4 minute read

Upper bearins cup

Models A-BF-BG-R

22. The engine and clutch are removed as an assembly. Remove hood and side plates, grille and radiator, muffler, fuel tank and hydraulic lines from hydraulic pump to unit. Disconnect engine front mount from timing gear cover. Disconnect steering shaft support from fuel tank support. Remove riveted pin from forward end of steering shaft universal joint, pull the shaft rearward until universal is free of wormshaft and swing front of shaft outward, pivoting on support at steering wheel. Disconnect electrical harness, governor throttle rod and choke control wire. Remove tube from air cleaner and carburetor and remove choke control support from clutch housing. Disconnect clutch release rod at pedal and with engine supported in hoist, remove engine rear mount bolts. NOTE: If tractor is equipped with hydraulic unit, it may be necessary to spread the frame side members slightly so as to free one of the right rear mount bolts from interference caused by the hydraulic piston connector. To spread the frame side members, use a jack placed between them just behind the clutch housing. Engine can be raised out of tractor. Reassembly is reverse of disassembly.

Model V

23. The engine and clutch are removed as an assembly. Remove hood and side plates, grille and radiator, starting motor, steering gear and steering gear shaft. Disconnect electrical harness and withdraw it rearward through hole in left side of bell housing. Remove propeller shaft cover. (To permit removal of cover after bolts have been removed, it is necessary to hold clutch in the disengaged position.) Disconnect clutch release rod at pedal, throttle rod at governor and choke control wire at carburetor. Disconnect radius rod at bell housing and front engine mount at frame cross member. Support engine in hoist and remove engine rear mounting bolts. Remove cotter pin retaining propeller shaft universal joint to clutch shaft and lift out engine. Reassembly is reverse of disassembly. Be sure that cotter pin hole in clutch shaft lines up with hole in propeller shaft universal joint and that starter rod and governor throttle rod are in proper position in rear engine mount spacer blocks.

CYLINDER HEAD

24. The cast iron cylinder head is retained to the block by cap screws on models A, BF, BG and R and by both cap screws and studs and nuts on the model V. To remove the cylinder head, remove the hood and muffler. Remove cylinder head cap screws and nuts from cylinder head studs and remove brackets for oil filter, coil, circuit breaker and air cleaner. Disconnect water outlet hose and remove head. Reassembly is reverse of disassembly. Cap screws and stud nuts should be tightened evenly from the center outward and to a torque of 35 foot pounds for model V tractors; 45 foot pounds for other models.

VALVES AND SEATS

25. Valves can be removed after removing cylinder head, valve chamber cover, manifolds and carburetor. Valve stems are fitted with round pin type spring seat (retainer) locks. To remove the spring seat locks any of the smaller K-D valve lifters or equivalent tool can be used. Valve face and seat angle is 30 degrees on both inlet and exhaust valves. Valves seat directly on the cast iron cylinder block; no inserts being used. Valve seats should be finished to a width of % inch.

VALVE GUIDES & SPRINGS

26. Guides can be pressed or driven out of the block through the valve chamber. Before removing old guides, measure the distance they protrude into valve chamber and install new guides to the same measurement. All guides of any one model should extend the same distance into the valve compartment. Check inside diameter of new guides after installation and resize, if necessary, by reaming. Clearance between valve stem and guide should be 0.001-0.003 on all models. Intake and exhaust valve springs are interchangeable in any one model.

CAM FOLLOWERS (TAPPETS)

27. Valve tappets, which operate dian adjusting screw and locknut. Re0.001. listed below: Inlet tappet gap, hot. 0.006 Exhaust tappet gap, hot (A-BF-BG-R) 0.008 Exhaust tappet gap, hot (V)... .0.006 Stem diameter (A-BF-BG-R)... .0.310 Stem diameter (V) 0.2475 Guide inside diameter (A-BF-BG-R) • .0.312 Guide inside diameter (V) 0.2495 Spring tension (A-BF-BG-R) . .40-44 lbs. @ 1 3/16 Spring tension (V) 33-37 lbs. @ 59/64 Valve & seat angle 30*

