Precautions for Use (3) Disassembling clearance adjustment parts Shims and washers used for clearance adjustment should be stored so that they can be reassembled in the identical conditions.

AL

(4) Disassembling linkage The adjustment values of the rod should be kept as is whenever possible. If the adjustment value must be changed for disassembly, measure the length prior to disassembly and record it so that the same dimensions can be obtained at reassembly.

IN

CO US N F E ID O E F N TS TI M AL GL : F O OR BA T L H

E

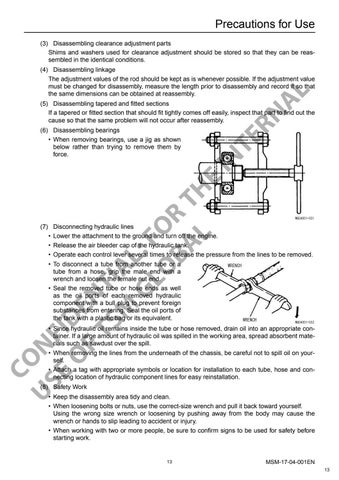

(6) Disassembling bearings • When removing bearings, use a jig as shown below rather than trying to remove them by force.

TE RN

(5) Disassembling tapered and fitted sections If a tapered or fitted section that should fit tightly comes off easily, inspect that part to find out the cause so that the same problem will not occur after reassembly.

(7) Disconnecting hydraulic lines

• Lower the attachment to the ground and turn off the engine. • Release the air bleeder cap of the hydraulic tank. • Operate each control lever several times to release the pressure from the lines to be removed. • To disconnect a tube from another tube or a tube from a hose, grip the male end with a wrench and loosen the female nut end. • Seal the removed tube or hose ends as well as the oil ports of each removed hydraulic component with a bull plug to prevent foreign substances from entering. Seal the oil ports of the tank with a plastic bag or its equivalent.

• Since hydraulic oil remains inside the tube or hose removed, drain oil into an appropriate container. If a large amount of hydraulic oil was spilled in the working area, spread absorbent materials such as sawdust over the spill. • When removing the lines from the underneath of the chassis, be careful not to spill oil on yourself. • Attach a tag with appropriate symbols or location for installation to each tube, hose and connecting location of hydraulic component lines for easy reinstallation.

(8) Safety Work

• Keep the disassembly area tidy and clean. • When loosening bolts or nuts, use the correct-size wrench and pull it back toward yourself. Using the wrong size wrench or loosening by pushing away from the body may cause the wrench or hands to slip leading to accident or injury. • When working with two or more people, be sure to confirm signs to be used for safety before starting work.

13

MSM-17-04-001EN 13