9 minute read

519 Telehandler HYDRAULICS

Boom Lift Cylinder Troubleshooting

NOTE: If the boom will lift but will not lower, replace the counterbalance valve on the lift cylinder.

Danger

Boom must be properly secured before any work is done on the lift cylinder or boom hydraulics.

Does the boom lift without a capacity load?

Test the pressure at the test port on the battery tray. Retract the boom to the end of the cylinder stroke and hold. Does the pressure gauge read 3350 psi (230 bar)?

YES

Repair or replace the control components.

Follow the Main Control Valve Pressure Pressure Troubleshooting procedure. Is the problem in the control valve?

Use an in-line flowmeter to test the pressure at the lift cylinder extend hose. Does the pressure gauge read 3350 psi (230 bar)?

Replace the counterbalance valve. Does the pressure gauge read 3350 psi (230 bar)?

Follow the Main Control Valve Pressure Troubleshooting procedure. Does the pressure gauge read 3350 psi (230 bar)?

Use an in-line flowmeter to test the pressure at the extend port of the lift cylinder. Does the pressure gauge read 3350 psi (230 bar) when cylinder is fully extended?

Remove the flowmeter.

Repair or replace the lift cylinder.

Adjust the relief valve in the Main Control Valve. Open the load control valve of the flowmeter and hold the joystick in the boom lower position. Does the pressure gauge read 3350 psi (230 bar)?

YES Remove the flowmeter.

YES YES Remove the flowmeter.

Repair or replace the relief valve in the Main Control Valve.

Remove and bench test the hydraulic gear pump. Does the hydraulic gear pump meet specifications?

Repair or replace the hydraulic gear pump.

Template Name: OML_1_col0-00000

Template Date: 1994_04_22

519 Telehandler HYDRAULICS

Boom Extend Cylinder Troubleshooting

NOTE: If the extend cylinder will extend but will not retract, replace the counterbalance valve on the cylinder.

Danger

Boom must be properly secured before any work is done on the extend cylinder or boom hydraulics.

Does the boom extend without a capacity load?

Test the pressure at the test port on the battery tray. Lower the boom to the end of the cylinder stroke and hold. Does the pressure gauge read 3350 psi (230 bar)?

Repair or replace the malfunctioning control components.

Use an in-line pressure gauge to test the extend pressure at the extend cylinder. Does the pressure gauge read 3350 psi 3350 psi (230 bar)?

Replace the counterbalance valve. Does the pressure gauge read 3350 psi (230 bar)?

Follow the Main Control Valve Pressure Troubleshooting procedure. Does the pressure gauge read 3350 psi (230 bar)?

Follow the Main Control Valve Pressure Troubleshooting procedure. Is the problem in the control valve?

Use an in-line flowmeter to test the pressure at the extend port of the lift cylinder. Does the pressure gauge read 3350 psi (230 bar)?

Remove the flowmeter.

Repair or replace the extend cylinder.

Adjust the relief valve in the Main Control Valve. Open the load control valve of the flowmeter and hold the joystick in the boom lower position. Does the pressure gauge read 3350 psi (230 bar)?

Remove the flowmeter.

Repair or replace the relief valve in the Main Control Valve.

Remove the flowmeter.

Remove and bench test the hydraulic gear pump. Does the hydraulic gear pump meet specifications?

Repair or replace the hydraulic gear pump.

Template Name: OML_1_col0-00000

Template Date: 1994_04_22

Attachment Tilt Cylinder Troubleshooting

NOTE: If the tilt cylinder will roll back but not lower, replace the counterbalance valve on the cylinder.

Danger

Boom must be properly secured before any work is done on the tilt cylinder or boom hydraulics.

Does the boom tilt operate without a capacity load?

Test the pressure at the test port on the battery tray. Lower the boom to the end of the cylinder stroke and hold. Does the pressure gauge read 3350 psi (230 bar)?

Repair or replace the malfunctioning control components.

Use an in-line pressure gauge to test the extend pressure at the extend cylinder. Does the pressure gauge read 3350 psi 3350 psi (230 bar)?

Replace the counterbalance valve. Does the pressure gauge read 3350 psi (230 bar)?

Follow the Main Control Valve Pressure Troubleshooting procedure. Does the pressure gauge read 3350 psi (230 bar)?

Follow the Main Control Valve Pressure Troubleshooting procedure. Is the problem in the control valve?