VALVE TIMING

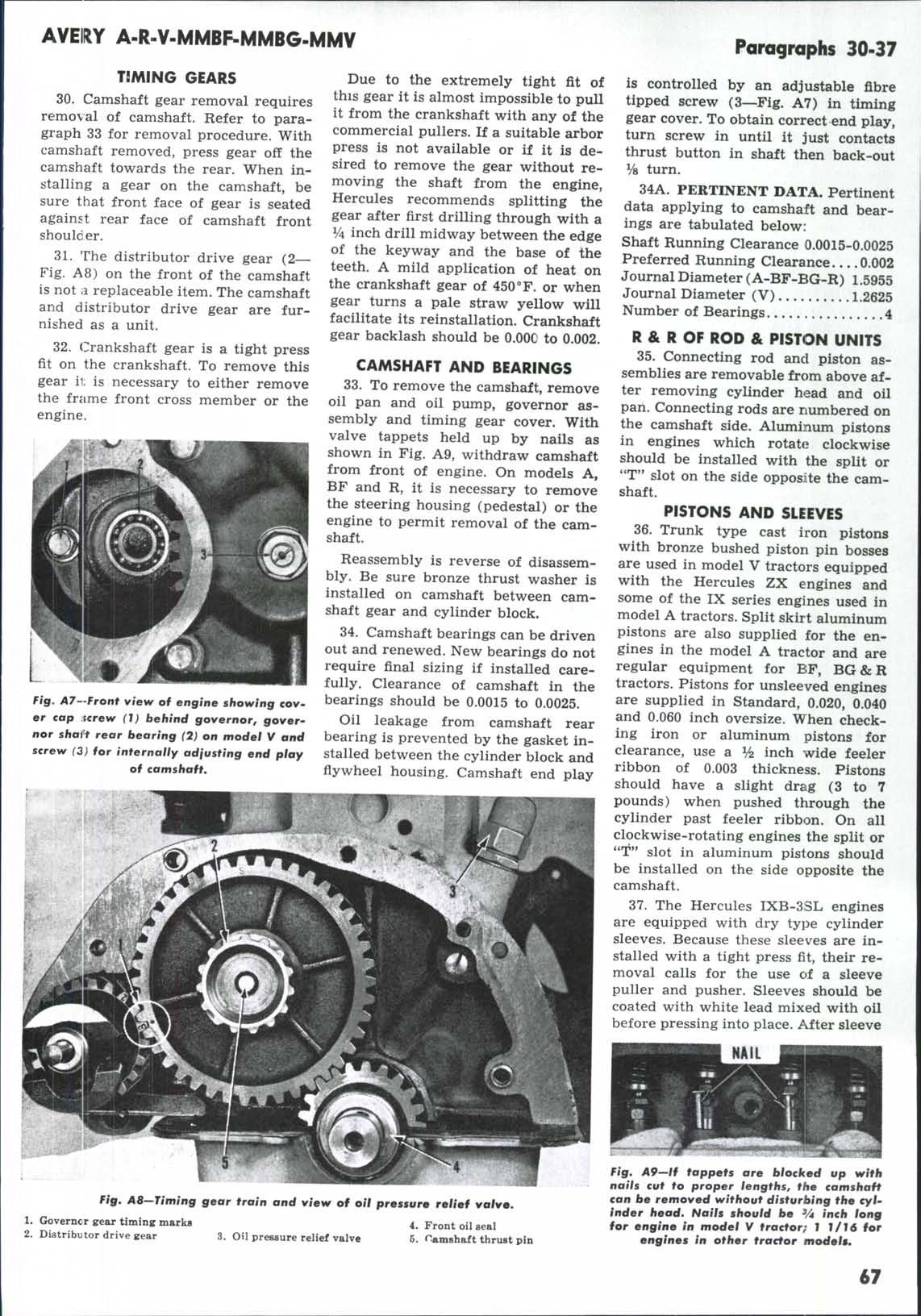

28. Valves are correctly timed when the punch mark on the camshaft gear lines up with the punch mark on the crankshaft gear (Fig. A6). With intake valve tappet adjusted to 0.006 inch, intake valve opens 5 degrees or 1^^ fiywheel teeth past top dead center.

