Transmission Overhaul Procedures-Bench Service M/S Endplay Shimming Procedure Special Instructions None

Special Tools •

Dial Indicator

Procedure 1.

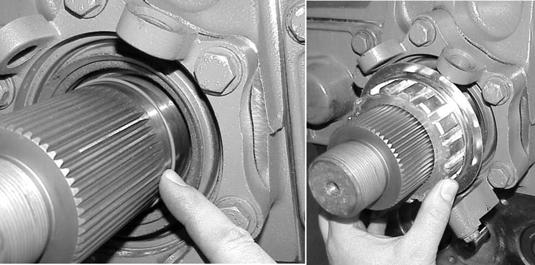

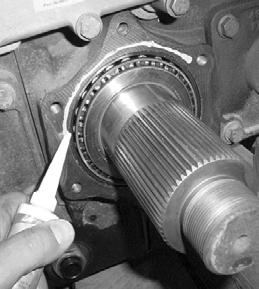

The output bearing must be fully seated on the auxiliary mainshaft before starting the shimming procedure. To insure this, install the speedometer rotor, output yoke, and nut. Torque the output nut to 450-500 lb-ft (610–677 Nm).

2.

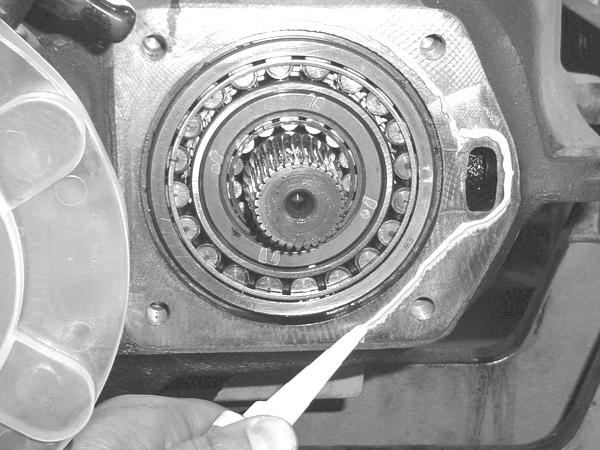

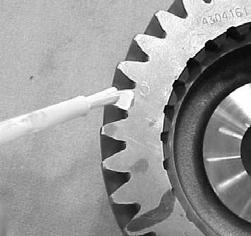

The input shaft bearing race must be fully seated in the front bearing cover to insure proper clearance. The use of an arbor press is recommended to insure the race is fully seated.

3.

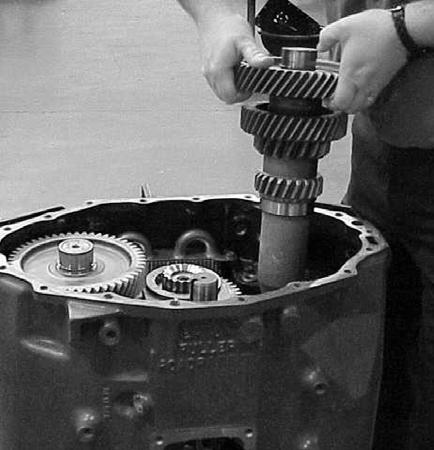

Transmission must be supported by the main case in a suitable stand that allows for the clutch housing to face upward and allow the output shaft to rotate freely.

4.

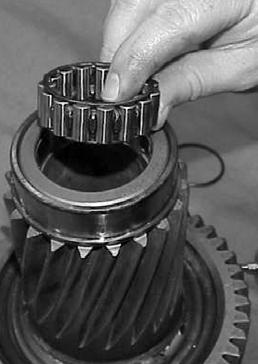

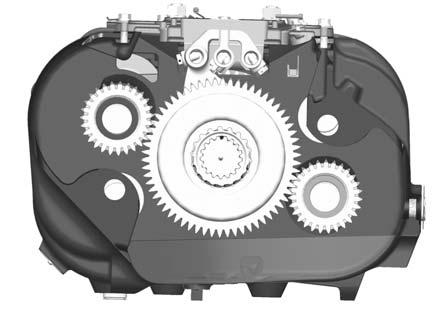

The transmission should be fully assembled minus the input shaft front bearing cover assembly and shift tower. Note: All bearings should be pre-lubed with transmission lube during assembly.