Use an in-line flowmeter to test the pressure at the extend port of the lift cylinder. Does the pressure gauge read 3350 psi (230 bar)?

Remove the flowmeter.

Repair or replace the tilt cylinder.

Adjust the relief valve in the Main Control Valve. Open the load control valve of the flowmeter and hold the joystick in the boom lower position. Does the pressure gauge read 3350 psi (230 bar)?

YES

Remove the flowmeter.

Repair or replace the relief valve in the Main Control Valve.

Remove the flowmeter.

Remove and bench test the hydraulic gear pump. Does the hydraulic gear pump meet specifications?

Repair or replace the hydraulic gear pump.

Template Name: OML_1_col0-00000

Template Date: 1994_04_22

519 Telehandler HYDRAULICS

BOOM SLAVE CYLINDER/FORK SELF LEVEL TROUBLESHOOTING

Boom must be properly secured before any work is done on the slave cylinder or boom hydraulics.

Tilt does not self level with boom raise or lower operations. Complete Attachment Tilt Cylinder Troubleshooting, is tilt cylinder functioning normally? YES

Install an in-line pressure gauge on port C of the isolation valve (between main control valve and 65 psi [4.5 bar] check valve) Does the pressure gauge read 65 psi (4.5 bar) or higher? slave cylinder ports. Does the pressure gauge read 3500 psi (240 bar) or higher during boom up/down cycles? valve.

NO Replace the tilt cylinder.

Install an in-line pressure gauge on both Replace the 65 psi (4.5 bar) check Repair or replace the Isolation Valve. Repair or replace the Slave cylinder.

Template Name: OML_1_col0-00000

Date:

Steering Circuit Troubleshooting

Test the pressure at the test port on the battery tray for the Main Control Valve. Cramp the steering fully to the right or left. Does the pressure gauge read 2400 psi (165 bar)?

Use an in-line flowmeter to test the pressure at port R of the Steer Control Unit. Does the pressure gauge read 2400 psi (165 bar)?

Use an in-line flowmeter to test the pressure at the front right steer cylinder. Does the pressure gauge read 2400 psi (165 bar)?

Use an in-line flowmeter to test the pressure at port P of the Steer Valve. Does the pressure gauge read 2400 psi (165 bar)?

Repair or replace the Steering Control Unit.

Repair or replace the front steer cylinder. NO YES

Repair or replace the rear steer cylinder.

Repair or replace the Steer Mode Valve.

Test the pressure at the test port on the battery tray. Does the pressure gauge read 3350 psi (230 bar) with a NO YES control function bottomed out?

Use an in-line flowmeter to test the pressure at port PF of the Main Control Valve while adjusting the steering relief valve. Can 2400 psi (165 bar) be obtained?

Repair or replace the hydraulic gear pump.

Remove the in-line flowmeter Replace the steering relief valve. Does the pressure read 2400 psi (165 bar)? YES NO Remove the in-line flowmeter. Replace the Main Control Valve.

Template Name: OML_1_col0-00000

Template Date: 1994_04_22

519 Telehandler

MA07N010

Template Name: OML_1_col0-00000

Template Date: 1994_04_22 519 Telehandler

Template Name: OML_2_col0-00000

Template Date: 1994_04_22

519 Telehandler HYDRAULICS

Hydraulic System Testing

Pump Pressure Test

NOTE: Before performing any hydraulic test, check for any visible leaks or component damage. Repair or replace the leaking component before proceeding with the tests.

Step 1

Step 3

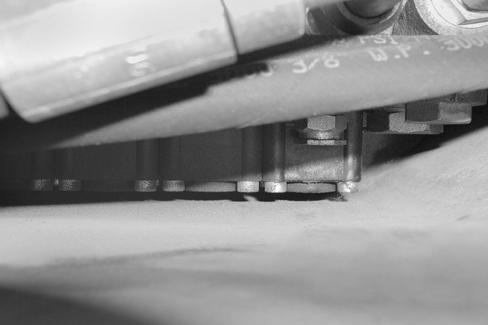

Loosen the nut (1) and turn the adjustment screw (2) clockwise to increase pressure.

NOTE: One turn is approximately 800 psi (55 bar).

Step 4

Connect a 5000 psi (350 bar) pressure gauge to the test port on the battery tray frame. With the engine running at full RPM and a hydraulic function bottomed out the gauge should read 3350 psi (230 bar).

