3 minute read

SERVICE INTERVALS CHART

Template Date: 1994_04_29Template Name: OM_1_col

TRIM THIS EDGE

LOAD HANDLING

WARNING: When using this machine to lift a load make sure that the machine is suitably equipped for this type of work. For this type of work, the machine must be equipped with safety valves, an overload indicator, a load handling chart corresponding to the type of attachment installed on the machine, and a load fixing point.

WARNING: Always work on flat, level ground which is clear of obstacles.!

Stabilize the load a few centimeters above the ground to check that it is balanced before lifting it. Movements must be steady and smooth. You can move quickly without being rough. When travelling with a load, always follow these instructions:

-Align the upperstructure with the undercarriage (work position). IMPORTANT: In the work position, the wheels which control the steering are at the rear. Therefore, the travel and steering controls are inverted. -Bring the load as close as possible to the undercarriage and the ground. -Always travel at a slow speed, using the travel control lever and with the front axle unlocked.

In the event of hydraulic system failure

Stop the engine immediately. Operate the emergency pump and use the control lever(s) to control the downward movement of the attachment until the load is resting on the ground.

188

TRIM THIS EDGE LEFT PAGE

SERVICE INSTRUCTIONS

Respect the service intervals by checking the hourmeter every day. Before starting any service work, park the machine on flat, firm ground, which is clear of obstacles, with the dipper retracted and the tool on the ground. To simplify maintenance and to reduce down time, place the upperstructure at right angles to the undercarriage and then remove the access panels. Unless otherwise specified, all maintenance operations must be carried out with the engine stopped and the key removed from the starter switch. It is preferable to wait for all circuits to cool down before starting work. Clean the grease fittings before lubrication. Clean around the plugs and filling orifices before adding oil. Make sure that no dust or dirt gets into the components or the circuits.

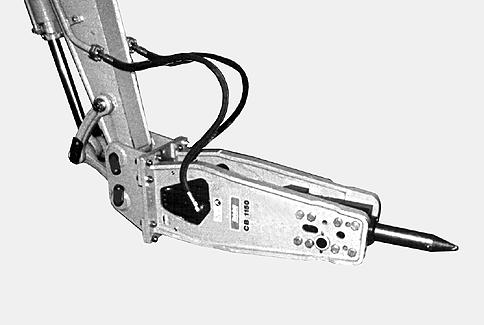

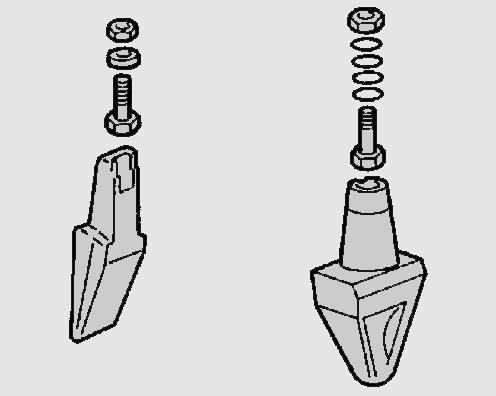

Check daily that the Quick Coupler or hydraulic breaker (if fitted) cylinder hoses are suitably positioned. NOTE: After greasing, put the colored plastic protective caps back on the grease fittings.

WARNING: There is a risk of serious injury if maintenance or repairs are not performed correctly. If you do not understand the maintenance procedures, consult your CASE Dealer.

WARNING: Leaving the attachment in the raised position or machine movements uncontrolled by an operator can result in serious injury. Before performing any maintenance work, the following steps must be carried out: 1. Park the machine on flat, level ground, then lower the stabilizers and the dozer blade (if fitted) until they are resting on the ground. 2. Lower the attachment until it is resting on the ground. 3. Stop the engine and remove the starter switch key. 4. Block the wheels to prevent any machine movement.

When servicing the machine, place a “Do Not Operate” tag on the instrument panel. Never leave the cab while the engine is running. Any modification to this machine without prior authorization from your CASE Dealer could cause serious injury. Do not make any modifications. IMPORTANT: If you use your machine in particularly harsh conditions (in a dusty or corrosive atmosphere, for example), the service intervals should be reduced accordingly. IMPORTANT: Respect the service intervals for all machine filters. Clean filters mean longer engine life.

189

TRIM THIS EDGE RIGHT PAGE TRIM THIS EDGE

Template Name: OM_1_colTemplate Date: 1994_04_29

Template Date: 1994_04_29Template Name: OM_1_col

TRIM THIS EDGE IMPORTANT: Do not pour used oil on the ground. Store the oil in sealed containers for collection by a company which will recycle or dispose of it.

HOURMETER

The hourmeter allows service operations to be scheduled. It works in the same way as a clock when the engine is running. Service intervals are carefully calculated to guarantee safe and efficient machine operation. Be sure to carry out all service operations properly, as defined in this manual.

CD99J021

190

TRIM THIS EDGE LEFT PAGE