Executive Summary

Executive Summary

Contractual Issues & Amendments

There were no disputes or default notices issued.

One transgression was reported against performance standard 2: Maintenance following the failure of the Bendigo Clear Water storage Liner in February 2023. Toll reductions were applied

Contractual alleviations were applied during periods of free chlorination at Bendigo and Castlemaine

Management Systems

Veolia maintains seven management systems to guide activities and to enable demonstration of good practice.Three of these systems are certified with relevant ISO standards and accreditation was maintained.

Partnering Projects

Initiatives & Innovations

Veolia continued to partner with Coliban Water on the development and delivery of projects to ensure long term water security to the region is maintained:

● Free chlorination of Bendigo. Kyneton and Castlemaine Networks

● Water Security Project -Strathfieldsaye tanks design

● Public Use of Open Waterways Health BasedTarget project

● Bendigo WaterTreatment Plant Clear Water Storage Bypass (permanent)

● McCay Reservoir raw water bypass

● Bendigo WaterTreatment Plant Clear Water Storage Bypass (temporary)

Numerous initiatives were introduced during 2022/23 to improve and optimise performance. Other initiatives included

● Attendance and presentations at water industry conferences

● Trunk Water Main assessment project

● Net Zero Greenhouse Gas emissions

Veolia commenced operations inAustralia in 1993 and in New Zealand in 1997. We partner with clients to deliver, operate and manage water and wastewater infrastructure, technologies and services. Service, value and a social and environmentally responsible approach is incorporated into everything we do.

In 1999, Coliban Water engaged Bendigo Water Services Pty, Ltd (a subsidiary of Veolia) to undertake theAqua project.The 25 year contract to Build, Own, Operate and Transfer water treatment plants and supporting infrastructure for Bendigo, Castlemaine and Kyneton is scheduled for completion in June 2027.

The water treatment plants form the hub of each system of plant, pipelines and storages.The major treatment plant processes comprise:

● pH and alkalinity adjustment for corrosion control

● Chemical coagulation, Membrane Filtration

● Ozonation and Biological activated carbon (BAC) filters

● Fluoridation

● Disinfection

● Waste wash water handling and recovery

Veolia has operated and maintained the 165 kilometre Goldfields Superpipe since September 2010.The Goldfields Superpipe transfers bulk raw water from the Waranga Western Channel (at Colbinabbin) and Lake Eppalock. Raw water can be transferred to Spring Gully Reservoir, Sandhurst Reservoir (servicing the Bendigo WaterTreatment Plant) and White Swan Reservoir (servicing the White Swan WaterTreatment Plant in Ballarat)