WARNING: The hose must be long enough to read the gauge while standing clear of the forklift.

Step 2

If the pressure is less than 3350 psi (230 bar) remove the relief valve cap on the main control valve.

If the pressure is still less than 3350 psi (230 bar) shut off the engine and disconnect the pressure gauge (1). Remove the pump from the machine (2). Repair or replace the gear pump.

Lift Cylinder Test

Danger

Boom must be properly secured before any work is done on the lift cylinder or boom hydraulics.

Step 5

Step 7

Start the engine, set the park brake and raise the boom approximately 3 feet (1 meter). Shut off the engine.

NOTE: If the boom lowers while the engine is OFF then replace the counterbalance valve. If the boom still lowers then proceed to next step.

Step 6

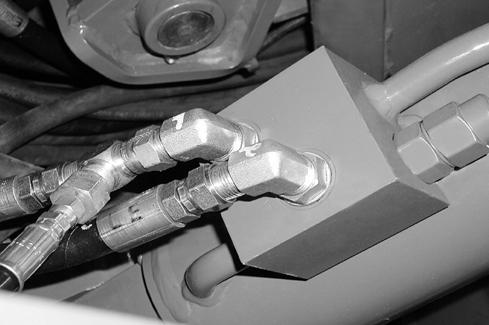

Remove the hose (1) from the left port (2) of the lift cylinder. Install a 3350 psi (230 bar) pressure gauge and hose (3) between the hose (1) and the port (2).

WARNING: The hose must be long enough to read the gauge while standing clear of the forklift.

