2 minute read

How to Assemble the Standard Shift Bar Housing

Special Instructions

Inspect shift blocks and shift yokes for wear.

Apply Eaton sealant #71208 or equivalent to the shift bar housing plugs which are used to plug oil cooler provision holes. The sealant should be applied so that at least 5 complete threads are covered.

Apply Eaton lockwire #1819 or equivalent to all shift bar housing assembly set screws in both blocks and yokes. The wire should anchor the capscrew at least 2 complete 360° turns. The lockwire ends should be trimmed and bent out of the way of any part interference.

Keep yoke bars in neutral while assembling.

Special Tools

• Typical Service Tools

Procedure -

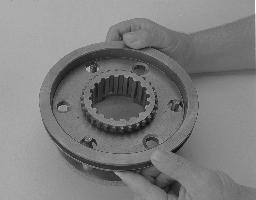

1. Assemble the 1st & reverse shift yoke assembly: a. Install the plunger in the 1st & reverse shift yoke bore, plunger shank to the outside. b. Install the spring into the bore over the plunger shank. c. Position the washer over the plunger shank. d. Install the snap ring.

2. Assemble the 3rd speed block assembly: a. Install the plunger in the 3rd shift block bore, plunger shank to the outside. b. Install the spring into the bore over the plunger shank. c. Install the plug and tighten to compress the spring. d. After plug bottoms out, back the plug out 1-11/2 turns. e. Complete the block assembly process by staking the plug through the small hole in block.

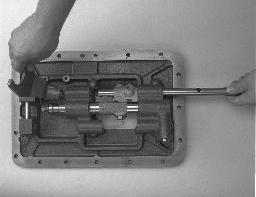

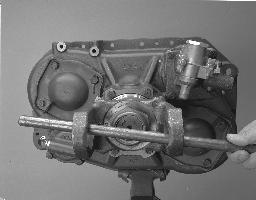

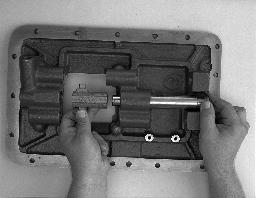

3. With the housing rear to the right, lay the assembly on a flat surface.

4. Install the select tube in the middle boss with key in the key slot.

5. As the select tube passes through the first boss, install the shift select block.

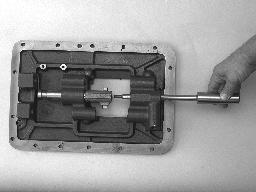

6. From the right, install the select interlock bar.

7. Install the range interlock bar, chamfered end in, notched side down.

8. At the middle yoke bar front end, install the washer, plain nut, and jam nut.

9. Install the interlock pin, centered between bosses.

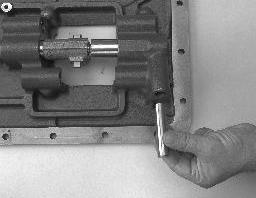

10.While installing the top yoke bar, position the shift yoke assembly and block assembly. The block assembly aligns with shift select block ear.

11.Install the lockscrews, tighten to 35-45 lb-ft of torque. Lockwire securely.

12.While installing the bottom yoke bar, position the shift yoke. The block assembly aligns with shift select block ear.

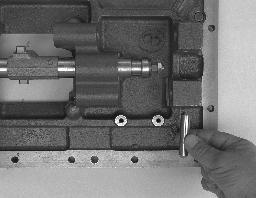

13.Install the lockscrew, tighten to 35-45 lb-ft of torque. Lockwire securely.

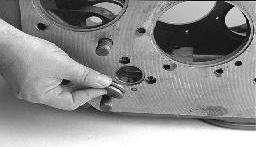

14.Turn the shift bar housing over, and install the anti-rotating pin and the two (2) sets of tension springs and balls.

Final Check

• Make sure interlocking system is working – can’t shift into 2 gears at the same time. • Make sure all capscrews are lockwired. • Make sure the anti-rotating pin and the two (2) sets of tension springs and balls are installed.