www.classicmachinery.net

AVEKY A-R-V-K4MBF-MMBG-MMY

Paragraphs 3-5

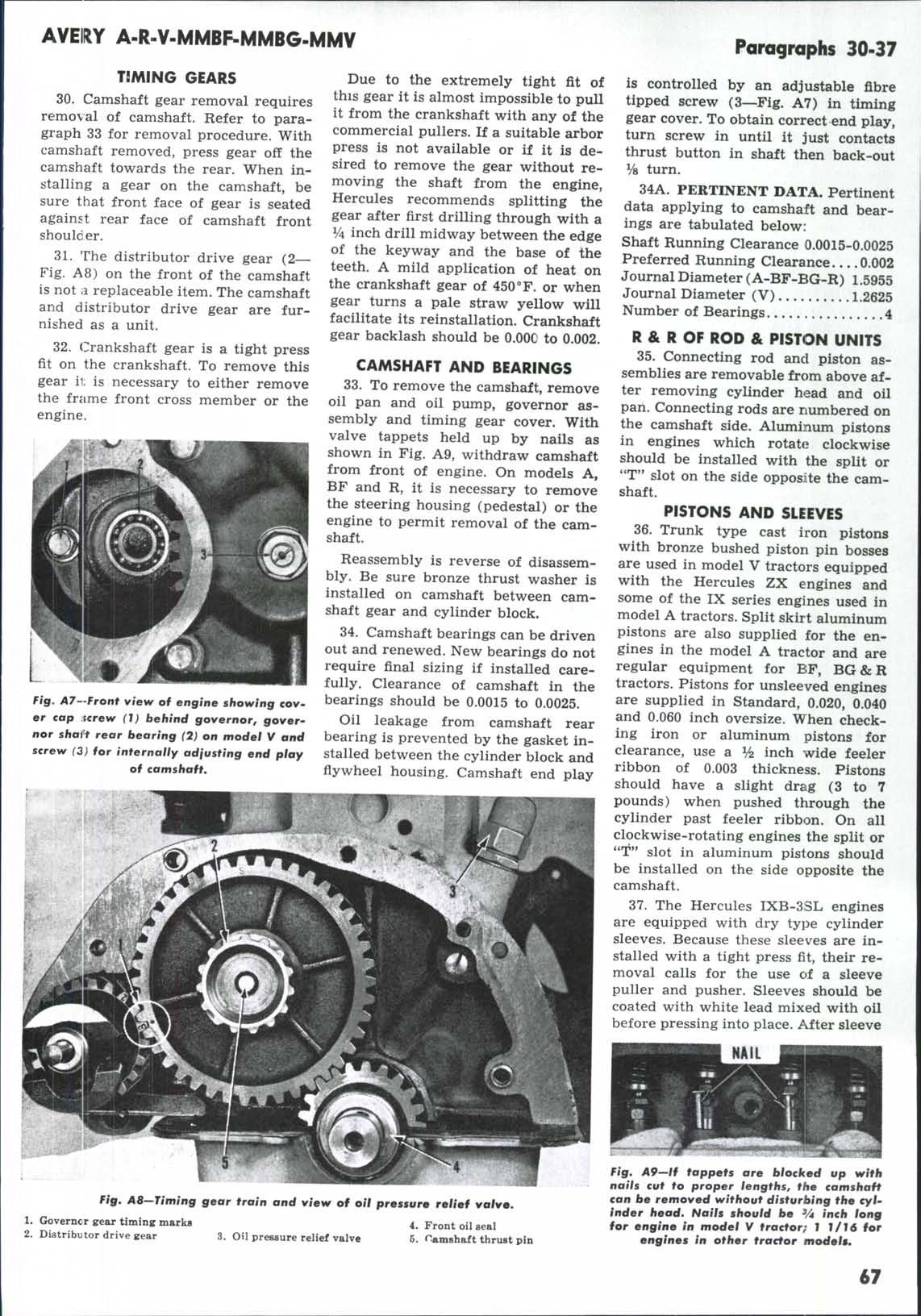

STEERING, TRICYCLE & AXLE TYPES Models A-BF-R On early production triqfde type tractors, the wheel carrying element is integral with the ste&ring vertical spindle as shown in Fig. A2. On letter production tricycle type tractors, the fork (23—Fig. A4) or lower spindle assembly (51) is detachably bolted to the steering vertical spindle (29A). Two adjustments are provided namely the uppier spindle (worm wheel shaft) end play aitd the steering worm end play. Excessive backlash in the gear is corrected by repositioning the worm wheel on its splines or by renewal of the mating gears. Worm wheel shaft (vertical spindle) and wormshait are carried in adjustable type roUer bearings.

