MAINTENANCE/ADJUSTMENTS

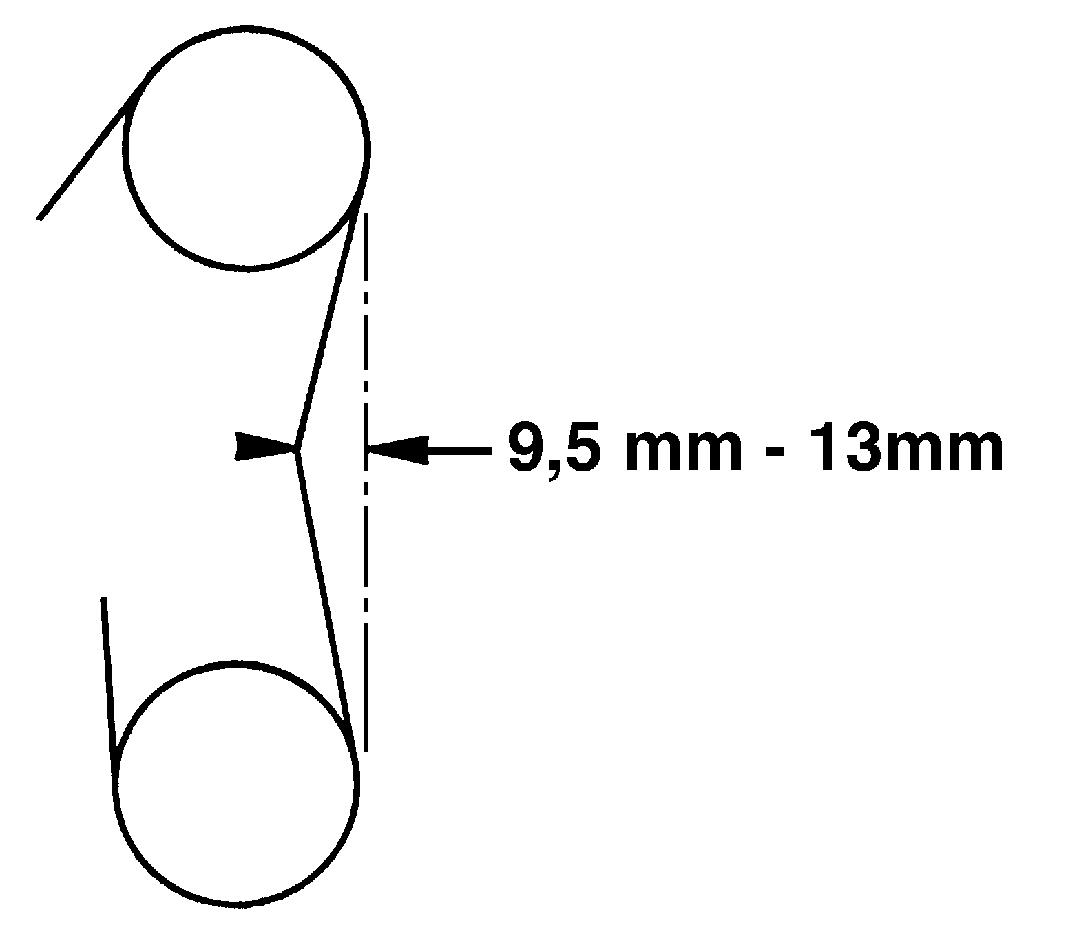

Recommended weekly checks Check the hook assembly for wear on the side which is in contact with the pin. Wear could increase the size of the pin aperture (maximum wear: 2 mm). If wear exceeds the maximum limit, consult your CASE Dealer. Check that the retaining pin is not damaged and is correctly in place. Replace it if necessary.

Quick Coupler malfunction IMPORTANT: Make sure that the attachment is resting on the ground before completing the following checks: In case of Quick Coupler malfunction, make sure that:

- The cylinder is not damaged or bent. - None of the hydraulic hoses is leaking, etc. If the problem persists after all these checks, consult your CASE Dealer.

!

WARNING: There is a risk of serious injury if maintenance or repairs are not carried out correctly. If you do not understand the maintenance procedures, consult your CASE Dealer.

TRIM THIS EDGE

- None of the pins is broken, bent or missing.

Alt= to hide template information Alt+ to display template information

QUICK COUPLER INSPECTION AND MAINTENANCE (optional)

IMPORTANT: When operating the Quick Coupler in particularly harsh conditions (in a dusty or corrosive atmosphere, for example), the service intervals should be reduced accordingly.

289

TRIM THIS EDGE RIGHT PAGE

Template Name: OM_1_col Template Date: 1994_04_29

Any modification to the Quick Coupler without prior authorization could cause serious injury. Do not make any modifications without authorization from your CASE Dealer.