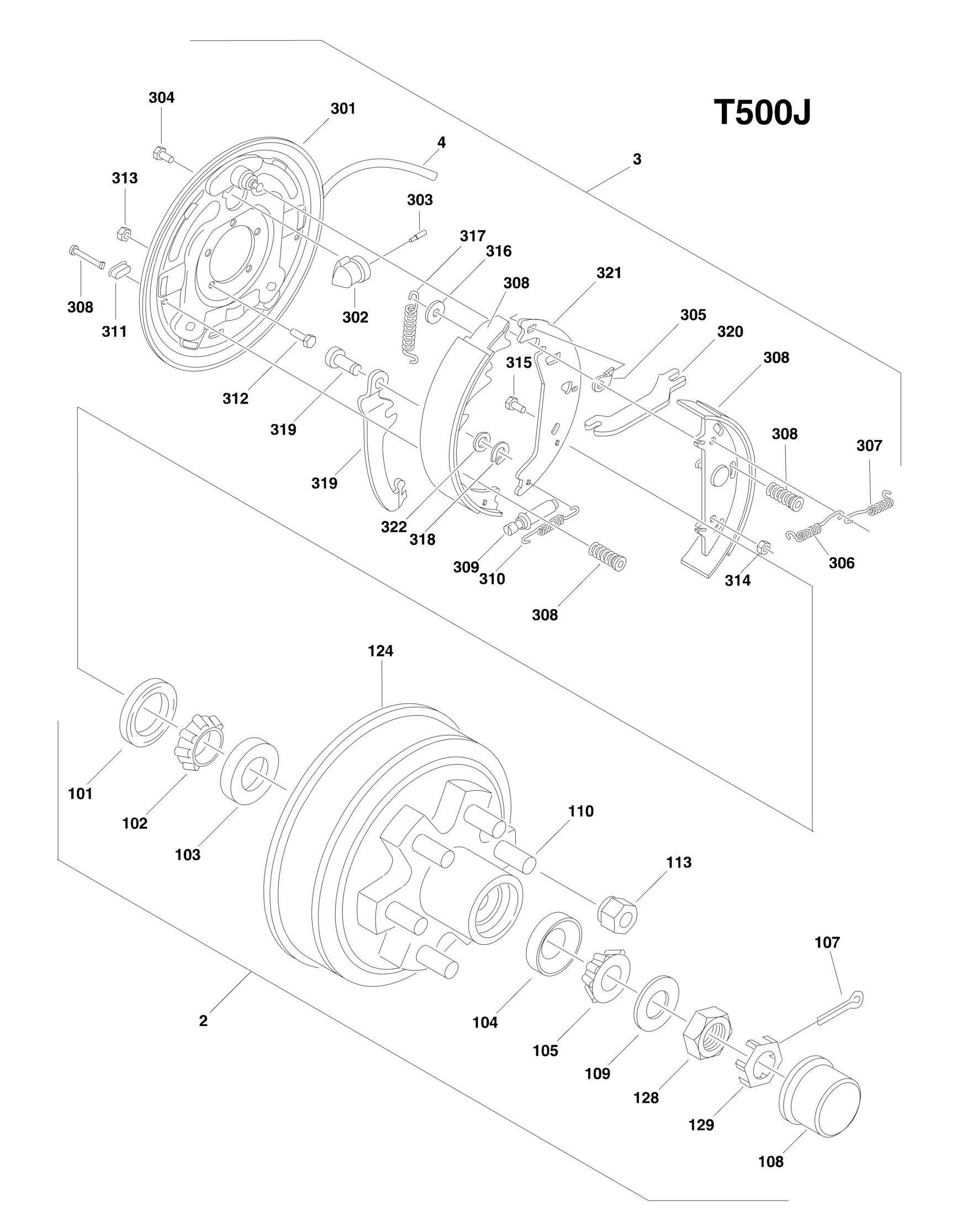

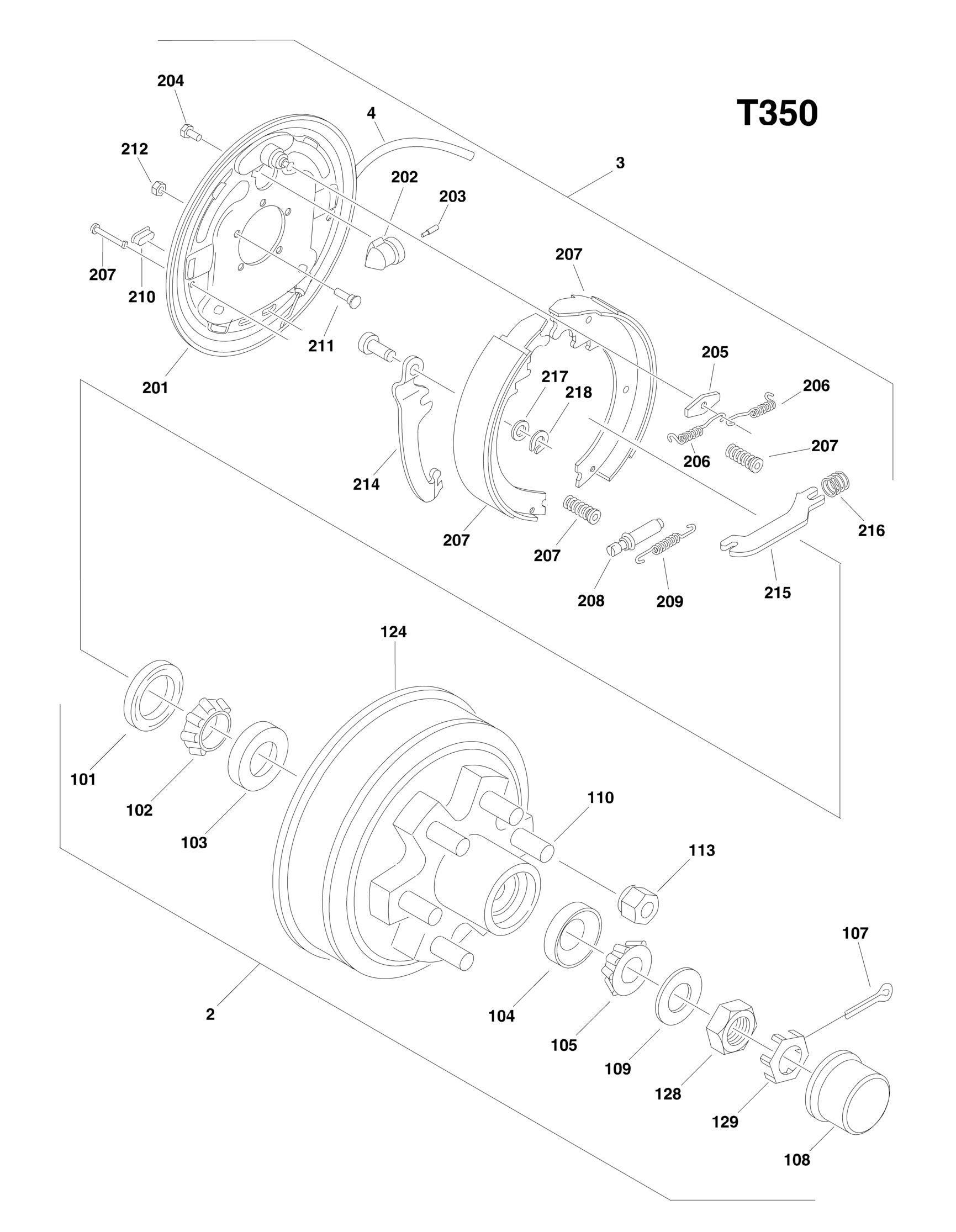

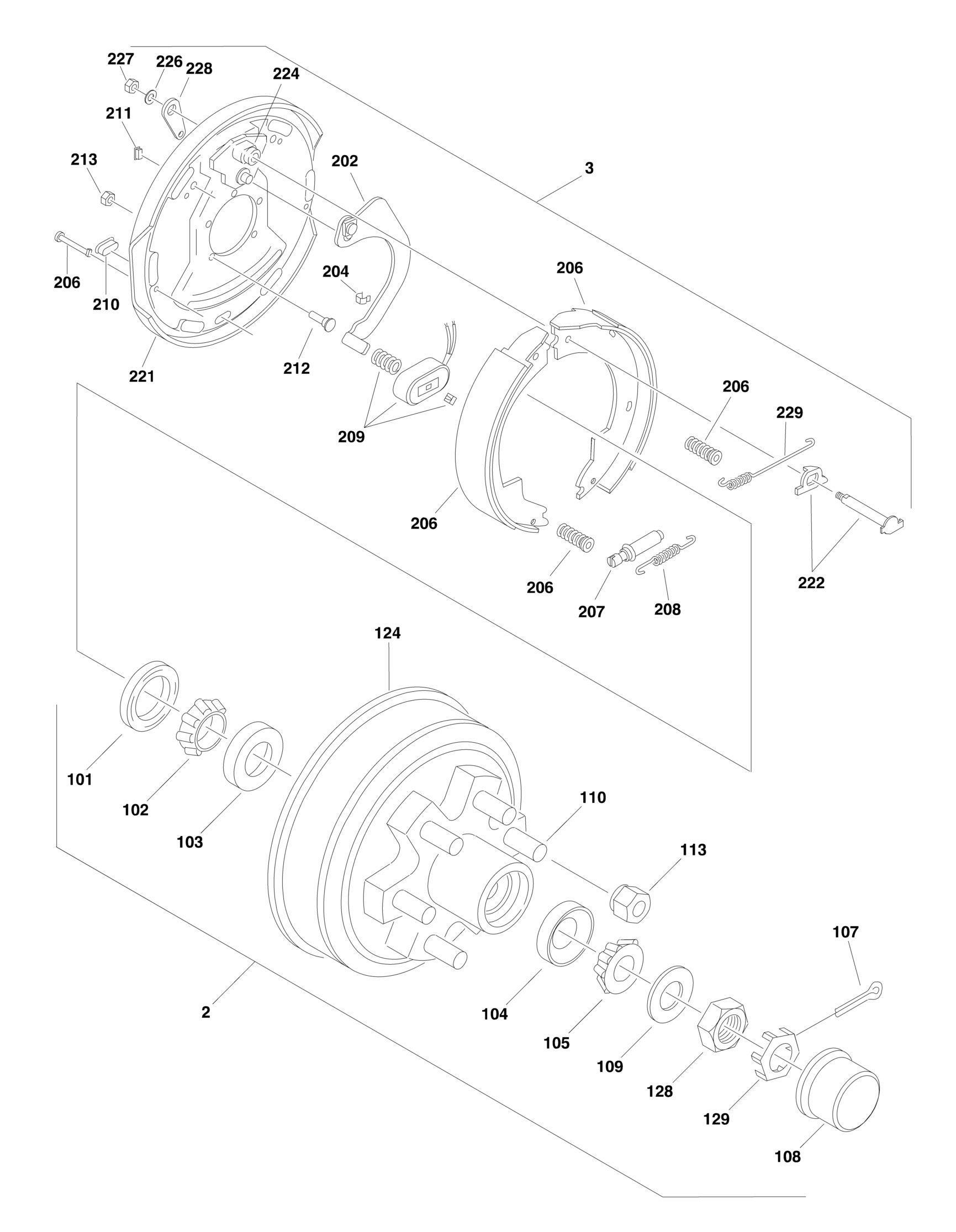

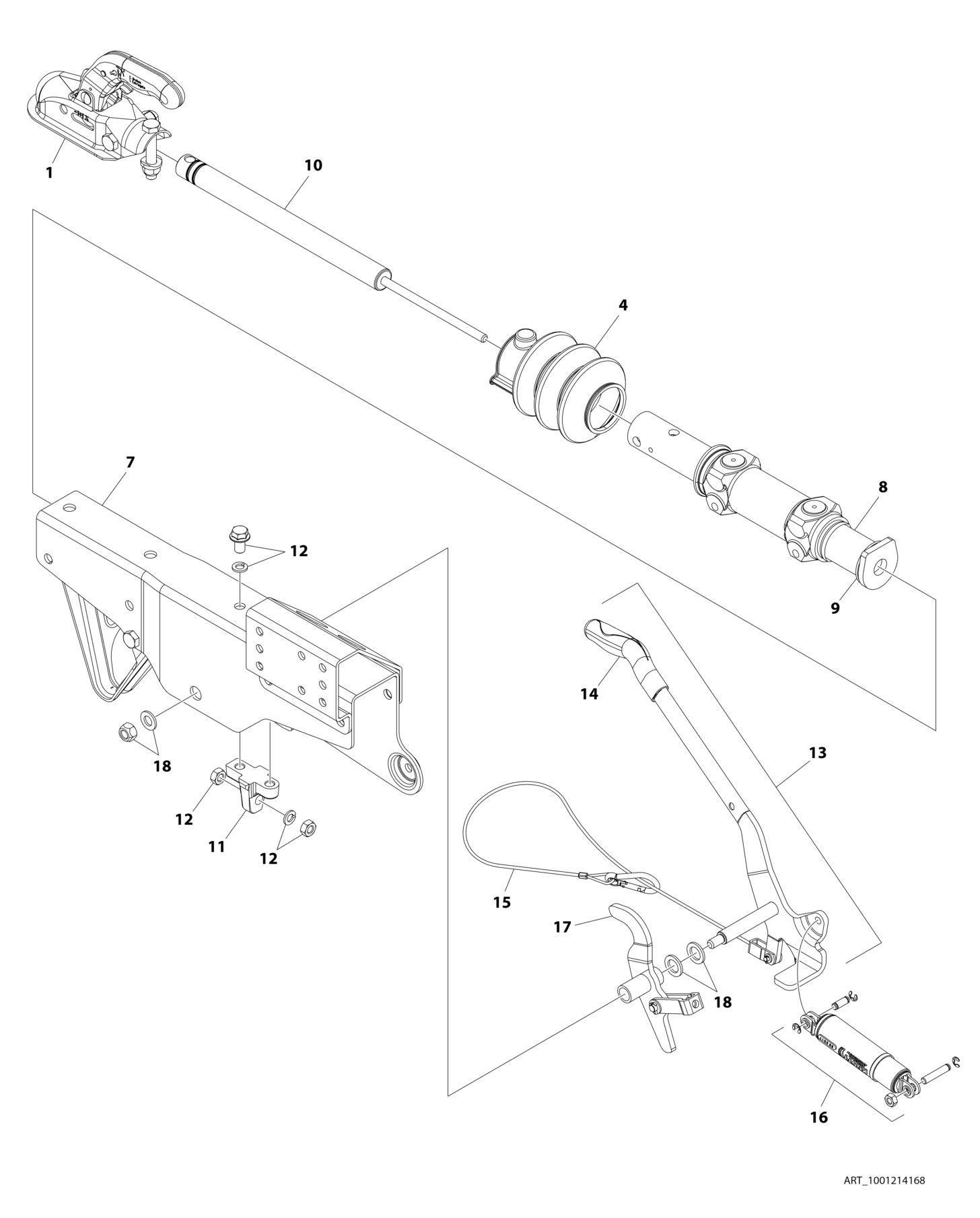

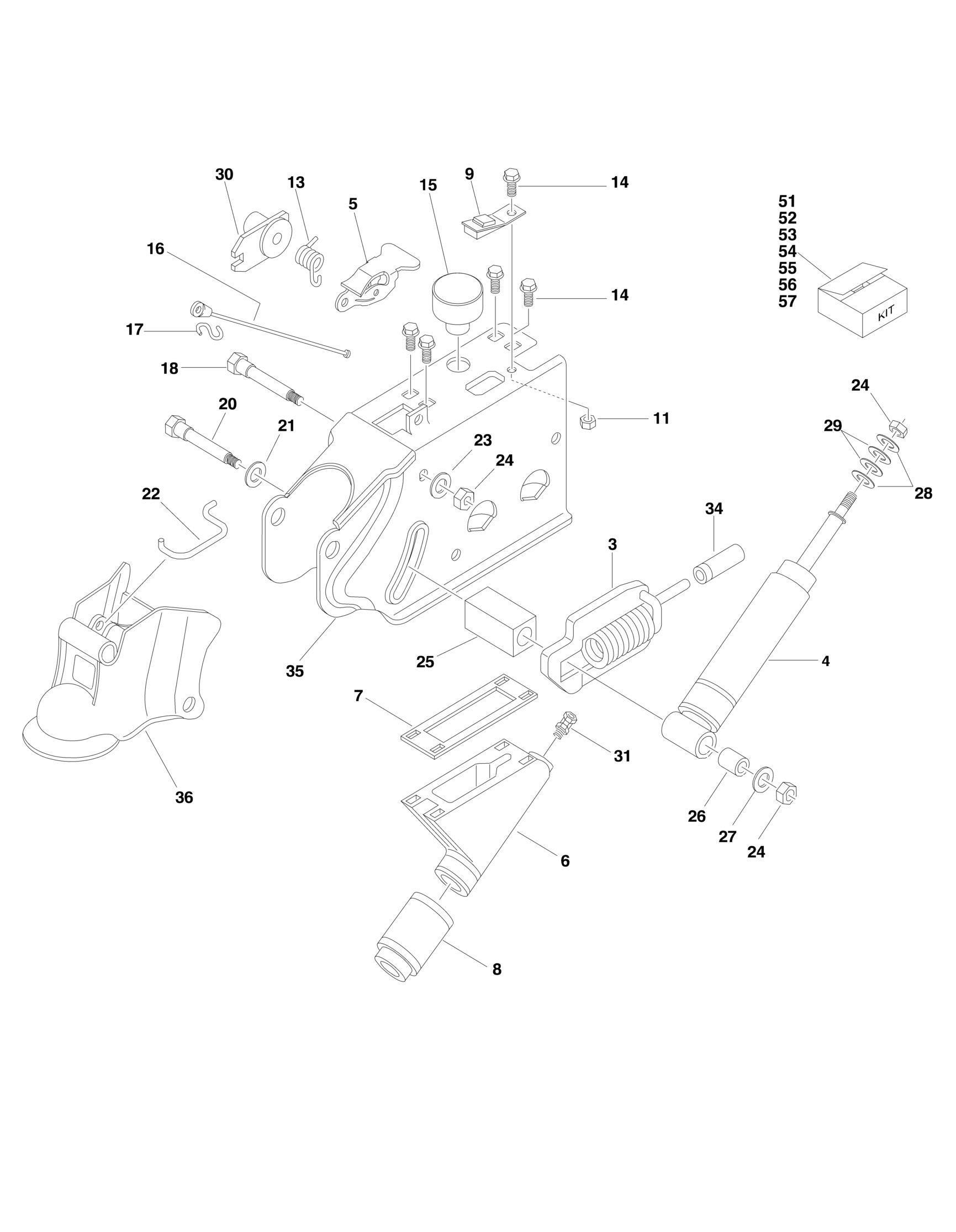

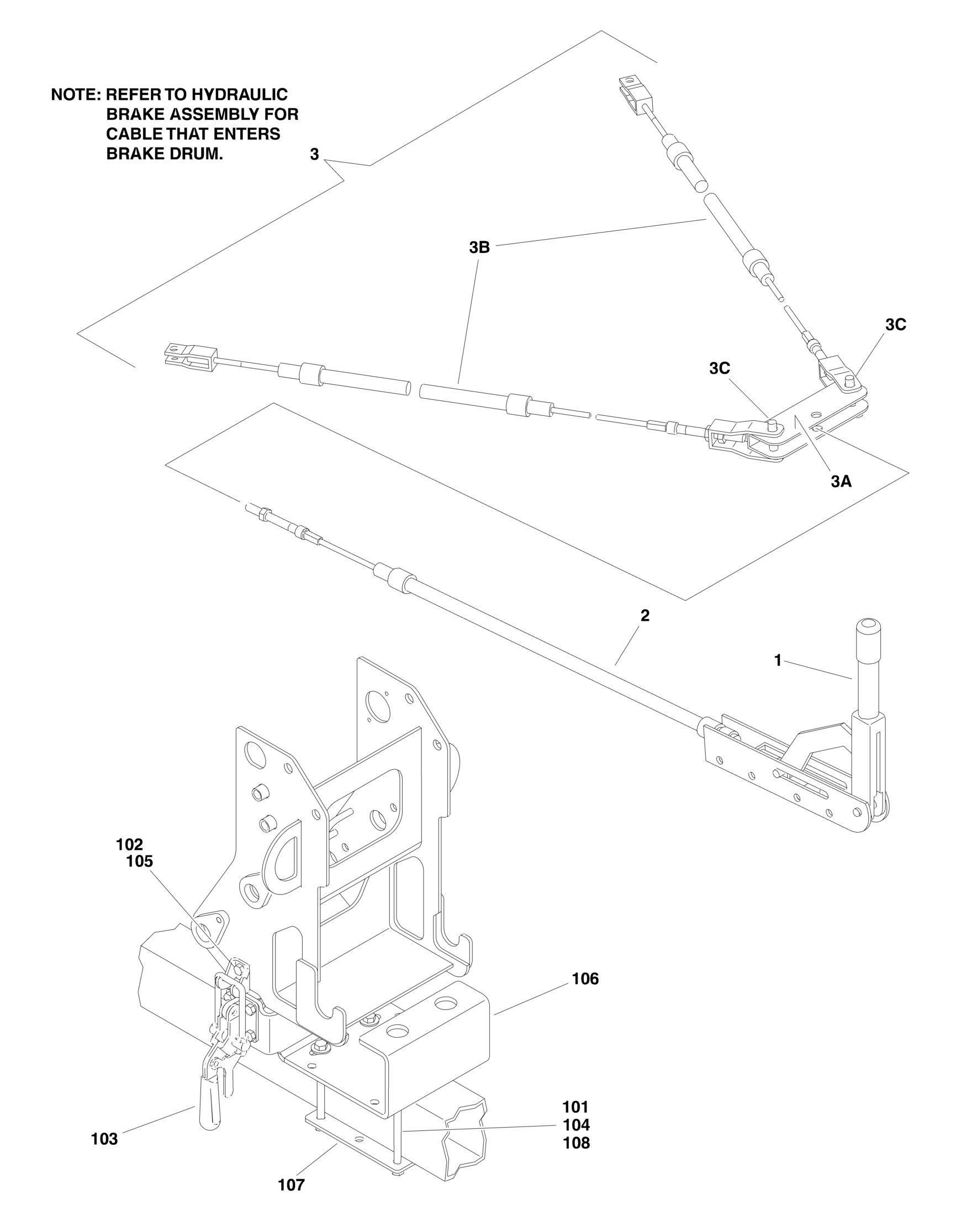

DESCRIPTION OUTRIGGER INSTALLATION Outrigger Installation