8 minute read

thanks

further reflection

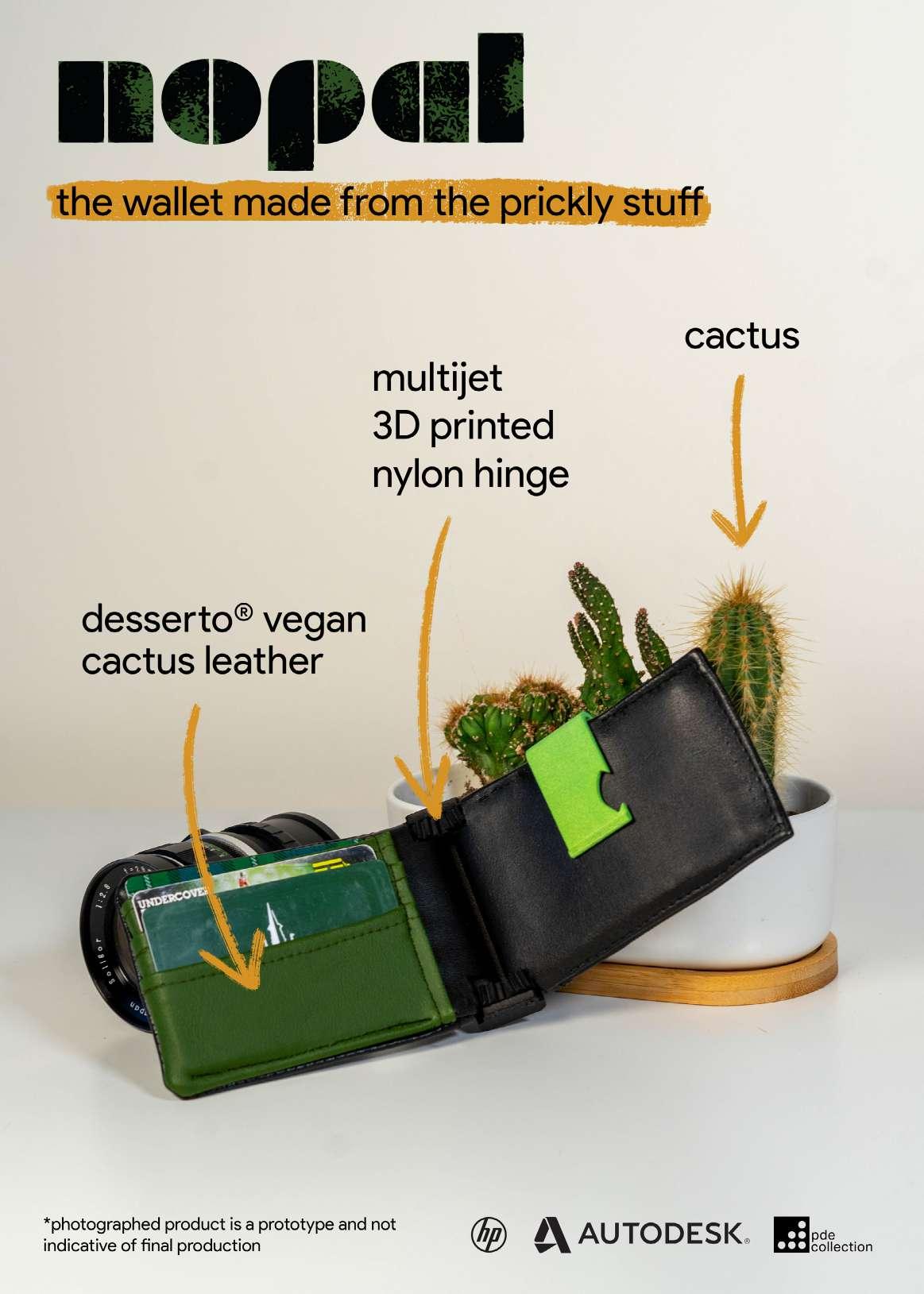

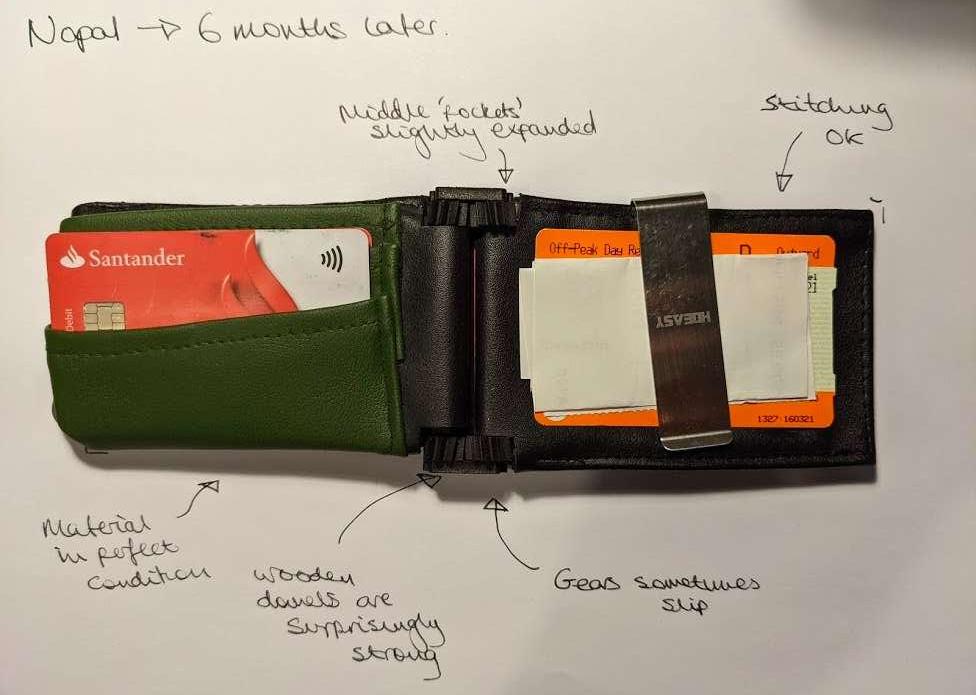

Looking back, what I didn’t grasp was the real purpose of my wallet, especially the use of the 3D printed hinge. This made it difficult to justify decisions as well as be able to evaluate my ideas. Having used nopal as my only wallet for 6 months, I think that I have discovered the answer. It’s just a bit of fun, a novelty, something to fiddle with and interact with when opening and closing the wallet. Nothing life-changing, however nice to have and adds a little joy to the very everyday task of purchasing an item. I find the overall design adds a bit of charm to a usually boring every-day item. I’ve had complements and interested questions about it, as well as further enquires as to where they can be purchased. The best thing I have noticed was the placement of the outside pockets, combined with the thickness of the HP 3D printed inserts. This allows both pockets to be used to store separate contactless cards for them to be used from within the wallet with a flick of the thumb. But it’s certainly not perfect. In the next few slides I will analyse my (albeit prototype) wallet for wear after 6 months and suggest ways in which it can be improved.

Advertisement

The contents of my nopal after 6 months of daily use the easiest way to open the wallet, with a single push of the thumb on the side.

