12.

FUEL SYSTEM

Service specifications Fuel filter replacement (After the first 100 hours during therunning-in period)

Every 500 hours

Clean the gauze strainer in the fuel lift pump

Every 500 hours

Drain primary water separator

As required

Fuel filter sediment removal

As required

Fuel tank sediment removal

As required

Fuel tank capacity

145 liters (38.3 US gals)

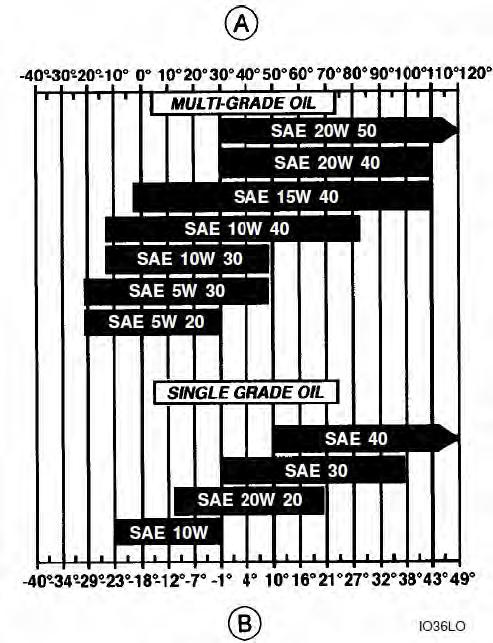

Type of fuel

“FLUIDS AND LUBRICANTS”

12.1 • •

Replacing the Primary Filter

Do not fill the new filter with fuel before installing it. Over tightening of bolt can damage the seal and the filter.

Tool required • One 17 mm (21/32 inch) wrench for hexagonal head bolts 1

PROCEDURE 1. 2. 3. 4. 5. 6. 7.

The primary fuel filter can be accessed by raising machine from loader end. Place a receptacle of a suitable capacity under the filter (1), unscrew the screw (2) located under the filter and allow the fuel to flow out. Then re tighten screw. Unscrew the bowl from the head, remove the filter cartridge and thoroughly clean the bowl. Apply a fine layer of oil or grease on the new filter seal. Install the new filter cartridge , and tighten the bowl. Vent the fuel system. See “Bleeding the system”. Remove the support strut and lower the loader attachment.

2

12.2 Replacing the Secondary Filter (Water Separator) 1. To access the engine see " Engine Access". 2. Remove the cartridge (1) by rotating in anticlockwise direction using a filter spanner. 3. Collect dripping fuel in a tray. 4. Discard the removed cartridge . 5. Clean the sealing surface of the filter head (2). 6. Apply a light film of oil to the rubber gasket of the new filter cartridge. 7. Screw in the new cartridge finger tight against the gasket. 8. Tighten the fuel filter cartridge with a final half turn using filter spanner. 9. Vent the fuel system. See "Bleeding the system". 10.Remove the safety strut and lower the loader attachment.

22

2

1