5.

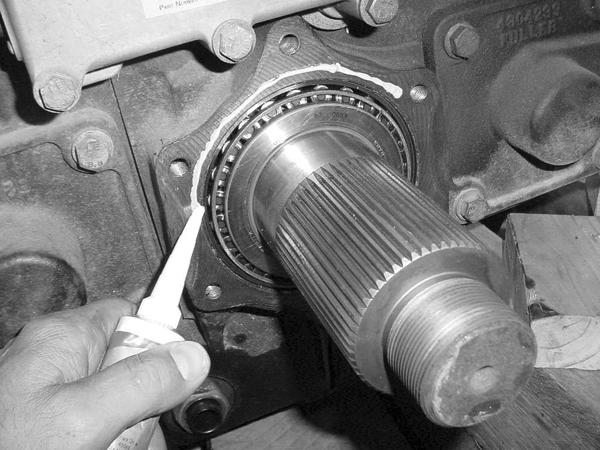

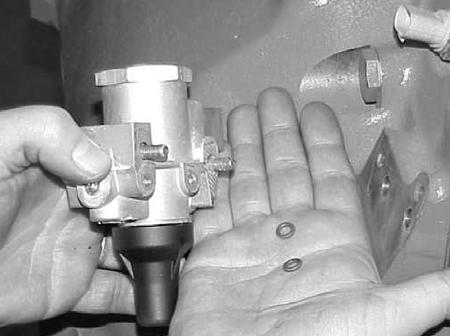

Start with (3) .020" shims (p/n 4304193) and use the threaded alignment pins if available.

6.

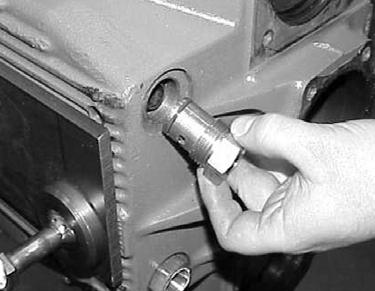

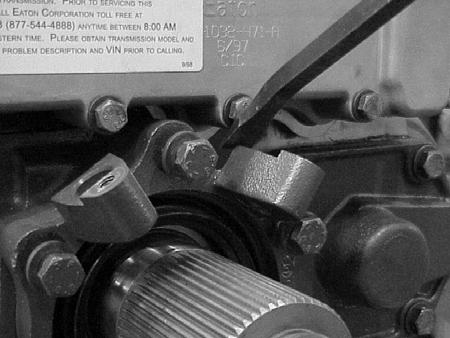

Install the front bearing cover assembly minus O-ring (5568540) to prevent damage to the O-ring. Note: Bearing cover capscrew holes will only line up one way.

7.

Install the (6) bearing cover capscrews and tighten to 47-52 lb-ft (63-70 Nm).

8.

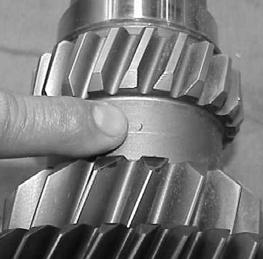

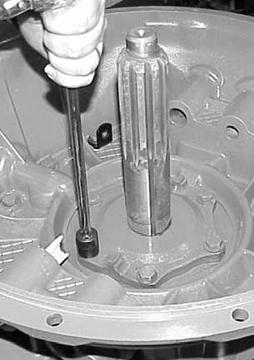

Rotate the input shaft to insure no binding has occurred during assembly, and to insure the bearings are seated.

137