8 minute read

Piston and Connecting Rod

Service Prior to Assembly

Dirt will cause premature wear of the rebuilt engine. During assembly, lubricate all moving parts lightly with engine oil or engine assembly lubricant (unless otherwise specified.) This will provide initial lubrication when the engine is started.

Crankshaft, Bearings and Bearing Cap Installation

1. Install the crankshaft bearing into the engine block and the crankshaft bearing caps. 2. Coat the crankshaft bearings with clean engine oil. 3. Install the crankshaft. 4. Install the crankshaft bearing caps with crankshaft bearings. 5. Be sure the cap directional arrows point toward the front of the engine block and the cap is in its original position. 6. Install the crankshaft bearing cap bolts and studs. 7. Thrust the crankshaft rearward to set and align the thrust bearings and the bearing caps. 8. Thrust the crankshaft forward to align the rear faces of the rear crankshaft bearing. 9. Tighten the crankshaft bearing cap bolts

Tightening torque 1st pass for crankshaft bearing 2.08 Kgf•m (15 lbf•ft) [20 N•m] cap bolts 2nd pass 10.66 Kgf•m (77 lbf•ft) [105 N•m]

10.Use a dial indicator or feeler gauge to measure end play between the front of the rear of the crankshaft bearing cap and the crankshaft thrust surface. If a feeler gauge is used, measure between the thrust surface of the crankshaft bearing and the crankshaft. Refer to General Specifications for clearance a Firmly thrust the crankshaft first rearward, then forward.This will align the crankshaft rear bearings and the crankshaft thrust surfaces. b With the crankshaft pushed forward, insert a feeler gauge between the crankshaft and the crankshaft bearing surface and then measure the clearance. Refer to Engine Mechanical Specifications. c If the correct end play cannot be obtained, verify that the correct size crankshaft bearing has been installed. Refer to Engine Mechanical specifications. d Inspect the crankshaft for binding. Turn the crankshaft to check for binding.If the crankshaft does not turn freely, then loosen the crankshaft bearing cap bolts, one crankshaft bearing cap at a time, until the tight crankshaft bearing is located. NO TE Burrs on the the crankshaft bearing cap, foreign matter between the crankshaft bearing and the engine block or the crankshaft bearing cap, or a faulty crankshaft bearing could cause a lack of clearance at the crankshaft bearing.

Important:In order to properly measure the crankshaft end play, the crankshaft, the crankshaft bearings, the crankshaft bearing caps,.and the crankshaft bearing cap bolts must be installed into the engine block and the bolts tightened to specifications.

Bearing Clearance Measuring Procedures

The crankshaft bearings are of the precision insert type and do not use shims for adjustment.If the clearances are excessive, then new upper and lower crankshaft bearings are available in the standard size and an undersize. The selective fitting of the crankshaft bearings are necessary in production in order to obtain close tolerances.For this reason, in one journal bore you may use one-ha;f of a standard crankshaft bearing with one-half of a undersize crankshaft bearing. In order to determine the correct replacement crankshaft bearing size, the crankshaft bearing clearance must be measured accurately.Either the micrometer or plastic gauge method may be used; however, the micrometer method gives more reliable results and is preferred.

-73-

Micrometer Method for Crankshaft

Bearings

1. Measure the crankshaft journal diameter with a micrometer in several places, approximately 90 degrees apart, and then average the measurements. 2. Determine the taper and the out-of-round of the crankshaft journal.Refer to Engine Mechanical

Specifications

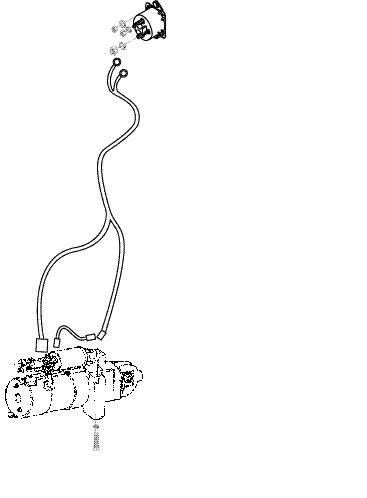

Crankshaft Rear Oil Seal and Housing Installation Tools Required • MCF-1073 (J 35621) Crankshaft Rear Oil Seal Installer Important: Always use a new crankshaft rear oil seal NO TE and new crankshaft rear oil seal housing gasket when you install the crankshaft rear oil seal housing.

