interim & proto 1

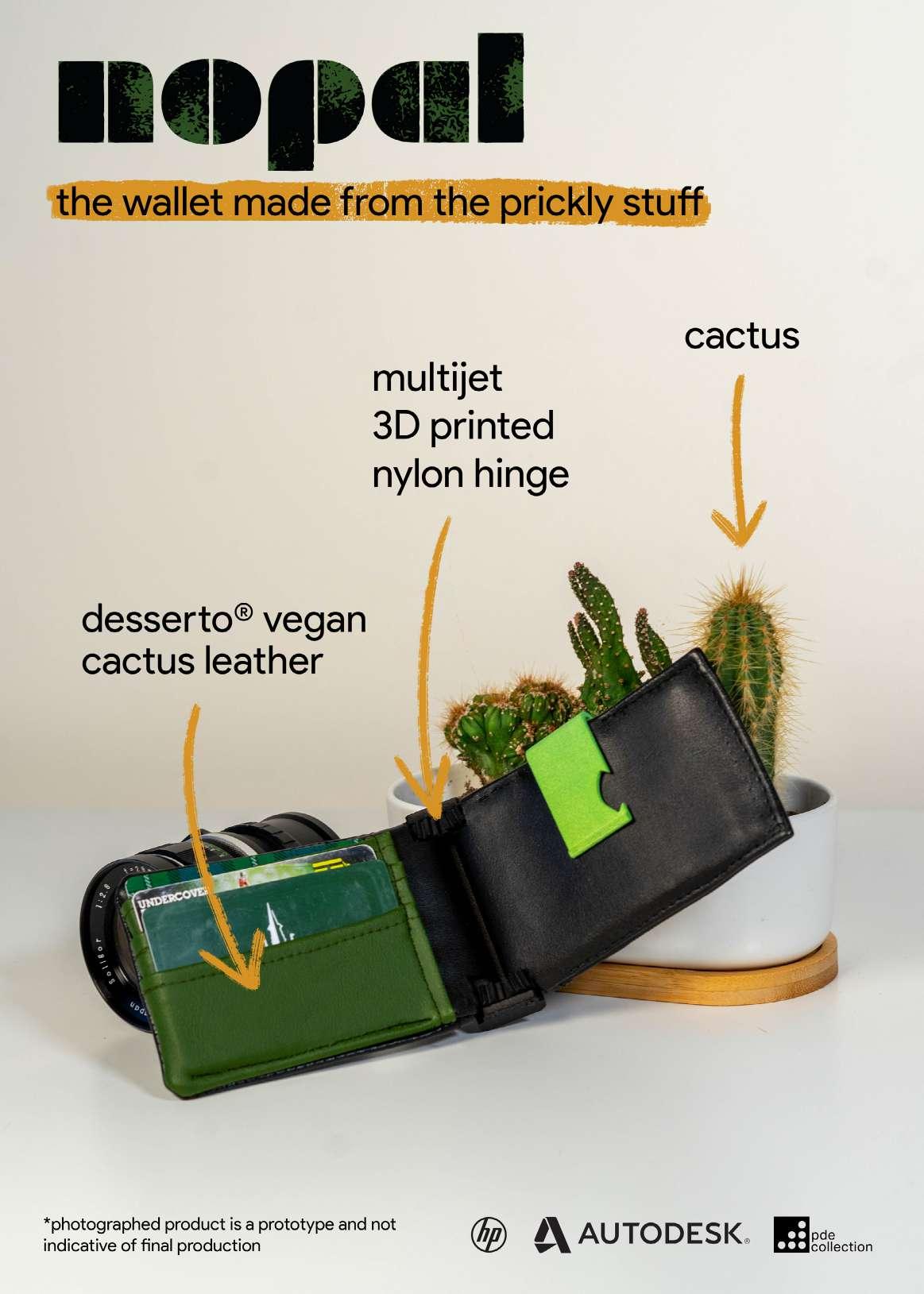

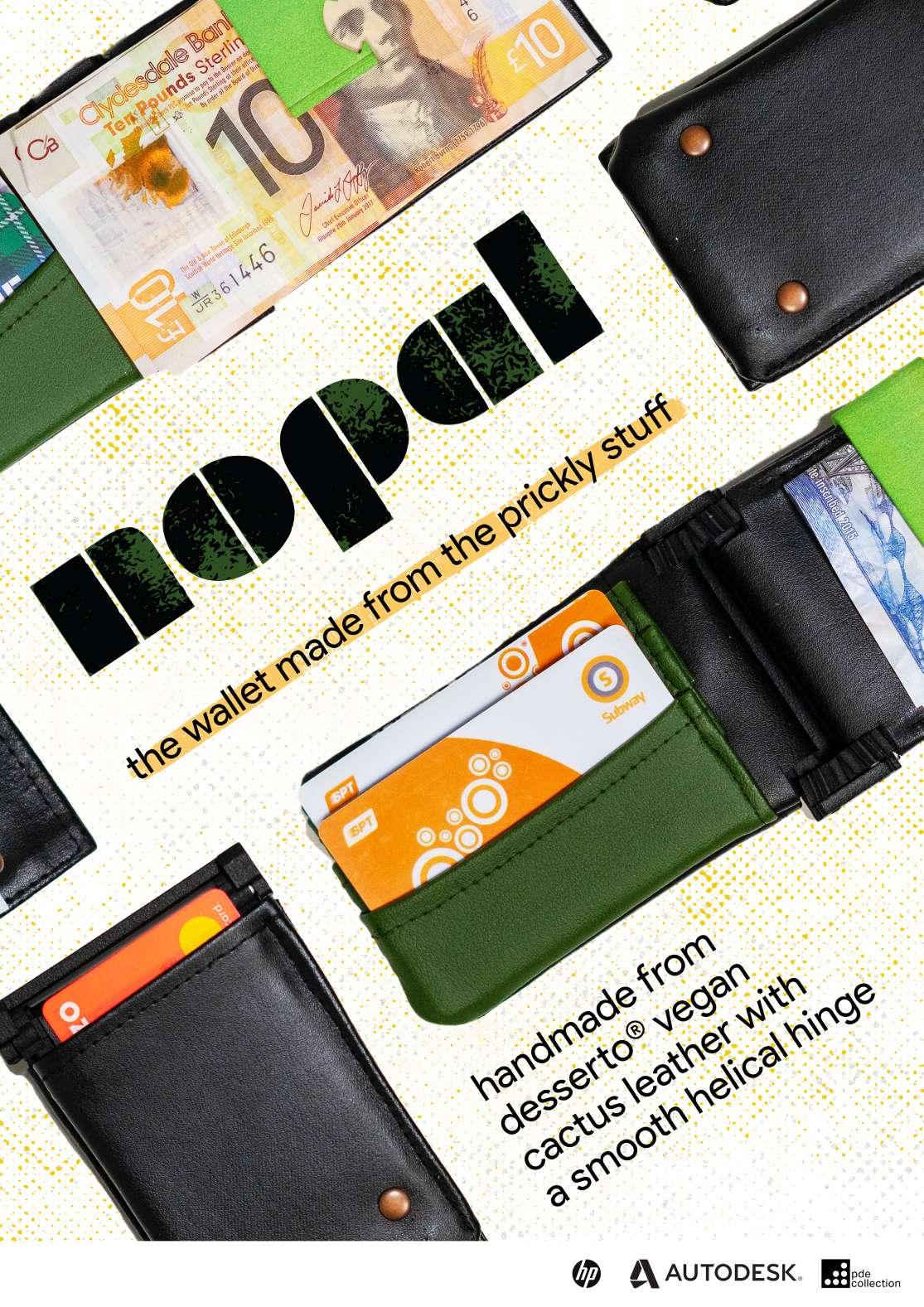

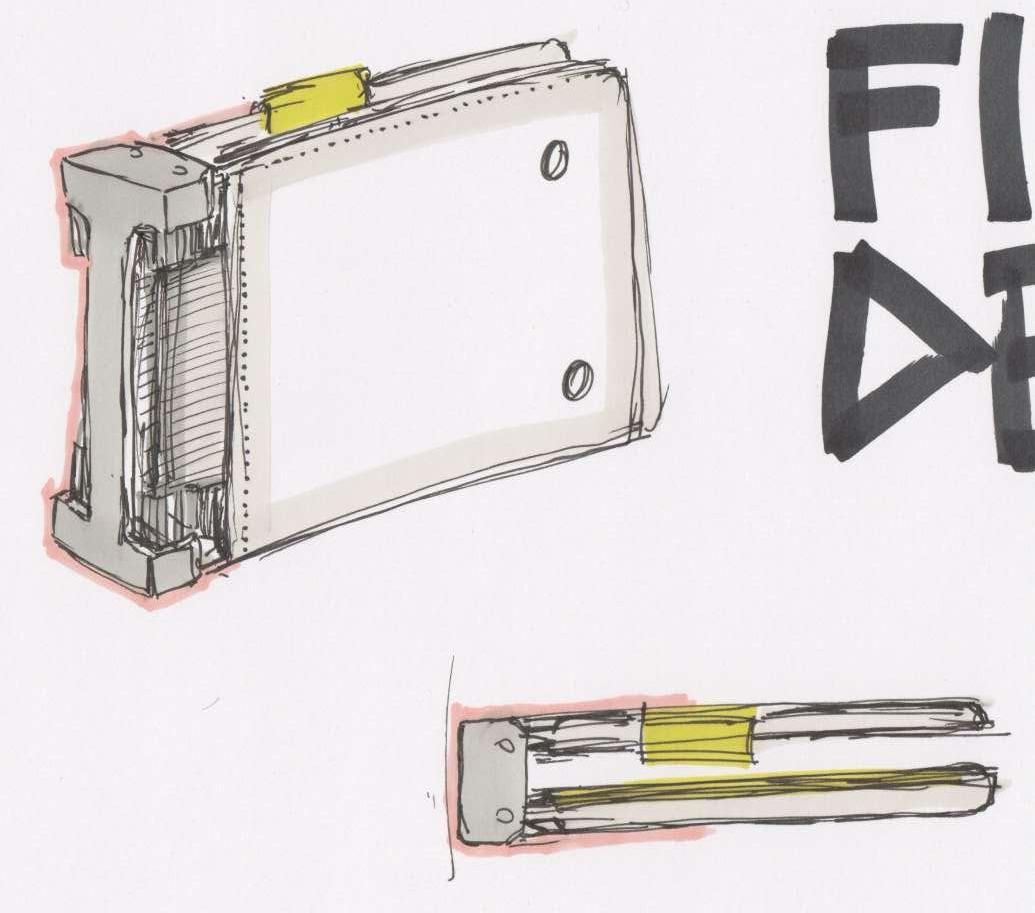

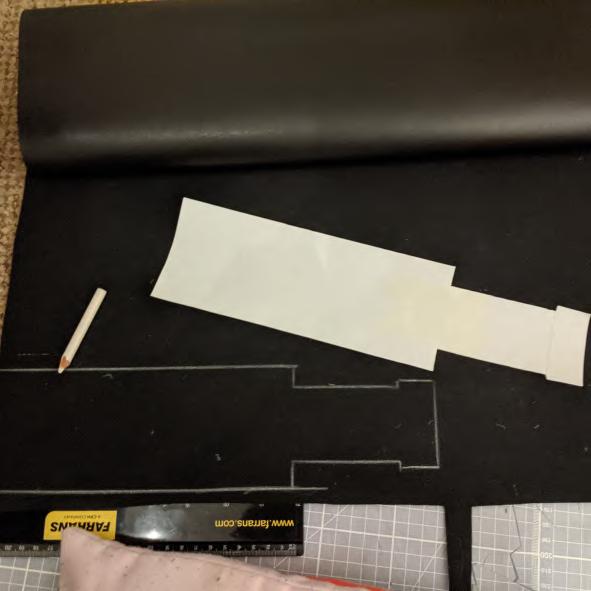

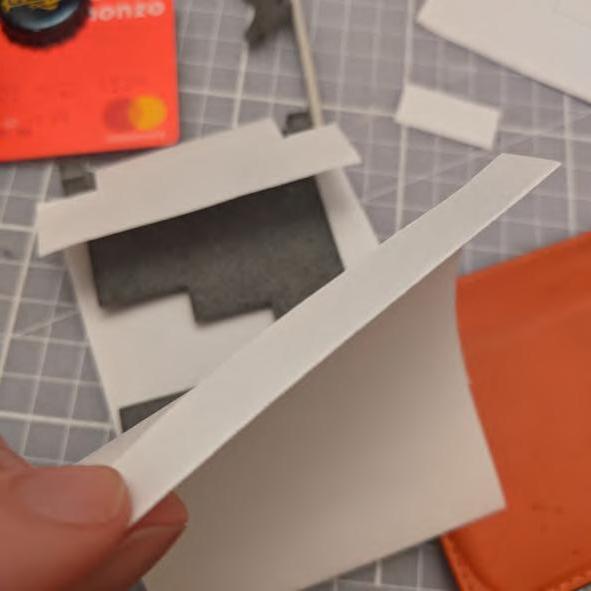

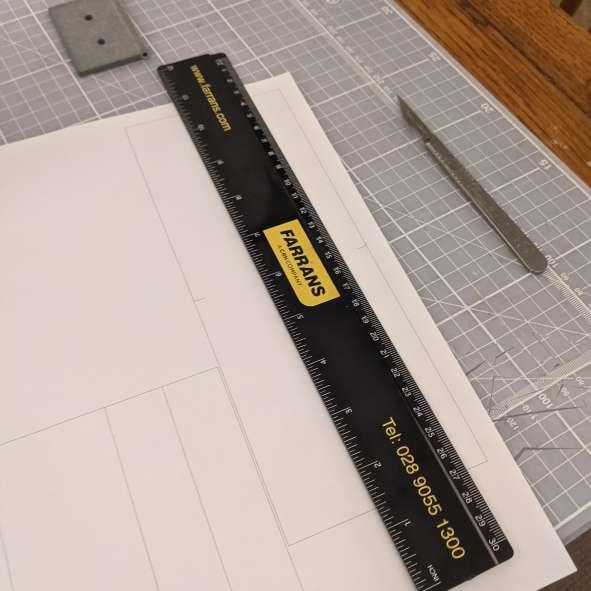

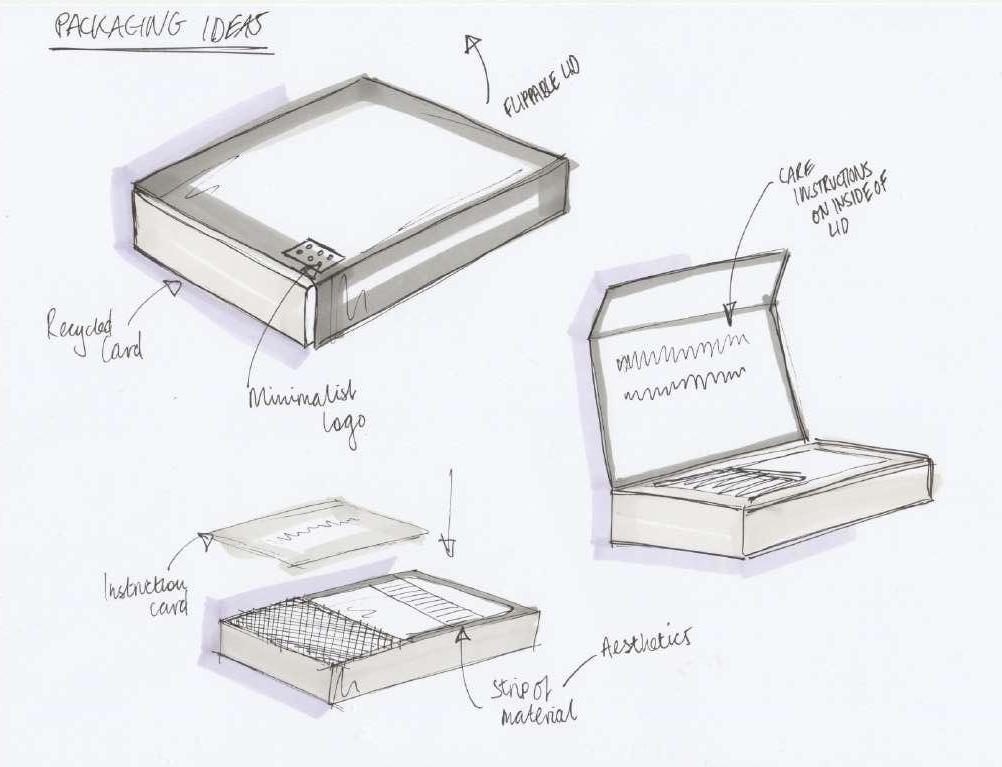