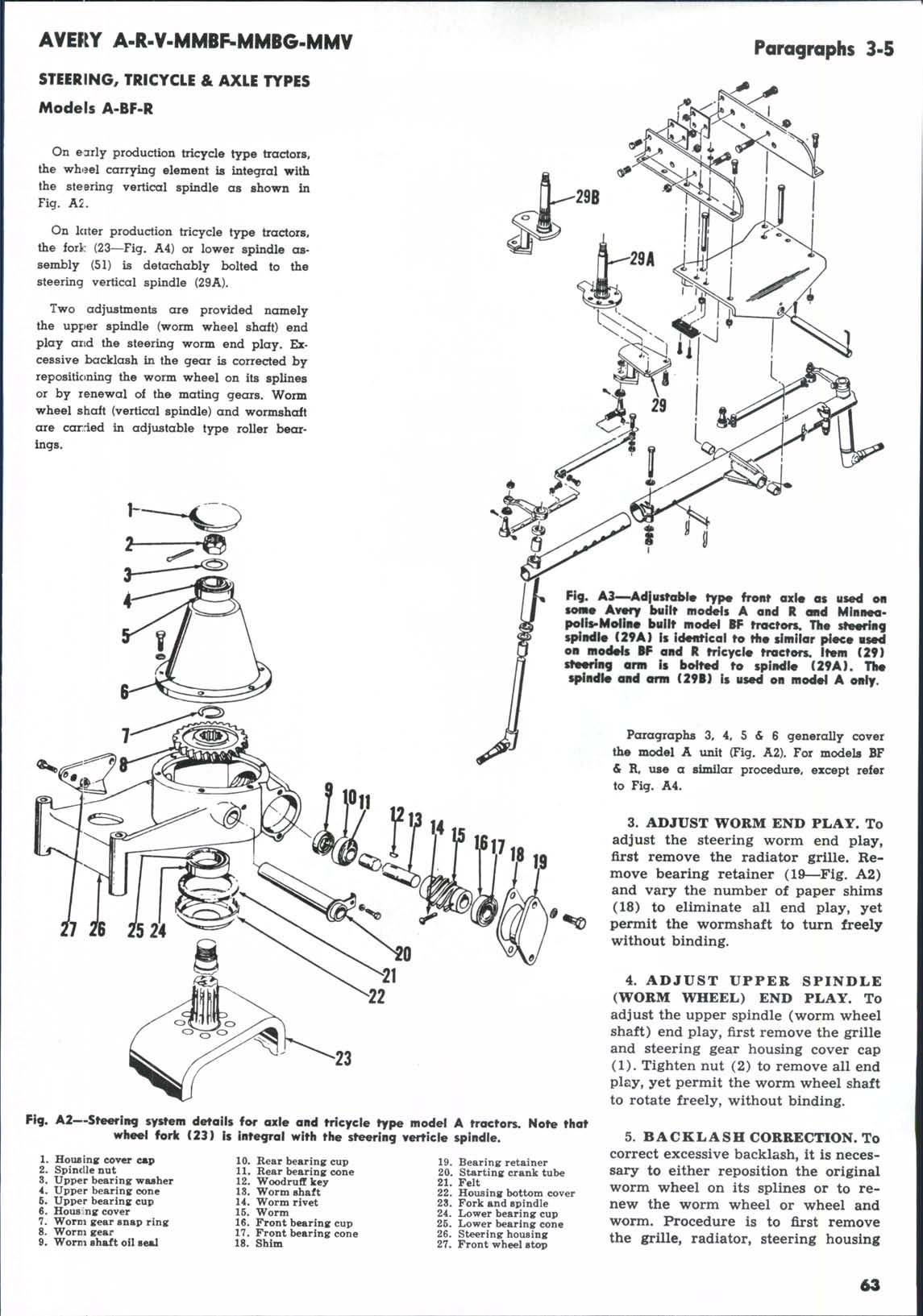

Fig. A3^Adiuttable type front axle as used on some Avwy built models A and R and i^inneapolis-Moliii# built model W tractors. The steering spindle (29A) is idenHcai to the similar piece usMi on models BF and R trieyeie tractors, itmn (29) steering arm is bolted to spindle (29A). The spindle and arm (29B) is used on modd A oiriy.

Paragraphs 3, 4, 5 & 6 generally cover the model A unit (Fig. A2). For models BF & R« use a similar procedure, except refer to Fig. A4.

