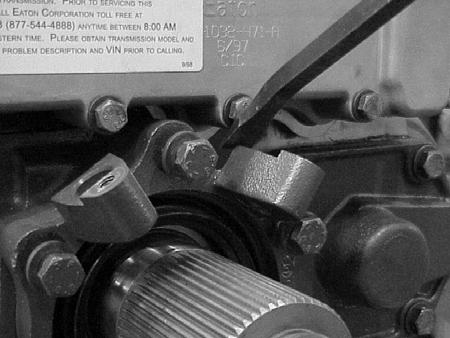

Tools Recommended Tools Some repair procedures pictured in this manual show the use of specialized tools. Their actual use is recommended as they make transmission repair easier, faster, and prevent costly damage to critical parts. But for the most part, ordinary mechanic’s tools such as socket wrenches, screwdrivers, etc., and other standard shop items such as a press, mauls and soft bars are all that is needed to successfully disassemble and assemble any Eaton Fuller Transmission.

Recommended Tools The following tables list and describe the typical tools required to properly service this model transmission above and beyond the necessary basic wrenches, sockets, screwdrivers, and prybars. Tools

General Tools The following tools are available from several tool manufacturers such as Snap-On, Mac, Craftsman, OTC, and many others. General Tools TOOL

PUPOSE

0 - 100 lb·ft 1/2" drive Torque Wrench.

General torquing of fasteners. (Typically 15-80 lb·ft.)

0 - 600 lb·ft 3/4" or 1" drive Torque Wrench.

Torquing of output nut to 500 lb·ft.

0 - 150 lb·in 3/8" drive Torque Wrench.

Torquing of pipe plugs 60-120 lb·in.

70 MM or 2 3/4" Socket - Standard Depth

To remove/install the output yoke nut

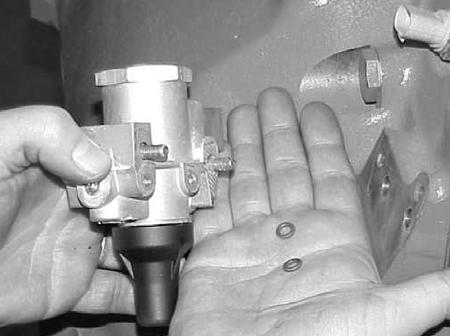

5/64” Allen Wrench Driver

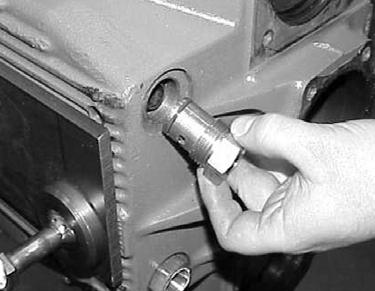

To remove/install eccentric pump set screw

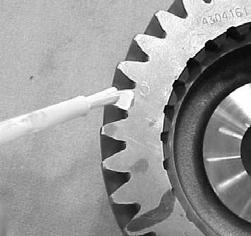

Snap Ring Pliers - small external

To remove/install snap ring at input shaft thrust washer

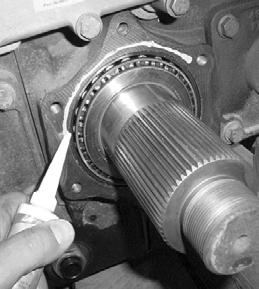

Snap Ring Pliers - medium external

To remove/install snap ring at rear of mainshaft

Snap Ring Pliers - small internal

To remove/install snap ring at range cylinder

Dial Indicator and Magnetic Base

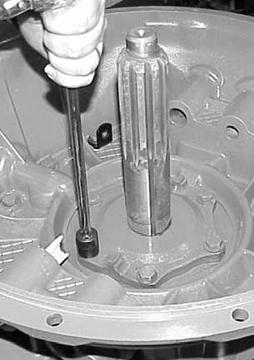

To check mainshaft endplay

(2) Rolling Head (Crow's Foot) Prybars

To remove the rear auxiliary countershaft bearings

Air Pressure Gauge 0 - 100 PSI (0-1034 kPa)

To troubleshoot and verify correct air system operation

14