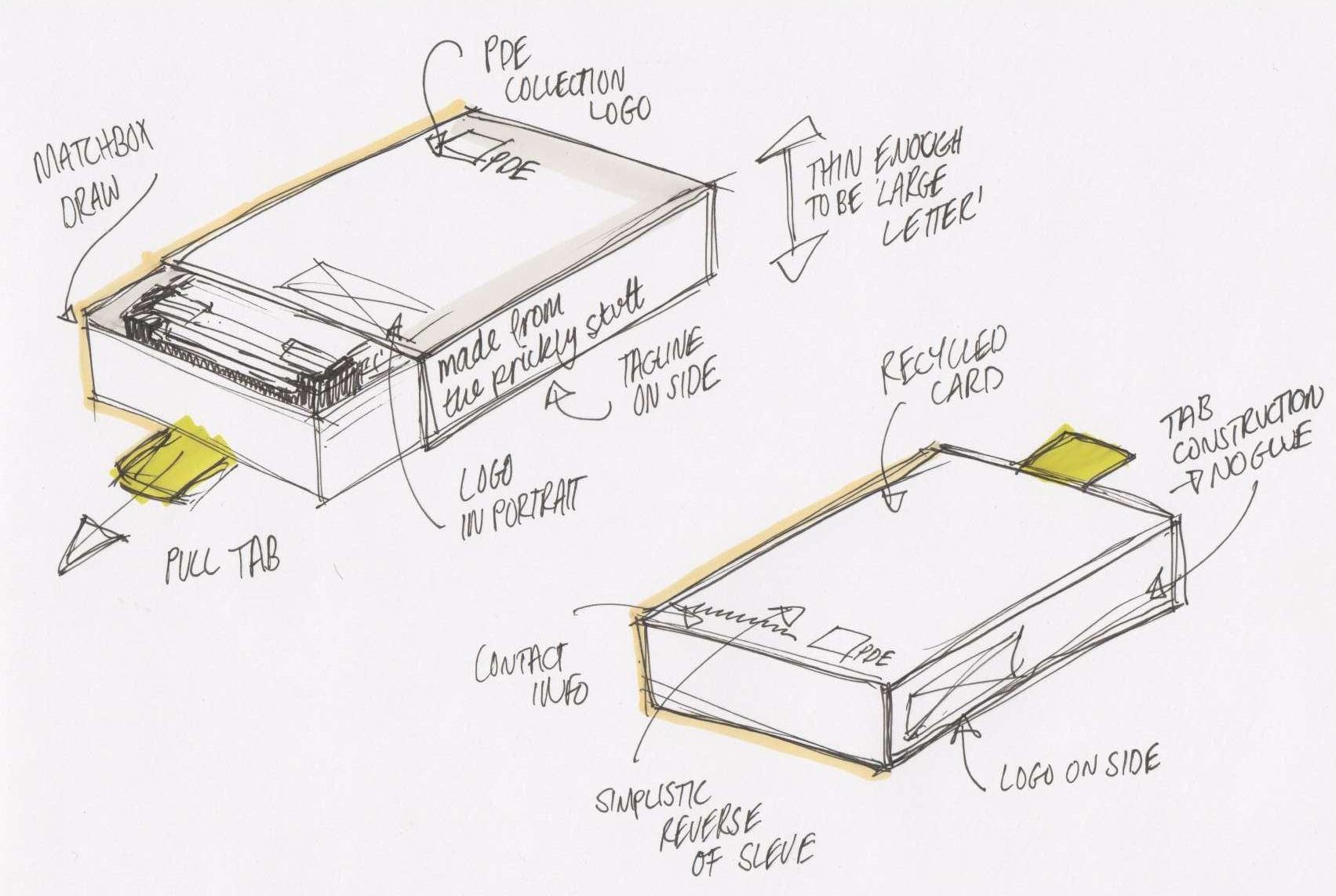

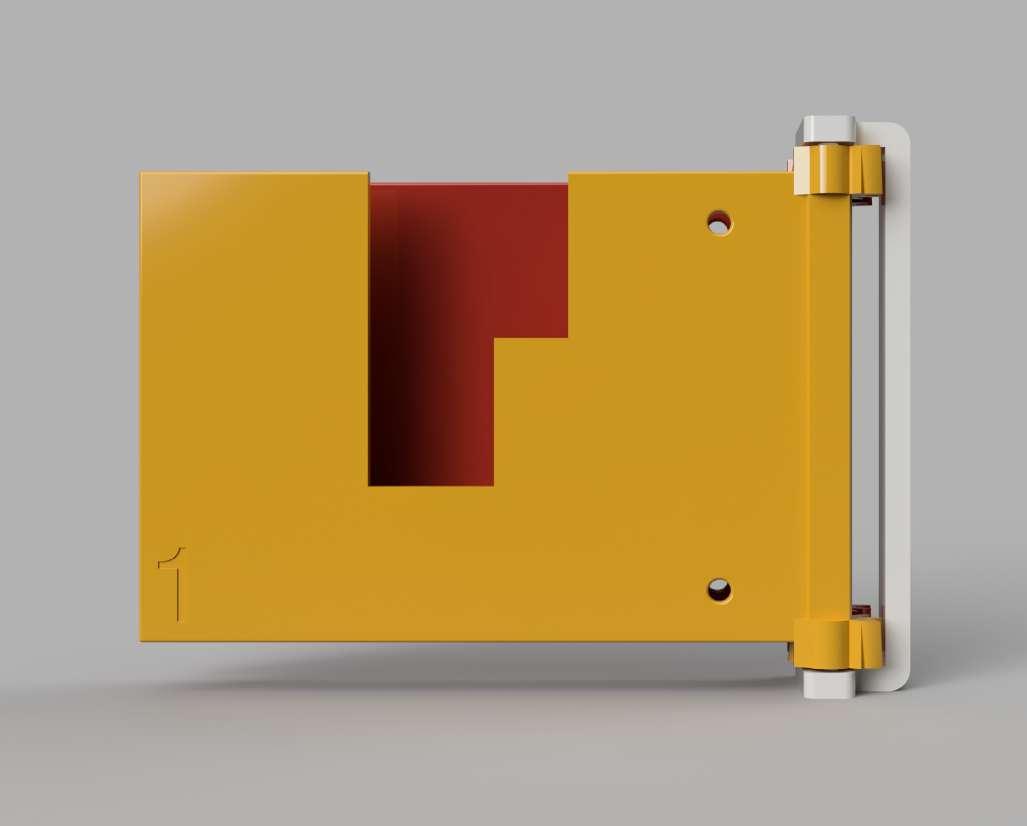

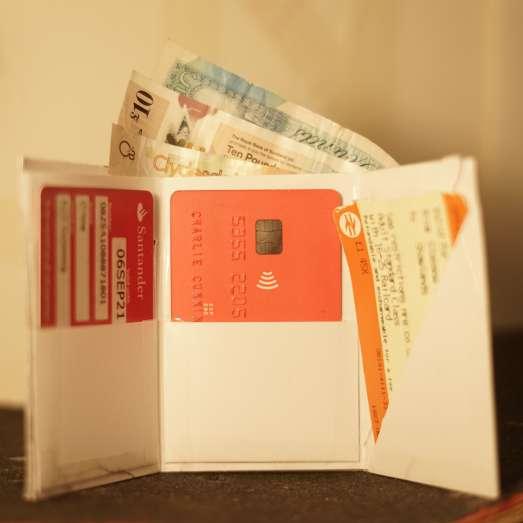

Interim presentation comments In the interim presentation I showed my work up to a group of my peers, as well as Hugh and Jen. I got a positive response as to the form and colour scheme I had chosen, however there were still some questions as to the thickness of the overall product. In my future prototyping, I will focus on trying to reduce the thickness of the each side of the wallet. My packaging was generally well received, with the matchbox shape being seen as a good compromise between overly fancy and incorporating too many moving elements and overly simple and dull. My focus from here will be on getting a good prototype in the final materials, and from there finalising my pattern design for final manufacture. Within prototype 1, I attempted to try out all the manufacturing techniques I’d need to practice in order to complete my final manufacture. This included, but was not limited to: • Precision template making • Cutting • Hemming • Inseams • Riveting This ended up being far more difficult than initially thought. Making templates consistently resulted in either printer errors due to my printer being from the middle ages or the template not surviving more than one trace. In order to fix this I could have used a thicker card, or laser cut acrylic. However with GSA being closed due to COVID I was not able to access these resources. I solved this issue by practicing tracing more carefully.

