1.4.2 FUNCTION OF MOMENT LIMITER • Do not remove, disassemble, or repair detectors. Do not move the detectors to another location from original position. • Should an object hit a detector or you find any damage on a detector, be sure to verify the actuation status of the auto stop. If you find any abnormality with the actuation of the auto stop, do not fail to fix it. • Do not turn ON (cancel) the emergency stop cancel switch unless you find an error or check/perform maintenance on detectors. Overloading can cause the hoisted load to fall, boom breakage, or overturning of this machine that can lead to serious accidents resulting in death or serious injury. • The machine will not stop automatically even if the crane is overloaded during the crane slewing operation. Do not slew the crane when being overloaded. • When the boom approaches the stop position during the operation, be sure to change the operation speed of the boom to low speed. With high-speed boom operation, the boom may overrun the specified stop position, causing serious accidents such as overturning of the machine resulting in death or serious injury. The moment limiter is a device installed to prevent the hoisted load from falling, the boom from breaking, or the machine from overturning due to overloading. Always check the operation of the moment limiter before crane operation to verify no abnormality.

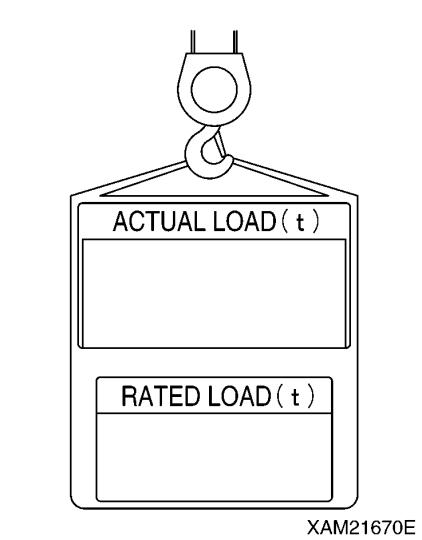

[1] MECHANISM OF MOMENT LIMITER The moment limiter calculates current "rated total load" by knowing the current boom position by the boom angle sensor and the boom length sensor, by knowing the outrigger extension condition by the outrigger position switch, and by knowing the number of wire falls (entered by the operator). Then by actually hoisting a load, the "read load" (hoist load) is sent from the pressure sensor of the derricking cylinder to the moment limiter. The moment limiter comparatively calculates between the "rated total load" computed out of the current position and the "actual load" (hoisted load), and issues an alarm if the result indicates the real load/rated total load=90 to 100%. If the calculation result indicates the actual load/rated total load=above 100%, an alarm is issued and the causes the boom operation to automatically stop. [2] DISPLAY OF THE MOMENT LIMITER ERROR MESSAGES The moment limiter performs self-diagnosis on the moment limiter display unit when an error is issued by the boom angle sensor, boom length sensor, pressure sensor, or when a circuit is opened or a connector is disconnected. The result is displayed on the “Rated Total Load Display” of the moment limiter display unit by an error code to notify the operator of the error. Immediately stop the use of the crane when an error code is displayed. See “Operation 1.4.9 Moment Limiter Error Causes and Actions to be Taken”.

3-17