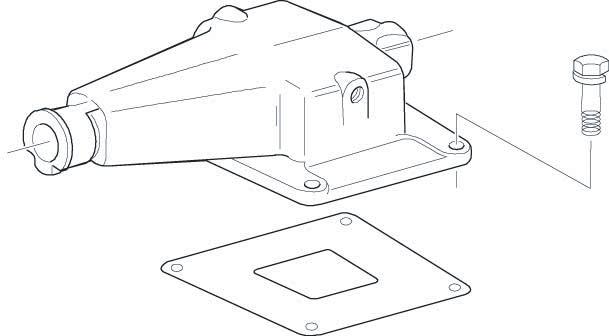

Transmission Overhaul Procedures-Bench Service Transmission Overhaul Procedures-Bench Service

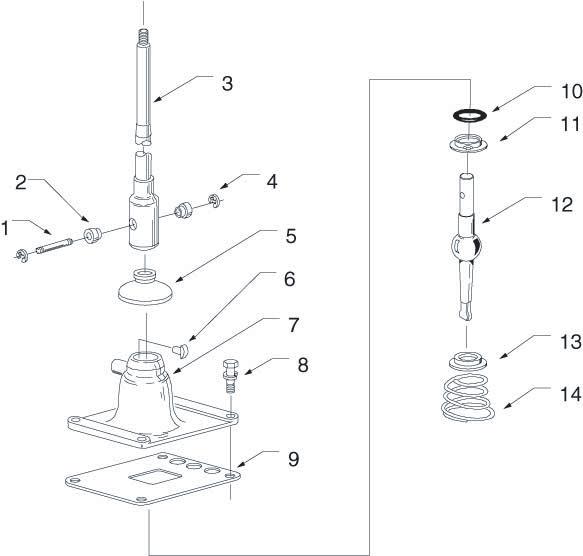

How to Assemble the Lower Reverse Idler Gear Assembly Special Instructions The new reverse idler shaft uses a snap ring in place of the capscrew.

Special Tools •

Torque Wrench 100 lb. ft. capacity

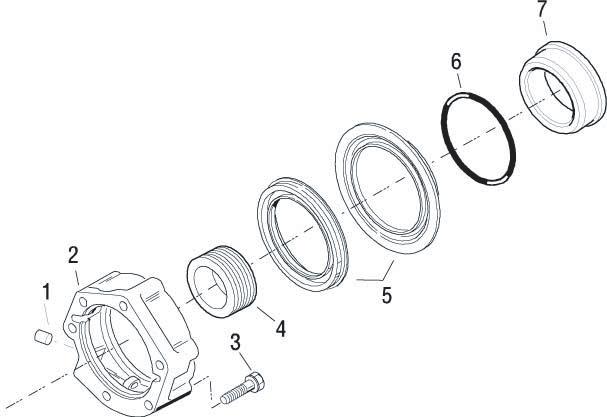

Previous Design

Current Design Snap Ring

Slotted Thrust Washer

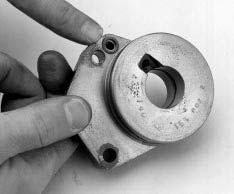

Inner Race

Snap Ring

Notched Thrust Washer Slotted Thrust Washer

Inner Race

Notched Thrust Washer

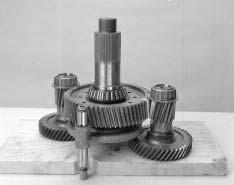

Reverse Idler Shaft Bearing

Reverse Idler Shaft

Reverse Idler Gear

Bearing

Washer

Reverse Idler Gear

Washer

Capscrew

Snap Ring

Procedure 1.

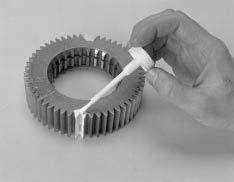

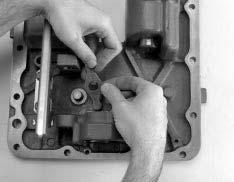

Position the reverse idler bearing and inner race into the reverse idler gear.

2.

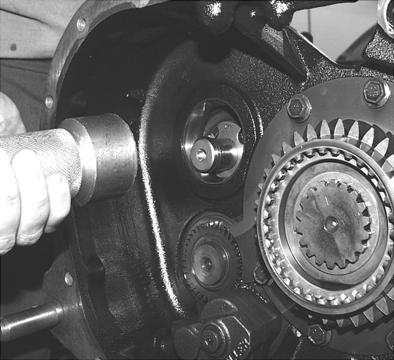

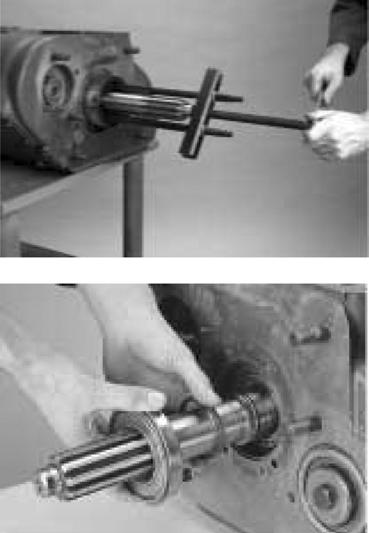

Hold the reverse idler gear and flat thrust washer in place in the main case, and insert the idler shaft, threaded end to the front, through the rear case bore and into the gear. Do not insert the reverse idler shaft into the main case support boss yet.

3.

Position the slotted thrust washer in front of the gear with a slot facing up. Note the word FRONT on the slotted washer, and make sure it faces the front of the transmission. Continue to feed the idler shaft forward through this washer and into the hole in the case boss.

4.

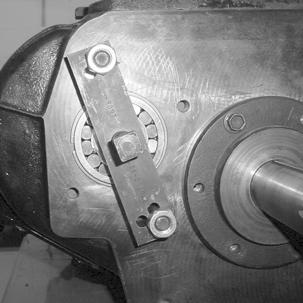

Slide the reverse idler shaft into the support boss bore, and with a soft bar and driver, drive the reverse idler shaft fully into position.

5.

Secure the shaft in position according to one of the procedures below:

5

165