1 minute read

hydraulic pump motor installation / removal—see figure 13 5

lubricate every shift

¢ Cutter head shear cylinder ¢ Cutter head shear cylinder pin (left and right) ¢ Cutter head shear cylinder to frame pin (left and right) ¢ Cutter head pivot pin (left and right) ¢ Conveyor roller

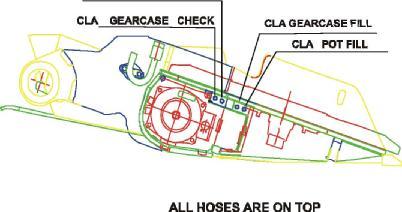

¢ Trailing cable for breaks or cracks in the cable cover ¢ Lighting systems for damage ¢ Conveyor flights for excessive wear or damage, and replace as necessary ¢ Cutter head mining bits for wear or damage, and replace as necessary ¢ Scrubber spray nozzles for blockage ¢ Check the lubrication levels of all the following components and fill as necessary: ¢ Gear cases (drum drive, gathering head, tram primary planetary, tram secondary planetary, tram idler) ¢ Tram drive (left and right) ¢ Drum drive (front and back, left and right) ¢ Front roller (left and right, tram idler) ¢ Lubricant levels of the oil reservoir ¢ Hydraulic fluid levels

¢ Gathering head lift cylinder ¢ Gathering head hinge pin ¢ Gathering head foot shaft ¢ Conveyor chain take-up pin ¢ Conveyor chain take-up locknut ¢ Conveyor swivel pin (upper and lower) ¢ Conveyor swing cylinder jack pins (front and rear) ¢ Conveyor-to-tractor frame pin ¢ Tractor frame stabilizer shoe pins (left and right) ¢ Clean and remove accumulated sludge: ¢ Scrubber filter screens ¢ Scubber inlet duct work ¢ Mist eliminator and sump

¢ All seals for leakage ¢ Gear case breathers (primary, gathering head) for airflow obstructions ¢ Entire front end for damage, and tighten all hardware ¢ Tram track for missing parts, wear, or damage ¢ All sprockets and idlers for wear or damage ¢ Hydraulic lines for wear and damage ¢ Drive sprocket shear pin bushings for wear/ damage