TIMING GEAR COVER

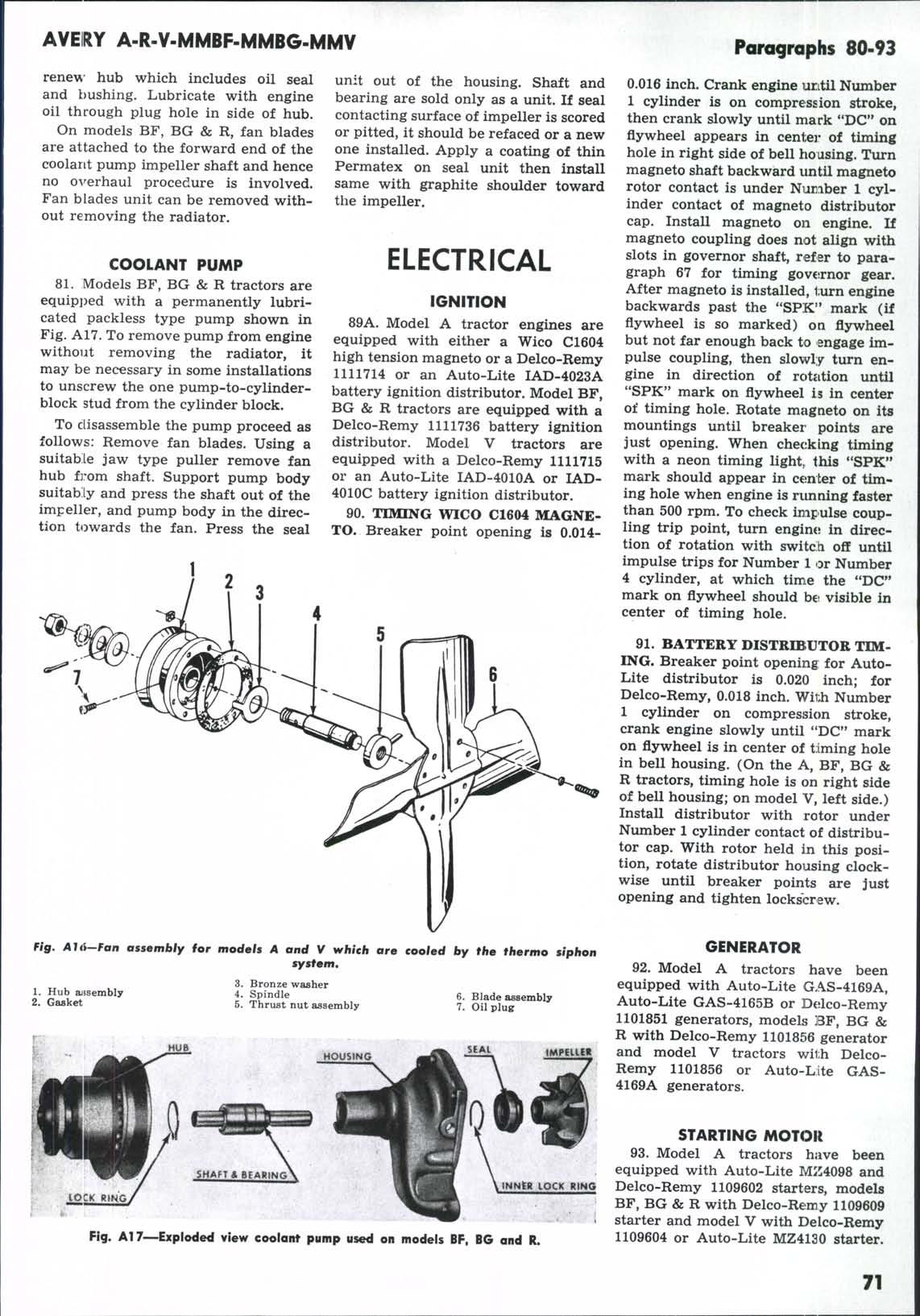

29. The timing gear cover can be removed without removing the engine. Remove hood and side plates, grille and radiator, fan assembly, crankshaft pulley and governor assembly. Remove cap screws retaining cover to engine (on **V*' series be sure to remove cover retaining cap screw (1— Fig. A7) located inside cover behind governor assembly. This cap screw is safe-tied with a wire where it protrudes through the rear of the timing gear case). Remove the four cap screws retaining oil oan to timing gear cover, loosen balance of oil pan cap screws and carefully part timing gear cover cover and front oil seal forward and lift cover off the seal. Oil seal can be slid off front of crankshaft. When installing new crankshaft front oil seal (4_j_Fig. A8) place seal on shaft with feather edge toward crankshaft gear.