nopal; 6 months

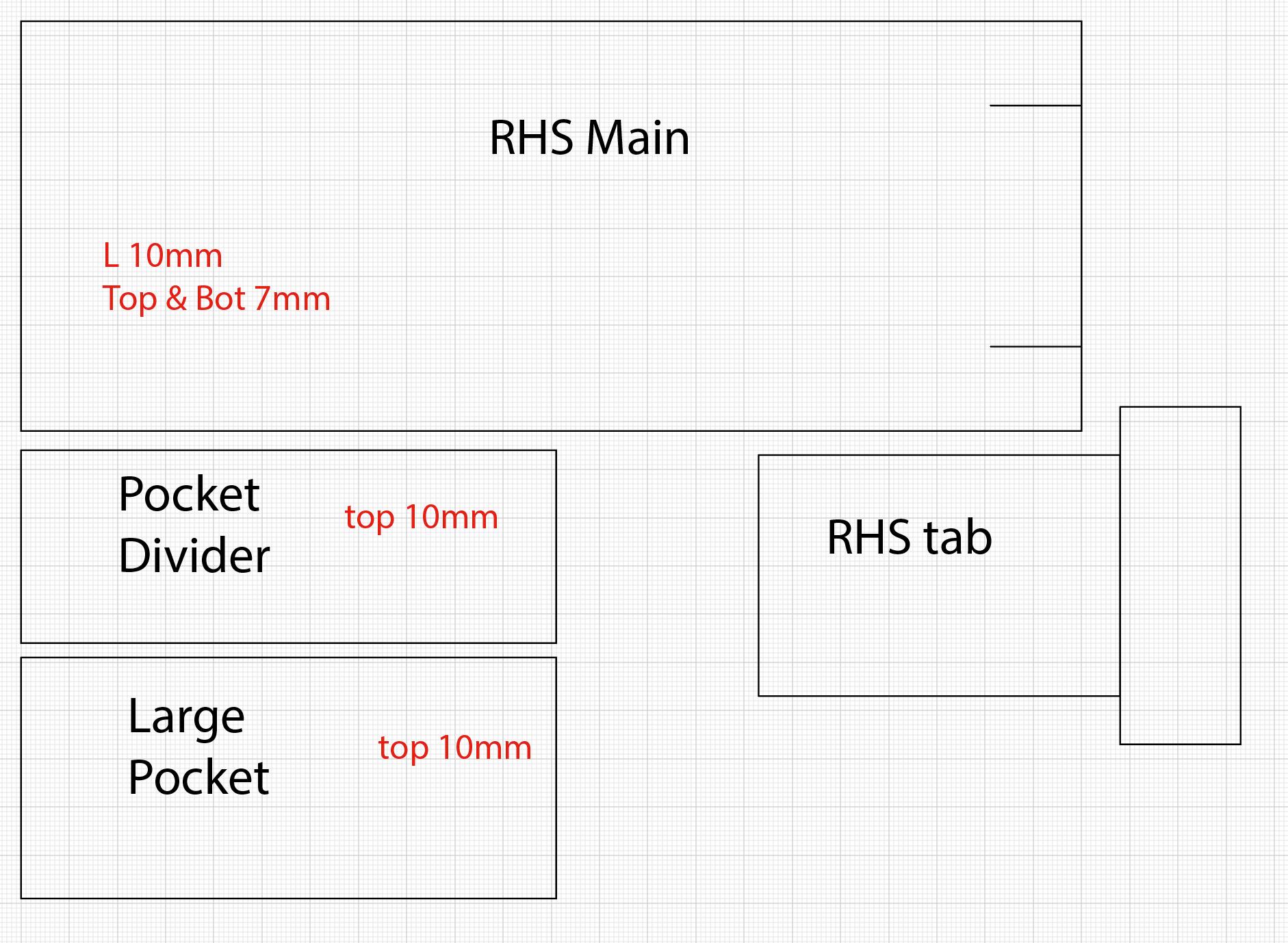

The HP MultiJet 3D printed helical hinge has proved exceptionally hard wearing, with no noticeable wear marks or scuffs on the gears and no discolouration on the frame. However the mechanism sometimes skips, leading to me having to bend the wallet to allow it to skip back a tooth. I suspect this isn’t the fault of the gears but the axles they are on. The wooden dowels have held up surprisingly well but were never a permanent solution, however a stop-gap solution due to the lead times of the HP 3D printer. Recreating the original design of ‘pegs’ to hold each wing in would be the best course of action to improve this, as the interference fit of the dowels worked well to secure them in place. Although, with enough time and iterations, creating an in-built hinge is possible. This would eliminate this potential breaking point as well as significantly simplifying assembly. This was my first prototype of the nopal design, with the main differences being the lack of 3D printed money clip. However the main body of the wallet is the same design - with better quality seams being implemented on the production models. The desserto cactus leather has lasted surprisingly well, with no marks or blemishes visible that were not originally there. This is certainly a strong point in this design. The black ‘thick’ desserto seems to have gained a slightly more supple feel than it originally had in a similar way to traditional leather. However, the green ‘desserto knit’ does in hindsight seem to be a tad too stretchy. Whilst allowing for more cards to fit in each pocket, it also means that it is easier for a card to fall out if it is placed on its own in the wallet. Combined with the difficulties this material gave me in manufacture, I think that I would change this to another desserto product if I was to reattempt nopal.