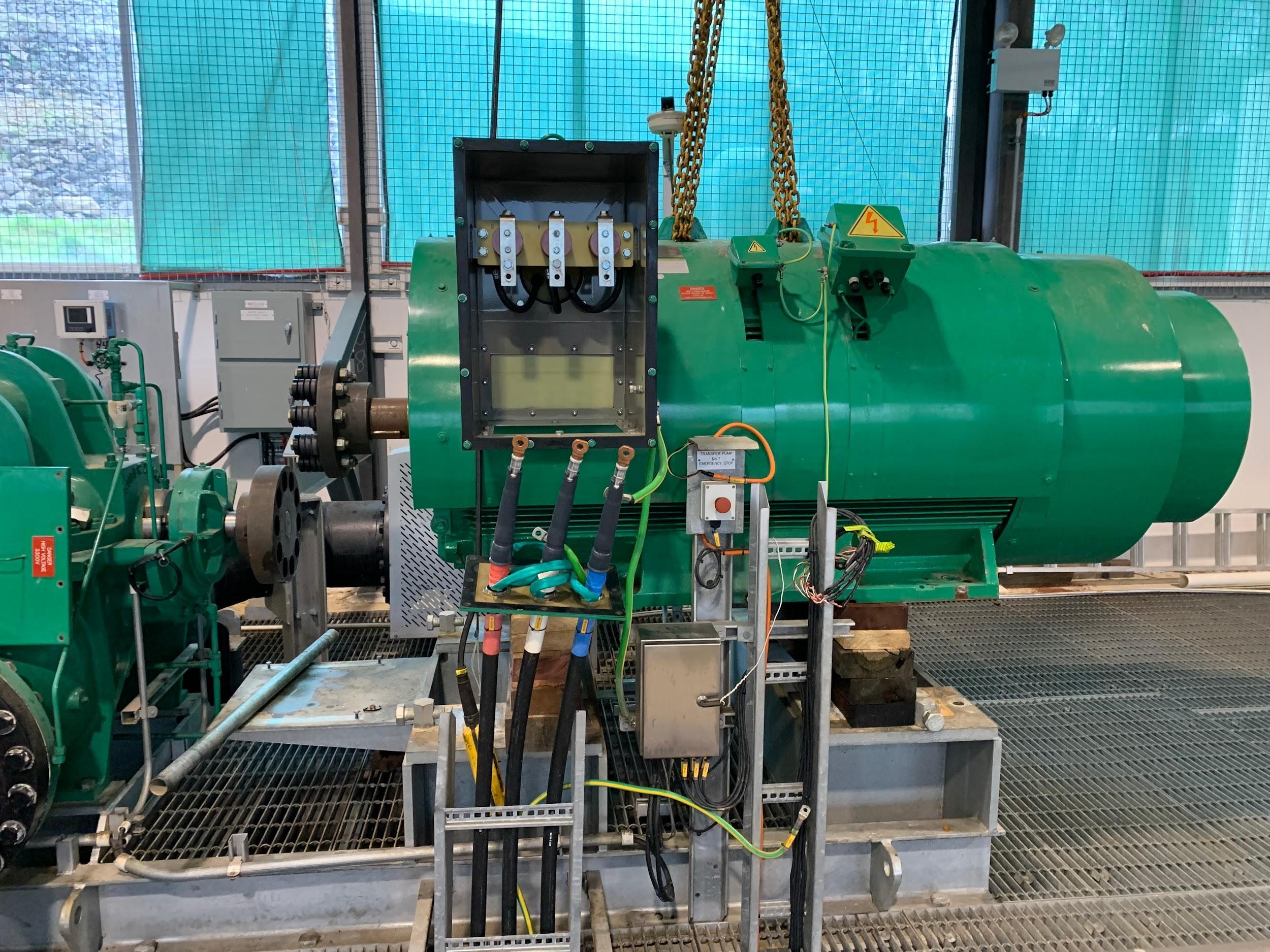

The Goldfields Superpipe was constructed to provide water supply security for both Bendigo and Ballarat for the next 50 years.The consequences of drought, climate change and projected population growth indicated the requirement to source alternative water supplies for the Bendigo region.The Goldfields Superpipe consists of six pumping stations, three raw water balance tanks and a mini hydroelectric turbine. It has a design capacity to deliver up to 165 MLof raw water per day

In 2019, the Goldfields Superpipe contract was re-negotiated and a contract renewal was executed for the continued operation and maintenance of the Goldfields Superpipe. This initial term is from 01/09/2019 to 31/08/2024, with the option of 2 x 2 year contract extensions.

Veolia offers a range of additional services to enhance the treatment and delivery of safe drinking water to Central Victorian WaterAuthorities

Network Management

The Veolia Goldfields Superpipe and Services team is based in Bendigo and has an extensive range of services and equipment to proactively address emerging issues within both potable and non potable water networks. In 2022, Hydrant Wizard was added to the toolbox to provide live fire plug and air valve replacements.

Smoke testing equipment

Chlorine disinfection trailer

AQUAdiag – mobile diagnostic unit for inline and laboratory analysis

Flushing, air scouring and swabbing of pipelines

Cathodic protection survey & inspections

HV Switching operations

CCTV pipeline surveys

Water Main Tappings & Line Stops: 15mm to 225mm drill

Rural Siphon CCTV Inspections

Veolia has an engineering and project management team based in Victoria. The team has extensive knowledge and experience in planning and delivering large scale water instructure projects. In 2022/23, the team was involved in various stages of the following projects:

The Veolia Research and Development teams continue to develop new technology to predict, monitor and detect risks within the water cycle.The following tools currently available from Veolia and which have potential application within our Coliban Water contracts are:

1. Trunk mains: Veolia is deploying an in-house methodology to assess the condition of trunk mains

2. Net Zero: Estimation and management of greenhouse gasses using the principles of Evaluation, Reduction, Green Energy alternatives and offsets

3. Technical community: Business support and Performance communities to share ideas and return on experience across the business lines

1 Health BasedTargets Upgrade Project 2 BWTPClear Water Storage bypass (Permanent) 3 CWTPRaw Water bypassSchedule 1 of theAqua deed consists of 36 performance standards covering water quality, quantity and system performance. Transgressions are reported to Coliban Water through Veolia’s early warning and incident reporting system. Monthly reports provide detailed performance against all contractual requirements. MonthlyToll payments are made in accordance with a formula in the Project Deed. Compliance with Performance Standards is summarized in theTables on the following pages.

Veolia reported 100% compliance to eight of the nine performance standards related to system management in 2022/23.

Systems Management

These include Health & Safety, Quality Systems, Environment, Complaints, and Raw water acceptance, Noise and Waste Products and Water Losses.

Anon-compliance was reported against Performance Standard 2: Maintenance in February 2023 relating to the failure of the Bendigo Clear water storage liner

25 parameters are monitored within the treatment processes at each of Bendigo, Castlemaine and Kyneton WaterTreatment Plants to enable compliance with 18 Performance Standards to be determined.

