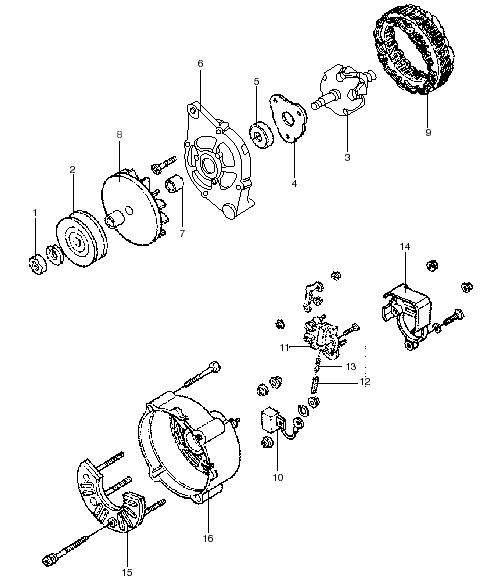

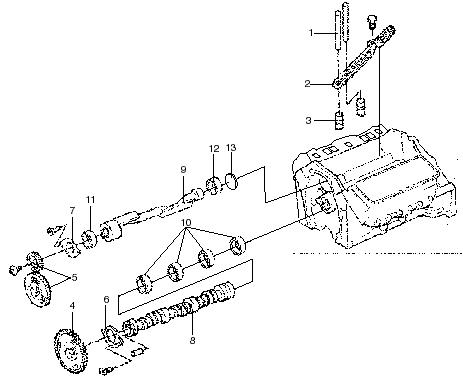

Crankshaft, Flywheel, Rear Seal, and Bearings

Service Prior to Assembly Dirt will cause premature wear of the rebuilt engine. During assembly, lubricate all moving parts lightly with engine oil or engine assembly lubricant (unless otherwise specified.) This will provide initial lubrication when the engine is started.

10. Use a dial indicator or feeler gauge to measure end play between the front of the rear of the crankshaft bearing cap and the crankshaft thrust surface. If a feeler gauge is used, measure between the thrust surface of the crankshaft bearing and the crankshaft. Refer to General Specifications for clearance

Crankshaft, Bearings and Bearing Cap Installation

a

1. Install the crankshaft bearing into the engine block and the crankshaft bearing caps. 2. Coat the crankshaft bearings with clean engine oil. 3. Install the crankshaft. 4. Install the crankshaft bearing caps with crankshaft bearings. 5. Be sure the cap directional arrows point toward the front of the engine block and the cap is in its original position. 6. Install the crankshaft bearing cap bolts and studs. 7. Thrust the crankshaft rearward to set and align the thrust bearings and the bearing caps. 8. Thrust the crankshaft forward to align the rear faces of the rear crankshaft bearing. 9. Tighten the crankshaft bearing cap bolts

b

c

d

N O T E

Tightening torque 1st pass for crankshaft bearing 2.08 Kgf•m (15 lbf•ft) [20 N•m] cap bolts 2nd pass 10.66 Kgf•m (77 lbf•ft) [105 N•m]

Firmly thrust the crankshaft first rearward, then forward. This will align the crankshaft rear bearings and the crankshaft thrust surfaces. With the crankshaft pushed forward, insert a feeler gauge between the crankshaft and the crankshaft bearing surface and then measure the clearance. Refer to Engine Mechanical Specifications. If the correct end play cannot be obtained, verify that the correct size crankshaft bearing has been installed. Refer to Engine Mechanical specifications. Inspect the crankshaft for binding. Turn the crankshaft to check for binding. If the crankshaft does not turn freely, then loosen the crankshaft bearing cap bolts, one crankshaft bearing cap at a time, until the tight crankshaft bearing is located. Burrs on the the crankshaft bearing cap, foreign matter between the crankshaft bearing and the engine block or the crankshaft bearing cap, or a faulty crankshaft bearing could cause a lack of clearance at the crankshaft bearing.

Bearing Clearance Measuring Procedures The crankshaft bearings are of the precision insert type and do not use shims for adjustment. If the clearances are excessive, then new upper and lower crankshaft bearings are available in the standard size and an undersize. The selective fitting of the crankshaft bearings are necessary in production in order to obtain close tolerances. For this reason, in one journal bore you may use one-ha;f of a standard crankshaft bearing with one-half of a undersize crankshaft bearing. In order to determine the correct replacement crankshaft bearing size, the crankshaft bearing clearance must be measured accurately. Either the micrometer or plastic gauge method may be used; however, the micrometer method gives more reliable results and is preferred.

Important: In order to properly measure the crankshaft end play, the crankshaft, the crankshaft bearings, the crankshaft bearing caps,. and the crankshaft bearing cap bolts must be installed into the engine block and the bolts tightened to specifications.

-73-