3 minute read

Front bearing cup

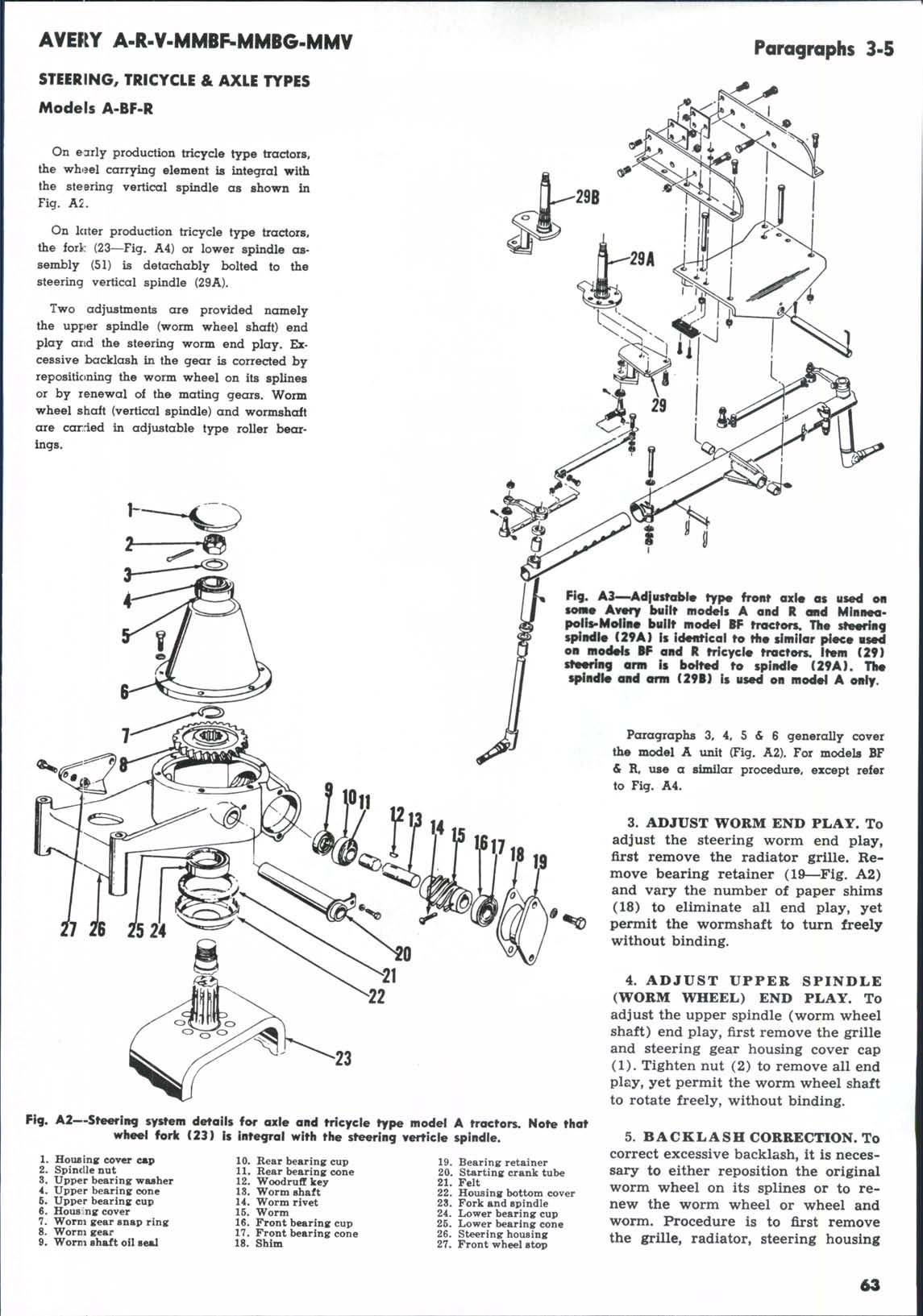

Wh€!n shaft is reinstalled, adjust the bearings by varying the shims (28) which are furnished in the three thicknesses of 0.004, 0.007 and 0.010. Desired bearing adjustment is an end play of 0.002-0.005. Install oil seal (27) with lip facing toward inside of case.