Process Monitoring

Delivery Point Monitoring

Compliance was achieved for all performance standards.

Compliance with Performance Standard 9 – Particles at each SP5, has been suspended since January 2016, following the installation of improved turbidity meters and the re-enactment of performance standard 7a- turbidity at each SP4.

Treated water is supplied to Coliban Water through fourteen delivery points.Ten parameters are monitored at various delivery points in each of the Bendigo, Castlemaine and Kyneton systems to enable compliance with Performance Standards to be monitored.

Compliance was achieved for all performance standards.

Planned events resulted in the alleviation of several performance standards in 2022/23. The events were undertaken to provide long term water quality and security to the regions.

Activities included

● Free Chlorination at Bendigo and Castlemaine, managed in accordance to Practice note 004

● Ongoing Free chlorination at Kyneton, managed in accordance to Practice note 005

Atotal of 16626MLof treated water was supplied to Coliban Water during 2022/23. This is a decrease of 1.2% from the previous year.

January 2022 had the highest total monthly flows. This is due to summer weather patterns. The highest daily flows recorded were:

● Bendigo at 75MLon 17/02/2023

● Castlemaine at 14 MLon 16/02/2023 and

● Kyneton at 6 MLon 10/04/2023. (Network Burst Main)

The performance of the Goldfields Superpipe Contract is assessed using six primary performance indicators which include maintenance, water quality monitoring and reporting and system performance. Monthly reports provide detailed performance against all contractual requirements.The Monthly Service Fee payments are calculated in accordance with the formula in the Project Deed

There was NO raw water transferred via the Goldfields Superpipe in 2022/23. (Note ~2MLwas transferred from Colbinabbin to Sandhurst during a pumping exercise)

Atotal of 890 ML was supplied via the Sandhurst Reservoir backflow pipeline into the Coliban Rural System.This supply was utilised to supplement Spring Gully Reservoir and Lockwood pipeline system.

Payments made to Veolia during 2022/23 are summarized as follows:

Financial payment for the management of the Goldfields Superpipe is determined via the Coliban Water- Central Highlands Water Joint Venture Invoices provide details of

● Operational Services

● Scheduled Services

● Unscheduled Services

● Support Services

● Additional Services

The Coliban Water and Veolia Key Performance Indicators (KPI’s) are developed from the partnership charter, to assess the health of the long term relationship.The key themes are:

A. Trust, Respect and Understanding

B. Sharing long term benefits. Being open minded to new opportunities

C. Prepare, participate and engage in all meetings

D. Truly listen, making sure to accept and hear the other person's point of view

E. Solving the problem through mutual participation - We are in this together.

F. Create shared value by actively fostering innovation

Performance measures are evaluated by Coliban Water and Veolia on a quarterly basis providing timely feedback on partnership achievements and hindering factors. In 2022/23, all measures met the acceptance criteria.

Coliban completed a net promoter survey for the Veolia operations. The survey was conducted by an external consultant to assess and gather feedback on Veolia’s operation, management and innovation performance. Coliban rated Veolia highly in all categories. Veolia appreciate the feedback and strive to continue to provide a value adding service to Coliban Water

There was one contractual Notices or Defaults issued under theAqua Deed

There were no contractual Notices or Defaults issued under the Superpipe Contract.

The AQUA 2000 contract provides a legally binding contract between Veolia and Coliban Water to ensure the supply of safe drinking water to the public. The 25-year contract has been in-place for 21 years. It is reviewed by Coliban and Veolia and amended, as required, to ensure best practices are maintained for financial and quality systems.

Six practices notes have been developed through the contract

● Practice Note 1;

○ Operational Management Strategy during anAlgal Bloom Event, signed 25 September 2012 (Performance Standard 8)

● Practice Note 2;

○ SupernatantTransfer to McCay Reservoir, signed 17th May 2014 (Performance Standard 8, 24 & 25) - Revised Dec 2021

● Practice Note 3;

○ New Works – to address the financial obligations for plant upgrade projects.

● Practice Note 4;

○ Contractual alleviations during free chlorination signed 18th October 2018

● Practice Note 5;

○ Management of Disinfection By-Products

During ongoing Free Chlorination signed 29thAugust 2019 (under review to include Castlemaine)

● Practice Note 6;Toll abatement

○ Calculation of Reduction inToll signed 18 December 2019

● Practice Note 7;

○ BP7 Interface Point 2020 has been revised and updated datedApril 2023

In 2022/23, Practice notes 4 and 5 were enacted to manage free chlorination at Bendigo, Castlemaine and Kyneton.

Veolia manages theAqua contract in compliance with OHS Management System

ANZ4801 and ISO 45001. In 2022/23, Veolia undertook external and internal audits, risk assessments, site inspections and hazard identification to drive continuous improvement in safety management systems.

