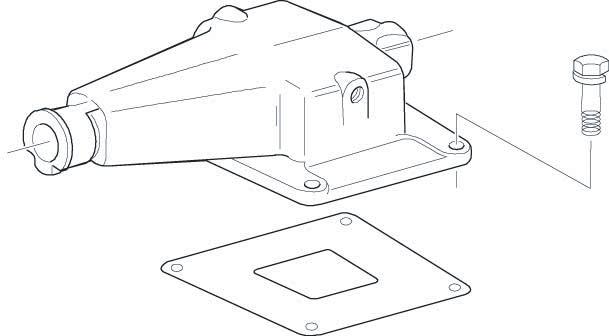

In-Vehicle Service Procedures How to Install Push-To-Connect Type Fittings Special Instructions None

Special Tools •

Air Line Cutting Tool

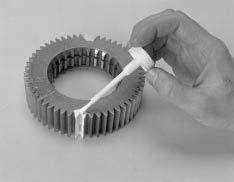

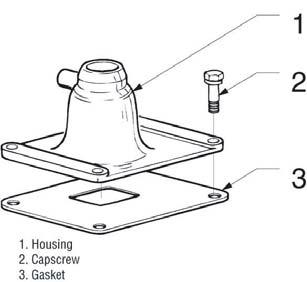

Procedure Check the threads of the fitting for thread sealant. If no sealant is present, apply Eaton®Fuller® thread sealant #71205 or equivalent.

2.

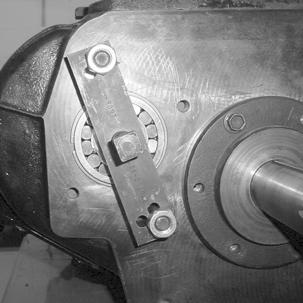

Install the fitting.

3.

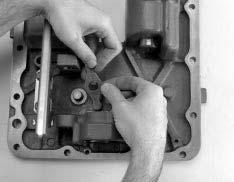

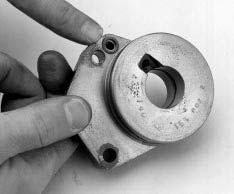

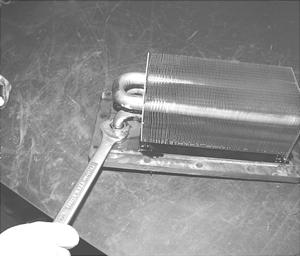

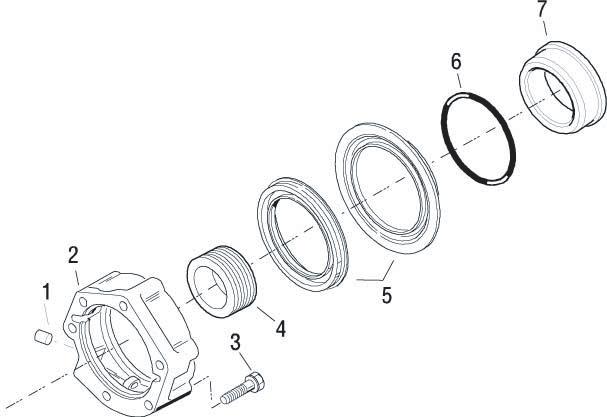

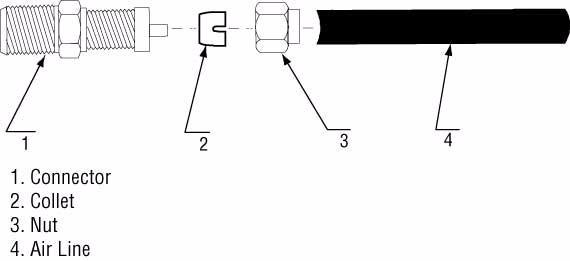

Inspect the air line for burrs or deformed areas. Trim the air line if necessary using a sharp razor blade or the air line cutting tool from kit K-2394. The cut must be smooth and square. If the tubing end is deformed or burred, the internal O-ring in the fitting will be damaged when the air line is inserted.

4.

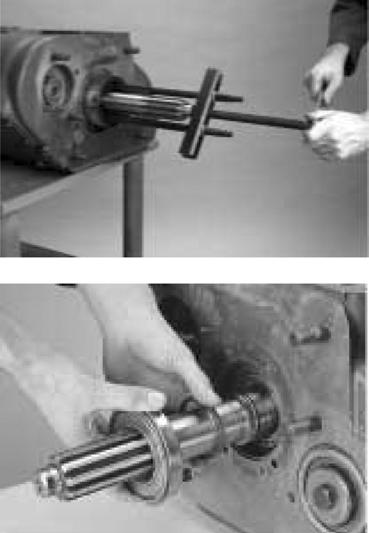

Push the air line into the fitting. It should insert approximately 3/4”. If it does not insert far enough or is difficult to insert, the fitting may be damaged and should be replaced. After inserting, give the air line a slight tug to make sure the line stays in place. If line does not stay in place, replace the fitting.

5.

Enable the vehicle air system. Allow the air tanks to pressurize, and check for leaks.

In-Vehicle Service Procedures

1.

3

69