1 minute read

conveyor assembly installation / removal—see figure 38 & 39 5

¢ Electrical system for damage, malfunctioning components, and loose or corroded connections ¢ The methane monitor is maintained according to manufacturers and regulatory specifications. ¢ Trailing cable connection at the power center of r permissibility according to Federal Regulations ( Part 75, Title 30 ). ¢ All lubrication fittings and plugs for proper installation as well as damage

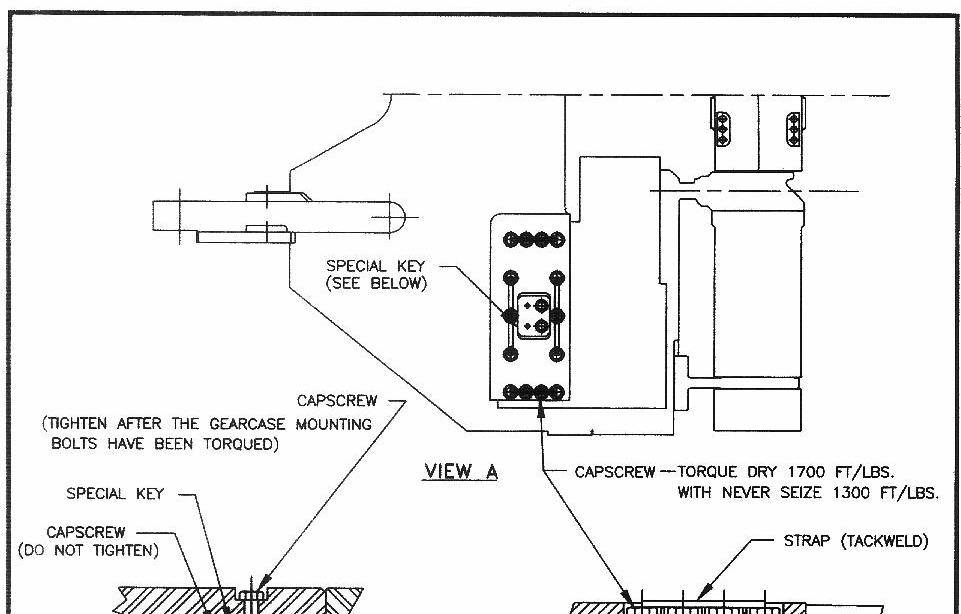

¢ All bolts and capscrews, and tighten as necessary ¢ All chain tensions, and adjust as necessary ¢ Drum drive clutch, and adjust as necessary ¢ Tram track tension, and adjust track take-up cylinder as needed ¢ Required hydraulic pressures, and make corrections to the hydraulic system by readjusting the appropriate relief valves ¢ Gathering head hinge pins for excessive movement, and adjust as necessary ¢ Conveyor tension springs for proper expansion and contraction during conveyor operation, and adjust as necessary.

¢ Return filter element ¢ Pilot circuit primary oil filter

¢ Clean all debris from motor frames ¢ Clean all heat exchangers ¢ Inspect motor bearings for lubricant leakage ¢ Check temperatures of bearings and frames ¢ Start motor and confirm that it accelerates to operating speed in an appropriate time ¢ Listen to the running motor for any unusual noises

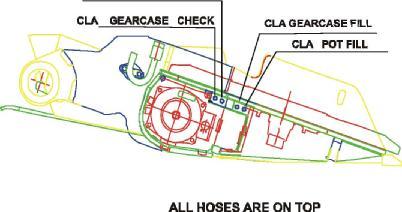

Drain and Fill lubricant in all gear cases (drum drive, gathering head, tram primary planetary, tram secondary planetary). Take oil sample prior to draining. Send Sample to DBT America for analysis. To gather the oil Sample for analysis please follow the following steps outlined on the following page.

check daily

replace when necessary

electric motor maintenance

every month

© DBT AMERICA 2005