The Veolia “Always Safe” Charter focuses on “Responsibility,Accountability and Resilience” to provide guiding principles for the always safe program. The program is about developing good behaviours, beliefs and values to build a safety culture within the organisation.

The framework provides

● Life saving rules as the minimum standards for 12 High risk protocols

● Always safe interactions to encourage safety discussions throughout the business

● Cultural Program to shape the behaviours and actions and decisions

In 2022/23, theAqua and Superpipe contracts reported

● zero LostTime Injury and

● zero MedicalTreatment Injury

Veolia’s commitment has resulted in a strong safety record without any LostTime Injuries (LTI) since 2009.

Management Systems

High Risk Management Standards

Bendigo Operations has a strong safety culture. Veolia has developed High Risk Management Standard (HRMS) to state the minimum requirements to prevent injuries to people and/or damage to the environment resulting from these activities.

The HRMS support theAlways Safe Culture andAlways Safe Sites programs. The programs drive continuous improvement across the sites through regular site inspections and hazard identification.

In 2022/23, 43 hazards were identified and projects were implemented to reduce the operational risks using the risk control framework of elimination, engineering and administration.

Veolia manages theAQUAcontracts in compliance with Quality Management System ISO 9001. In 2022/23, Veolia undertook external and internal audits and management review procedures . The program provides collaboration and knowledge sharing and drives continuous improvement across the business.

Veolia Corporate Services implemented continuous improvement activities on

● Business management system

● Learning Management System

● Veolia Business Intelligence dashboard

● Human Resources Management systems

● Marketing and media

● Project management

● Professional development of operations and technical staff

Veolia manages theAQUAand Goldfields Superpipe contracts in compliance with Environmental Management System ISO 14001. In 2022/23, Veolia undertook external and internal audits and internal inspections to identify risks and hazards. Corrective actions were developed and implemented to address the Observations and Opportunities for Improvement and promotes Veolia Continuous Improvement Program.

In 2022/23, environmental initiatives included corporate social responsibility (CSR) targets for the following:

Initiatives undertaken include

● Improved monitoring of energy and chemical usage

● Stormwater Management

● Maintain and encourage Waste Recovery Programs

● Volunteering participation – Clean UpAustralia Day

● Gender Equality awareness

● ReconciliationAction Plan

● Bendigo SolarArray

Veolia are continually looking for opportunities to reduce the environmental footprint of water treatment operations through

● Chemical usage to meet process conditions

● Chemical selection

● Asset conditions and replacement

● Waste production and disposal

● AQUAenergy usage was offset by ~80MwH of solar power in 22/23

Across the Bendigo operations, waste products are managed to reduce the environmental impacts and reliance on landfill. Initiatives include

● Waste Reduction

● Segregation of recyclable and general waste

● Recycling of products

● Use of sustainable products

● Disposal of prescribed industrial waste and hazardous chemicals through approved methods

● Staff training

Veolia actively promote workplace diversity and Inclusion Initiatives. In 2022, employee resource groups (ERG) were established to help drive cultural change and make a real difference for our people. ERG’s have been established for

Cultural & Social Diversity Employee Resource Group

Cultural & Social Diversity Employee Resource Group

Bendigo WTPhas a 3 year trade waste agreement with Coliban Water approved on 10/05/2022 to allow neutralisation waste to be discharged to the Bendigo Sewer system. In 2022/23, 23 MLwas discharged to sewer

Septic and Neutralisation waste from Castlemaine and Kyneton WTP’s is carted to Kyneton Water Reclamation plant. In 2022/23, approximately 3000 KLwas transferred to KWRP.

Since October 2022, Veolia has incurred a gate fee for disposal of the waste.

Teamgage is our monthly survey that allows us to share feedback in a quick and easy way on a regular basis. It is a way of engaging with employees to provide continuous feedback on performance and morale.

Employees are encourage to provide feedback on the core behaviours of

● Solidarity,

● Responsibility,

● Respect,

● Innovation,

● Customer focus,

● Always safe, and

● Optimism

Veolia is firmly committed to developing meaningful partnerships within the communities where we live and work. Our employees are at the center of this commitment as our most valuable asset, it is vital that our employees feel valued and proud of where they work.

In 2022/23, the Bendigo team volunteered time and services to participate in Clean Up Australia Day. The local team collected several tandem trailer loads of illegally dumped rubbish for the local bushland surrounding the Bendigo Water treatment plant.

Veolia maintains a risk register that describes identified risks, assesses associated likelihoods and consequences of occurrence, and records actions to control the risks.

