2 minute read

How to Assemble the Range Cylinder Assembly

Special Instructions

Apply Eaton lubricant #71214 or equivalent to all shift cylinder assembly and insert valve O-rings so a film covers the entire surface of each O-ring.

Apply Eaton rust preventative #71213 or equivalent to all shift cylinder walls and yoke bars, cover the entire yoke bar surface that comes in contact with the shift cylinder O-ring.

Apply Eaton lockwire #1619 or equivalent to the shift yoke capscrews. The lockwire should anchor each capscrew head securely to the yoke or to the second capscrew which fastens to the yoke bar. The lockwire should be twisted together, trimmed, and bent out of the way of other parts.

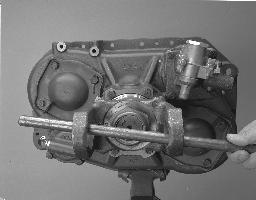

Special Tools

• Typical Service Tools

Procedure -

1. If previously removed, install the interlock pin in the cylinder housing. ("A" Series Only).

2. If previously removed, install the roll pin. ("A" Series Only).

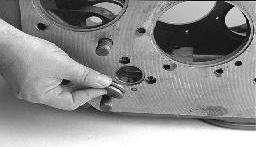

3. If previously removed, in the cylinder housing bore, install the small O-ring.

4. If previously removed, on the piston I.D. and O.D., install the piston O-rings.

5. Position a new gasket on the cylinder housing mounting surface.

6. From the rear, with the air passage away from the rear bearing cover, install the cylinder housing.

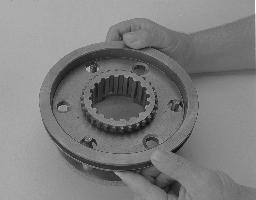

7. Place the range shift yoke, with the threaded yoke hub up and HI range synchronizer towards the front, in the sliding clutch slot.

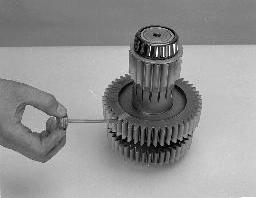

8. Place the range shift yoke and synchronizer assembly on the output shaft, engaging the sliding clutch splines.

9. With the yoke bar threaded-end, insert the yoke bar into the range cylinder housing bore, through the range shift yoke hub. Align the bar notches with range shift yoke lockscrew holes.

10.Install the two (2) yoke bar retaining capscrews, tighten to 50-65 lb-ft of torque.

11.From the rear, insert the piston. Push it in as far as it will go.

12.Secure the piston with the retaining nut, tighten to 70-85 lbft of torque.

13.If previously removed, install, in one of the cylinder cover bores, the insert valve, nipple in the proper direction.

14.If previously removed, install, over the insert valve, the insert valve retaining nut. Tighten the retaining nut to 40-50 lbft of torque. Repeat for other insert valve.

15.Position a new gasket on the cylinder housing cover mounting surface. The gasket air passage must align with the housing air passage.

16.Over the gasket, position the range cylinder cover.

17.Apply Eaton/Fuller sealant #71205 or equivalent to the retaining capscrews.

18.Install the capscrews, tighten to 20-25 lb-ft of torque.

Final Check

• Make sure all capscrews are tighten to their proper torque. • Make sure gaskets were used at the appropriate positions.