CHAPTER 14 OPTIONAL FEATURES & ACCESSORIES NOTE:

LIQUID SIDES

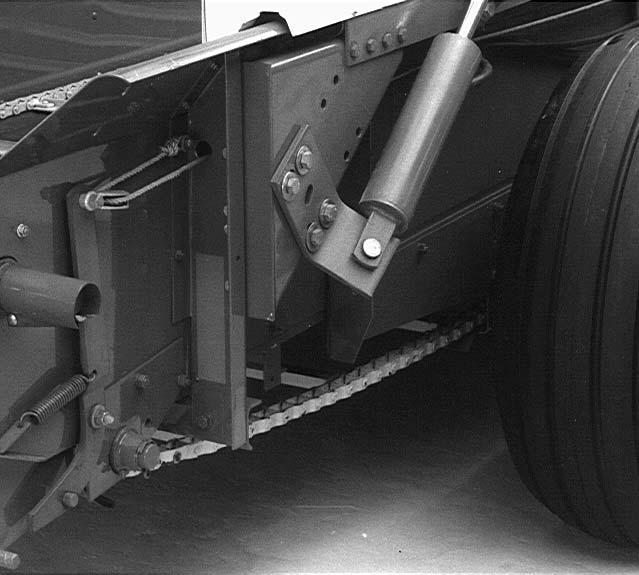

HYDRAULIC ENDGATE

Liquid sides are available for model 1177, 1217 and 1287 Spreaders. They will eliminate the many problems occurring when hauling soupy manure to the field in a box Spreader. The liquid sides must be used with the hydraulic endgate. The Litter Pan Kit should also be used for maximum effectiveness.

Installation information for all of the Optional Features & Accessories, described in this chapter, is provided in the Set-up & Assembly chapter, except for the safety chain, which is described in the Transporting chapter. See your Gehl dealer for proper kit numbers.

Hydraulic endgate packages are available to retain manure with a high liquid content. The endgate can be installed on a single beater Spreader or on a Spreader with the optional Upper Beater Kit installed.

HYDRAULIC FEED CONTROL This option allows the operator to hydraulically control the apron speed quadrant from the tractor cab.

LITTER PAN

With this kit, the feed control quadrant is stroked by the cylinder. With each stroke, the quadrant is advanced. An indicator decal indicates which feed notch is engaged. After advancing the quadrant, the cylinder should be returned to the starting position. This allows the quadrant to rotate backward slightly against the stop.

If the Spreader is going to be transported on public highways, a litter pan should be obtained and installed to prevent manure from falling out the back of the Spreader and onto the highway.

NOTE:

The litter pan is NOT designed to retain material with a high liquid content nor to support the weight of material during transit.

NOTE:

If the Spreader is equipped with both a hydraulic endgate and hydraulic feed control, the tractor used must have dual hydraulic outlets to operate two hydraulic cylinders.

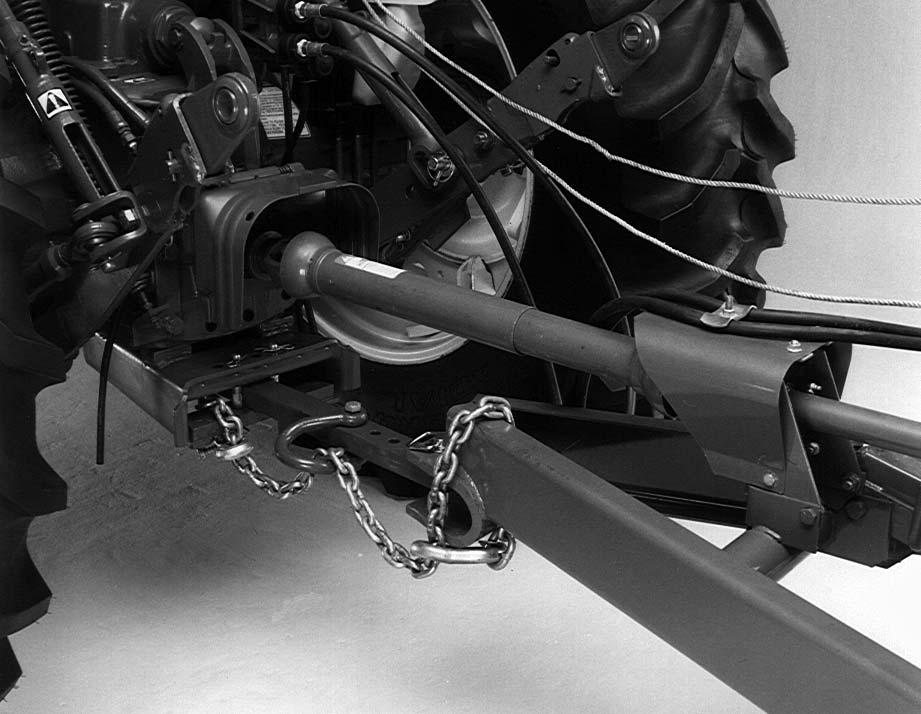

SAFETY CHAINS If the Spreader is going to be transported on public highways, a Safety Chain Kit should be installed, per details in the Transporting chapter. The kit includes a safety chain, a clevis and appropriate attaching hardware. Consult your dealer for the proper size safety chain for your individual Spreader.

SECOND BEATER & DRIVE ASSEMBLY As needed, the Spreader can be equipped with a second beater and drive assembly. The beater and drive assembly is designed to be installed on a Spreader to improve spreading high-piled solid manure.

SHEAR BOLTS Shear bolts for the apron transmission shear device is contained in a single shear bolt package. The shear bolt package contains (8) 3/8 x 1-1/2″ (9.5 mm x 38 mm) Grade 5 shear bolts and locknuts.

SLOW SPEED APRON SPROCKET

SPLASH SHIELD

A slow speed apron drive sprocket is available through service parts. The sprocket will slow the speed of the apron for lighter applications of manure.

The Spreader can be equipped with a Splash Shield Kit to prevent high liquid content manure from spilling over the front of the Spreader while traveling to the field. The splash shield can be conveniently attached to the top front edge of the Spreader using the hardware provided.

Speeds will be slowed from 4.5 fpm (137 cm/min) to 2.2 fpm (68 cm/min) on the 1177, 1217 and 1287 model Spreaders, and from 4.6 fpm (140 cm/min) to 3.0 fpm (91 cm/min) on the 1410 model Spreader in the slow speed position.

907540/DP0704

54

Printed in U.S.A.