In 2023, theAQUAstrategic risk register was reviewed to apply the operational experience of aging condition of asset. The review identified strategic risks to

● Kyneton Clear Water Storage

● Specimen Hill clear water storage

● Bendigo Ozone generators

● Castlemaine Raw water bypass

Mitigation controls are being developed to reduce the risk and ensure timely replacement of assets to ensure the long term security of water production across the AQUAplants and business continuity of the Bendigo operations

The integrity of the Bendigo WaterTreatment Plant Clear Water Storage has been compromised by multiple splits in the bottom liner f the storage. The splits have not resulted in water quality issues.

The situation was stabilised and safe drinking water continued to be safely supplied to the community.

Contingency plans were developed to mitigate the risk of catastrophic failure and provide continued supply of drinking water.

1. Emergency CWS bypass from CWS inlet to outlet of the raw water screen shed

2. Temporary CWS 600mm bypass from CWS inlet to re-purposed oxidation tank

3. Reconfiguration of Network to reduce reliance on CWS.

4. Fast track project to replace CWS storage liner (previously scheduled for 2024)

5. Management of underdrain water via return to Sandhurst reservoir

Construction works on the temporary bypass commenced in March 2023. Works included

● Relocate Raw water pump for the CWS bypass to Oxidation tank

● Installation of submersible pump in the CWS inlet

● Construction of temporary CWS ie.3 x 1.4MLtemporary tanks and retrofitting the reclaimed water tank as a 0.5MLCWS

● Pipework to connect to temporary tanks

● Ongoing monitoring, internal inspection and repairs to existing CWS

● Developing Operations Manuals, control philosophies and commissioning plans

Initiatives and Innovation

Veolia undertook immediate actions to develop and implement contingency plans to secure water supplies to Bendigo in the event of a catastrophic failure of the CWS.

This involved

1. Source and installed emergency diesel pumps

2. Installing 3 layflat pipes to divert treated water from the CWS inlet directly to the network.

3. Refitting and disinfecting screen shed for drinking water

4. Management of underdrain flows

The works were completed within a week

Emergency layflat pipeworkTemporary CWS 600mm bypass from CWS inlet to re-purposed oxidation tank

Construction works on the temporary bypass commenced in March 2023. Works included

● Installation of submersible pump in the CWS inlet

● Construction of temporary CWS ie.3 x 1.4MLtemporary tanks

● Retrofitting the reclaimed water tank and Oxidation tanks as CWS

● Pipework to connect to temporary tanks

● Ongoing monitoring, internal inspection and repairs to existing CWS

Installation of submersible pump

Sludge drying beds infilled for the construction ofTemporary Storage tanks

Retrofit Oxidation tank

Retrofit Reclaimed water tank

Sludge drying beds infilled for the construction ofTemporary Storage tanks

Retrofit Oxidation tank

Retrofit Reclaimed water tank

Veolia maintains an Incident Management System that details responsibilities in response to various levels of incidents.This system is used continuously during the year to respond and report on incidents. In 2022/23, there were 106 incidents identified and managed through the Veolia system. Over 83% of incidents recorded were classified as Hazard Identification/Near Miss or Insignificant (Early Warning) incidents. The approach allows proactive risk management to prevent the occurrence of major incidents. There was one major incidents reported in 2022/23 relating to the BWTPCWS liner failure.

In September 2022, a leak from the BP2 interface point cabinet was reported to Veolia. Investigations found the source was on the 40mm water supply pipe to the Big Hill interface point BP2. The PVC pipe was cracked and required an isolation of the interface point and Coliban's Big Hill pump station while the pipe was repaired.There was risk of low pressure at the interface during the isolation for repairs.

Veolia liaised with Coliban Water during the event to fill Big Hill tanks before isolation of the main, to ensure continuity of supply to customers. Leak was repaired with no interruption to customers and insignificant risk categorisation. (Incident 17665374)

On 12/04/2023, Coliban Water experienced a major water main burst in Kyneton. The burst resulted in the KWTPCWS being emptied in ~2 hours. Veolia undertook corrective actions including

● Notified Coliban Water of abnormally high flow

● Increased plant flow in an attempt to maintain supply

● Mobilise team for recovery

● Liaise with Service Stream operators - provide information for isolation

● Restart plant with no service water - temporary connection installed

● Additional sampling

● Malmsbury Chlorination

● Tylden tanks isolation and reinstatement

● Pipe scours and air release

The burst caused faults with the KP2 flow meter readings for a 4 day period. Volumes have been manually calculated during this period. Veolia participated in an incident debriefing with Coliban Water to understand the root causes and lessons learnt from the incident. Veolia has also undertaken an internal debriefing to build resilience and continuous improvement into the management and operation of the treatment plants. Key actions include

● Review incident management communications and roles and responsibilities

Kyneton WaterTreatment Plant Clear water storage was emptied in ~2 hours after a burst in the networkIn October 2022, major flooding was predicted for the Coliban and Campaspe Regions. Flood models indicated a very high risk to the Eppalock Pump Station. Veolia and the Joint Venture implemented the flood response plan to minimise damage and risk to the assets.This included the following activities:

