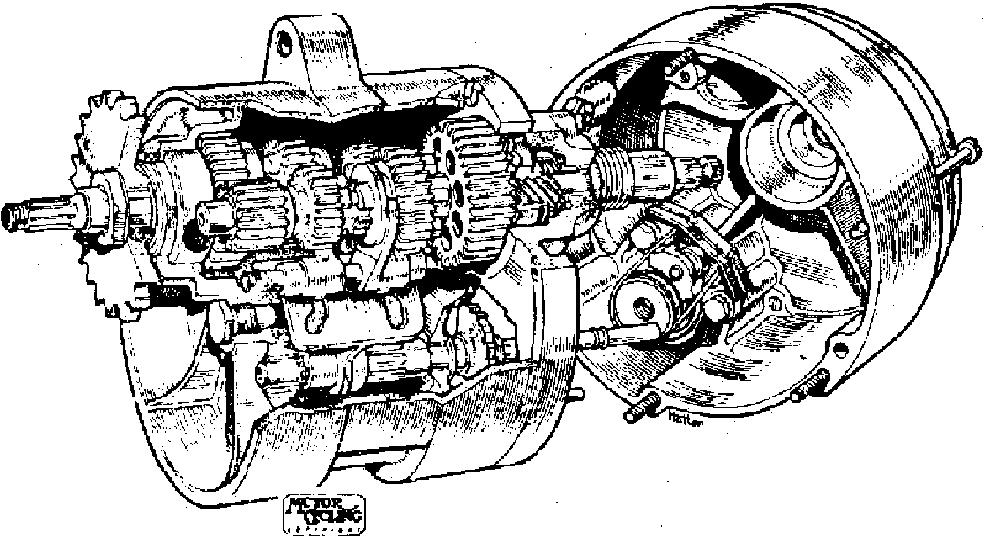

THE GEAR BOX 250 c.c. and 350 c.c. Lightweight Models It will be seen in Fig. 13 that the gear box internals are situated above the centre line of the gear box shell. It is for this reason that at least three pints of engine oil must be filled and maintained for satisfactory lubrication. POSSIBLE FAULTS

Top gear disengages. This is most likely to occur on early type gear boxes before 7988 (250 c.c.) and 2300 (350 c.c). To rectify, discard the sleeve gear 041273 and sliding gear 041276 as shown in Fig. 3. Replace the sleeve gear with modified type 044075, also sliding gear 044076, which use undercut dogs for positive engagement. Should the fault develop on a later type gear box, the plunger 042835 may be damaged on the extreme end, or the spring for plunger 040045 is weak allowing the gear to disengage. Both gears must be changed to convert. Third gear only disengages. The only remedy is to renew the two third gear pinions 041276 and 041277. Usually this is due to bad gear changing and possibly clutch drag. Bottom gear only disengages. This can only be due to end play between the first gear pinion and kickstarter bush. To remedy, use a shim washer .020" thick placed over the layshaft between the pinion and kickstarter bush. Difficulty in selecting the gears. Usually due to a distorted pawl spring 041327 preventing the pawl from rocking. Gear pedal does not centralise. The footchange pedal spring is broken. Replace with improved cross over type 043453. Separate the legs when fitting.

FIG 13 Lightweight gearbox with end cover removed 54