desserto news

Since I originally made the decision to use desserto, it seems the company has had a great 6 months. Desserto is now working with UK high street retailer H&M, creating a range of cactus leather goods (including wallets). This material, as well as other alternate leather seem to be an up and coming trend, with high end car manufacturers such as Tesla and Ferrari offering vegan leather options. As well as this, desserto has created a student programme, allowing access to the entire catalogue without minimum orders as well as a free swatch book. This would have been invaluable when choosing my materials, as I would have been able to trial working with them before ordering large quantities. Overall I am very happy with my choice in materials, as I think that both the desserto and HP MultiJet 3D print hit the perfect balance between unusual material and useful properties. If I was to re-do the graphics and marketing strategies, I would put more emphasis on the materials the product is made out of, possibly drawing analogies to high end companies and products that use them.

improvements

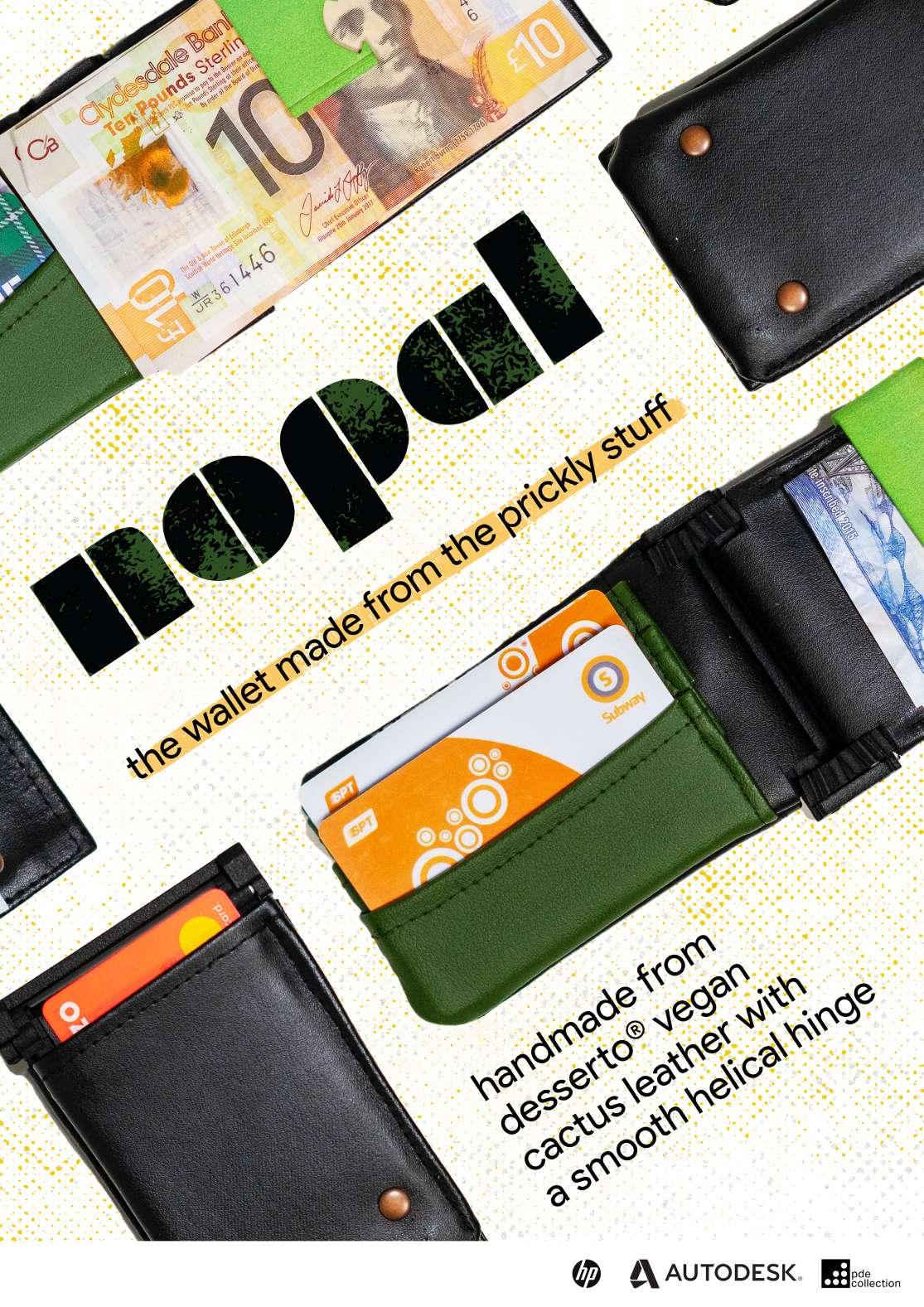

