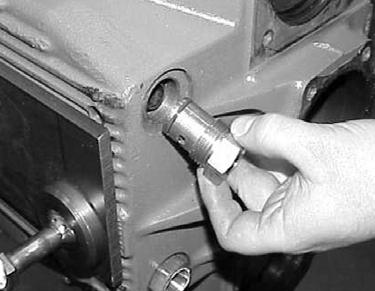

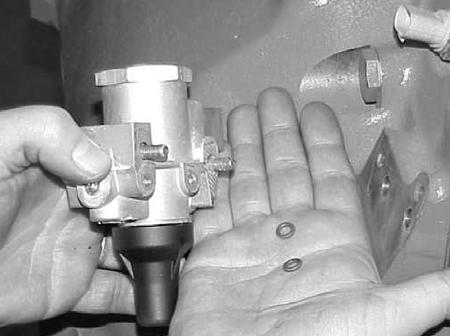

In-Vehicle Service Procedures Reverse Switch Operation and Testing Special Instructions The reverse switch is a normally open ball switch. When the transmission is shifted into reverse, a ramp on the reverse yoke bar contacts and raises a pin. The pin depresses the ball on the switch, which closes the switch contact, allowing current to flow through the switch and light up the vehicle's backup lights.

Special Tools Typical Service Tools

Procedure 1.

Disconnect the wiring from the switch.

2.

Connect an ohm meter to check for continuity.

3.

Place the transmission shift lever in any position except reverse. If the switch is working properly, the ohm meter should read open or infinity. If it is not, remove the switch and recheck it for continuity. Replace as necessary.

4.

In-Vehicle Service Procedures

•

1.

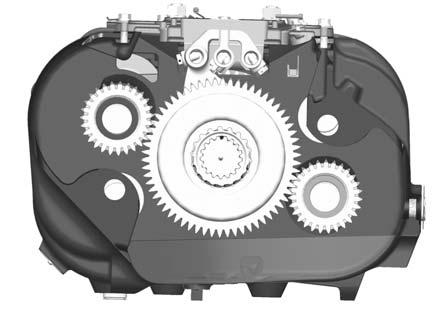

Reverse Position (Rev Switch Active)

2.

Shift Position Diagram

Place the transmission shift lever in the reverse position. If the switch is working properly, the ohm meter should register continuity, or a small reading. If it does not, remove the switch and recheck it for continuity. Replace as necessary. Also, check for sticking or excessive wear of the reverse pin.

1

R

3

1

5

7 4

2

8

9 6

10

2

44