1 minute read

SPEED SHIFTER ASSEMBLY & MOUNTING

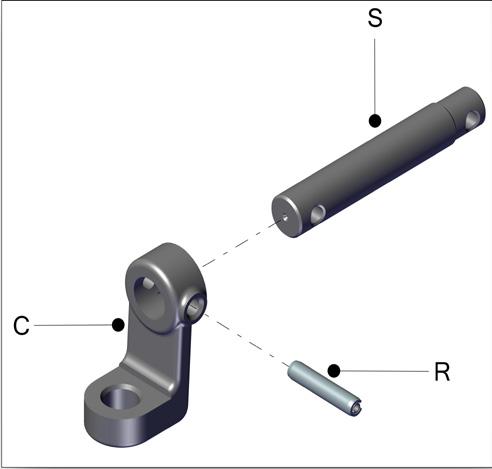

Assemble outer cam Link (C) and shaft speed shifting (S) locking it with roll pin (R)

NOTE- Ensure free rotation of shaft

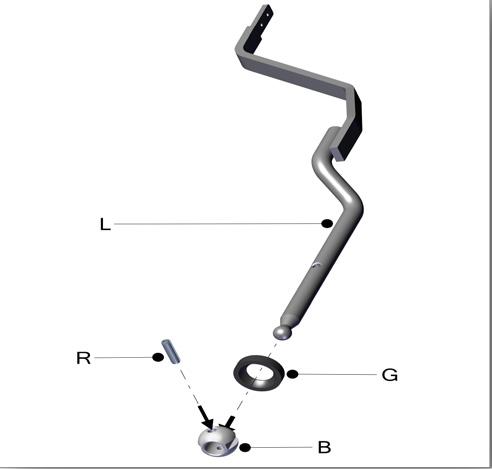

Take upper Gear shifter on lever and then assemble the ball pivot (B) on lever (L) and lock both with roll pin (R).

5

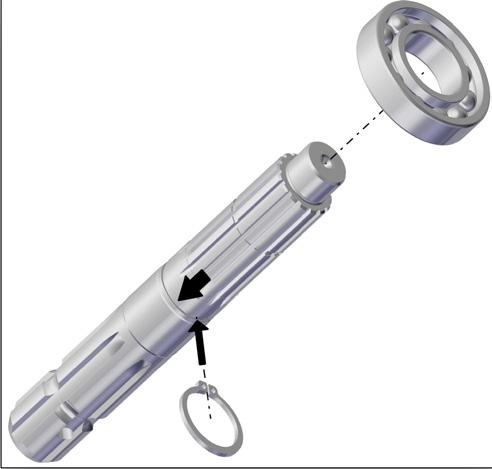

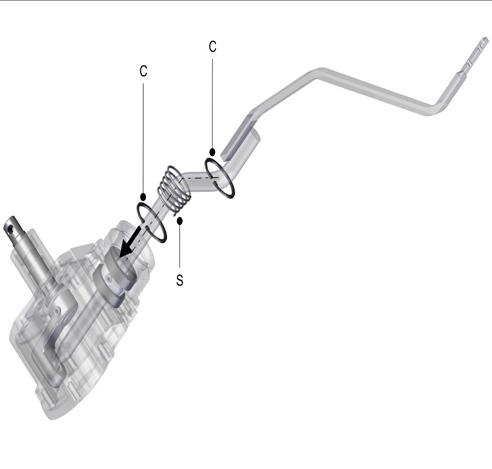

Insert Circlip internal (C) with straight circlip plier. Insert Conical spring (S). Insert the Circlip Internal (C) in dropbox

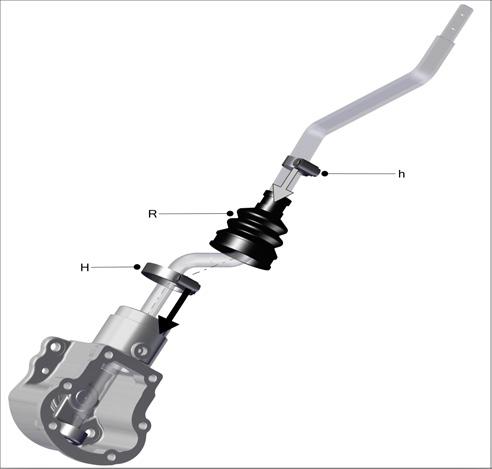

Cover dropbox upper open end & shifter lever with rubber boot(R). Fix it with hose clip (h) on lever & on dropbox with hose clip (H).

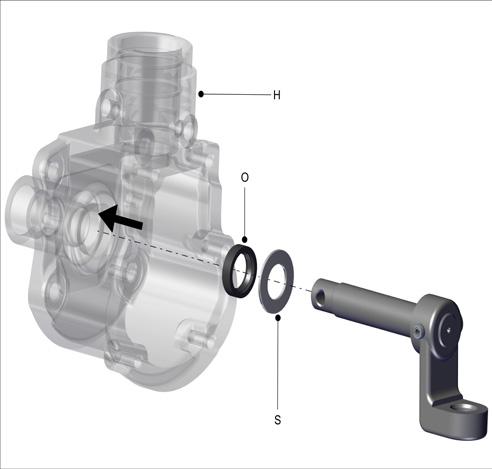

Take speed shifter housing (H) and press oil seal (O) in it. Insert the shaft gate shifter with spacer stopper (S) in housing (H).

Insert the gear shifter (G) followed by assembly (S) of speed shifter lever and ball pivot gear shifter in speed shifter housing

Use thread lock sealant for bolts. Apply grease between outer cam link and lever’s ball end. Check free movement of gear lever in all gear positions.

