MAINTENANCE PROCEDURES AT 500 HOURS OR 6 MONTHS Maintenance Procedures - Overview General Information All maintenance checks and inspections listed in previous maintenance intervals must also be performed at this time, in addition to those listed under this maintenance interval.

Fuel Filter (Spin-On Type) General Information Cummins Common Rail Fuel System The Cummins Common Rail fuel system requires the use of two fuel filters. The suction side filter must have the following characteristics: •

water-separating

•

10-micron rating

•

water-drain valve

•

always chassis mounted.

Fleetguard FS1003 meets these requirements. The pressure side filter must have the following characteristics: •

3-micron rating

•

engine mounted or chassis mounted.

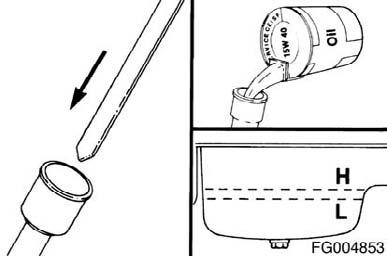

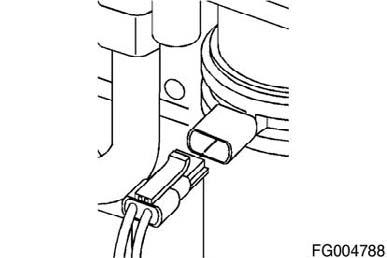

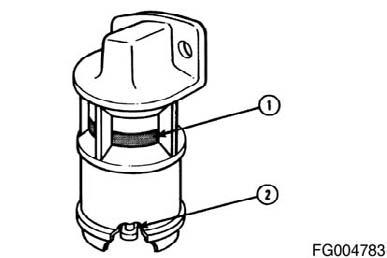

Fleetguard FF5580 meets these requirements. Refer to Section E for Engine Identification. The CM850 engine uses the Cummins Common Rail fuel system. Remove Disconnect the wiring harness from the fuel heater, if equipped as a option of pre-fuel filter. Loosen and remove the fuel filter. Make sure the seal ring does not stick to the filter head. Remove the ring with an O-ring pick, if necessary.

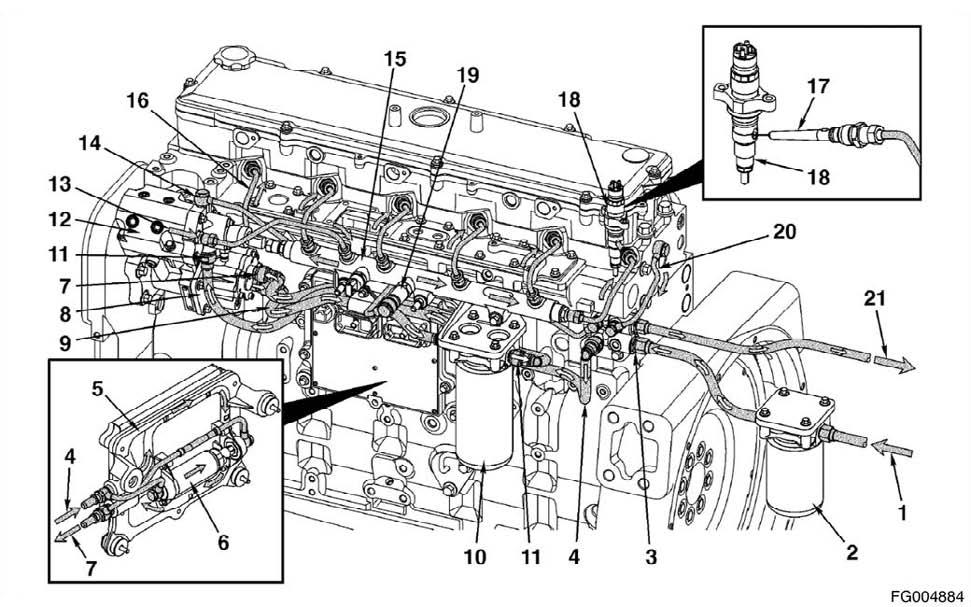

Figure 71

QSL9CumminsEng

QSL9 Cummins Engine Page 75