4 minute read

CHAPTER 8 LUBRICATION

General Information Caution

NEVER attempt to lubricate this unit when any part of the machine is in motion. ALWAYS BE SURE to exercise the MANDATORY SAFETY SHUTDOWN PROCEDURE (page 8) BEFORE proceeding to lubricate this equipment.

It is important to apply sufficient oil and grease to prevent excessive part wear and early failure.

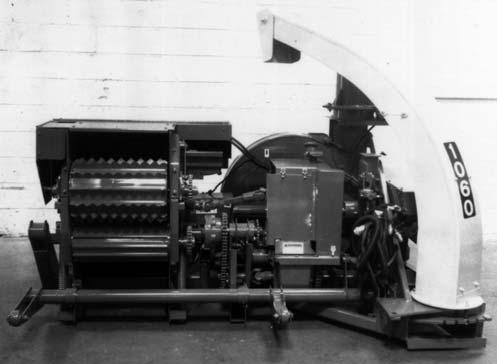

TRANSMISSION LUBRICATION (Figs. 50 & 51)

The lubricant level in both the Bevel Gearbox and Shifter Transmission should be checked after every 200 hours of operation and replenished, when necessary.

The Bevel Gearbox requires 7 U.S. Pints (3.3 liters) of SAE #140 EP Gear Lube. The Shifter Transmission has two oil reservoirs. The front reservoir requires 7 U.S. Pints (3.3 liters) of SAE 10W40 motor oil and is filled through the Breather Plug hole in the front of the Reverse Delay Switch, as shown.

NOTE: Do NOT remove the Reverse Delay Switch; this Switch MUST be precisely set for proper operation of the ’’reverse engagement’’ cycle.

The rear Reservoir requires 1 U.S. Pint (0.5 liter) of SAE 10W40 motor oil and is filled by removing the Plate on which the rear Reservoir Breather is mounted.

Both the Bevel Gearbox and the Shifter Transmission should be checked occasionally for oil drips and dust accumulation around the Seals. Oil drips or dust accumulation indicates that the Seals are leaking. Oil which is tan in color and foams excessively indicates that it has water present. Unless rust spots appear inside the Housings, the fluid does NOT require replacement.

NOTE: Do NOT overfill either assembly; only fill them to the bottom of their Level Plug holes.

Spinner Gearbox

The Spinner Gearbox requires 1 U.S. Quart (1 liter) of lithium-base grease. The Gearbox is packed at the factory and requires NO further attention unless service is performed on the Gearbox requiring removal and replacement of the grease.

NOTE: 1 U.S. Quart (1 liter) of lithium-base grease will fill about 1/2 of the Gearbox volume. Overfilling the Gearbox will cause grease to be forced out around the Shafts and Bearings.

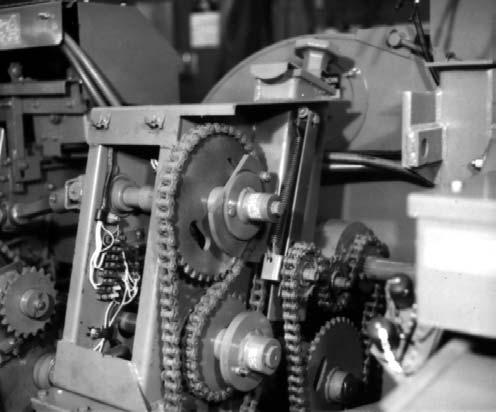

Drive Chains

Lubricate all Drive Chains every 6 to 8 hours of operation using a good grade of foaming aerosol lubricant such as NAPA Chain and Cable Lubricant. This type of lubricant increases the life of the Chain 3 to 4 times over those lubricated at 8 hour intervals with new or used motor oil. The recommended method is to spray the entire length of Chain on the center of the Rollers. It is more effective to oil Chains after use, while they are still warm.

NOTE: To minimize wear on the Sprockets, the Chains should be replaced after they become worn 3% longer than their original length or otherwise when the Tightener (where provided) has reached the end of its adjustment.

Ammonia Silage Additive

NOTE: Gehl Company does NOT recommend running ammonia silage additives through any part of the Harvester because of their damaging effects on Bearings.

If an ammonia silage additive must be added to the silage in the field, certain precautions MUST be taken. It should only be introduced at the Blower in the top portion of the Blower Outlet, in order to keep the ammonia away from the Bearings. The ammonia will cause the oil-carrying substance of the grease to dissolve in the Bearings causing them to fail. Special grease MUST be used which can withstand the ammonia vapor effects. Two greases which stand-up fairly well in the presence of ammonia are Aero Shell #7 (by Shell Oil Co.) and Chevron SRI (by Chevron Oil Co.). But, even these two greases will have to be replenished twice a day in those Bearings which are exposed to ammonia vapor.