229. BEVEL PINION (COUNTERSHAFT) SHAFT. This shaft cannot be purchased separately. It is sold only in combination with the bevel ring gear as a matched set. To remove this shaft from the transmission, it is necessary to first remove the transmissio:i and final drives as a unit from the tractor as outlined in paragraph

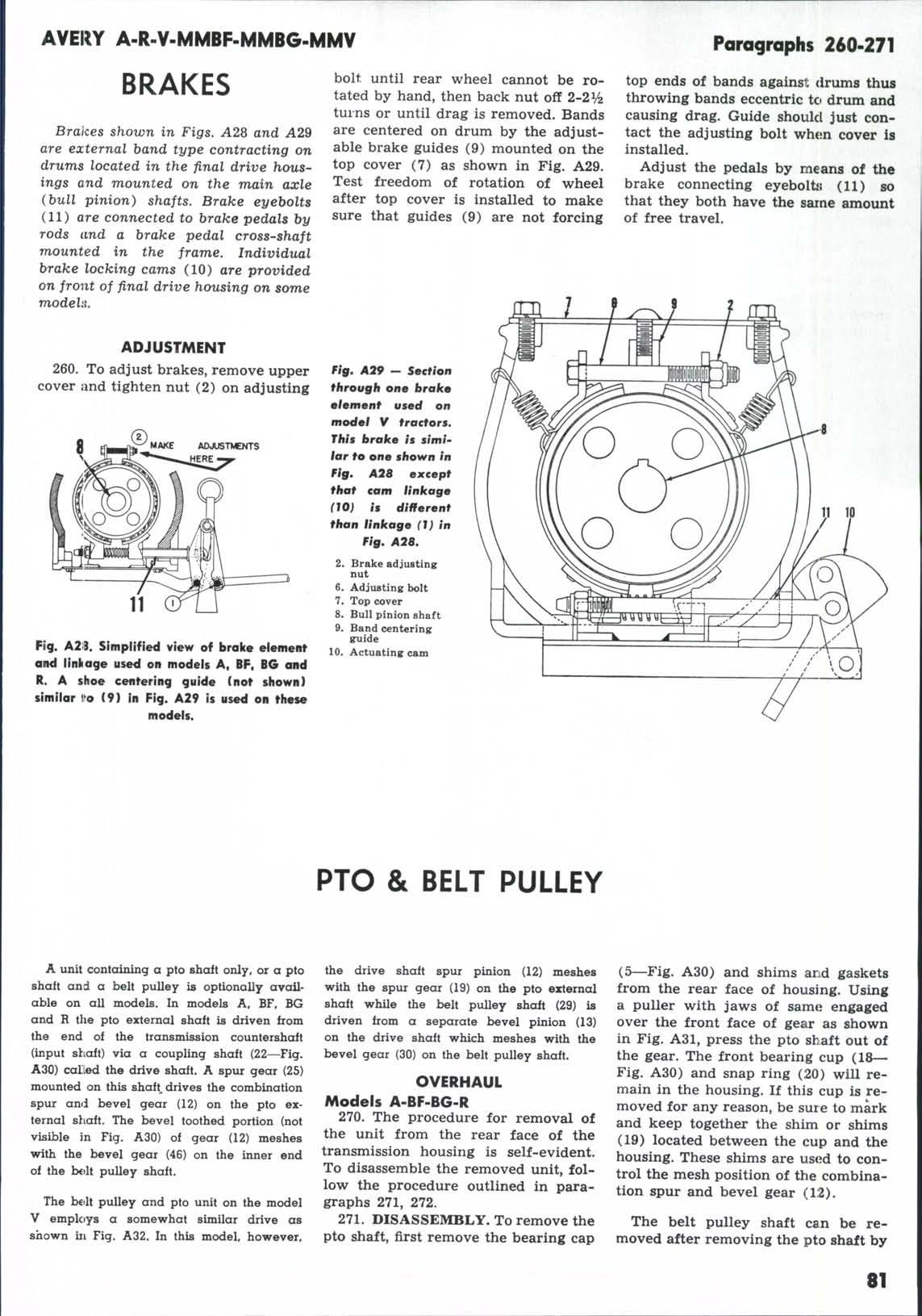

Diiierential unit is oi the two-pinion open in the transmission case. The bevel ring gear is held to the one-piece differential case b^' rivets in the models A, BF, BG and R and by cap screws in the model V. R & R AND OVERHAUL

231. To remove the differential assemblj-^ from the transmission case, first detach the final drive units from the transmission case as per paragraph 250 and remove the rear cover or com220. Unbolt both of the final drive units from the transmission case. Remove the side cover and the rear cover or combination belt pulley and pto unit from rear of case. Remove the differential bearing carriers from transmission case and lift out the differential unit. Be careful not to mix the carrier shims. Remove front bearing cap (32) and bearing adjusting nut (34). Bump the shaft rearward until front bearing cone (35) is forced off shaft. Bump shaft rearward and

DIFFERENTIAL

off if used. Remove differential bearing carriers (6—Fig. A24) and lift mission case. 232. To disassemble differential, remove pinion pin lockpin (5) by drivpin (4), pinions (2) and side gears (13). When reassembling, be sure to lock the pinion pin lockpin in case by out of case and withdraw gears through side cover opening.