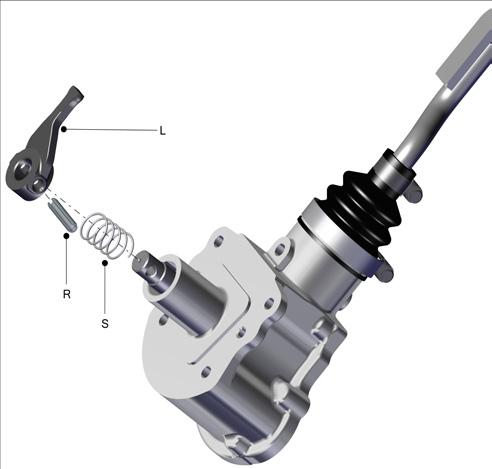

Insert the spring bias (S) on shaft and Fit cam link inner (L) with roll pin (R)

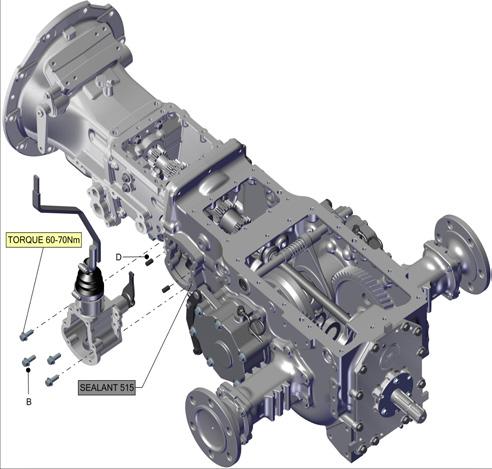

Insert the shifter mounting dowel (D) on housing. Mount shifter sub assy with 515 sealant & tight it with 4 bolts (B). torque (60-70Nm)

1 Speed Pto Shaft And Gears Assembly And Mounting

Take diff case (17) & insert bevel gear RH (B) & LH (A) with thrust washers (C).

Insert 2 bevel pinion (12) with Pinion Thrust Washers (13) in differential case

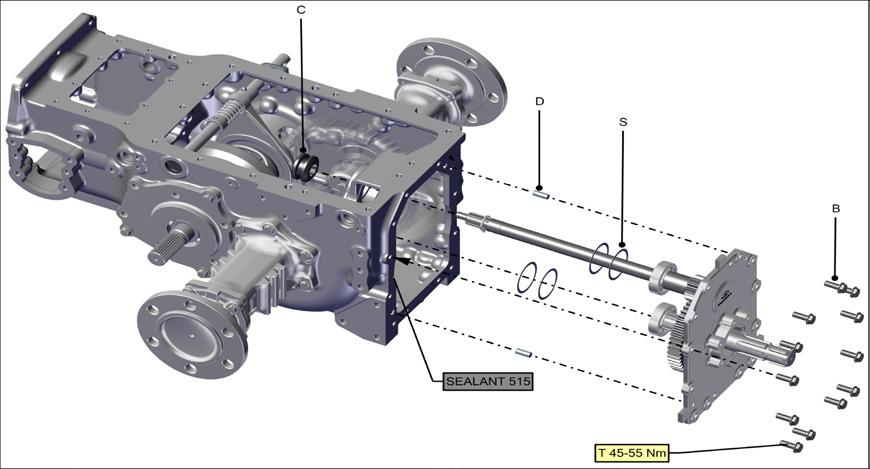

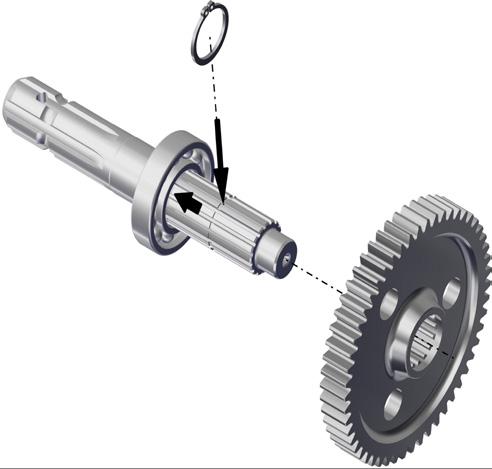

Insert PTO shifting coupling (C) to driving shaft end. Insert the PTO output Shims (S) in rear housing to adjust gap between driven & driving shaft bearing with rear housing Fit two dowels (D) on rear housing. Dock PTO housing to Rear housing with bolts (B) & sealant 515. Apply Torque

Insert bevel pinion shaft (16) through both pinion. Press roll pin (11) after aligning Diff Case and shaft holes by Dolly for roll pin pressing

Apply sealant 638 on ring gear and Insert ring gear (9)on Differential Case

Mount the bolt (8) & apply torque 118-125 Nm

NOTE:-

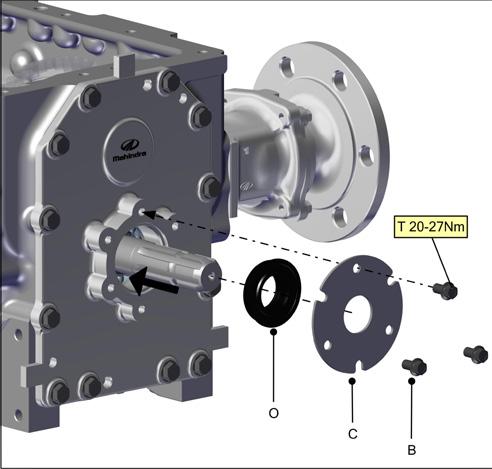

Press PTO output oil seal (O) in housing

Fitment of PTO cover plate (C) with 3 bolts (B). Apply Torque (20-27Nm)

Ensure free rotation of ball bearings after assembly.

No Grease should be applied during assembly. Assembly should be free from dust and foreign particles.

Shimming to be done as required

Keep float of 0.1mm