1 minute read

Magnetic Speedometer

How to Remove the Oil Seal - Magnetic Speedometer

Special Instructions

Prior to replacing the seal, carefully inspect the transmission to make sure the oil leakage is coming from the seal. Pay particular attention to the speedometer parts, rear bearing cover gasket surfaces, rear countershaft bearing covers, and shift bar housing. For additional information on rear seal service, refer to the Seal Maintenance Guide TCSM-0912.

Special Tools

• Brass drift • Item T1: Output yoke puller • Item T15: Slide hammer

See Tool Information

Procedure -

1. Disconnect the driveshaft and U-joint from the output yoke according to the OEM or driveshaft manufacturer’s instructions.

2. Shift the transmission into 1st gear or low gear (Low Range) to prevent the output yoke from turning when loosening the output yoke nut.

3. Remove the output yoke nut using a 70 mm or 2 3/4" socket.

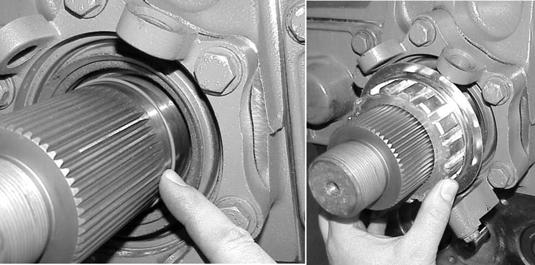

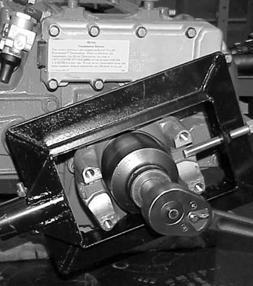

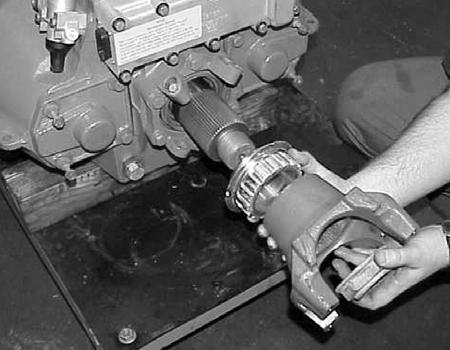

4. Use an output yoke puller to remove the output yoke (Tool ref. ID T1).

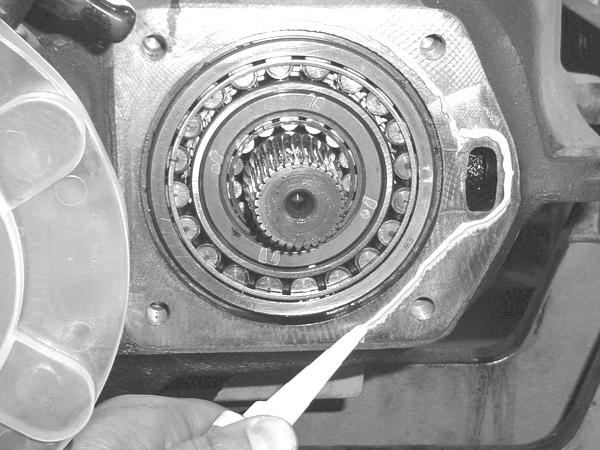

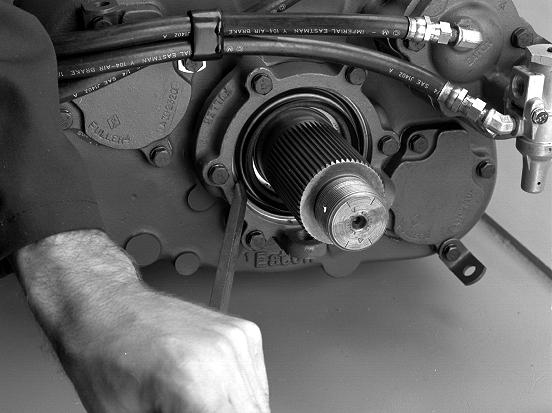

5. Remove the speedometer sensors from the rear bearing cover.

TIP: If the sensor is a thread in type, note the number of threads exposed so the sensor can be reinstalled to the same depth. If the sensor is a push in type, remove the hold down capscrew and pull the sensor out of the bore.

6. Remove the speedometer rotor/seal sleeve and the O-ring.

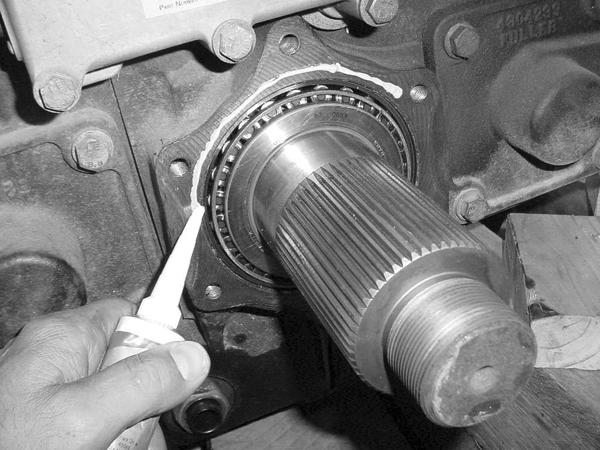

7. Pry the seal out using a large screwdriver or prybar in the metal groove of the seal.

NOTE: The seal will be damaged during removal and must be replaced.

8. Remove seal slinger from the speedometer rotor/seal sleeve using a brass drift and hammer.

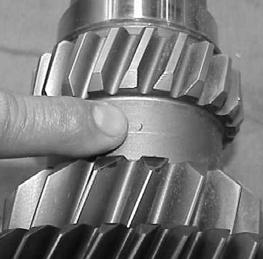

9. Inspect all parts of the oil seal for wear, scratches, burrs, or other damage.

NOTE: Replace the seal surface if it is worn or damaged. Do not attempt to salvage the seal mating surface with crocus cloth, filing, etc.