1 minute read

Months

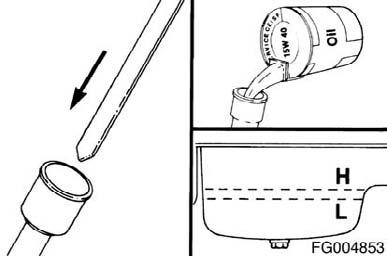

For additional lubricating oil recommendations and oil pan capacity information, refer to Maintenance Specifications (Section V).

MAINTENANCE PROCEDURES AT 250 HOURS OR 3 MONTHS

Maintenance Procedures - Overview

General Information

All maintenance checks and inspections listed in previous maintenance intervals must also be performed at this time, in addition to those listed under this maintenance interval.

Air Cleaner Restriction

Maintenance Check

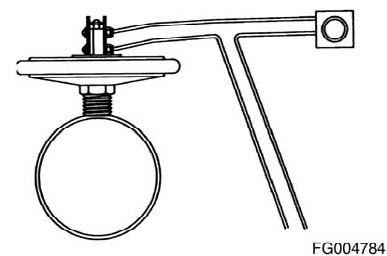

Mechanical Indicator NOTE: Do not remove the felt washer from the indicator. The felt washer absorbs moisture. A mechanical restriction indicator is available to indicate excessive air restriction through a dry-type air cleaner. This instrument can be mounted in the air cleaner outlet or on the instrument panel. The red flag (1) in the window gradually rises as the cartridge loads with dirt. After changing or replacing the cartridge, reset the indicator by pushing the reset button (2). Restriction or vacuum indicators need to be installed as close as possible to the turbocharger air inlet in order to obtain a true indication of restrictions.

CAUTION!

Never operate the engine without an air cleaner. Intake air must be filtered to prevent dirt and debris from entering the engine and causing premature wear. Figure 66

QSL9 Cummins Engine Page 72 QSL9CumminsEng

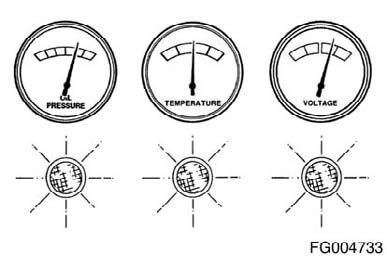

Vacuum Indicator Vacuum switches actuate a warning light on the instrument panel when the air restriction becomes excessive.

Figure 67

Charge-Air Cooler

Maintenance Check

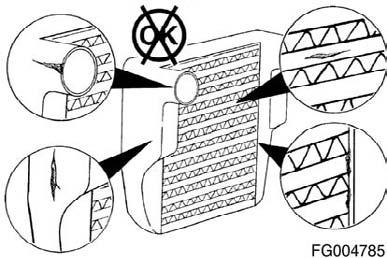

Inspect the charge-air cooler (CAC) for dirt and debris blocking the fins. Check for cracks, holes, or other damage. If damage is found, refer to the vehicle, vessel, or equipment manufacturer.

Figure 68

Charge-Air Piping

Maintenance Check

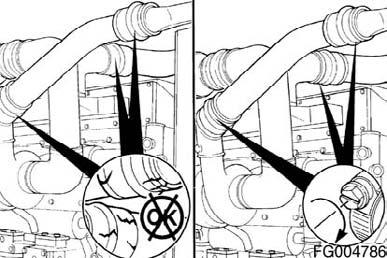

Inspect the charge-air piping and hoses for leaks, holes, cracks, or loose connections. Tighten the hose clamps if necessary. Refer to the vehicle or equipment manufacturer's specifications for the correct torque value.

Figure 69

QSL9CumminsEng QSL9 Cummins Engine Page 73

Maintenance Check

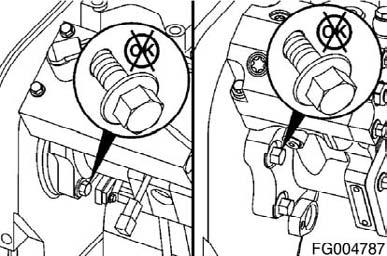

Inspect the fuel injection pump mounting nuts, including the support bracket, for loose or damaged hardware.