1 minute read

prototyping III

Advertisement

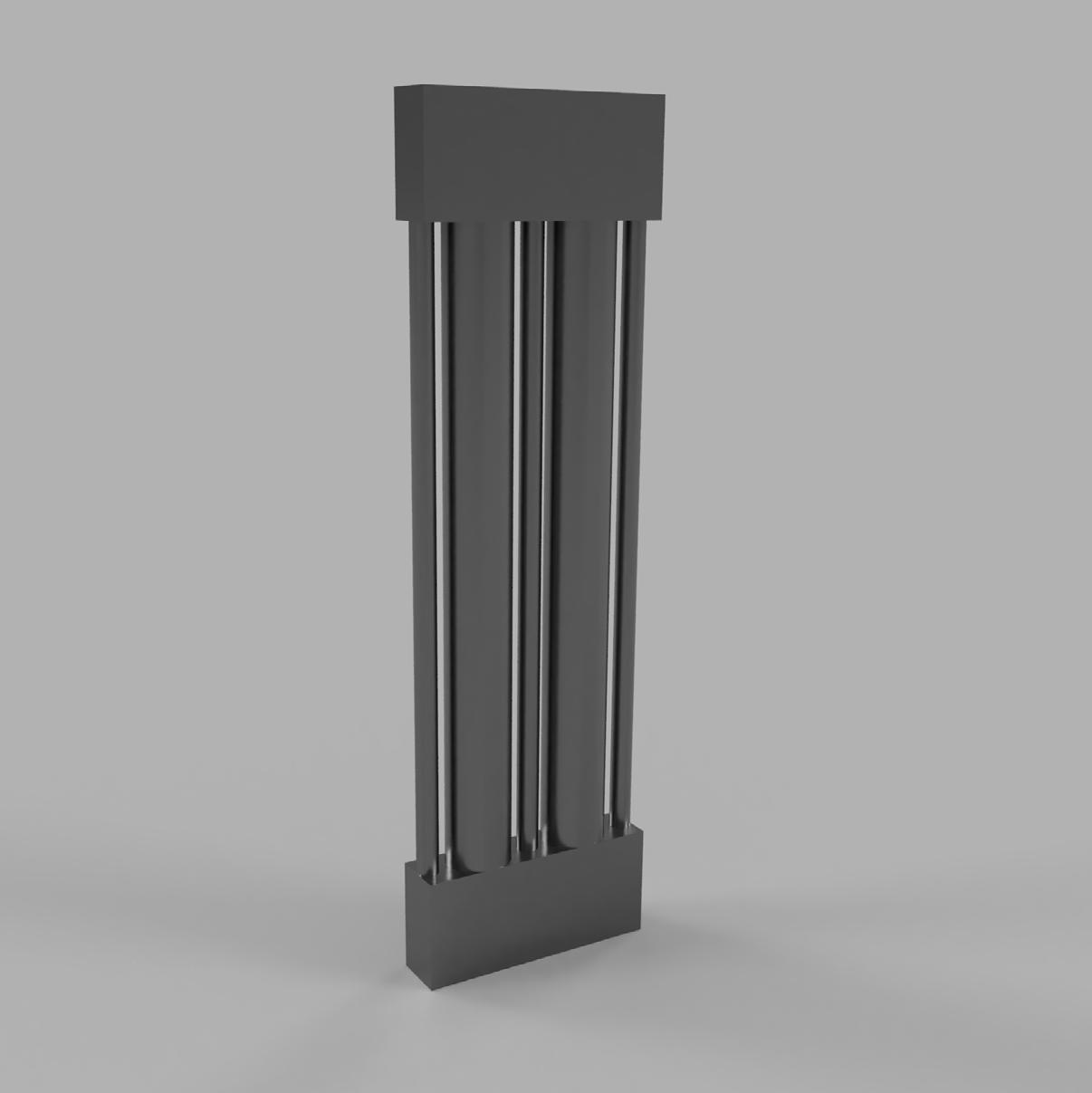

Initial CAD exploration

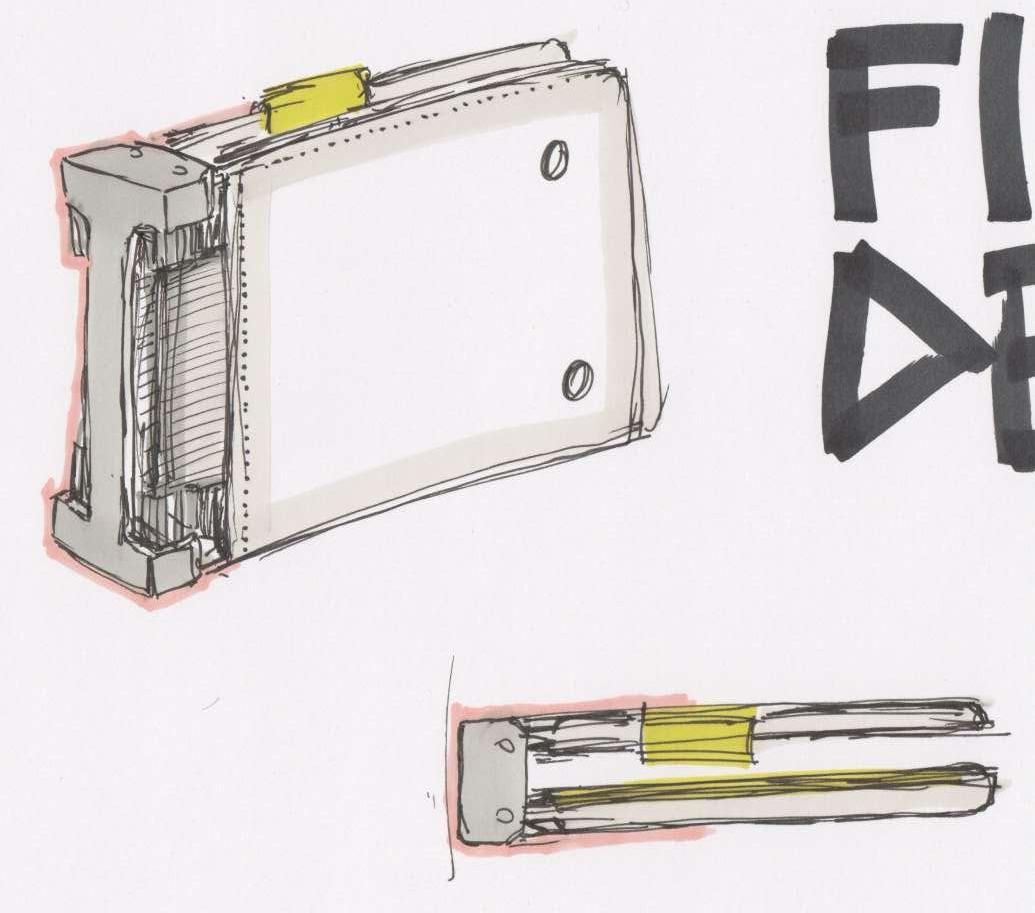

Using fusion 360 to model and render, I created two different three-wing hinge designs. Using HP’s 3D print technology, these can be manufactured to very small, sub mm tolerance. As I was using such a precise manufacture technique, I tried on one of my models to print the entire assembly as one piece, meaning the hinge would be stronger. The other model was made using a more traditional hinge, with snap-on wings. This could mean that i could explore the possibility of the wallet being modular, with different, interchangeable wings that could be swapped out dependant on the user’s use case. Furthermore, in future revisions I could use generative design techniques to maximise the strength whilst minimising the weight of the hinge.

So What?

Learnt the basics of fusion 360 Tested the ability of HP 3D printers to print small assembly components

What Now?

Wait for the prints to return, then user test Explore using generative to create stronger/lighter hinge Explore hinges with only two sides.