rectly in bores in the cylinder block, are of the mushroom type fitted with move of valve tappets requires removal of camshaft. Clearance between tappet and cylinder block is 0.00075-

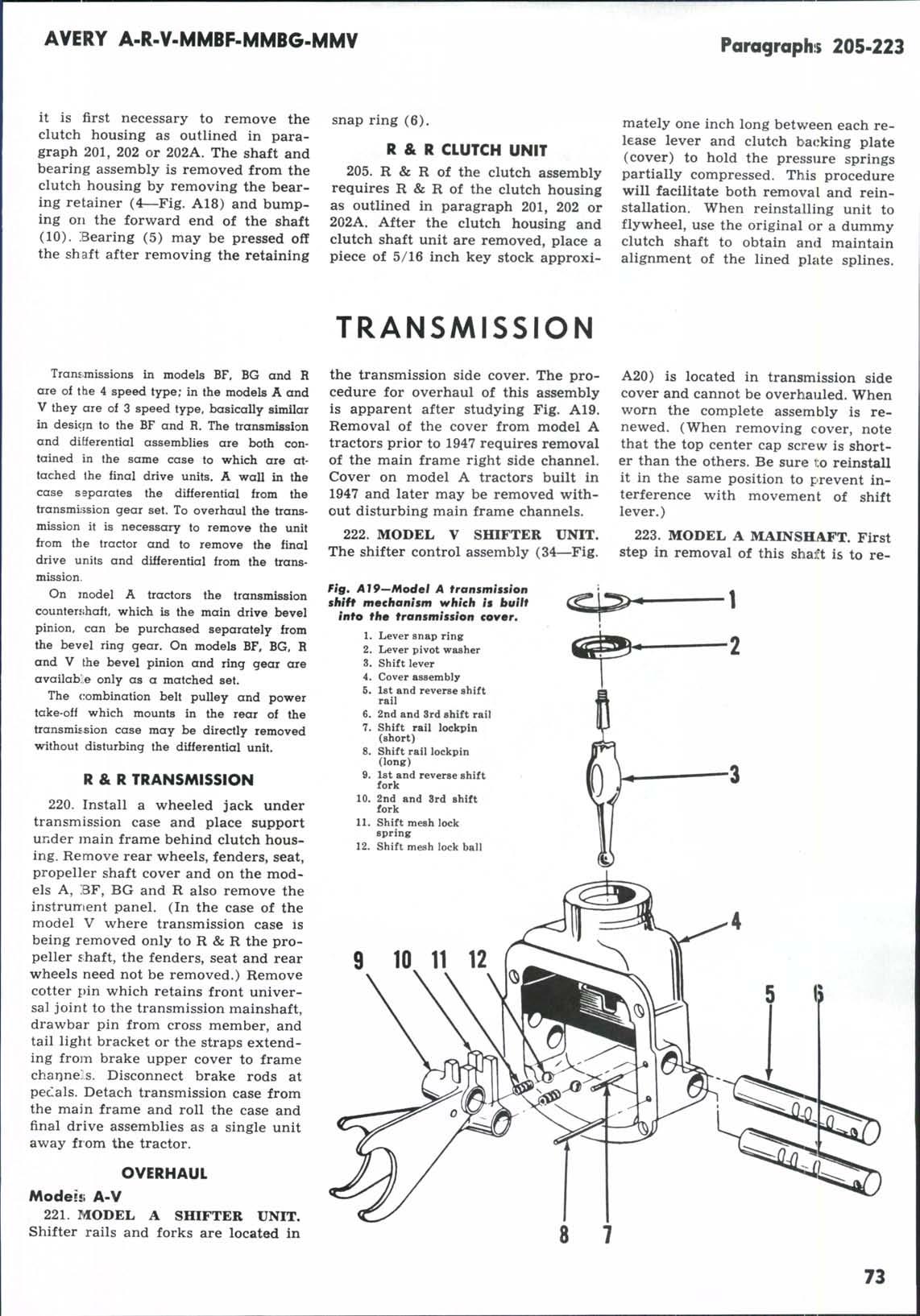

Pertinent data on valve system are from oil pan gasket. Pull timing gear