3 minute read

Maintenance Guidelines

Maintenance Guidelines - Overview

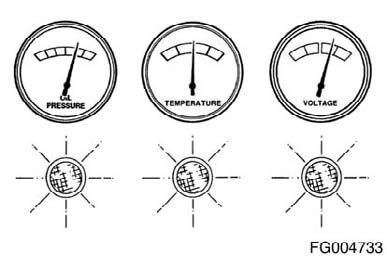

Cummins Inc. recommends that the engine be maintained according to the Maintenance Schedule in this section. If the engine is operating in ambient temperatures below -18°C [0°F] or above 38°C [100°F], perform maintenance at shorter intervals. Shorter maintenance intervals are also required if the engine is operated in a dusty environment or if frequent stops are made. Contact your authorized dealer and local Cummins Authorized Repair Location for recommended maintenance intervals. Some of these maintenance procedures require special tools or must be completed by qualified personnel. Contact your local Cummins Authorized Repair Location for detailed information. If your engine is equipped with a component or accessory not manufactured by Cummins Inc., refer to the component manufacturer's maintenance recommendations. Use the chart provided in this section as a convenient way to record maintenance performed.

Tool Requirements

Most of the maintenance operations described in this manual can be performed with common hand tools (metric and S.A.E. wrenches, sockets, and screwdrivers). The following is a list of special service tools required for some maintenance operations:

Tool Part Number Description

ST-1273 Pressure gauge 3375045 Torque wrench (0 to 175 ft-lb) 3375049 Oil filter wrench 3376807 Engine coolant and fuel filter wrench 3822524 Belt tension gauge, click type (v-belts and v-ribbed with 4 or 5 ribs) 3822525 Belt tension gauge, click type (v-ribbed with 6 to 12 ribs) 3824556 Charge air cooler (CAC) pressure kit 3824591 Engine barring gear 3824783 Torque wrench (0 to 300 in-lb)

CC-2800 Refractometer

CC-2802 Coolant test kit 3824842 M10 Compuchek fitting

Contact your authorized dealer and nearest Cummins Authorized Repair Location for the required service tools.

QSL9 Cummins Engine Page 64 QSL9CumminsEng

A computer is required to run the OEM software. Contact your authorized dealer and Cummins Authorized Repair Location for information on hardware requirements.

Maintenance Schedule

Perform maintenance at whichever interval occurs first. At each scheduled maintenance interval, perform all previous maintenance checks that are due for scheduled maintenance.

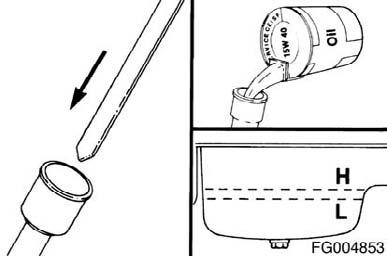

Daily or Refueling - Maintenance Check

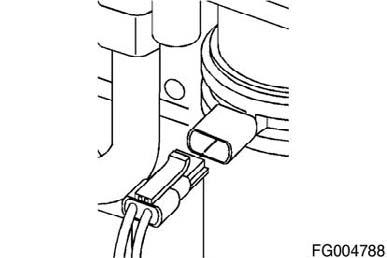

Section 3 Air Intake Piping - check Every 250 Hours or 3 Months Cooling Fan - check Crankcase Breather Tube - check Engine Coolant Level - check Fuel-Water Separator - drain Engine Lubricating Oil Level - check Section 4 Air Cleaner Restriction - check Every 500 Hours or 6 Months Charge Air Piping - check Charge Air Cooler - check Fuel Injection Pump Mounting - check Section 5 Fuel Filters (Cummins and OEM supplied) - replace Every 1,000 Hours or 1 Year Cooling System - check Coolant Filter - replace Lubricating Oil Filter and Oil - replace Batteries - check Battery Cables and Connections - check Section 6 Drive Belts - check Every 2,000 Hours or 2 Years Fan Hub Belt Driven - check Cooling Fan Belt Tensioner - check Section 7 Cooling System - drain/flush/fill Every 5000 Hours or 4 Years Vibration Damper, rubber - check Vibration Damper, Viscous - check Engine Steam Cleaning - clean Engine Mounts - check Section 8 Overhead Set - adjust

QSL9CumminsEng QSL9 Cummins Engine Page 65

Severe Heavy Medium

Fuel Consumption > 25 (liter /h) 20 to 25 (liter/h) < 20 (liter /h) > 6.6 (gallon/h) 5.5 to 6.6 (gallon/h) < 5.3 (gallon/h)

ACEA E5 (API CH-4) CES 20076 250 300 500

ACEA E5 (API CI-4) CES 20078 250 350 500

1. Limit oil change interval to 250-hour maximum for oil grades if 40% of the operating time is in ambient temperatures above 38°C (100°F) to prevent engine damage to oil degradation resulting from high oil temperature. 2. We don't recommended the use of CF or CG grade oils. If CF or CG oil must be used, make the oil drain intervals half of the API CH-4 values. 3. Engine oil drain intervals need to be reduced by 50% when fuel sulfur content exceeds 0.5% (5,000 ppm) 4. Oil filters must CES 10065 (Cummins Engineering Spec.) specifications. Fleetguard LF9009 meets and exceeds these requirements. 5. Valvoline Premium Blue meet CES 20076 standards. - recommended in North America.