● Relocation of motors 5 & 6 from Epplack to theAxe Creek Pump Station

● Motor 7 was disconnected and raised 600mm above the 2011 flood level, as it was not possible to safely remove it from the site

● Isolation of the power supply to the site

The flooding occurred onThursday 13th of October 2022, and substantially exceeded the January 2011 flood event, with the final flood level approximately 2.5 metres above the upper floor level. (The January 2011 flood level was approximately 600mm above the upper floor level)

The flood resulted in total flooding of the Eppalock pump station and associated equipment, including the HV switch room and associated equipment, the 22 kVa transformer and associated equipment and partial flooding of the incoming HV RMU

The GSPJV made a decision to handover the site to the Veolia GSPteam to manage and implement the flood recovery work, including management of the flood damage insurance claim. Major actions to date include:

● Prioritisation of the dewatering and cleaning the building and salvageable equipment

● Engaged Styles Power Solutions to restore partial power to the site to allow the commencement of testing, repairing and replacement of electrical equipment at the site

● NHP/Rockwell engaged to carry out VSD inspections

● CJ Pearce Pty Ltd engaged to inspect, clean and assess theTamco HV switchgear

● Site inspections by CHW insurance assessors and forensic engineer

● HV inspections of the HV RMU and incoming HV kiosk

Flooding of Eppalock Pump Station exceeded historic flood levels Internal damage of Pump Station following the floodsVeolia and Coliban Water create innovative solutions through encouraging and supporting new ideas to drive development and value creations.

In September 2022, Veolia undertook a detailed condition assessment of a high risk trunk main in Echuca.These works were the final stage following of the pre-condition assessment of 9.5km trunk mains undertaken in 2021.The watermain was installed in 1941

The 2022 assessment included physical excavation of the water main at 4 site to allow actual measurement of the following parameters:

● pipe thickness

● pipe depth

● soil corrosivity

● electrical potential

Upon completion of the testing, of a cathodic protection sacrificial anode and test point was physically connected to the pipeline at each test site, to provide ongoing protection against corrosion

The study found the pipeline was in very good condition at all 4 sites

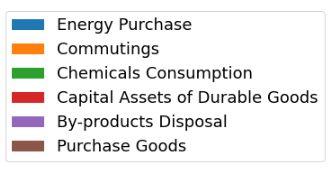

Net Zero is a Veolia Innovation to help water utilities reach there net Zero carbon emissions goals. The tool has 4 pillars

1. Evaluation- using Greenpath software to accurately estimate the water, waste and energy usage of the existing operation

2. Reduction - Optimise processes -using OCEAN and PEARL software tools and equipment upgrades

3. Green energy - to help water utilities manage the implementation of green energy production units - solar, wind or methane digesters

4. Offset - to help water utilities generate carbon offsets for the unavoidable GHG

We estimated the emissions from our three plants at

● ~5,700 tons co2e / year (fy 2021-2022)

● 0.35 ton co2e / ml water produced (fy 2021-2022)

The greenpath analysis revealed that emissions are mainly due to energy and chemical use

Bendigo

Castlemaine Kyneton

Bendigo

Castlemaine Kyneton

Water Quality

Veolia addresses water quality through a risk based approach to identify and mitigate potential water quality issues.

Monitoring

Routine monitoring programs have been developed using a three tier program of online, internal and external laboratory analysis to ensure timely identification and response to WQ risks.

The comprehensive monitoring programs and trend analysis of water quality throughout the treatment process allowed for process control and optimization of the plant’s performance and timely mitigation controls to emerging WQ risks. Process optimization ensured treated drinking water maintained compliance with contractual and regulatory requirements. Routine monitoring is supplemented by additional testing programs during periods of variable raw water quality and high risk events.

Planning and forecasting of seasonal variations and operational projects provided opportunities to develop contingency plans to address potential process issues. Issues identified included bromate, manganese, blue green algae, chlorine demand and supply demand.

Veolia provide a high level of continued education and training to operators and support staff. The skilled, experienced staff proactively identify water quality risks and undertake preventative measures to maintain a high standard in drinking water quality. In 2022/23, Veolia staff undertook refresher training in Water Quality Risk Management and Critical Control Plans.

Veolia provided learning pathways in accordance with Victorian Framework for Water Treatment Operator’s Competencies: Best Practice Guidelines In 2023, the Bendigo operations team has eight operators certified under the scheme.

In March 2023, a regulator audit was undertaken for the Coliban Water Drinking Water Risk Management plan. The audit included a review of Veolia’s management procedures and a site visit to Castlemaine WaterTreatment plant. No non-compliances were reported. 1 OFI was noted and will be managed through the partnership.