Graphics and Marketing Looking back at my graphical campaign, I really like the idea and form of the poster, however I think that it could have been executed differently. Instead of assembling it digitally using Photoshop, i think it would be more effective if shot as a single photo. This would really highlight the versatility of the wallet, and remove the ‘uncanny valley’ nature of the poster. This would mean I could use the logo physically, perhaps printing it to look like a bank note and clipping it into a wallet. This could help brand cohesiveness. I would also align the background to the angle of the wallets correctly.

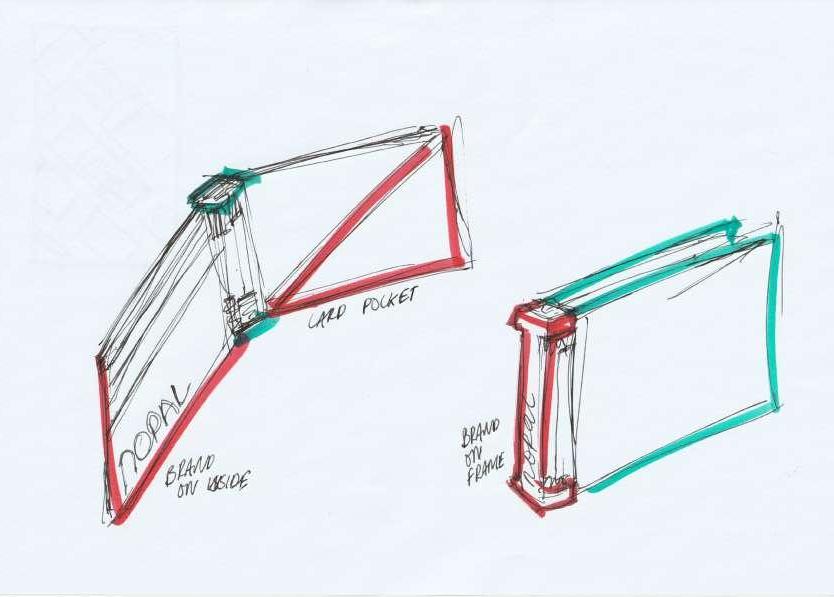

Initial sketch of potetial second poster attempt

Product As well as incorporating the technical improvement previously mentioned, i feel the wallet needs a quirky internal design to match the materials. Using inspiration from my original wallet concepts, I could use the split pocket from concept 1 instead of the money clip, which would allow for tickets,folded notes and coins to be used, as well as giving a funky triangular aesthetic to the inside of the wallet. As well as this, I feel that the brand could be included in the product. Embossing the logo into the frame or press branding it into the inside pockets could create a nice motif. Furthermore, working newer desserto materials would allow me to offer more colourways of nopal. I feel that this would increase overall appeal.

