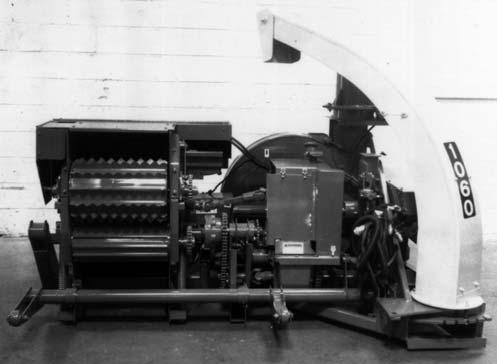

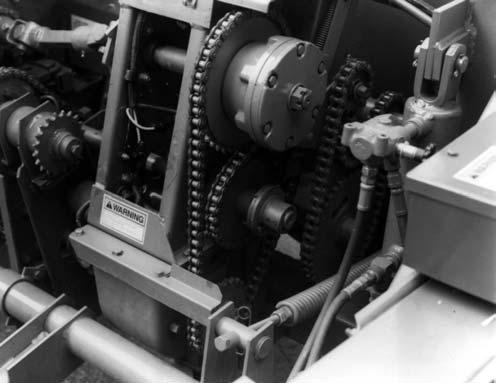

HARVESTER WITH SHEAR BOLT-PROTECTED FEED ROLL & ATTACHMENT DRIVES OPERATING FEED ROLLS & ATTACHMENT (Fig. 17) The Electric Clutch and Shifter Transmission combination is used to stop the Feed Rolls and the Attachment, to run them forward (to bring the crop into the Cutting Cylinder) or, to run the Feed Rolls backwards (to reverse plugged material back out of the Cutting Cylinder area). Shifting the Transmission is accomplished by appropriate activations and settings of Switches on the Control Box which is mounted on the tractor. To feed material into the Harvester, set the Feed Roll toggle Switch to the “Forward” position. The Transmission will continue operating in the “Forward” mode until the Feed Roll Toggle Switch is reset to the “Off” position.

exceeds 6″ (152 mm) or if an obstruction gets between the Feed Rolls, the Shear Bolt in Upper Feed Roll Drive will shear and thus stop Feed Roll operation and the crop will NOT feed into the Cutting Cylinder. If the Shear Bolt has failed, it is possible to reverse the plugging material out of the Feed Roll area by idling the tractor and shifting the Feed Roll Drive Transmission into reverse.

NOTE:

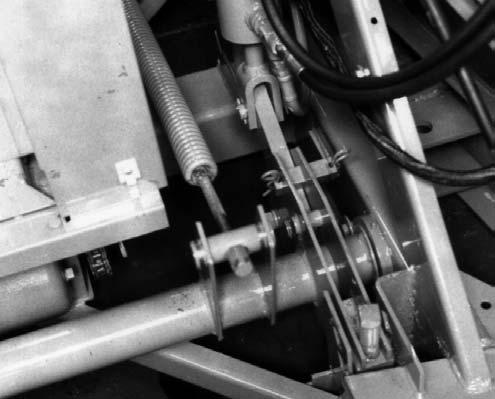

Upper Feed Roll Drive is protected by a One-way Shear Bolt Protective Device. This mechanism allows the Drive to be reversed before installing a new Shear Bolt. The Shear Bolt holes will self-align, when the Feed Rolls are reversed.

OVERLOAD PROTECTION (Fig. 16)

To stop the Feed Rolls and the Attachment, turn off the power to the system by placing the Feed Roll Toggle Switch to the “Off” position.

1

CAUTION BEFORE leaving the tractor, ALWAYS turn Control Box Power Keyswitch OFF and remove the Key and take it with you for your own safety and to avoid unnecessary drain on your tractor battery.

To back material out of the Feed Rolls and Attachment, set the Feed Roll Control Toggle Switch to the “Reverse” position and hold it there momentarily while observing the crop as it reverses-out of the Feed Rolls and Attachment; this process should only take 3 to 4 seconds. If the “Reverse” position is held continuously for more than 12 seconds, the Circuit Breaker will trip-out to protect the Shifting Solenoid. To reset the Breaker, wait at least 10 seconds and then, depress the Button to reset the Breaker.

UNPLUGGING THE FEED ROLLS By design, the Feed Rolls allow various mat thicknesses to pass between them. If however, the mat thickness

26

3 2

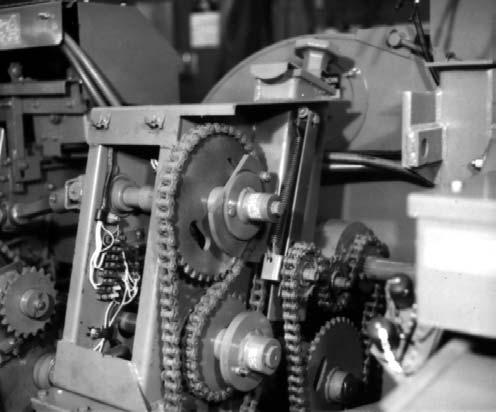

1 – Upper Roller Drive One-way Shear Bolt Protective Device 2 – 1/4 x 1-1/2 Grade 8 Shear Bolt & Hexagon Lock Nut 3 – Lower Roller Drive Shear Flange

Fig. 16

The Upper Feed Roll Drive is protected by a One-way Shear Bolt Protective Device. The Protective Device allows the Feed Rolls to be reversed without having to first replace the sheared Bolt. The Shear Device uses a 1/4 x 1-1/2 Grade 8 Shear Bolt. To install a replacement Bolt, BE SURE to first idle the tractor and then reverse the Feed Roll Transmission to align the mounting holes in the Protective Device. Additional Shear Bolts are provided in the Toolbox.