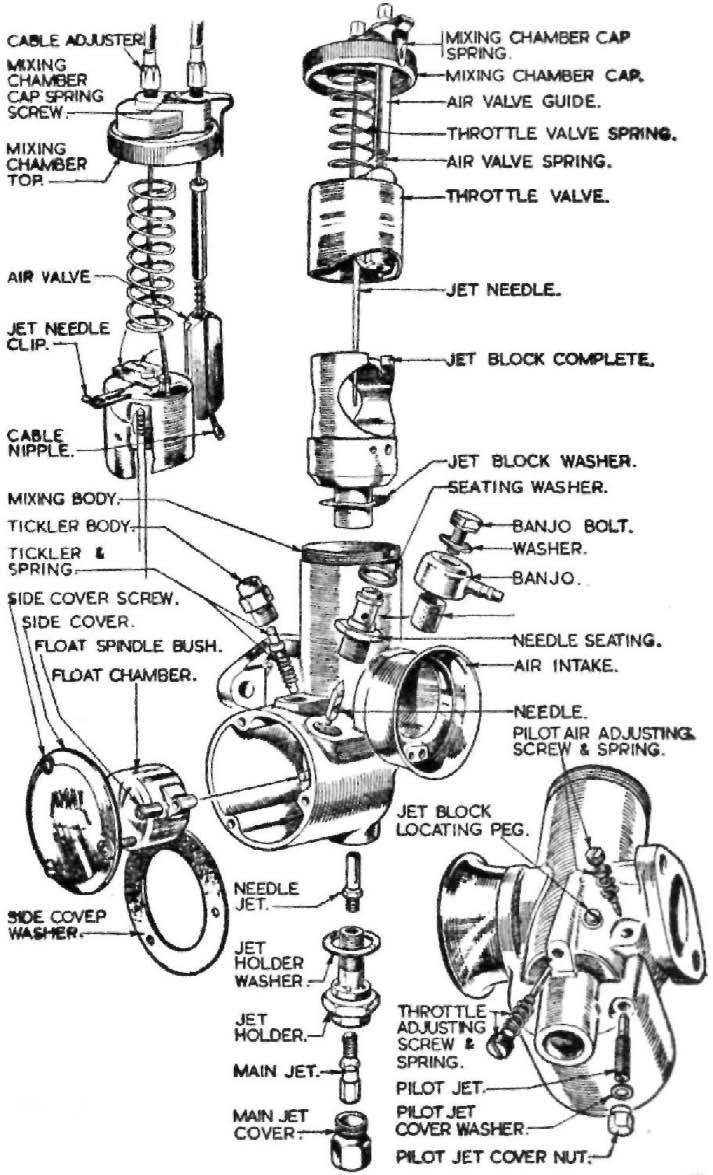

Air leaks either at junction of carburetter and inlet manifold, or by reason of badly worn inlet valve stems or guides. Faulty engine valve seatings. Sparking plug faulty, or its points set too closely. Ignition advanced too much. Contact breaker points dirty, pitted, loose or set too closely. High-tension wire defective. Pilot jet not operating correctly. Partially choked or incorrect air supply. Rockers adjusted too closely. Heavy petrol consumption may be due to: Late ignition setting. Bad air leaks. Probably at carburetter or manifold joints. Weakened valve springs. Leaky float (causing flooding). Taper needle extension insufficient. Poor compression, due to worn piston rings or defective valve seatings. (Test compression with throttle wide open.) Carburetter flooding. If the carburetter is flooding, the float spindle bush (Fig. 31) may be pinched between the float swivel and the float chamber cap. Reduce slightly the width of the tube or renew the gasket for the cover. Exercise care to avoid over tightening the pilot jet which can deform its seating in the mixing chamber. A defective jet block fibre washer will allow fuel to leak across the choke. Notes on Carburation. The main jet originally fitted is deemed to be the most suitable. There should be no necessity to alter the main jet size without good reason, Le. by. fitting an air filter, running with an open exhaust pipe system or at specified altitudes. Riders with considerable experience can, after driving at full throttle for at least a third of a mile decide, after 'reading' the sparking plug if the main jet size is suitable or otherwise. Without such experience it is preferable to drive at full throttle and close the air lever Âź". If the engine speed increases,. the main jet is small. Conversely, if the engine speed decreases, the main jet is large. Jet alterations should he made in stages of 10 c.c. increase in jet size, viz. size 200 to 210.

