BI619026

Your safety _________________________________________________ If hydraulic hose couplers are difficult to disconnect or cannot be disconnected, the hydraulic line may still be pressurized. Be sure to depressurize the line before disconnecting couplers. Secure the connectors of the hydraulic elements only with the proper coupling clamps. Always fasten the clamps completely and with both sides. Never use nails, wire or similar materials for securing. After finishing repair work, check all connectors and connections for leaks before pressurizing the system again.

permissible hoses

Use only hydraulic hoses approved for the prevailing pressures. Do not use any hydraulic hoses with damaged connectors or worn orings. Replace hydraulic hoses only with hoses of the same or a higher quality.

© DBT AMERICA 2005

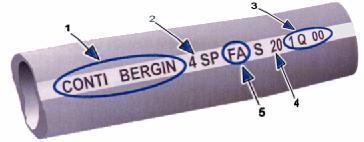

Observe the date of manufacture stamped on the hydraulic hoses. Never use hydraulic hoses which are more than 2 years old, even if they have no visible signs of damage.

1. manufacturer 2. hose type 3. date of manufacture 1st quarter 2000

4. nominal diameter 5. flame-resistant and antistatic

Never try to hold a jumping hydraulic hose. Depressurize the line in question immediately. Never try to repair damaged hydraulic hoses. Replace hydraulic hoses at the first suspicion of damage.

________________________________________________________________ 2.8 VUVR / 03___ DBT – 25M SERIES CONTINUOUS MINER ©