1. Install the new gasket and the crankshaft rear oil housing on to the studs.

MCF-1073 (J 35621-B)

Tightening torque for rear oil seal housing1.52 Kgf•m (11 lbf•ft) [15 N•m] nuts and bolts

2. Install the rear oil seal housing nuts and bolts. a.Tighten the crankshaft rear oil seal housing.

3. Coat the new oil seal entirely with clean engine oil. 4. Install the seal onto the MCF-1073 (J 35621). 5. Install the MCF-1073 (J 35621) onto the rear of the crankshaft.Tighten the screws snugly to ensure the seal is installed squarely over the crankshaft. 6. Install the crankshaft rear oil seal to the crankshaft and the crankshaft rear oil seal housing.Tighten the wing nut on the MCF-1073 (J 35621) until the oil seal bottoms. 7. Remove the MCF-1073 (J 35621) from the crankshaft rear oil seal housing.

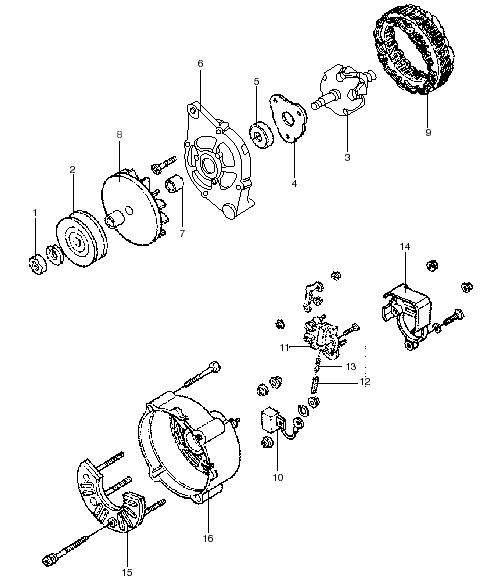

Engine Flywheel Installation

1. Install the engine flywheel to crankshaft. 2. Align the locator hole to the pin. 3. Install the engine flywheel bolts.

Tightening torque for engine flywheel 10.25 Kgf•m (74 lbf•ft) [100 N•m] bolts

4. Install the transmission.

-74-

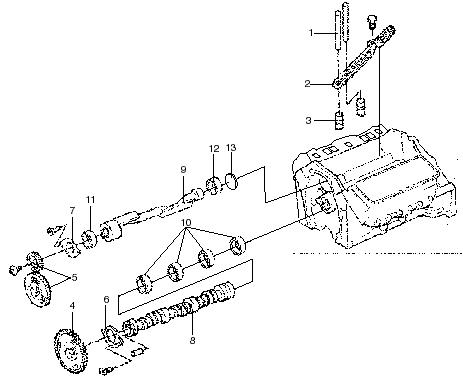

Cylinder Block

Cleaning and Inspection

T= 4.3-6.0 kgf•m (31.1-43.4 lbf•ft) [42-59 N•m]

Disassembly steps

1.Engine support (R.H.) 2.Engine support (L.H.) 3.Cylinder block

-75-

T=4.3-6.0 kgf•m (31.1-43.4 lbf•ft) [42-59 N•m]

7EN0035

Cylinder Block Cleaning

1. Remove the front oil gallery plugs.

2. Remove the rear oil gallery plugs. 3. Disconnect the pump oil pressure switch and fitting. 4. Clean the following areas: • The engine block in solvent • The gasket surfaces • The coolant passages • The oil passages 5. Check and inspect the cylinder walls for scratches and signs of seizure.If necessary, rebore the cylinders to oversize or replace the cylinder block. 6. Measure cylinder bores following areas: • Diameter • Out-of-round • Taper • Excessive ring ridge 7. If excessive wear is found, rebore the cylinders to oversize and replace the pistons and piston rings.

Checking should be made at the positions shown in the figure.

