2 minute read

2.24 DO’S AND DON’TS DURING CRANE OPERATIONS

• Always set the outriggers on level, solid ground when performing the crane operations.

• Never perform travelling hoist or the crane operations without setting the outriggers. The machine will be unstable and overturn, leading to serious accidents.

Advertisement

• See the cautions given in the Safety besides the do’s and don’ts in this section.

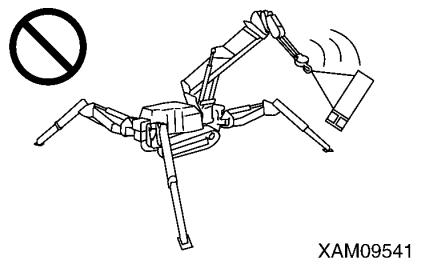

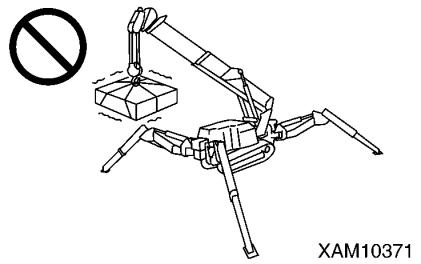

[1] DON’T OPERATE WITH SLEWING FORCE

Drawing in or lifting the load with slewing operation is prohibited.

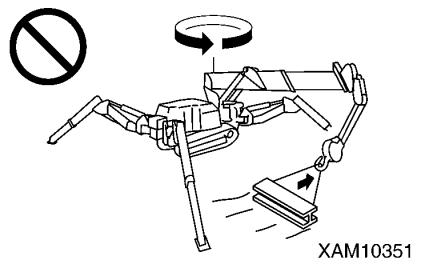

[2] DON’T OPERATE WITH DERRICKING FORCE

Drawing in or lifting the load with boom derricking operation is prohibited.

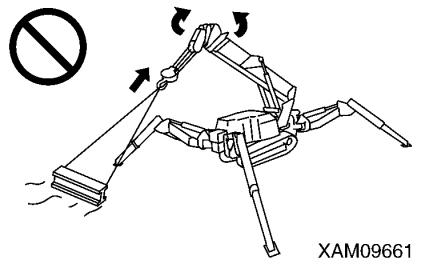

[3] DON’T PULL SIDEWARD, DRAW IN OR HOIST DIAGONALLY

Pulling sideward, drawing in, or hoisting diagonally applies unreasonable force on the machine. It not only damages the machine body, but is also dangerous. Never operate in these ways. The hook must come right above the centre of gravity of the load hoisted.

[4] DON’T OPERATE VIOLENTLY DURING OPERATION

Do not operate the lever suddenly. Especially, the “slewing”, “boom lowering”, and “hook lowering” must be operated at low speed.

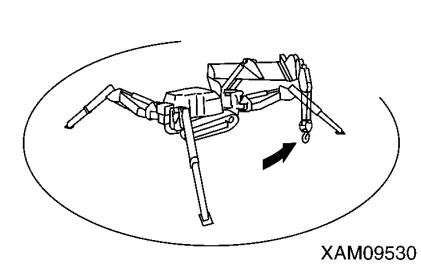

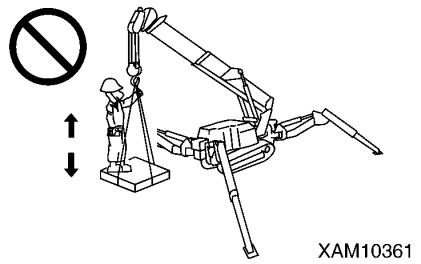

[5] DON’T ALLOW ACCESS INTO WORKING RADIUS

Do not let people into the working radius, such as permitting an operator to go under the hoisted load.

[6] DON’T USE FOR ANYTHING OTHER THAN MAIN APPLICATIONS

Do not move people up/down with the crane.

[7] DON’T PERFORM UNREASONABLE OPERATIONS

Operations requiring more than the machine performance can cause accidents.

Particularly, the crane operations must be carried out according to the total rated load chart.

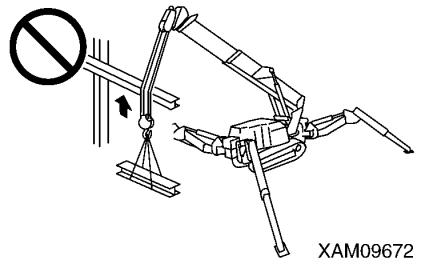

[8] DON’T WIND WIRE BY FORCE

Be careful not to hook the wire rope over a tree or steel beam while working.

If it gets stuck with something, do not force to wind the wire. Untangle and then wind the wire.

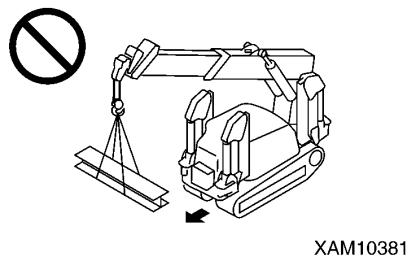

[9] DON’T ATTEMPT TRAVELLING A HOISTED LOAD

Traveling with hoisted load or operating crane without outriggers set may cause crane to tip. Do not perform these operations

3. HANDLING RUBBER TRACKS

3.1 GOOD USE

While the rubber tracks demonstrate many advantages thanks to its performance characteristic to the material, it has a weak point in strength. Therefore, we would like you to sufficiently understand the characteristics of the rubber tracks and to respect the do’s and don’ts and observe the cautions on handling so that the life of the rubber tracks can be extended and its advantages exercised.

Be sure to read “3.3 Dos and Don’ts with Rubber Tracks” and “3.4 Cautions in Using Rubber Tracks” in the Operation before using the machine.

3.2 WARRANTY

Verification of proper tension of the rubber tracks, maintenance of rubber tracks, and damage caused by the fault of customers such as not respecting the do’s and don’ts or not observing caution whilst working, for example, “worked at the site where there were objects that may tear the rubber blocks, such as steel plates, U-shaped gutters, corners of bricks, corners of sheer broken stones and rocks, reinforcing steels, and iron scraps”, are not covered by warranty.