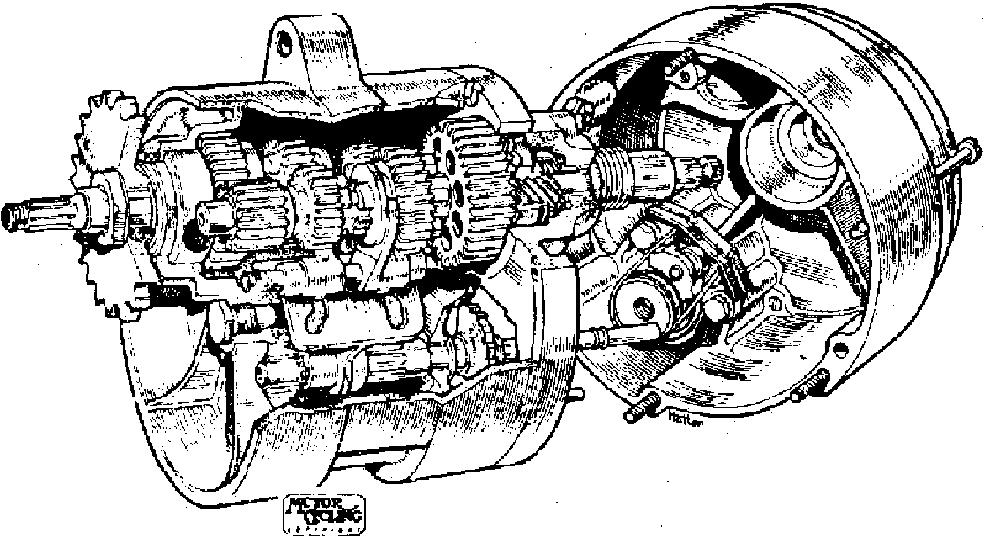

WIPAC ALTERNATOR

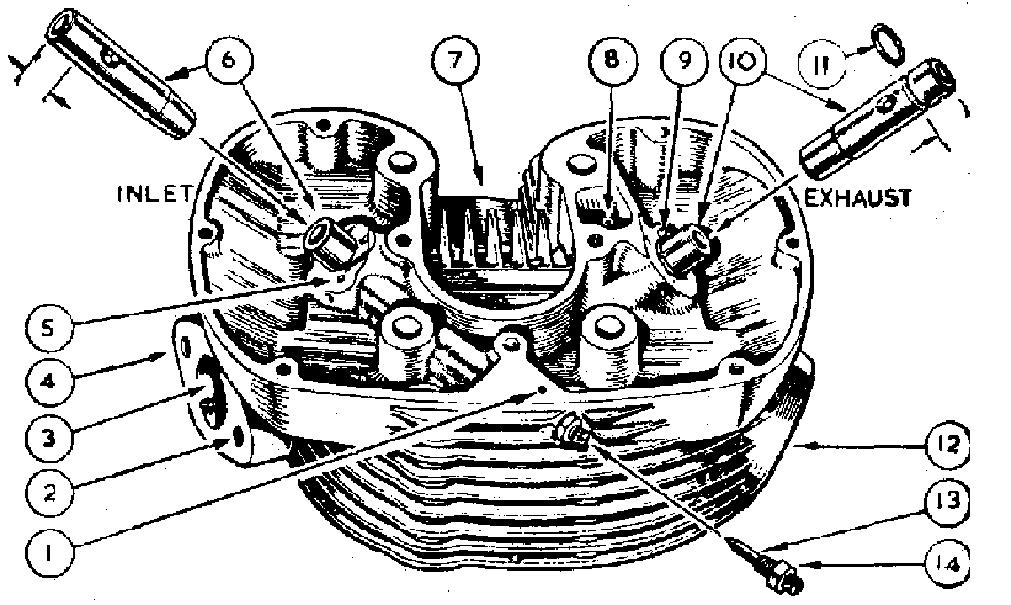

The series 114 Alternator consists of a six pole Stator ring 5" in diameter with six coils and a six pole permanent magnet rotor. There are three main leads coloured white, light green and Orange. Three coils are connected in series to white and light green, the other three coils are connected in series to white and orange. The output from these coils is a.c. converted to d.c. by means of a bridge-connected metal rectifier. The output of the alternator is controlled through the switch on the headlamp and connects three or six coils according to its position. Emergency starting. The emergency position is intended for starting when the battery is discharged. This position is marked 'EMG' on the ignition switch. 104