Oiling

Apply motor oil on all of the points listed at the intervals specified.

Lubricate Every 10 Hours (or Daily)

The Rotating Telescoping PTO Drive Guard

Lubricate Every 50 Hours

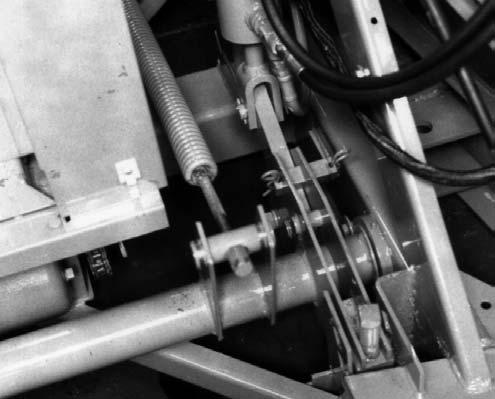

Torque Sensor Contact Pivot Points (Torque Sensorequipped models ONLY)

Blower Belt Idler Pivot Points

Rear Feed Roll Guides (both sides)

Knife Sharpener Guide Bearings (10 places)

Lubricate Every 100 Hours (or Annually)

Drawbar Pivot Pin

All Hinged-Cover Hinges

Feed Roll Spring Strap Pivots (both sides)

Feed Roll Stabilizer Pivots (both sides)

Spout Control Worm Bearings

Hydraulic Circuits

The Harvester can be equipped with one or two hydraulically-powered control systems; the standard Attachment Lift Cylinder/Knife Sharpener system and an optional Tongue Control system. BE SURE to check and maintain the tractor hydraulic fluid level in accordance with the total circuit requirements of your particular Harvester. Only the Knife Sharpener Hydraulic system is primed at the factory.

Greasing

NOTE: Grease all fittings on a prescribed basis, at the intervals of operation listed, before and after storing the unit, and as otherwise listed. Use a good grade of lithium-base grease.

Wipe dirt from the fittings before greasing to prevent dirt from being forced into the Bearing or pivot. Replace any missing fittings when noticed. Force grease into the fitting until it comes out at the Bearing Seal or the Shaft. To minimize dirt build-up, avoid excessive greasing.

NOTE: In addition to the fittings, repack the Wheel Bearings at least once a year. Apply a coat of grease, at least twice each season, to Front Feed Roll Guides (both sides) and the Spout Worm and Gear. Periodically, lubricate the Telescoping Drive Shaft and Tube.

Grease Fitting Locations

Grease Every 10 Hours (or Daily)

1.Telescoping Drive (2 places for 1-3/8 Drive or 3 places for 1-3/4 Drive)

2.Main Drive Cross

3.Right Feed Roll Stabilizer Bar Bearing

4.Left Feed Roll Stabilizer Bar Bearing

5.Right Feed Roll Guide Bearing

6.Left Feed Roll Guide Bearing

7.Upper Feed Roll Drive (3 places)

8.Lift Tube Cast Bearing

9.Cylinder Drive Crosses (2 places)

10.Right Lift Tube Sleeve Bearing

11.Left Lift Tube Sleeve Bearing

12.Overrunning Clutch (2 places)

13.Electric Clutch Hub

14.Attachment Drive Cross

Grease Every 50 Hours

15.Blower Outlet Flange* (2 places)

16.Remote Rear Blower Bearing

17.Spinner Drive Bearing

18.Right Cylinder Bearing Housing

* To distribute the grease over the entire Flange area, first grease both fittings at one position. Then, rotate the Deflector 90° and grease both fittings again. Then, rotate the Spout back-and-forth a couple of times to spread the grease.

19.Right Lower Rear Feed Roll Bearing

20.Right Lower Front Feed Roll Bearing

21.Right Upper Front Feed Roll Bearing

22.Right Upper Rear Feed Roll Bearing

23.Remote Left Lower Front Feed Roll Bearing

24.Remote Left Lower Rear Feed Roll Bearing

25.Left Cylinder Bearing Housing

26.Remote Left Upper Front Feed Roll Bearing

27.Remote Left Upper Rear Feed Roll Bearing

28.Front Blower Bearing

29.Feed Roll Input Chain Idler Arm Pivot

Grease Every 100 Hours (or Annually)

30.Knife Sharpener Torque Arm

31.Knife Sharpener Motor Adjustment Screw

32.Left Quick-switch Attachment Drive Hub

Grease Each Time a Bolt is Sheared or At Lease Once a Year

33.Feed Roll Shear Flange (Shear Bolt-equipped models ONLY)

Grease Each Time an Attachment is Changed or At Lease Once a Year

34.Left Lift Roller

35.Right Lift Roller