1 minute read

How to Assemble the Synchronizer Assembly

Special Instructions

Assembly should be done on a clean, flat surface slightly lower than your waist.

Pins on the Low range synchronizer must line up with the chamfered holes on the sliding clutch bottom.

When compress the HI range synchronizer springs cover with a shop rag. In the event compression is not achieved the first time, this prevents the springs from leaving the bench area.

Special Tools

• Shop rag

Procedure -

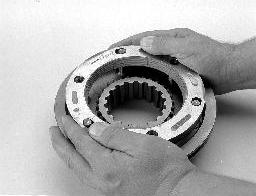

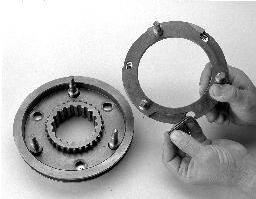

1. On the bench place the larger LO range synchronizer ring face down with pins up.

2. With the sliding clutch recessed side up, place the sliding clutch on the LO range synchronizer pins.

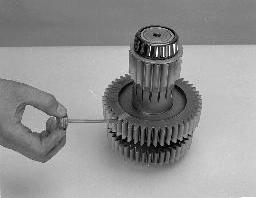

3. In the HI range synchronizer bores, install the three (3) springs.

4. Place the HI range synchronizer ring over the LO range synchronizer ring. Rotate the HI range synchronizer until the springs are seated against the pins.

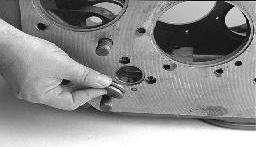

5. With the shop rag, cover the assembly.

6. Apply downward pressure to the HI range synchronizer ring while twisting counterclockwise. This compresses the springs to fully seat HI range on the LO range synchronizer.

Final Check

• Make sure there are three springs and are fully compressed. • Make sure you can move the sliding clutch from HI to

LO range and back.