T350 ANSI and ANSI Export Specs Outrigger Installation T350 Australian and CE Specs Outrigger Installation T500J ANSI and ANSI Export Specs Outrigger Installation T500J Australian and CE Specs Bolt 10mm x 30mm Locknut 10mm Pin Options: Pin T350 Pin T500J Pin Options: Pin T350 Pin T500J Keeper, Pin Flatwasher 10mm Locknut 4mm Capscrew 4mm x 40mm Outrigger Sub-Assembly (See Items 101-114 for Breakdown) Outrigger Sub-Assembly T350 ANSI and ANSI Export Specs Outrigger Sub-Assembly T350 Australian and CE Specs Outrigger Sub-Assembly T500J ANSI and ANSI Export Specs (Prior to SN 0030000236) Outrigger Sub-Assembly T500J ANSI and ANSI Export Specs (SN 0030000236 through 0030012032) Outrigger Sub-Assembly T500J Australian and CE Specs (Prior to SN 0030000236) Outrigger Sub-Assembly T500J Australian and CE Specs (SN 0030000236 through 0030012032) Flatwasher 4mm Pin Options: Pin T350 Pin T500J Ring, Retaining Options: Ring, Retaining T350 Ring, Retaining T500J Ring, Retaining Options: Ring, Retaining T350 Ring, Retaining T500J Decal - Pad Load Options: Decal - Pad Load T350 Decal - Pad Load T500J Thrustwasher, Oilite Thrustwasher, Oilite OUTRIGGER SUB-ASSEMBLY Outrigger Sub-Assembly T350 ANSI and ANSI Export Specs Outrigger Sub-Assembly T350 Australian and CE Specs Outrigger Sub-Assembly T500J ANSI and ANSI Export Specs (Prior to SN 0030000236) Outrigger Sub-Assembly T500J ANSI and ANSI Export Specs (SN 0030000236 through 0030012032) Outrigger Sub-Assembly T500J Australian and CE Specs

T350/T500J

REV G B I D

G E F C C

115