1 minute read

proto 3 ii

proto 4

Advertisement

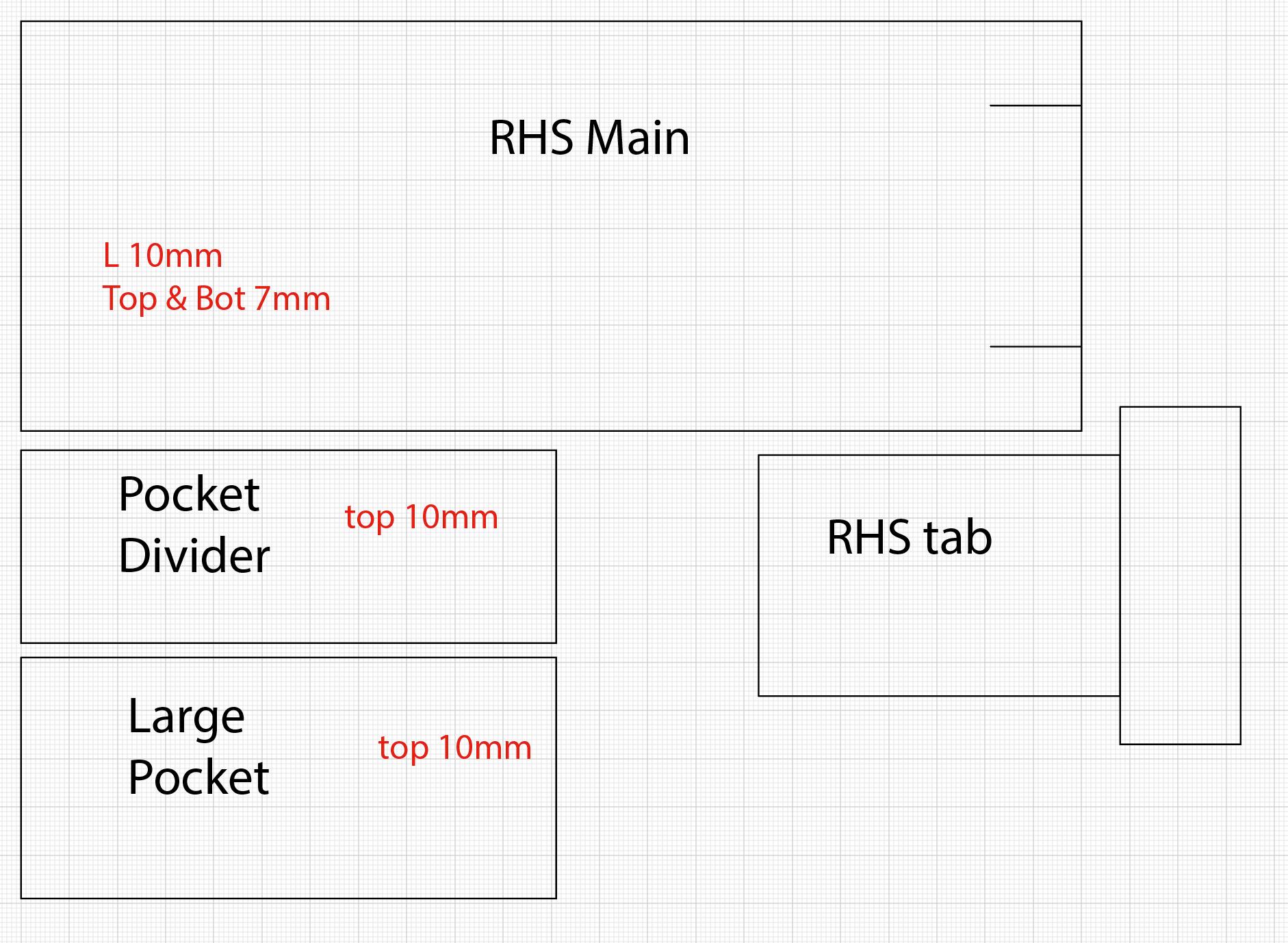

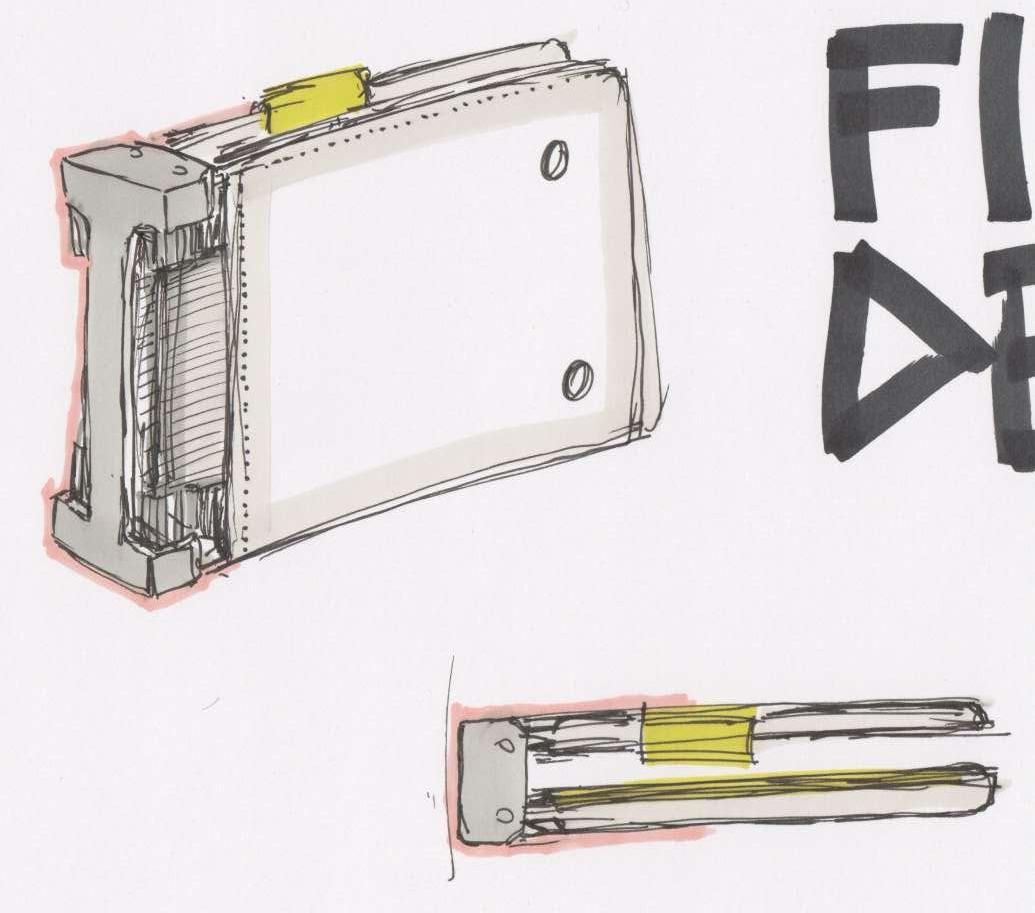

Iterating on prototype 3, I tried using a longer tab, that would intersect where the rivets would go through in order to create a tight seal to the sides of the wallet. I also sought to tidy up the edges of the wallet, aiming to minimise overall thickness. As well as this, I tried to leave a gap in the edge for the money clip to be inserted. As is becoming a theme, all this was more difficult than initially thought. By over-stitching the edges of the wallet, I had made the inside pocket significantly smaller, meaning the tab would no longer fit - creating unsightly ripples in the fabric, and even when cut down it barely fit. In future revisions I would have to learn to stitch closer to the edge. This would also look better. Furthermore, I discovered another characteristic of desserto - it’s ability to melt when under high heat. This was both a blessing and a curse, wherein if I tried to iron it on a too high temperature it melted to my pressing fabric and ruined both the pressing fabric and the desserto. However I could use this melting to my advantage. When heated up slightly (a shade above two dots on my iron) it would slightly melt into itself. Not enough to effect the surface finish, but enough to cover up needle holes from imperfect stitching. This helped massively as it meant I could re-do stitching multiple times and the material could ‘heal’. I also discovered my sewing machine really didn’t like going through more than 8 layers of desserto stiff. I went and bought thicker leathermaking needles. Iron set too high RIP needle 1