1 minute read

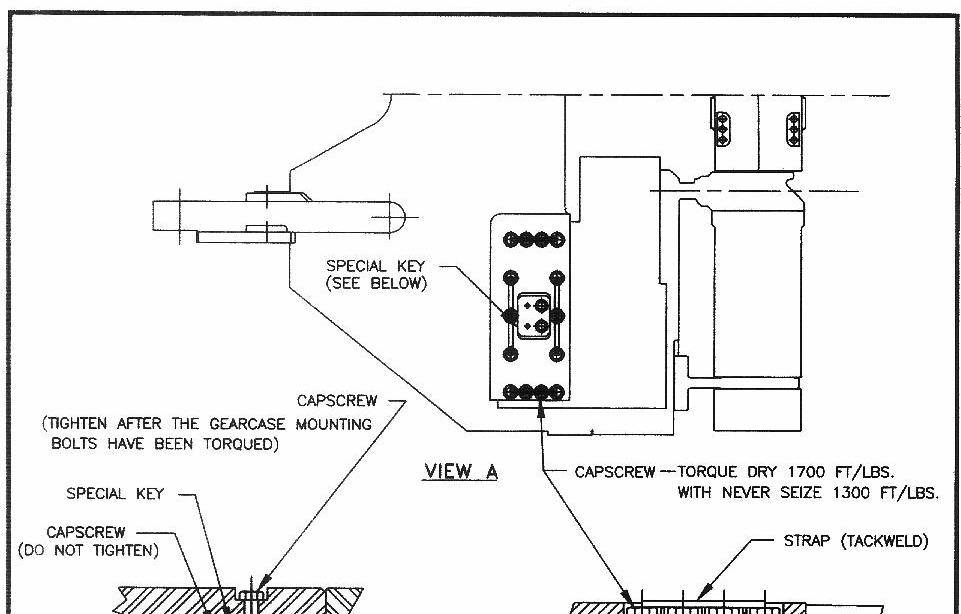

swivel pin installation / removal—see figure-41 5

electrical motor maintenance

every three months

¢ Clean motors thoroughly. ¢ Inspect couplings, belts, belt guards, mounting frame bolts, end-shield bolts, and mechanical fastenings for mechanical soundness and tightness ¢ Check end play of rotor shaft ¢ Operate motors at normal load and temperature ¢ Measure and record motor insulation resistance and temperature ¢ The DC tram motors require regular preventive maintenance.

Inspect the commutator, cable rigging, and brushes. The commutator should be dark brown with no signs of burning.

Check for brush wear and spring tension. replace all of the brushes when replacement is necessary.

Replace oil reservoir breather.

every six months

annually

Lubricate the right and left cutterhead motor bearings (front and rear).

¢ Clean motor thoroughly. ¢ Lubricate ball bearings, if required. Record the date the motor was lubricated. ¢ Inspect all gaskets, particularly lubricant seals, and replace as needed. ¢ Check operating speed. ¢ Inspect and tighten all electrical connections ¢ Inspect fans for loose or damaged blades ¢ Run motor and examine drive for smooth operation and lack of excessive Vibration. ¢ Check current readings and compare with normal value on motor nameplate and previously recorded values ¢ Check motor mounts, end-shields, couplings, and shaft keys for looseness. ¢ Inspect all covers, belt guards, and other guards for damage, and tighten until securely fastened.

Drain, flush, and refill the entire hydraulic system.

¢ Inspect all windings and insulation ¢ Clean and repair insulation as needed ¢ Measure resistance and record ¢ Check for and remove any magnetic particles

© DBT AMERICA 2005