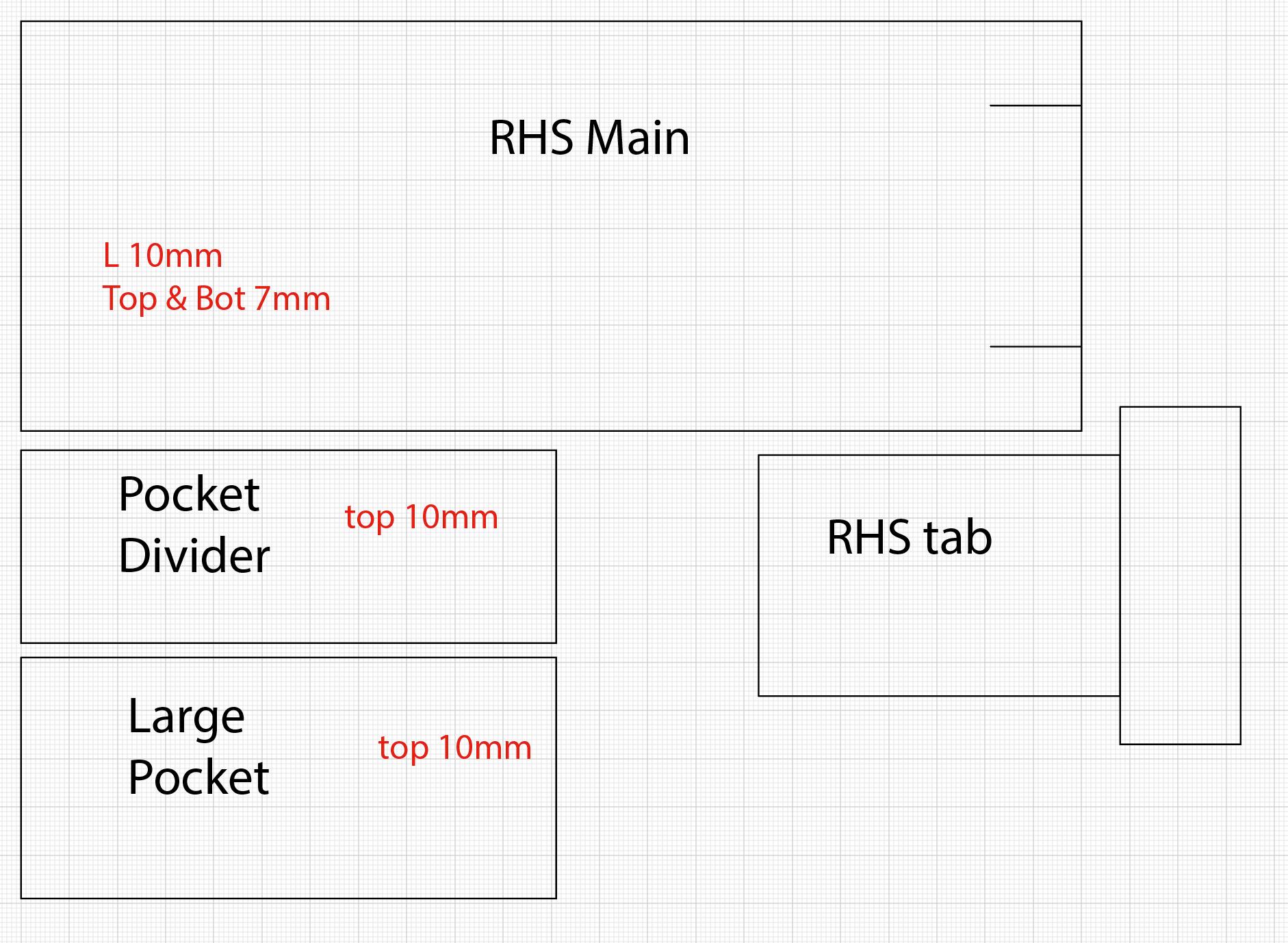

Initially I tried cutting my material using a sharp scalpel, however quickly realised that this was not good enough, as it left rough edges when cutting the knit backed fabric, and took multiple attempts to cut through the stiff fabric. In order to correct this I purchased fabric specific scissors, which cut both fabrics with ease. Creating an inseam worked well, allowing for a good level of finish and sharp corners when reversed. However, due to the nature of the fabric it did not press down very well. In order to combat this, I stitched round the edges at various distances from the edge to test what would look the nicest. I settled on a small stitching gap of 3mm. I tried joining parts together with rivets and this worked well, however the rivet would dimple in the middle. This was no longer a problem after I had acquired a rivet punch.