-76-

Cylinder Block Inspection

1. All expansion plugs for lack of fit or leakage. 2. Valve lifter bores for deep scratches and deposits. 3. Cracks in the block. • Cylinder walls • Coolant jackets • Engine mount bosses • Main bearing webs 4. Main bearing bores and caps. • All main bearing bores should be rounded and uniform in ID at all of the bearing supports. • The area where the main bearing inserts contact the main bearing bore should be smooth. • If a main bearing cap is found to be damaged, replace the cap and line-bore the block. 5. Cylinder head mounting surface for flatness, using a precision straight edge and feeler gage. a.Set the straight edge on the sealing surface to be inspected. b.Take the feeler gage at various locations, check the gap between the straight edge and the sealing surface. c.If the gap is greater than 0.05 mm (0.002 in.) within 152 mm (6 in.) at any sealing location, the block must be replaced. d.If the gap is found to be less than 0.05 mm (0.002 in.) at any sealing location and a cause for leakage is suspected, then the minor irregularities may be carefully machined from the block. 6. Oil pan, timing cover, and intake manifold mounting surfaces for nicks.Minor irregularites may be cleaned up with a flat file.

Standard value:0.05 mm (0.002 in.) Limit:0.1 mm (0.004 in.) Grinding limit value:0.2 mm (0.008 in.)

Cylinder BlockC AU TIO N!

Caution:Do not grind the mating surfaces of the cylinder block and cylinder head beyond 0.2 mm (0.008 in.) of total grinding limit.

-77-

Reboring the Cylinders

Important: Handle the pistons with care.Do not force the pistons through the cylinders until you hone the cylinder to the correct size.The piston can be distorted through careless handling. 1. To determine the size of the oversize piston to be used in all cylinders, choose the cylinder that requires the largest amount of reboring and use its size as the basis for all piston sizes. 2. Two kinds of oversize pistons are available; 0.50mm (0.02in.) O.S.and 1.00mm (0.039in.)

O.S.Those oversizes are based on the piston skirt

O.D.measured along the datum line as shown in the figure.For all cylinders, select oversize pistons with the same diameter. 3. From the piston O.D.measurement, calculate the valve of the cylinder bore to which every cylinder is to be rebored.

Rebore diameter = Piston O.D.+ 0.02mm (8 x 10-4 in.) to 0.04mm (1.6 x 10-3 in.) (Cylinder-to-piston clearance) - 0.02 mm (8 x 10-4 in.) (honing allowance) 4. Rebore all cylinders to the calculated diameter.

NO TE Reboring should be made in the order of the cylinders numbers to prevent warping due to C AU TIO N!

excessive temperature.

5. With a hone, a.Recondition the cylinders that have less than 0.025mm (0.0010in.) wear or taper. b.Bore and hone the cylinders that have more than 0.025mm (0.0010in.) of wear or taper to the smallest oversize piston that will permit complete resurfacing of all the cylinders. 6. Hone the cylinders to the finished size (piston O.D. + piston-to-cylinder clearance). • During the honing operations occasionally: –Clean the cylinder bore. –Measure the cylinder bore for a proper piston fit. 7. Perform the following procedure to bore and hone the cylinders.Use proper boring equipment, as recommended by the manufacturer. a.Draw a flat file across the top of the cylinder head block several times to remove any burrs or gasket materials.If the cylinder head block is not completely smooth and flat, tilt the boring bar to produce an incorrect angle of the cylinder to the crankshaft. b.Finish the honing operation with a 45-65 degree cross-hatch pattern on the cylinder walls.The finish marks should be clean but not sharp, free from imbedded particles and torn or faded metal. 8. Reinstall the pistons: a.Measure the piston 11.5 mm (0.45 in.) from the bottom of the piston skirt and at right angles to the piston pin to install the piston correctly. b.Bore the cylinder to the same diameter as the piston. c.Hone the cylinder to provide the specified clearance.Use proper boring equipment, as recommended by the manufacturer. d.Check each cylinder for proper cylinder-to-piston clearance.

Standard value:0.02-0.04 mm (8x10-4-1.6x10-3 in.)

-78-