Veolia reviewed theAQUAdeed and the application of the water quality performance standards to ensure compliance and management to current regulatory and public health risks. Veolia revised versions of management plans that are referred to in the AQUADeed. No changes were required to the

● Water Quality Response Plan

● Taste and Odour Management Plan

● Algal Management and Response Plan

In February 2023, Coliban Water issued Version 11 of the Coliban Water Drinking Water Quality Risk Management plan. Version 11 included review of the critical control plans and setpoints across theAQUAsites.

In March 2023, Veolia requested temporary changes to disinfection setpoints to allow adequate residual disinfection following deterioration of raw water quality following the October 2022 regional floods.

In June 2023, Veolia reverted to the original setpoints following the stabilization of raw water quality.

Veolia has a proprietary contract asset renewal management system (CARMS).

The CARMS system is specifically designed to:

● Identify future asset performance and deterioration

● Serve as a reliable decision support tool to manage risk

● Provide long term cost forecast models for the facility

● Generate a prioritised annual asset renewal plan

Asset Improvement Projects are managed through the Veolia assets & projects team through the Management of change procedure.

The project delivery model provides flexibility to tailor the skills, qualifications and operational experience of staff to the works.

Veolia’s management of change procedure ensures changes are

● Managed effectively and efficiently

● Authorised at the appropriate level;

● Communicated to stakeholder groups;

● Risk assessed;

● Records and documentation updated;

In 2022/23, 9 MOC were raised for the AQUA plants.

● OperationalTechnology - fix the basics

● Lauriston Pump renewal

● ElectricalArc FlashingAssessments

● Turbidity meter upgrades

● MCC remote switching

● Autodrain solenoid on air receivers

● Tylden Emergency bypass pipework

● TyldenTank Replacement

● CWTPair compressor replacement with VSD to reduce energy consumption

Lauriston Pump ReplacementKey Projects completed in 2022/23 included:

Water Security

● Tylden Emergency Bypass Pipework

● TyldenTank Replacement

● Upgrade toTurbidity meters

● Supplement BAC carbon supplies

● Digital flow meters for Fluoride dosing

● CWTPmembrane replacement all 7 cells

● Membrane replacement BWTPCells 4 and 8

Safety & Environment

● ElectricalArc FlashAssessments

● MCC remote Switching

● Process optimization (coagulation, and disinfection set points)

● BWTPfront gate upgrades

● BWTP platforms and gates modifications for membrane access

● CWTPair compressor replaced with VSD

● Chemical storage bund recoating at Kyneton

Air compressors were replaced with new technology equipped with variable speed drives (VSD) . The VSD enables longer run times to match plant demand. This reduces the high energy demand on startup and provides a constant baseline during low demand periods.

The new air compressor will reduce energy consumption

In the water treatment process

Operational Technology

● IT firewall and router consolidation and upgrades at all sites, including redundancy improvements

● Local 4G antenna install at McCay WTP to reduce reliance on McCay Reservoir dam wall for internet comms

● Cyber Security Appliances deployment at all sites, allowing for monitoring of network activity and vulnerabilities

CWTPAir Compressor replaced with VSDMaintenance Systems -AQUA

Veolia’s preventative maintenance schedule targets critical failure modes to maximize plant availability and minimize unexpected breakdowns.

During the year 2170 maintenance work orders were raised. Less than 5% of works were in response to breakdowns, with 91% of works being completed as preventative maintenance.

All statutory work orders were completed within 30 days from becoming due.

Additional works were undertaken to improve plant performance and ensure a continuous supply of high quality treated water.

Maintenance Systems - Goldfields Superpipe

Maintenance on the Goldfields Superpipe is currently carried out via the issue of work orders via the Veolia VAMS asset management system

1105 maintenance work orders were raised during the 2022-23 financial year. Approximately 1% of works were in response to breakdowns, with the majority of works (97.4%) completed as preventative maintenance

During March 2023, Veolia managed the Eppalock Pump Station gutter and downpipe replacement project

The project was quite complex, as it required the contractor (PlumbWorx Bendigo) to work at heights and above water, with all access to the gutter and flashings via a crane and work cage.

The contractor also assisted Veolia with the removal of broken glass from the flood damaged windows (whilst they were onsite with the crane and cagei work)

The project was completed on time and on budget

Apumping trial from Colbinabbin to White Swan was carried out during May 2023. The trial was conducted to evaluate the operability of the pipeline and pump stations, as there had been no major pumping events since May 2015.

The trial tested the operational readiness of the Goldfields Superpipe and identified several operational issues (see below). It has also has highlighted the importance of carrying out full maintenance pumping events for both the Northern and Southern link to ensure the system is a viable “raw water” resource for Central Highlands Water and Coliban Water respectively.

