3 minute read

519 Telehandler HYDRAULICS

Tilt Cylinder Counterbalance Valve Quick Test

STEP 23

Install a 5000 psi (350 bar) pressure gauge and hose on the battery tray test port.

WARNING: The hose must be long enough to observe the pressure gauge from inside the cab or standing clear of the forklift.

STEP 24

Start the engine and run at high idle. Tilt the attachment mount up until the tilt cylinder reaches the end of its stroke and hold the joystick in the TILT UP position. The pressure gauge should read 3350 psi (230 bar).

If the pressure is less than 3350 psi (230 bar) go to Step 27 of the Tilt Cylinder Direct Test.

If the pressure is 3350 psi (230 bar), proceed to the next step.

Step 25

Watch the pressure gauge as the attachment mount is slowly tilted down. The pressure gauge should read 3350 psi (230 bar) when the attachment mount reaches the full downward position.

If the pressure is less than 3350 psi (230 bar), proceed to the next step.

Tilt Cylinder Counterbalance Valve Direct Test

Step 26

Shut off the engine. Install a 5000 psi (350 bar) pressure gauge and hose (1) between the tilt cylinder rod end (tilt down) port (2) and the supply hose (3).

Step 27

Start the engine and run at high idle. Watch the pressure gauge as the attachment is slowly tilted DOWN. The pressure gauge should read 3350 psi (230 bar) when the attachment mount reaches its full downward tilt position. Shut off the engine.

If the pressure is more or less than 3350 psi (230 bar) replace the counterbalance valve.

Template Name: OML_2_col0-00000

Template Date: 1994_04_22

519 Telehandler HYDRAULICS

Extension Cylinder Quick Test

Step 28

Install a 5000 psi (350 bar) pressure gauge and hose on the test port on the battery tray.

WARNING: The hose must be long enough to observe the pressure gauge from inside the cab or standing clear of the forklift.

Step 29

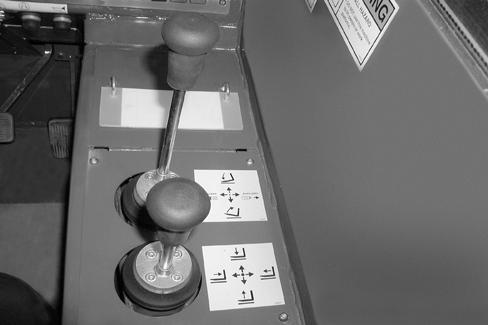

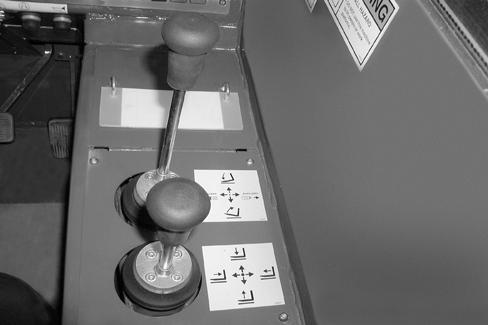

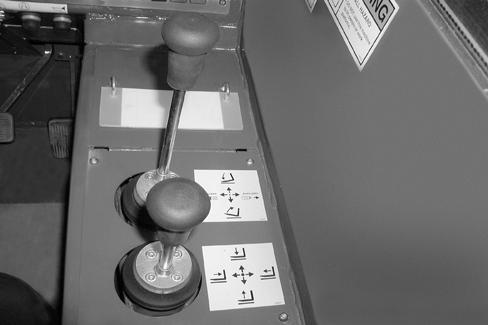

Start the engine and run at high idle. Retract the boom until the boom extension cylinder is at the end of its stroke and hold the joystick in the RETRACT position. The pressure gauge should read 3350 psi (230 bar).

If the pressure is more than 3350 psi (230 bar) proceed to the Main Control valve Pressure Relief Test and Adjustment section of this manual.

If the pressure is less than 3350 psi (230 bar), proceed to the next step.

If the pressure is 3350 psi (230 bar), but the extension cylinder is not working properly, check the boom or extension cylinder barrel for damage.

Step 30

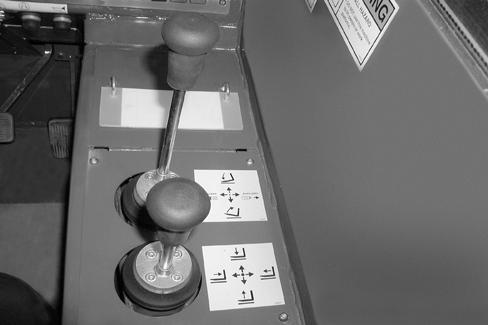

Lower the boom until the lift cylinder is at the end of its stroke and hold the joystick in the BOOM LOWER position. The pressure gauge should read 3350 psi (230 bar).

If the pressure is less than 3350 psi (230 bar), proceed to the Main Control Valve Pressure Relief Test and Adjustment section of this manual before proceeding to the next step.

If the pressure is 3350 psi (230 bar), proceed to the next step.

Extension Cylinder Direct Test

Step 31

Shut off the engine. Remove the hose (1) from the retract tube fitting. Install a 5000 psi (350 bar) pressure gauge (2) on the hose fitting and plug the retract tube fitting (3).

WARNING: The hose must be long enough to observe the pressure gauge from inside the cab or standing clear of the forklift.

Step 32

Extension Cylinder Relief Test

Step 34

Start the engine and run at high idle. Move the joystick into the BOOM RETRACT position and hold. The pressure gauge should read 3350 psi (230 bar).

If the pressure is 3350 psi (230 bar), repair or replace the counterbalance valve. If cylinder does not work properly once reconnected then replace the cylinder.

If the pressure is less than 3350 psi (230 bar), proceed to the Main Control Valve Pressure Relief Test and Adjusting Section.

Step 33

Shut off the engine. Remove the pressure gauge (1) from the retract hose fitting (2) and install the retract hose to the retract tube fitting (3).

WARNING: The hose must be long enough to read the gauge while standing clear of the forklift.

Remove the hose (1) from the extend tube fitting (2). Install a 5000 psi (350 bar) pressure gauge (3) on the hose fitting and plug the extend tube fitting.

Step 35

G1107011

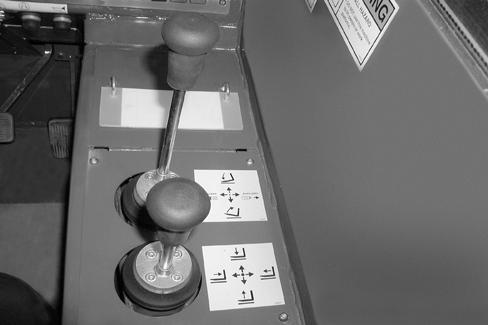

Start the engine and run at high idle. Move the joystick into the BOOM EXTEND position and hold. The pressure gauge should read 3350 psi (230 bar) once the boom reaches full extension.

If the pressure is more or less than 3350 psi (230 bar), proceed to the Main Control Valve Pressure Relief Test and Adjustment Section.