2 minute read

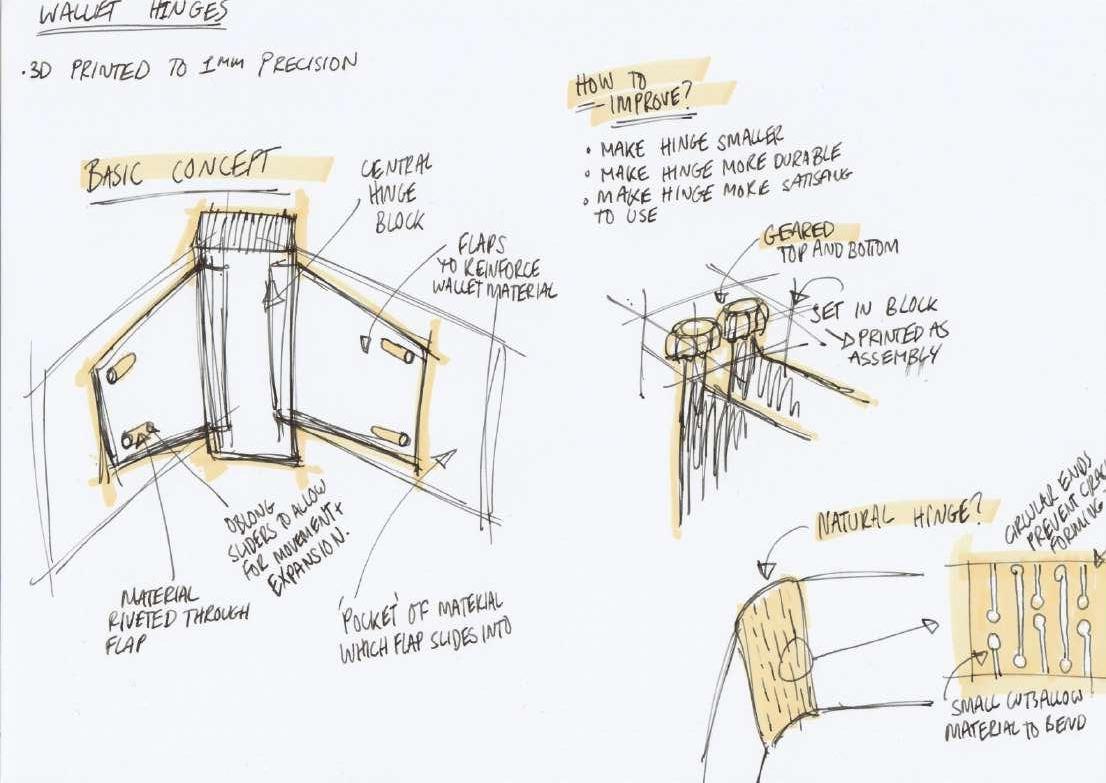

hinge ideas

From my tutorial with Hugh, I explored the concept of updating the wallet hinge for a digital age. From my previous mood board, I looked at modern, disruptive hinge design, like the hinges on the Galaxy Z Flip and Surface book. These are both geared hinges, however extremely complex. Looking at my production method I would not be able to create a hinge to the tolerance needed, so I have to look to simplify these. The surface and Z flip embody two different philosophies, with the z flip trying to hide the hinge away by using covers that always surround the hinge mechanism. This not only protects the hinge from dust, but further integrates it into the design of the phone. The surface however uses the hinge as a design feature, with an aesthetically pleasing side which shows off the mechanism. Both of these approaches have their merits, however creating a covered hinge may make my product too bulky. I shall try and design and develop both of these in order to see what method works in context of my product.

Advertisement

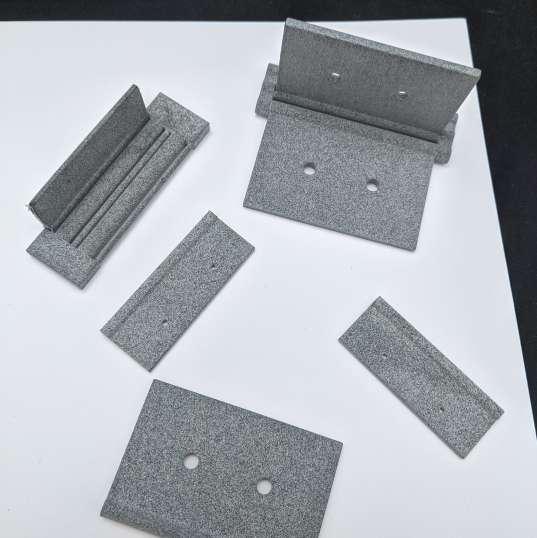

analysis of 3D print

Analysis of HP 3D printing

My initial impressions of the HP 3D printing were great, with the material feeling solid, and having a great, almost concrete-like texture to it. As well as this, the process created good features, down to a 1mm precision. When testing the structural rigidity, I found that even at 2mm thickness, it was very difficult to deform. However, upon closer inspection, I found there were issues with the way I was working with the process. When initially designing these parts, I had left a 0.5mm gap for tolerance when printing as an assembly. This was not enough to remove powder between bodies, and caused too much friction on the joint to the point of fracture. I will have to consider this in future when thinking about tolerance in my designs.

So What? • Looked at my first attempt at printing using HP multijet • Discovered limitations of printing as assembly and print as parts What Now? • Take these observations and use them in the next round of printing to improve the quality of output