The pre-sized bushing (39) for the 4th speed gear is renewable. The fore and aft or mesh position of the pinion shaft is not adjustable. 'V^^'hen reinstalling shaft to case tighten the bearing adjusting nut (34) until a very slight rotational drag is obtained. If drag cannot be obtained remove a shim (37). Lock the adjusting nut by staking a section of it into the groove in shaft. 230. REVERSE IDLER. The bevel pinion shaft must be removed as per paragraph 229 before the reverse idler lock plate (3) and bump shaft out of case. The pre-sized bushing (6) for the gear is renewable.

case type mounted back of a dividing wall

bination belt pulley and power take

differential unit from rear of transing out of differential case (11) with a thin drift punch, then remove pinion can be removed. Remove reverse idler

burring sides of hole with a punch.

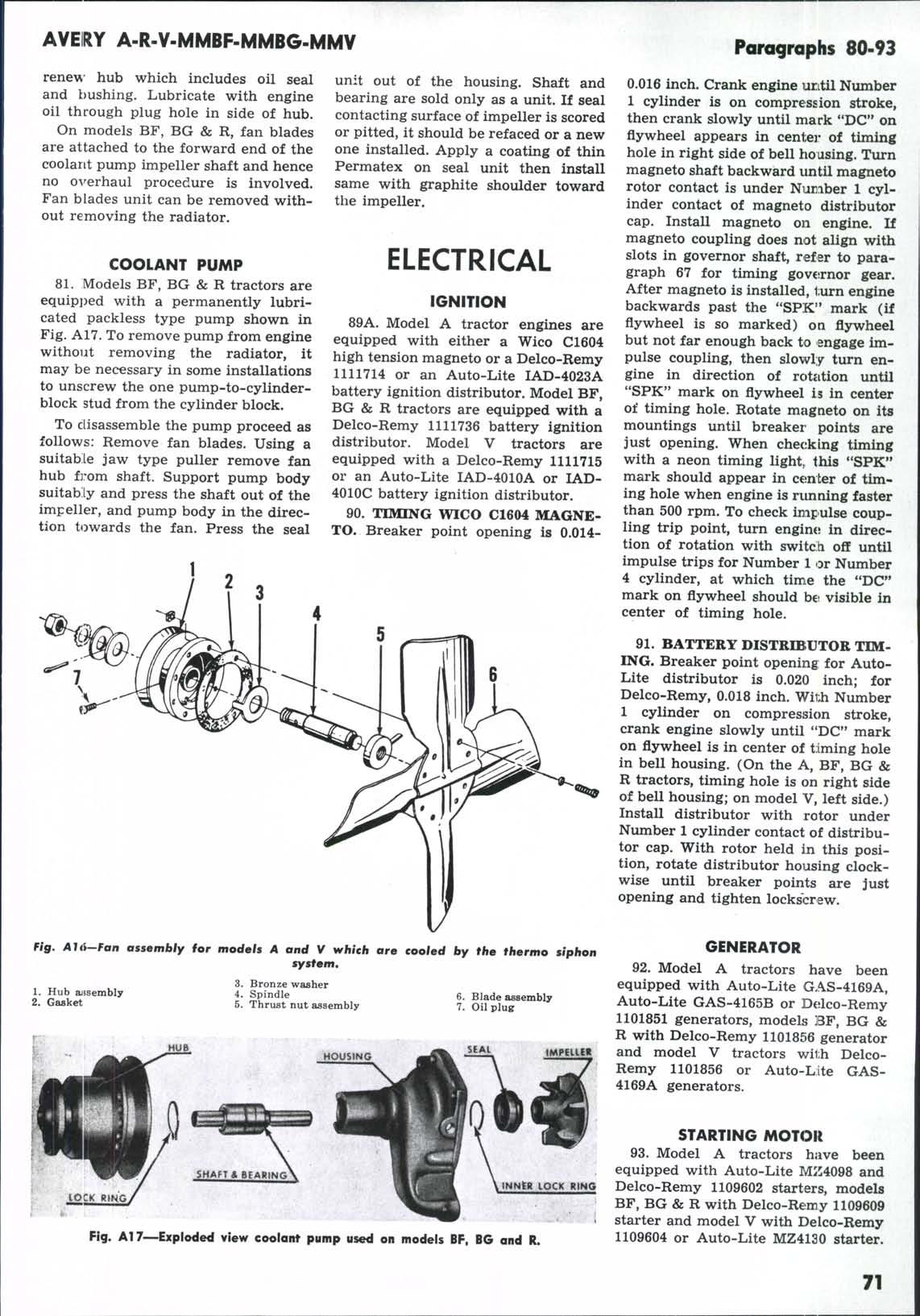

The preferred method of removing the ring gear attaching rivets is by drilling. When re-riveting, temporarily bolt the gear to the case to assist in getting a tight joint and to avoid distortion. After ring gear in attached, check trueness of unit at ring gear back face using a dial indicator with unit in its carriers or betv/een centers of a lathe. Total run-out should not exceed 0.003. Where ring gear is attached to differential cas<2 by cap screws, use only heat treated or high nickel screws as replacements. 233. Reinstall differential in transmission case and adjust carrier bear