Preventive Maintenance Inspection Table 1:

What to Check For

Action to be Done

Speedometer nections

Con-

Speedometer cables should not be loose. Should be an O-Ring or gasket between the mating speedometer sleeve and the rear bearing cover.

Applied hydraulic thread sealant #71208 to threads. Torque speedometer sleeve to 35-50 Lbf-ft. Replace the O-ring/gasket if damaged or missing.

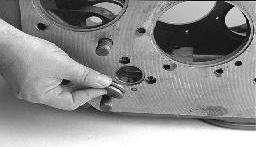

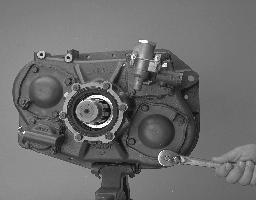

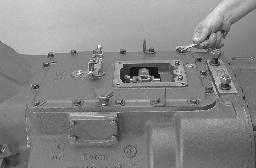

Rear Bearing Cover capscrews, Gasket, and Nylon Collar

Check retaining capscrews for tightness. Verify nylon collar and gasket are installed at the chamfered hole, aligned near the mechanical speedometer opening. Verify that a rear bearing cover gasket is in place.

Apply Eaton Sealant #71205 to the capscrew threads. Torque capscrews to 35-45 Lbf-ft.Use new parts if need to replace. Apply Eaton Sealant #71205 to the capscrew threads. Torque capscrews to 35-45 Lbf-ft. Install a new gasket if rear bearing cover was removed.

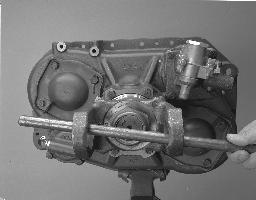

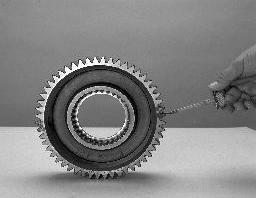

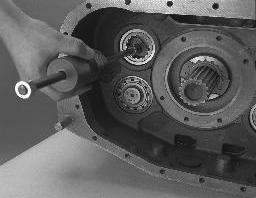

Output Yoke Retaining Nut

Check the output yoke retaining nut for tightness.

Torque the output yoke retaining nut to 450-500 Lbf-ft. Do not over torque nut.

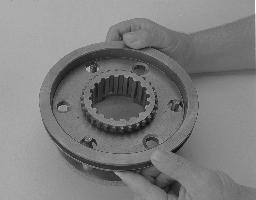

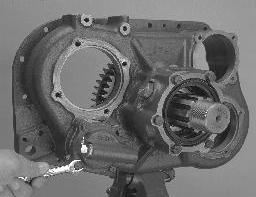

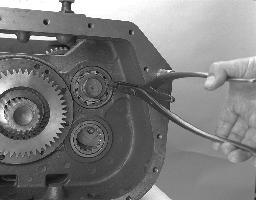

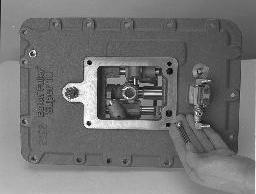

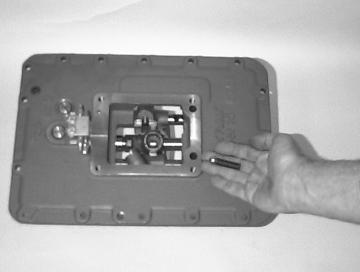

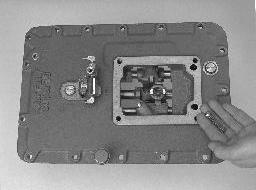

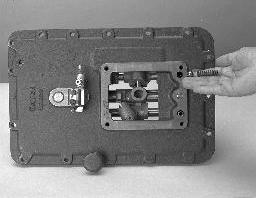

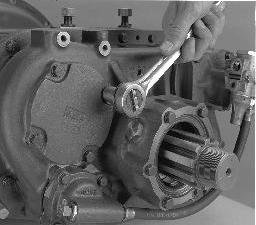

PTO Covers Openings

Check the capscrews for tightness.

Apply Eaton Sealant #71205 to the capscrew threads. Tighten 6 bolt PTO capscrews to 35-45 Lbf-ft. Tighten 8 bolt PTO capscrews to 50-65 Lbf-ft.

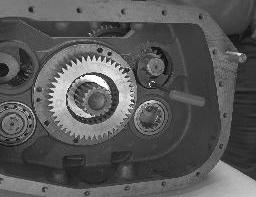

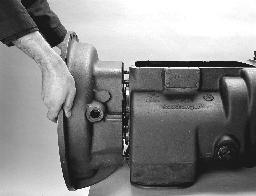

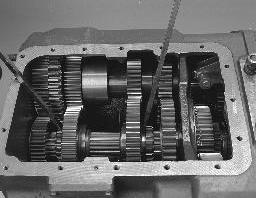

Grey Iron Parts

Check front bearing cover, front case, shift bar housing, rear bearing cover, and clutch housing for cracks or breaks.

Replace parts found to be damaged.

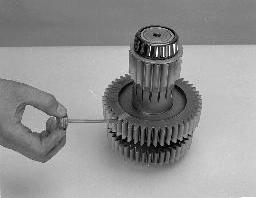

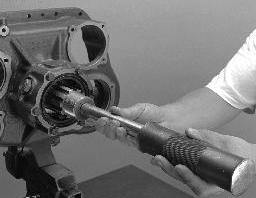

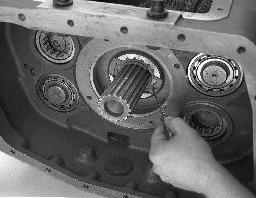

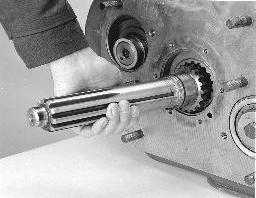

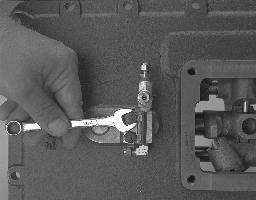

Front Bearing Cover

Check return threads for damage. Check the capscrews for tightness.

If threads damaged, replace the input shaft. Tighten the capscrews to 35-45 Lbf-ft.

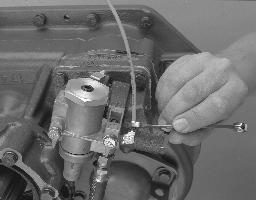

Oil Cooler and Oil Filter

Check all connections, fittings, hoses, and filter element for tightness.

Tighten any loose fittings.

Oil Drain Plug, Oil Fill Plug

Check the oil drain plug and the oil fill plug for leakage.

Torque the drain plug to 45-55 Lbf-ft. Torque the oil fill plug to 60-70 Lbf-ft.

and

20

Preventive Maintenance

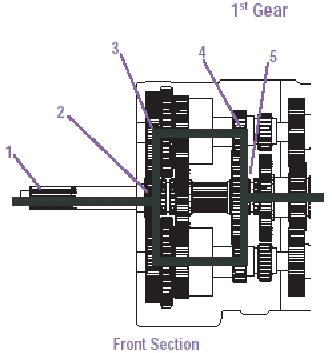

Part to inspect