3. ADJUST WORM END PLAY. To adjust the steering worm end play, first remove the radiator grille. Remove bearing retainer (19—Fig. A2) and vary the number of paper shims (18) to eliminate all end play, yet permit the wormshaft to turn freely without binding. 4. ADJUST UPPER SPINDLE (WORM WHEEL) END PLAY. To adjust the upper spindle (worm wheel shaft) end play, first remove the grille and steering gear housing cover cap (1). Tighten nut (2) to remove all end play, yet permit the worm wheel shaft to rotate freely, without binding.

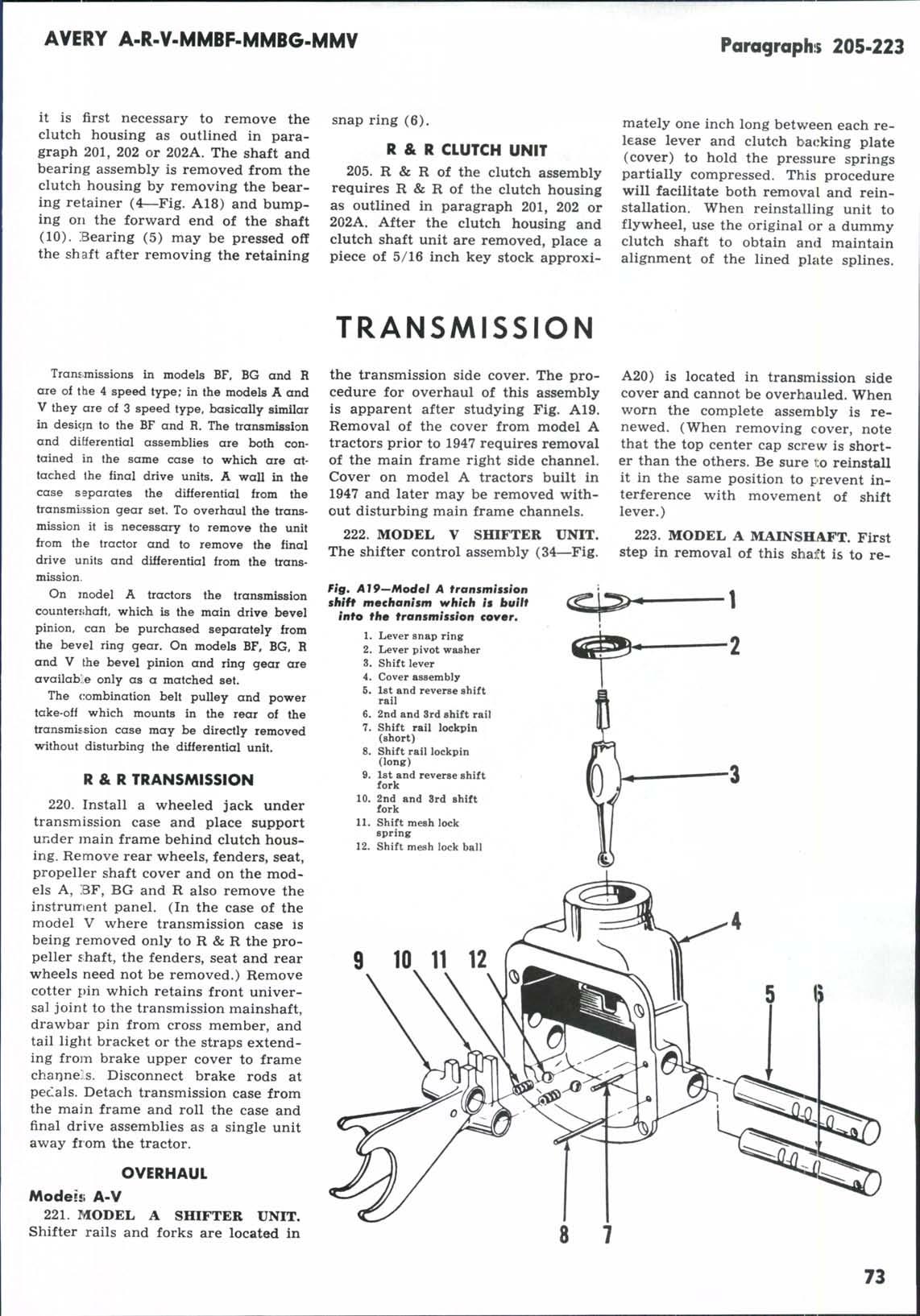

23 A2—Steering system details for axie and trieyeie type model A tractors. Note that wheel fork (23) it integral with the steering vertiele spindle. 1. 2. 3. 4. 5. 6. 7. 8. 9.

Hoiuing cover c«p Spindle nut Upper bearinar waaher Upper bearing cone Upper bearins cup Hou8:!n2 cover Worm eear snap rin^ Worm s:ear Womi shaft oil seal

10. 11. 12. IS. 14. 15. 16. 17. 18.