Template Name: OML_2_col0-00000

Step 8

G1107011

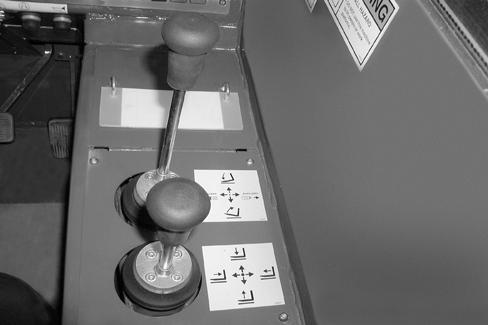

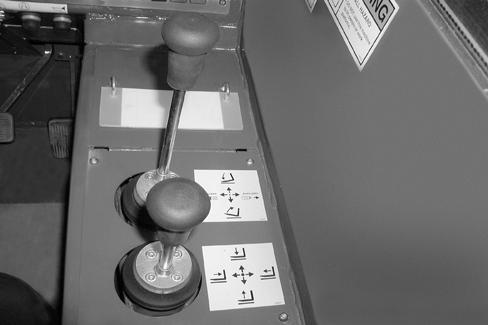

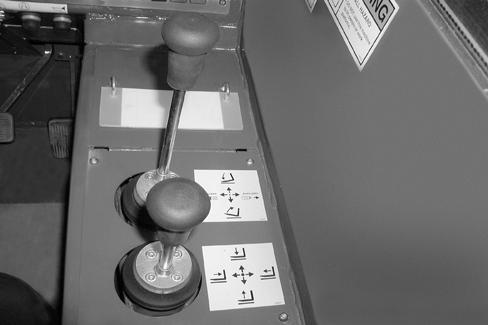

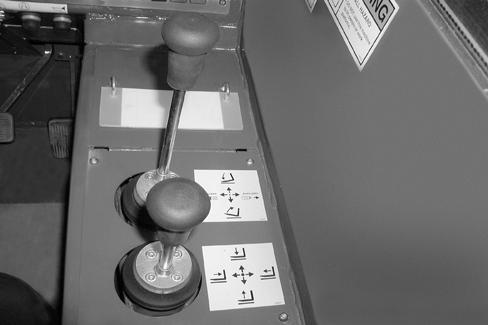

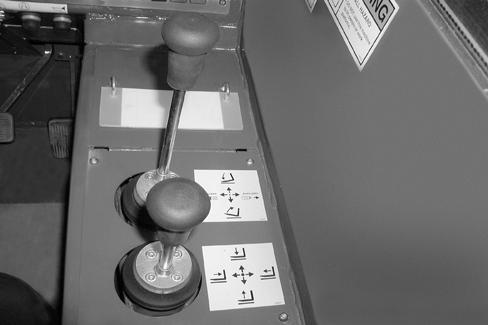

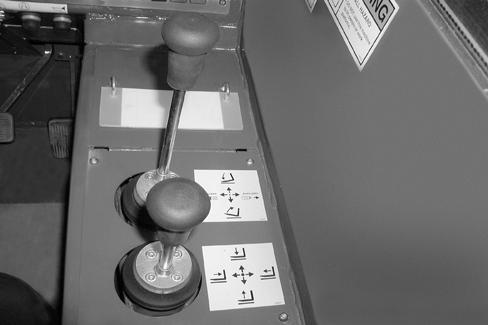

Start the engine and remove the support stand. Watch the pressure gauge and slowly move the joystick to the lower po sition. The pressure gauge should read 3350 psi (230 bar) when the boom reaches the lowered position.

If the pressure gauge reading steadily drops then replace or repair the cylinder.

If the pressure remains then repeat this process for the other port with the boom in the up position. Replace of repair the cylinder if it does not hold the pressure.

Step 9

G0907003

Start the engine and lower the boom onto a support stand. Shut off the engine.

Template Name: OML_2_col0-00000

Template Date: 1994_04_22

519 Telehandler HYDRAULICS

Tilt Cylinder Quick Test

STEP 10

Install a 5000 psi (350 bar) pressure gauge and hose on the test port on the battery tray frame.

WARNING: The hose must be long enough to observe the pressure gauge from inside the cab or standing clear of the forklift.

STEP 11

Start the engine and run at high idle. Retract the boom until the extend cylinder is at the end of its stroke and hold the joystick in the RETRACT position. The pressure gauge should read 3350 psi (230 bar).

IF the pressure is more or less than 3350 psi (230 bar) proceed to the Main Control Valve Pressure Relief Test and Adjustment section of this manual.

STEP 12

G1107011

Tilt the attachment mount up until the tilt cylinder reaches the end of its stroke and hold the joystick in the TILT UP position. The pressure gauge should read 3350 psi (230 bar).

If the pressure is at 3350 psi (230 bar), but the tilt cylinder does not work, check the hoses and steel tubes between the control valve and tilt cylinder or check the cylinder barrel for damage.

If the pressure is le ss than 3350 psi (230 bar) proceed to the next step.

Tilt Cylinder Direct Test

STEP 13

G1107023

Shut off the engine. Remove the hose (1) from the piston (tilt up) port (2) of the tilt cylinder. Cap the cylinder port. Install a 5000 psi (350 bar) pressure gauge (3) and hose on the cylinder supply hose.

WARNING: The hose must be long enough to read the gauge while standing clear of the forklift.

Step 14

Step 16

Start the engine and run at high idle. Hold the joystick into the TILT UP position. The pressure gauge should read 3350 psi (230 bar).

If the pressure is 3350 psi (230 bar), replace or repair the counterbalance valve. If the cylinder still does not move after reconnecting then repair or replace the tilt cyinder.

If the pressure is less than 3350 psi (230 bar), proceed to the next step.

Step 15

Shut off the engine. Re move the slave cylinder hydraulic hoses. Install plugs in the hose ends and caps on the cylinder fittings.

Step 17

Start the engine and run at high idle. Hold the joystick in the TILT UP position.

If the pressure gauge reads 3350 psi (230 bar), repair or replace the slave cylinder.

If the pressure is less than 3350 psi (230 bar), proceed to the next step.

STEP 18

Step 21

Replace

STEP 19

Repeat Step 15.

If 3350 psi (230 bar) cannot be reached by replacing the relief valve, repair or replace the isolation valve.

STEP 20

Shut off the engine. Remove the pressure gauge from the tilt up supply hose (1) and remove the cap from the cylinder port (2). Install the hose on the cylinder.

Remove the supply hose (1) from the rod (tilt down) port (2) of the tilt cylinder. Cap the cylinder port and install a 5000 psi (350 bar) pressure gauge and hose (3) on the cylinder supply hose.

WARNING: The hose must be long enough to read the gage while standing clear of the forklift.

STEP 22

Start the engine and run at high idle. Hold the joystick in the TILT DOWN position until the cylinder reaches the end of its stroke. Hold the joystick in the TILT DOWN position. The pressure gauge should read 3350 psi (230 bar).

Template Name: OML_2_col

Template Date: 1994_04_22