Some of the issues identified follow:

● SCADAcontrol and communications issues

● Pump serviceability and lubrication

● Water quality monitoring

● Flow meter verification (with actual flows of water)

Maintenance Systems - Goldfields Superpipe

Major projects undertaken included:

Eppalock Pump station flood scenario (Sept 2022)

The key findings from the trial included:

● SiteAccess in the event of power failure

● Incorporate provision of portable trailer mounted generator

● Operational risks

● SHEQ risks in relation to the safe lift/relocation of the pumps

● Communications protocols

● Update manuals and contact details

The exercise provided a “real life” understanding and valuable experience for the actual major flooding event that occurred one month later (in October 2022)

Further improvements have been identified from the emergency flooding event, which are being incorporated into a formal Procedure and Work Instruction to cover any future major events

Various minor capital works improvements were undertaken including

● Easement and maintenance inspections at air valves and scour sites

● Sampling at Lake Eppalock and Waranga Channel

● Annual flow meter verifications

● Annual crane and davit point inspections

● VSD inspections

● Routine GAMAwork orders

● Installation of a Pressure Monitoring Station at bthe Eppalock junction valve site (to improve SCADAcontrol of pumping operations between Colbinabbin and Eppalock/Sandhurst)

Veolia is invested in partnering with Coliban Water to secure long term sustainable water security solutions within the Coliban region.

Veolia is partnering with Coliban water to develop and design a practicable solution to bypass the Bendigo clear water storage. The works will allow for future augmentation of Bendigo water storages providing increased water security.

In 2022/23, project achievements included

● Tender management roles and responsibilities determined

● Concept design validation

● Geotechnical investigations

● Determine lead times of critical components

● Flora and fauna survey completed by Coliban

● Survey works completed

● Project reporting

On-water Recreational activities increased the microbial risks within the catchment. In 2022/23 Veolia undertook detailed concept designs and project planning at Bendigo, Castlemaine and Kyneton to meet the Health Based targets. Contracts were signed in 2023 to commence UV augmentation projects at all treatment plants.

Works are scheduled to commence at Castlemaine and Kyneton in Q3 2023.

Additional works are under proposal at Bendigo to enhance primary disinfection contact times through the construction of a chlorine contact tank.

Veolia participated in a technical review of the StrathfieldsayeTanks Project.

Discussions outlined:

● Project background/objectives

● Concept design and delivery

● Veolia delivery main pressure and supply, interface point and valving arrangements (including mini hydro option)

● Spring Gully Recycled WaterTank potable water connection

Partnership opportunities for the operations, maintenance and asset management of the tanks to provide water security and sustainability to the supply zone, will continue in 2023/24

The interconnection between the treated water and raw water pipes at CWTPwas identified as a high risk to water security and quality.

Veolia and Coliban Waterparticipated in several workshops to determine engineering options to reduce the risks.

Veolia has commenced planning works to install double block and bleed in 2022/23. The works will be structured to minimise risks to water security.

Veolia has provided non-contractual services to Coliban

In 2022/23, these included

● Free chlorination of Kyneton and Castlemaine Networks

● Catchment monitoring for assessment of microbial risk as a result of “on water” recreational activities

● Tank chlorinations at Echuca West, Marong, Big Hill and Malmsbury

● Tank cleaning and chlorination at the Belvoir Park tanks

● Installation and commissioning of a new PRV and by-pass at Belvoir Park Road

● Operator Secondment to Cohuna, Gunbower and Echuca WTP’s

● Chlorination and WQ sampling of the Elmore Flood relief accommodation facility

● Inglewood “Hydrant Wizard” repair

Additional Services within the Coliban region

Veolia has the capacity to undertake a range of additional network services including

● Aquadiag mobile WQ diagnostic van

● Smoke testing,

● Line stops and tappings

● Mains chlorination and flushing

● Valve replacements

● Network water quality monitoring

In 2022/23, the following works were undertaken for external land developers within the Coliban region.

Service New Mains Disinfection

Number of jobs 28 (11490 meters)

In October 2022, Central Victoria experienced major flooding impacting water and wastewater services across the Coliban Water region.

Veolia provided assistance by

● Operational assistance and secondment to Cohuna, Gunbower and Echuca WTP’s

● Construct a temporary bypass ofTylden tanks to reduce the need for water cartage

● Twice weekly involvement in flood response workshop

● Additional water quality monitoring of upstream water sources and process units

● Assist with Network management and recovery

○ Management of tanks and water quality at Elmore Emergency Centre

○ Temporary chlorine dosing at Echuca tanks.

○ Chlorine flush and burn at Gunbower

○ Raw water main flush at Heathcote

Coliban Water and Veolia recognized the strengths and long term benefits of its partnership, outlined in the Partnership Charter as we strive to work together to improve the region’s water security. The partnership is based on trust and respect, shared long-term benefits and understanding.