Rear bearing cup Rear bearing cone Woodruff key Worm shaft Worm rivet Worm Front bearing cup Front bearing cone Shim

19. 20. 21. 22. 23. 24. 2fi. 26. 27.

Bearing retainer Starting crank tube Felt Housing bottom cover Fork and spindle Lower bearing cup Lower bearing cone Steering bousing Front wheel stop

5. BACKLASH CORRECTION. To correct excessive backlash, it is necessary to either reposition the original worm wheel on its splines or to renew the worm wheel or wheel and worm. Procedure is to first remove the grille, radiator, steering housing

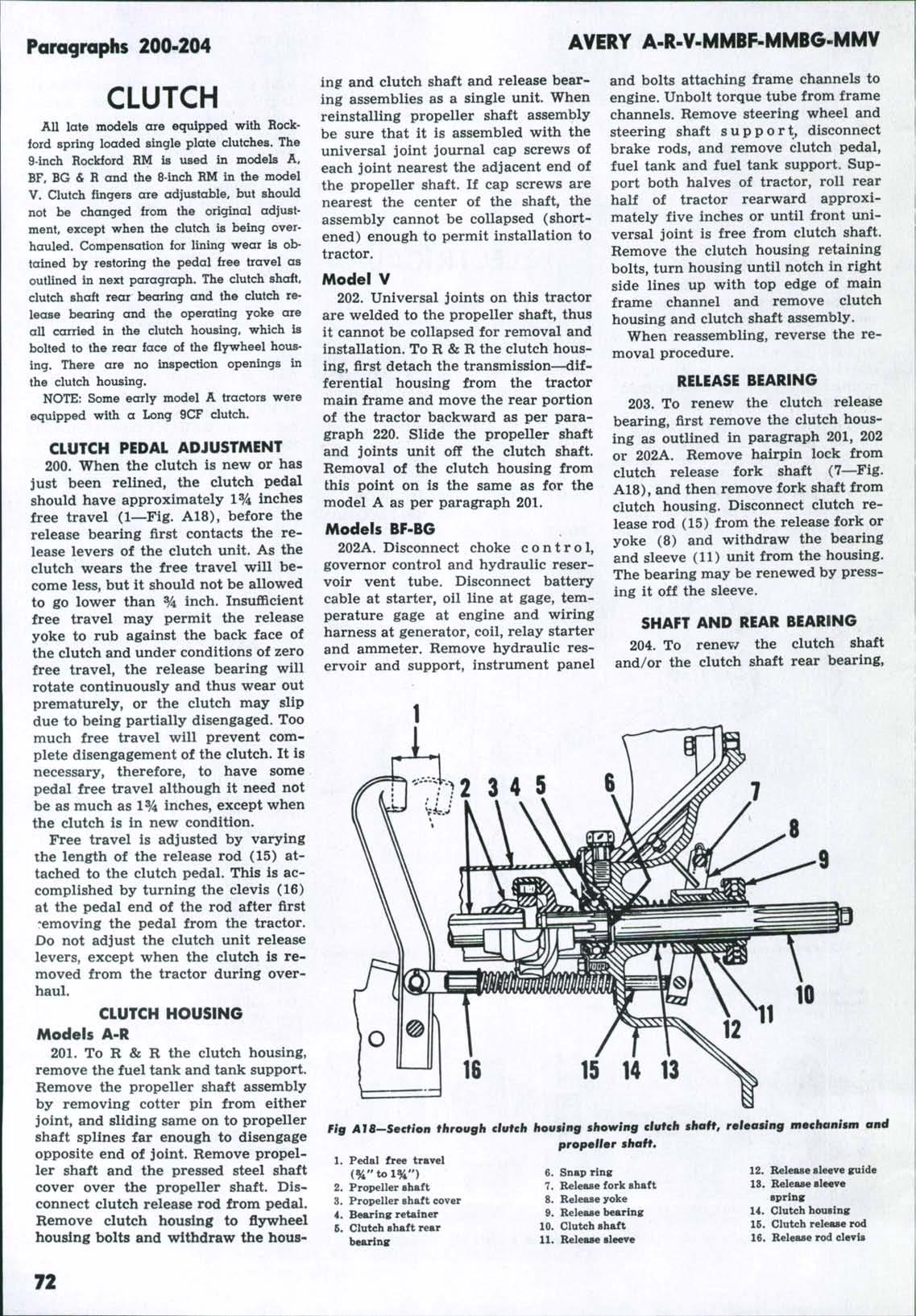

63