packaging

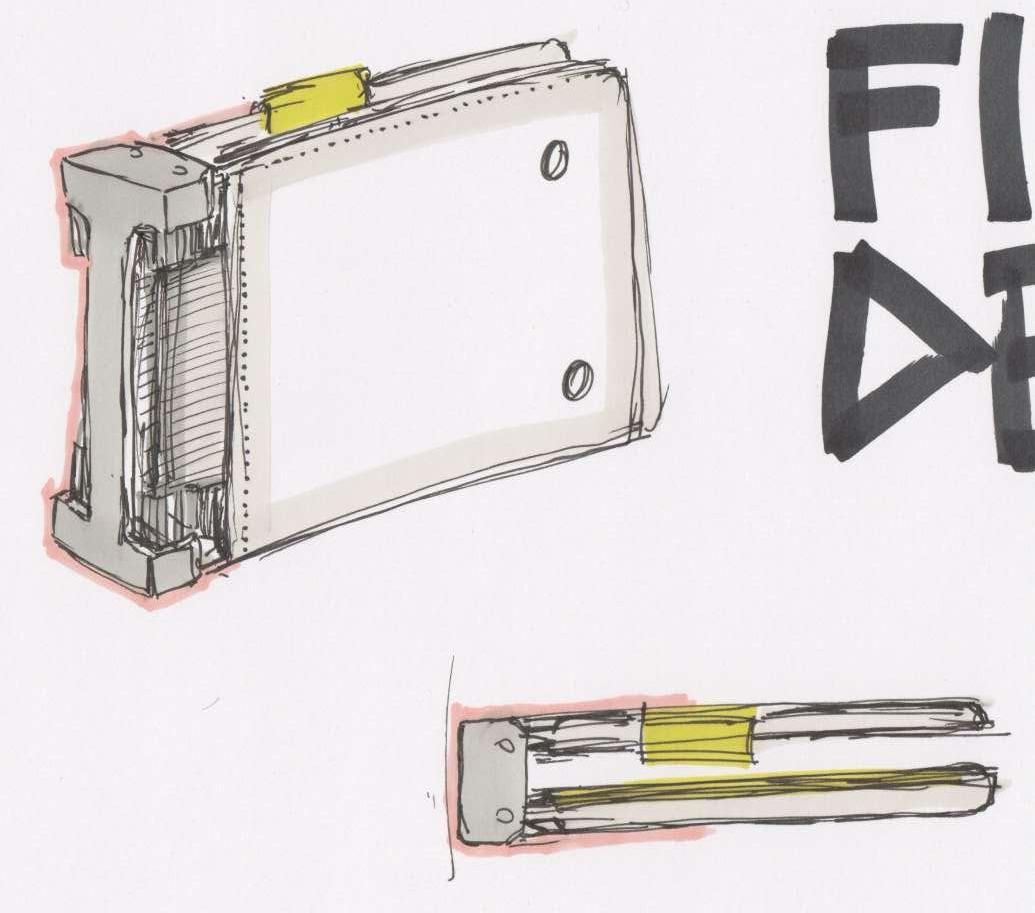

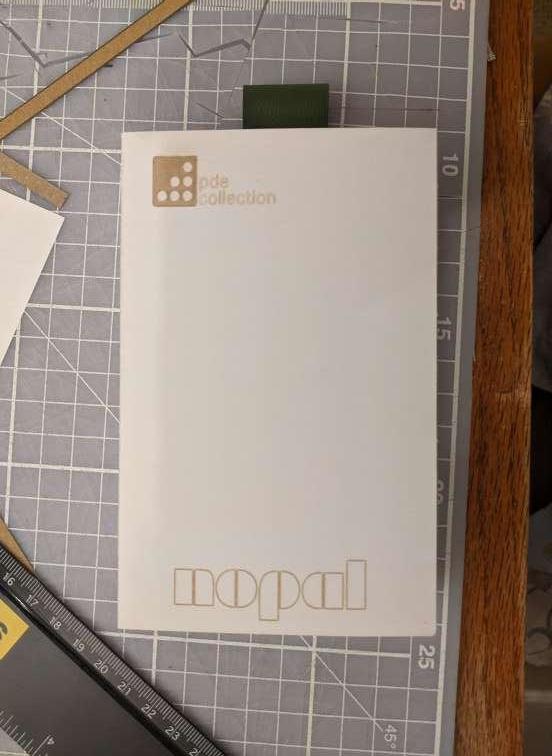

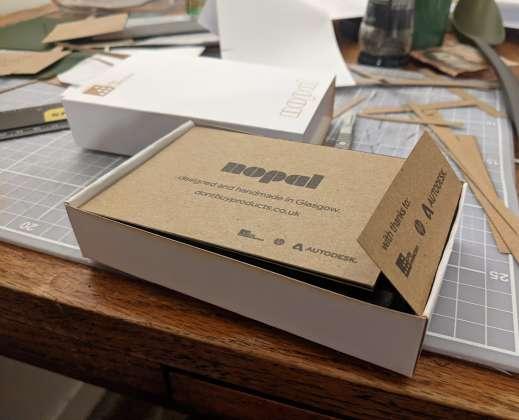

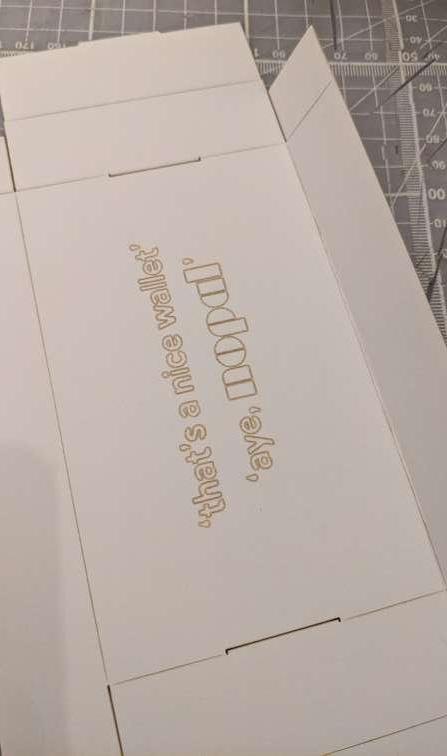

My packaging did not arrive in time for the initial hand in nor for the photoshoot for marketing materials, however it did arrive in time to send out to customers. It consisted of an outer card slide casing covering an inner card tray, which had an offcut of desserto knit stapled to it as a handle. This staple was the only fastener used in the entire construction. Covering the wallet was an information sheet with some details about nopal, as well as cleaning information. A small wrap-around piece was used to prominently display the HP, Autodesk and PDE collection logos whilst doubling as a tab to lever the wallet out of its housing. This was printed on recycled cardboard to minimise environmental impact. These information sheets worked well and looked inviting whilst professional. Overall I was in two minds about the packaging. With some refinement, i think this design would work well - especially reducing the height of the casing in order to create an interference fit with the tray, creating more resistance for a more satisfying opening experience. As well as this, I thought the integration of the nopal material on the outside was a nice touch, as it provides a tactile element to the user’s first interaction with the product. However I was not the most impressed with either the laser cutting or the material choice. The laser left unsightly burn marks that needed to be manually wiped off with a rubber. This is tolerable for a batch of 5, however would be too labour intensive for continued manufacture. Die cutting and lithographic printing would be a solution for larger batch manufacture. As well as this, I could have used recycled card instead of white card on the outside of the packaging to bring the packaging more in line with the environmentally friendly ethos of the product.

thanks

Huge Thanks to:

Hugh - organisation, general loveliness and exquisite HP wrangling. <3. Jen - comments & encouragement when I thought the project was a write-off. Maryam & HP Staff - a lot of $$$ worth of free 3D printing, delivered to my door. Ashleigh - Incredible help with manufacture, and use of sewing machine. My Mother - Lending of equiptment and endless encouragement Alice and Croxley Danes School Staff - For use of their laser cutter for packaging manufacture.

I couldn’t have done this without you.

sorry Hugh.